Ball mill load status identification method based on the convolutional neural network, optimized support vector machine model, and intelligent grinding media

-

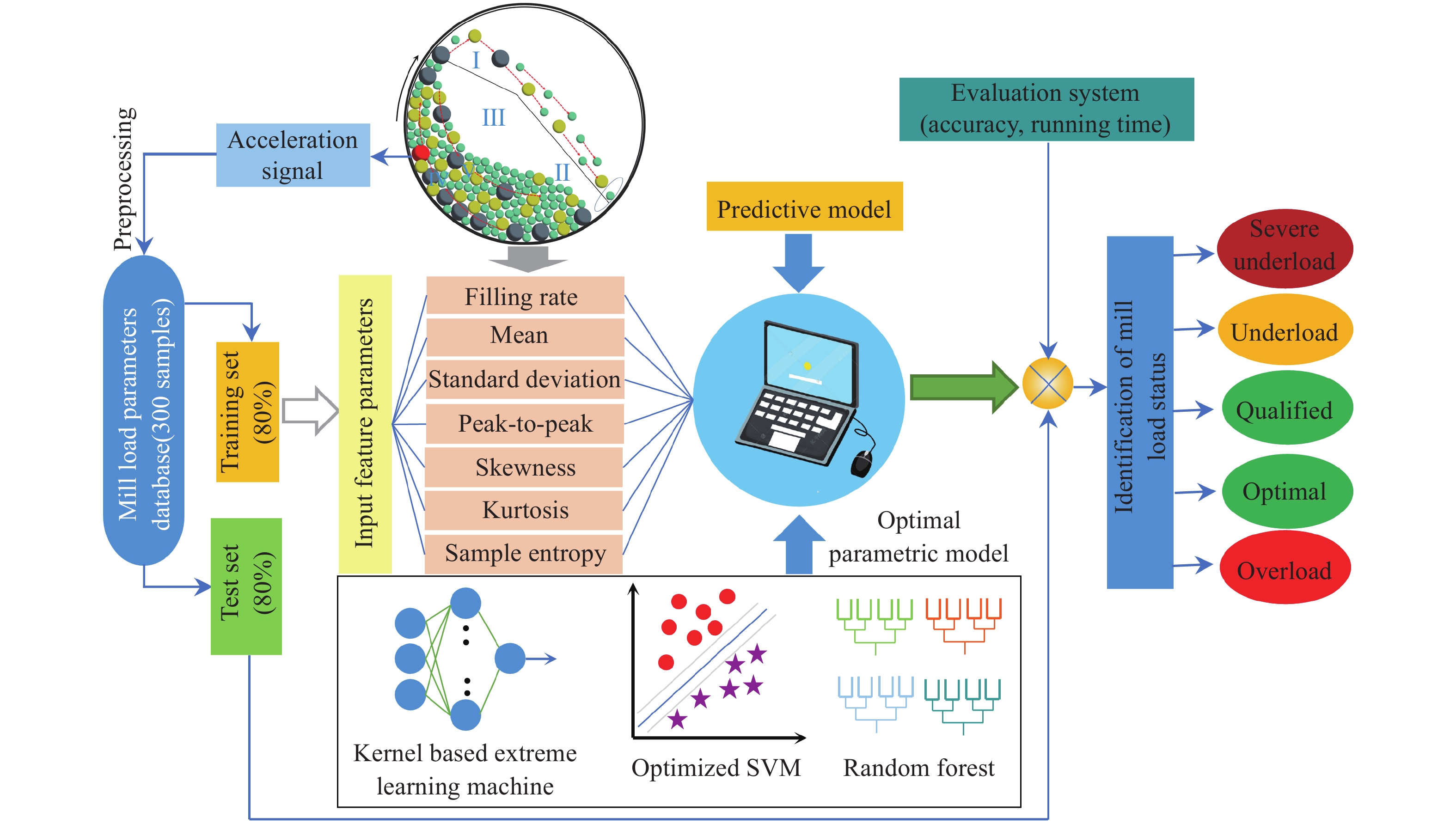

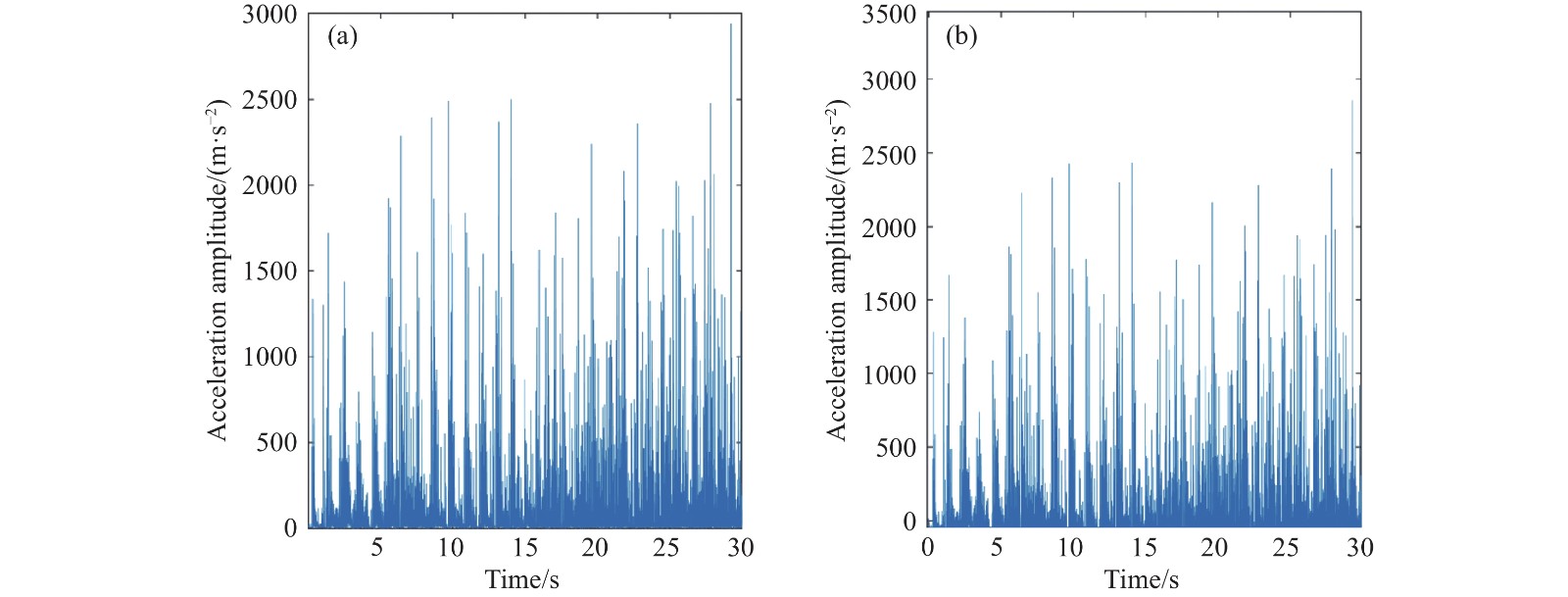

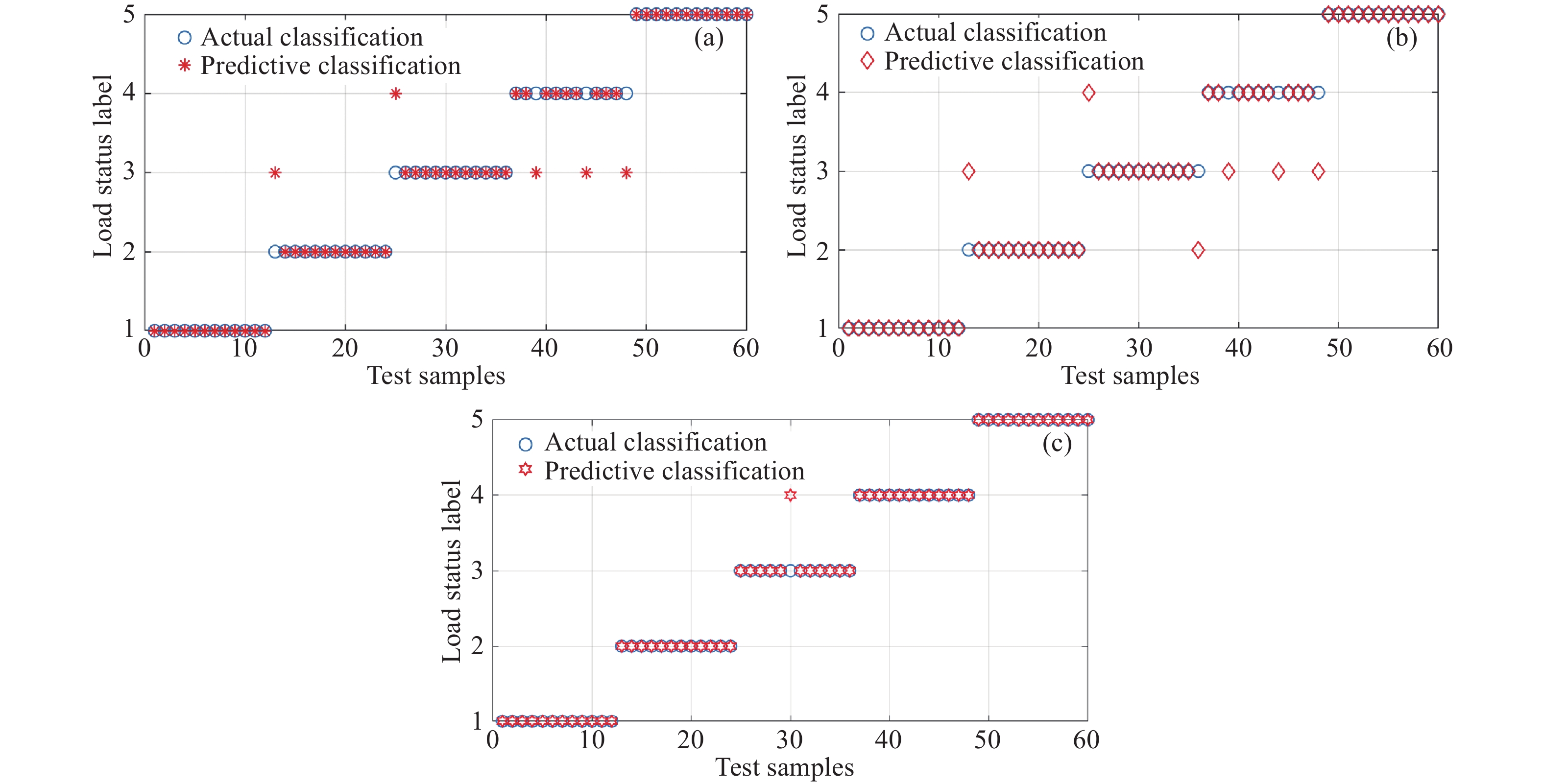

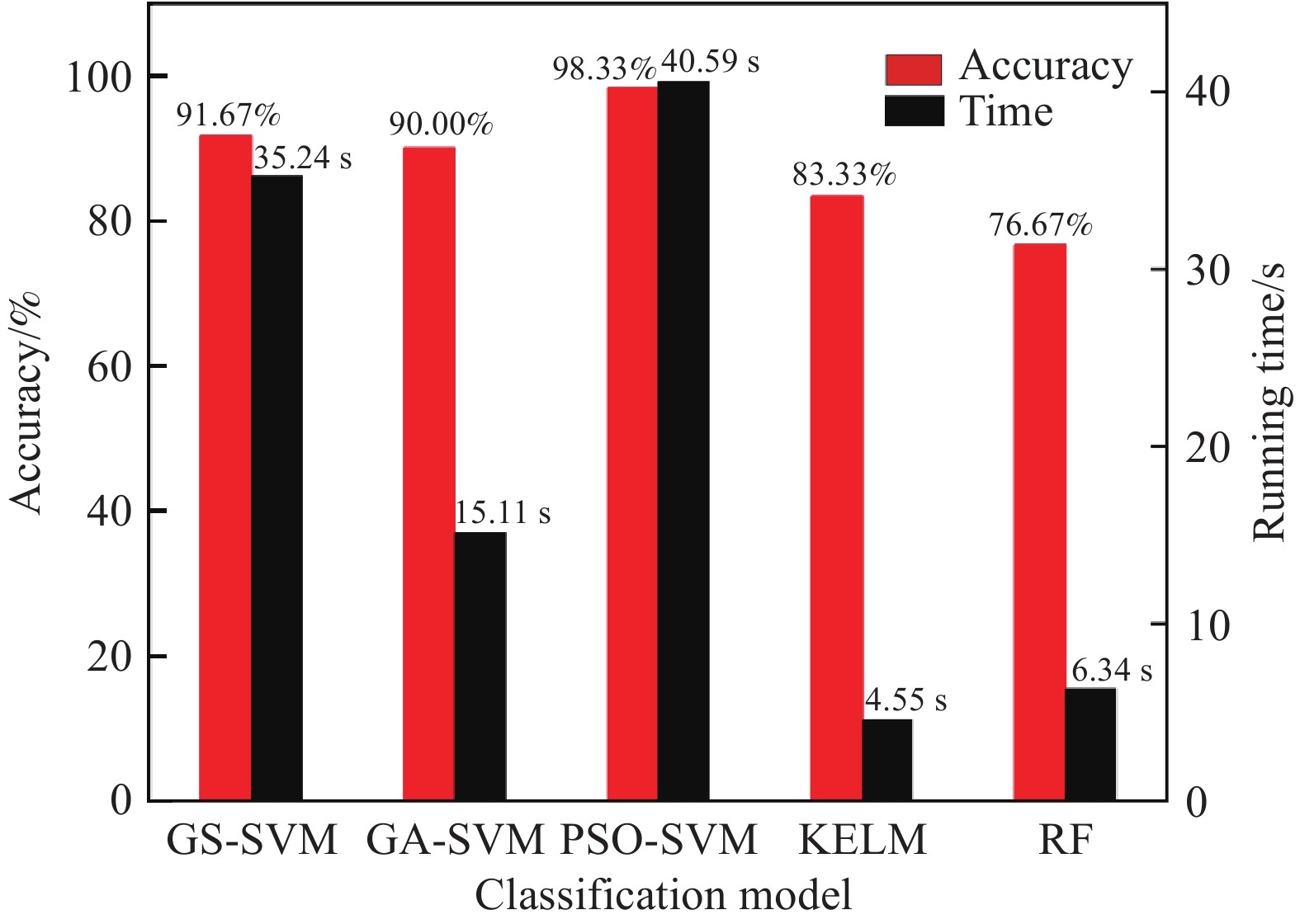

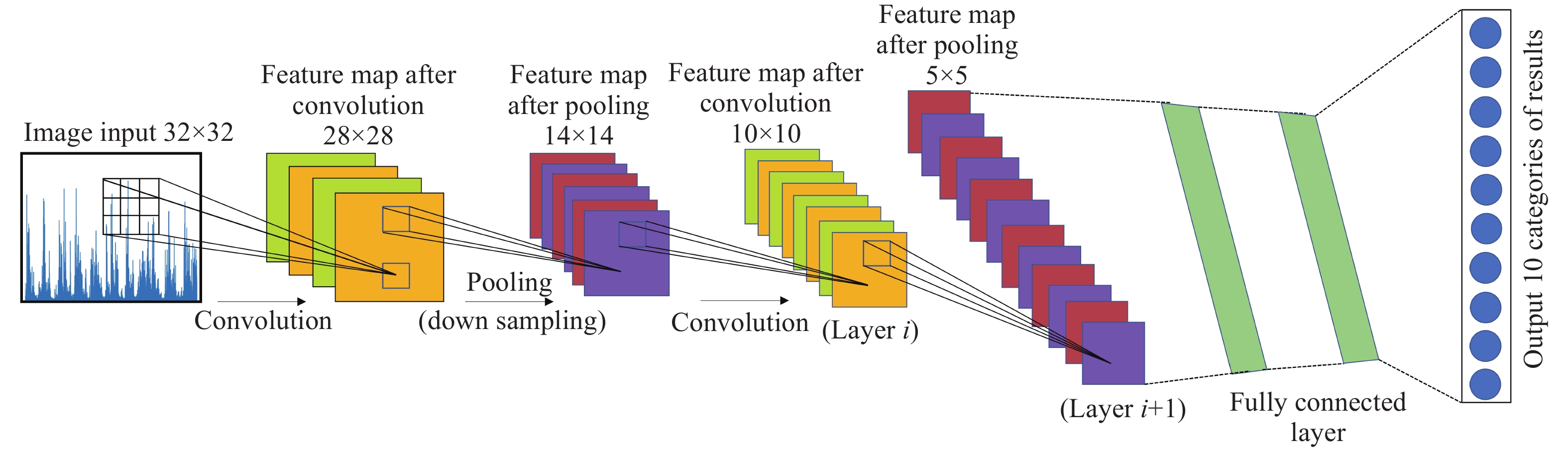

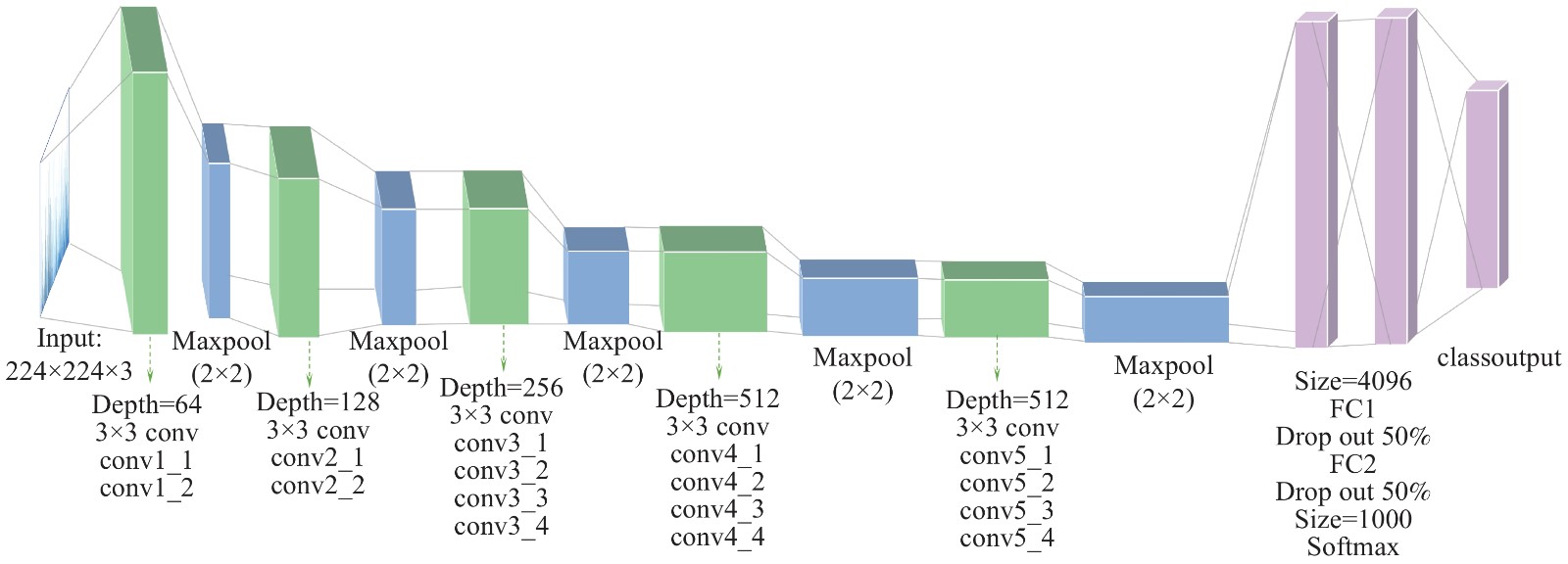

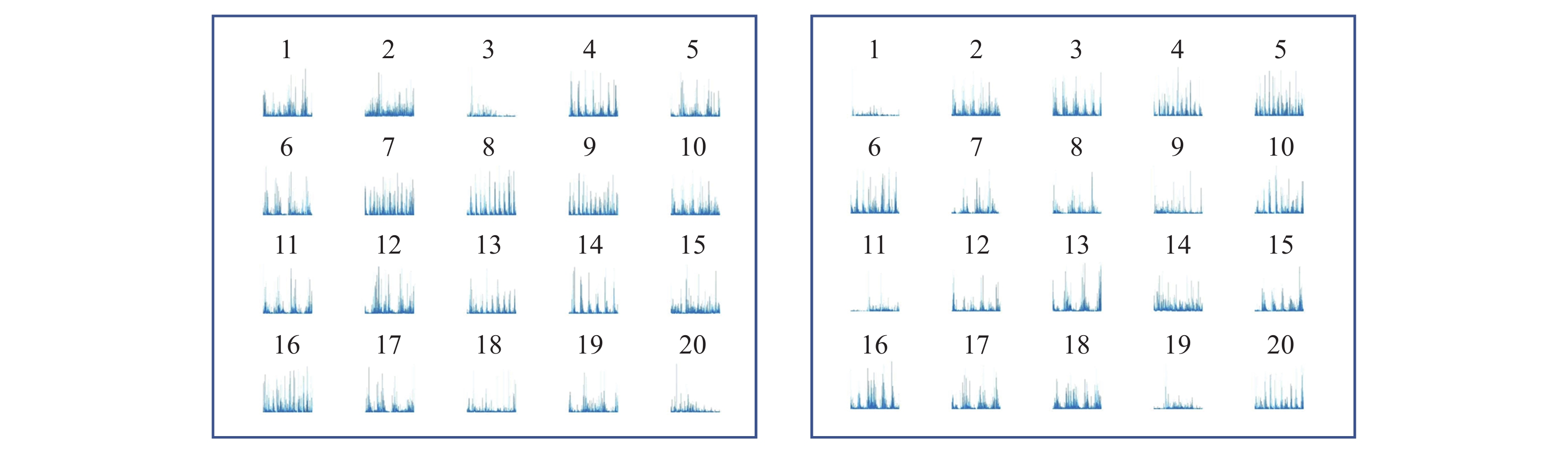

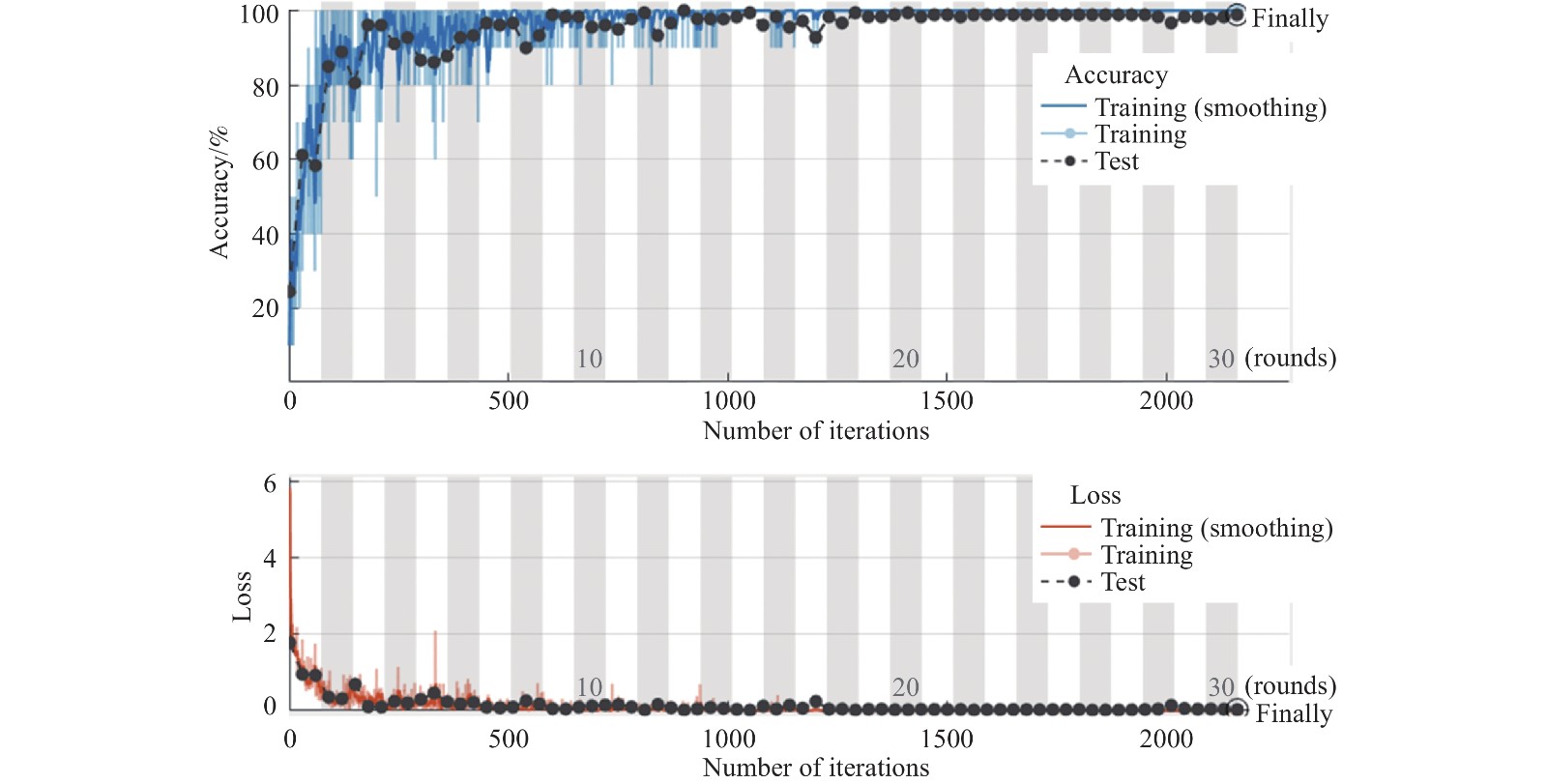

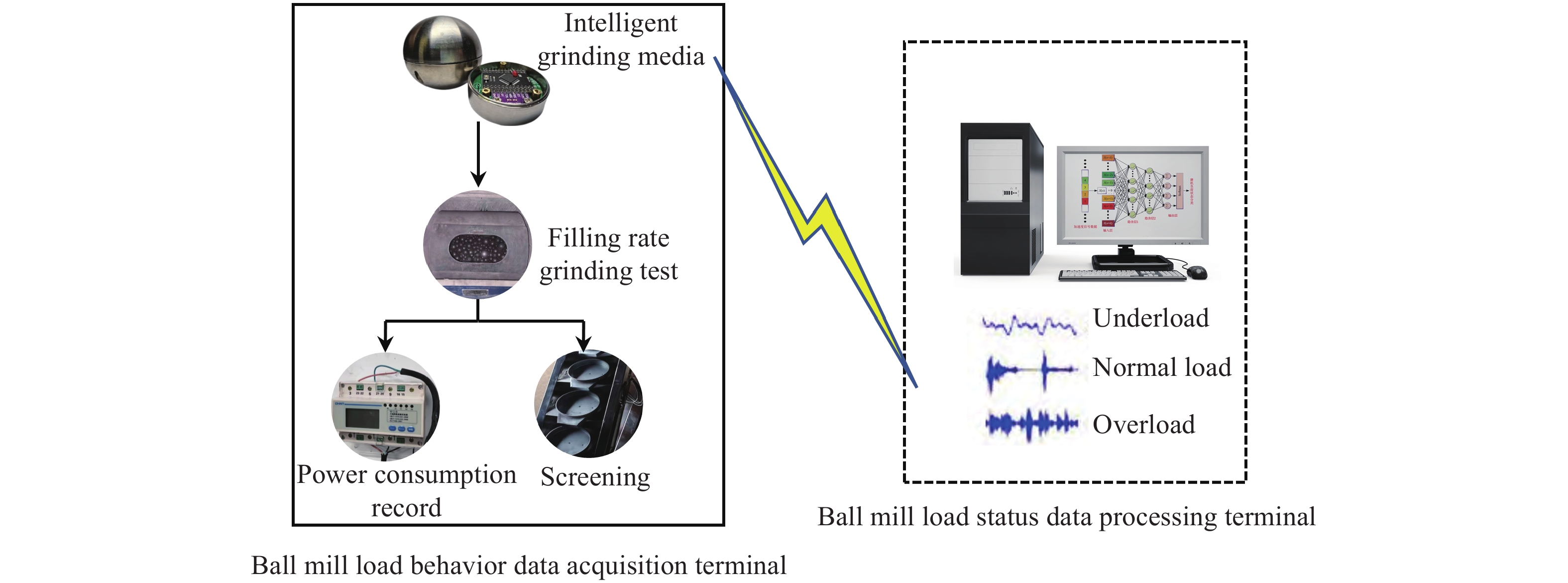

摘要: 當前球磨機負荷檢測方法難以準確評估磨機內部變化,給磨機綜合運行狀態的控制和優化帶來較大難度。本文設計了一款內嵌加速度傳感器且與鋼球介質物理性質相一致的智能磨礦介質用于識別磨機負荷,開展了不同充填率等磨礦條件下的磨礦試驗,設計磨礦效果系數劃分磨機負荷狀態;分別采用了卷積神經網絡方法(CNN)和優化的支持向量機(SVM)模型對智能磨礦介質獲取的加速度信號進行球磨機負荷識別。基于優化的SVM模型將獲取的一維加速度信號進行互補集合經驗模態分解算法(CEEMD)去噪、時域特征值和樣本熵提取等預處理,將上述磨機負荷的特征向量分別輸入GA?SVM、GS?SVM、PSO?SVM分類模型進行訓練,研究表明,PSO?SVM模型的識別準確率可達98.33%,但存在訓練過程繁瑣,耗費時間長的問題。在圖像識別領域具有優秀應用能力的CNN模型是把智能磨礦介質檢測加速度信號數據轉換為二維圖片后直接輸入基于VGG19網絡的CNN模型進行分類識別,磨機負荷分類識別準確率高于優化的SVM模型,可達98.89%,在保證識別準確率的同時有效節約了計算時間。基于CNN的智能磨礦介質球磨機負荷識別方法可為實現球磨機負荷檢測與在線評估提供重要解決方案與技術保障。Abstract: A ball mill is important grinding equipment in a concentrator, and the accurate detection of the load status ensures that the ball mill runs in the best state, which helps optimize the grinding process, ensure the stable operation of the ball mill equipment, and save energy. The current mainstream detection methods cannot easily detect the movement inside the ball mill. Mill load requires a more efficient and direct detection method. In this study, the SM ?500 mm×500 mm ball mill was taken as the research object. Through theoretical analysis and simulation, intelligent grinding media with an embedded triaxial acceleration sensor and physical properties similar to that of ordinary steel ball media were designed to identify the mill load, and grinding experiments with different filling rates and other grinding conditions were conducted. Results revealed that the filling rate and the material to ball ratio are the important factors affecting the ?0.074 mm size products. Taking the grinding effect coefficient as an index to distinguish different load states and grinding effects, the best load state can be achieved under the conditions of 40% filling rate, 1∶37 material to ball ratio, and ~6 kg sample weight. The ball mill load was evaluated using the convolutional neural network (CNN) method and optimized support vector machine (SVM) models from the acceleration signal obtained by the intelligent grinding media. For the optimized SVM models, preprocessing of the acquired one-dimensional acceleration signal, including complementary ensemble empirical mode decomposition algorithm denoising, time-domain eigenvalue extraction, and sample entropy, was conducted. The feature vectors of mill load were included in the genetic algorithm and SVM (GA?SVM), grid search and SVM (GS?SVM), and partial swarm optimization and SVM (PSO?SVM) classification models for training. The research results revealed that the recognition accuracy of the PSO?SVM algorithm reaches 98.33%, but the training process tends to be tedious and time-consuming. For the CNN algorithm with excellent applicability in the field of image recognition, the detected acceleration signal data were converted into two-dimensional pictures and directly inputted into the CNN model based on the VGG19 network for classification and recognition. The classification and recognition accuracy of the mill load of the CNN method (i.e., 98.89%) was higher than that of the optimized SVM algorithm. Moreover, the calculation time of the CNN method was shorter than that of the optimized SVM algorithm. The ball mill load status identification method using the intelligent grinding media and CNN method could provide critical solutions and technical support for load detection and online evaluation.

-

Key words:

- mill load /

- intelligent grinding media /

- sample entropy /

- CNN /

- SVM

-

圖 4 三種優化的SVM模型的負荷狀態分類識別結果.(a)GS?SVM分類結果;(b)GA?SVM分類結果;(c)PSO?SVM分類結果

Figure 4. Results of load status classification and recognition of the three improved support vector machine methods: (a) results of GS?SVM classification model; (b) results of GA?SVM classification model; (c) results of PSO?SVM classification model

表 1 5種負荷狀態參數劃分結果

Table 1. Five kinds of load state parameter division results

Label Filling rate/% Yield of ?200 mesh/% Power consumption/

(kW·h)Grinding effect coefficient Load state 1 10 22.81 0.221 0.447 Severe underload 2 20 33.44 0.226 0.641 Underload 3 30 52.92 0.233 0.989 Qualified 4 40 68.48 0.236 1.258 Optimal 5 50 70.07 0.244 1.244 Overload 表 2 SVM常用核函數

Table 2. Commonly used kernel functions of the support vector machine

Kernel function name Expression Linear kernel function ${ {k} }\left( { { {\boldsymbol{x} }_{{i} } }{{,} }{ {\boldsymbol{x} }_{{j} } } } \right){{ = } }{ {\boldsymbol{x} }_{{i} } }^{\rm T} { {\boldsymbol{x} }_{{j} } }$ Radial basis function (RBF) kernel ${ {k} }\left( { { {\boldsymbol{x} }_{ {i} } },{ {\boldsymbol{x} }_{ {j} } } } \right) = \exp ( - { {g} }\parallel { {\boldsymbol{x} }_{ {i} } },{ {\boldsymbol{x} }_{ {j} } }{\parallel ^2})$ Polynomial kernel function ${ {k} }\left( { { {\boldsymbol{x} }_{{i} } },{ {\boldsymbol{x} }_{{j} } } } \right) = {\left[ { {{g} }({ {\boldsymbol{x} }_{{i} } } \cdot { {\boldsymbol{x} }_{{j} } }) + {{C} } } \right]^{{d} } }$ Sigmoid kernel function ${{k} }\left( { { {\boldsymbol{x} }_{{i} } },{ {\boldsymbol{x} }_{{j} } } } \right) = \tanh \left[ { {{g} }({ {\boldsymbol{x} }_{{i} } } \cdot { {\boldsymbol{x} }_{{j} } }) + {{C} } } \right]$ 表 3 三種典型工況下的樣本熵值

Table 3. Sample entropy values under three typical working conditions

Samples Underload Normal load Overload Original Reconstructed Original Reconstructed Original Reconstructed 1 0.89 0.87 0.48 0.50 0.35 0.38 2 0.84 1.06 0.51 0.47 0.32 0.39 3 0.79 0.99 0.49 0.55 0.31 0.36 4 0.92 1.01 0.43 0.54 0.31 0.39 5 0.77 0.90 0.41 0.48 0.29 0.40 Mean 0.84 0.97 0.46 0.51 0.32 0.38 表 4 不同負荷狀態下的部分待訓練特征向量

Table 4. Feature vectors to be trained under different load conditions

Serial number Filling rate/ % Peak-to-peak Mean Standard deviation Skewness Kurtosis Sample entropy 1 10 236.91 9.71 10.78 4.45 44.94 1.16 2 10 275.67 7.28 9.46 5.75 78.78 0.90 … … … … … … … … 61 20 306.59 10.35 18.63 5.85 53.51 0.65 62 20 342.41 9.24 17.60 6.21 58.81 0.58 … … … … … … … … 121 30 285.08 8.79 16.17 6.21 61.26 0.63 122 30 265.04 9.34 17.74 5.64 47.87 0.54 … … … … … … … … 181 40 319.24 9.13 19.01 5.60 46.51 0.53 182 40 290.03 9.87 20.76 5.50 44.32 0.48 … … … … … … … … 299 50 284.15 6.47 16.86 7.23 74.09 0.32 300 50 299.88 5.96 15.68 7.80 87.21 0.33 久色视频表 5 三種優化SVM模型對磨機負荷狀態的識別結果

Table 5. Recognition results of the three improved support vector machine models on the load state of the mill

Classification model Best (C, g) Training accuracy/% Test accuracy/% GS?SVM (64, 2.83) 91.00 91.67 GA?SVM (70.09, 9.44) 94.33 90.00 PSO?SVM (260.94, 2.36) 96.33 98.33 -

參考文獻

[1] Tang J, Tian F Q, Jia M Y, et al. Rotating Mechanical Equipment Load Soft Measurement Based on Frequency Spectrum Data Drive. Beijing: National Defense Industry Press, 2015湯健, 田福慶, 賈美英. 基于頻譜數據驅動的旋轉機械設備負荷軟測量. 北京: 國防工業出版社, 2015 [2] Tang J, Chai T Y, Zhao L J, et al. Ensemble modeling for parameters of ball-mill load in grinding process based on frequency spectrum of shell vibration. Control Theory Appl, 2012, 29(2): 183湯健, 柴天佑, 趙立杰, 等. 基于振動頻譜的磨礦過程球磨機負荷參數集成建模方法. 控制理論與應用, 2012, 29(2):183 [3] Góralczyk M, Krot P, Zimroz R, et al. Increasing energy efficiency and productivity of the comminution process in tumbling Mills by indirect measurements of internal dynamics—an overview. Energies, 2020, 13(24): 6735 doi: 10.3390/en13246735 [4] Clermont B, Haas D B, Hancotte O. Real time mill management tools stabilizing your milling process // Proceeding of third International Platinum Conference. Sharjah, 2008, 13 [5] Tang J, Yan G W, Liu Z, et al. Experimental analysis of wet mill load parameter based on multiple channel mechanical signals under multiple grinding conditions. Miner Eng, 2020, 159: 106609 doi: 10.1016/j.mineng.2020.106609 [6] Yoshida T, Kuratani F, Ito T, et al. Vibration characteristics of an operating ball mill. J Phys:Conf Ser, 2019, 1264(1): 012016 doi: 10.1088/1742-6596/1264/1/012016 [7] Dunn D J, Martin R G. Measurement of impact forces in ball mills. Min Eng, 1978, 30(4): 384 [8] Rolf L, Vongluekiet T. Measurement of energy distributions in ball Mills. Ger Chem Eng, 1984, 7(5): 287 [9] Gao R X, Thelen W. Sensor-integrated grinding balls for on-line load distribution measurement in ball Mills. Proc Inst Mech Eng B J Eng Manuf, 1994, 208(3): 183 doi: 10.1243/PIME_PROC_1994_208_077_02 [10] Martins S, Li W, Radziszewski P, et al. Validating the instrumented ball outputs with simple trajectories. Miner Eng, 2008, 21(11): 782 doi: 10.1016/j.mineng.2008.05.016 [11] Martins S, Li W, Radziszewski P, et al. Experimental and simulated instrumented ball in a tumbling mill—A comparison. Miner Eng, 2013, 43-44: 79 doi: 10.1016/j.mineng.2012.09.002 [12] Yin Z X, Peng Y X, Zhu Z C, et al. Effect of mill speed and slurry filling on the charge dynamics by an instrumented ball. Adv Powder Technol, 2019, 30(8): 1611 doi: 10.1016/j.apt.2019.05.009 [13] Yin Z X. Study on Breakage and Size Distribution Behaviour of Iron Ore Particle in Ball Mills [Dissertation]. Xuzhou: China University of Mining and Technology, 2020尹自信. 球磨機鐵礦石顆粒破碎及粒度分布行為研究[學位論文]. 徐州: 中國礦業大學, 2020 [14] Wang T, Zou W J, Xu R J, et al. Assessing load in ball mill using instrumented grinding media. Miner Eng, 2021, 173: 107198 doi: 10.1016/j.mineng.2021.107198 [15] Huang Y Q, Xiao Q F, Guo Y X, et al. Comparison test and application study on grinding of a copper mine in Jiangxi Province. Gold Sci Technol, 2019, 27(2): 278黃胤淇, 肖慶飛, 郭運鑫, 等. 江西某銅礦磨礦對比試驗及應用研究. 黃金科學技術, 2019, 27(2):278 [16] Xue S H, Tan J P, Shi L X, et al. Rope tension fault diagnosis in hoisting systems based on vibration signals using EEMD, improved permutation entropy, and PSO-SVM. Entropy, 2020, 22(2): 209 doi: 10.3390/e22020209 [17] Li C P, Zheng Y X, Zhang J, et al. Ore grade interpolation model based on support vector machines optimized by genetic algorithms. J Univ Sci Technol Beijing, 2013, 35(7): 837李翠平, 鄭瑤瑕, 張佳, 等. 基于遺傳算法優化的支持向量機品位插值模型. 北京科技大學學報, 2013, 35(7):837 [18] Zhou J M, Wang F L, Zhang C C, et al. An intelligent method for rolling bearing evaluation using feature optimization and GA?SVM. J Vib Shock, 2021, 40(4): 227 doi: 10.13465/j.cnki.jvs.2021.04.031周建民, 王發令, 張臣臣, 等. 基于特征優選和GA?SVM的滾動軸承智能評估方法. 振動與沖擊, 2021, 40(4):227 doi: 10.13465/j.cnki.jvs.2021.04.031 [19] Wang L, Zhang A Y, Li J J, et al. PSO?SVM gesture recognition method based on time-frequency combination features. J Chang Univ Sci Technol, 2021, 44(4): 104王亮, 張安元, 李佳佳, 等. 基于時頻組合特征的PSO?SVM手勢識別方法. 長春理工大學學報(自然科學版), 2021, 44(4):104 [20] Wu X P, Wang F M. The research of trend remove based on the principle of least-squares method. Microcomput Inf, 2008, 24(30): 254 doi: 10.3969/j.issn.1008-0570.2008.30.102吳夏平, 王福明. 基于最小二乘法原理的趨勢項處理研究. 微計算機信息, 2008, 24(30):254 doi: 10.3969/j.issn.1008-0570.2008.30.102 [21] Yeh J R, Shieh J S, Huang N E. Complementary ensemble empirical mode decomposition: A novel noise enhanced data analysis method. Adv Adapt Data Anal, 2010, 2(2): 135 doi: 10.1142/S1793536910000422 [22] Cai G P, Liu X, Dai C C, et al. Load state identification method for ball mills based on improved EWT, multiscale fuzzy entropy and AEPSO_PNN classification. Processes, 2019, 7(10): 725 doi: 10.3390/pr7100725 [23] Xiong Y. Research on Load Prediction of Ball Mill Based on Vibration Feature Extraction [Dissertation]. Ganzhou: Jiangxi University of Science and Technology, 2016熊洋. 基于振動特征提取的球磨機負荷預測研究[學位論文]. 贛州: 江西理工大學, 2016 [24] Zhang X Q, Liang J, Zhang X, et al. Combined model for ultra short-term wind power prediction based on sample entropy and extreme learning machine. Proc CSEE, 2013, 33(25): 33 doi: 10.13334/j.0258-8013.pcsee.2013.25.012張學清, 梁軍, 張熙, 等. 基于樣本熵和極端學習機的超短期風電功率組合預測模型. 中國電機工程學報, 2013, 33(25):33 doi: 10.13334/j.0258-8013.pcsee.2013.25.012 [25] Liu Y J, Wang B H, Li R P, et al. Relapse risk prediction for children with henoch-sch?nlein purpura based on GA?SVM. Int J Bioautomation, 2020, 24(2): 117 doi: 10.7546/ijba.2020.24.2.000608 [26] Pinedo-Sánchez L A, Mercado-Ravell D A, Carballo-Monsivais C A. Vibration analysis in bearings for failure prevention using CNN. J Braz Soc Mech Sci Eng, 2020, 42(12): 1 [27] Ma Y F, Jia X S, Bai H J, et al. Fault diagnosis of compressed vibration signal based on 1-dimensional CNN with optimized parameters. Syst Eng Electron, 2020, 42(9): 1911 doi: 10.3969/j.issn.1001-506X.2020.09.05馬云飛, 賈希勝, 白華軍, 等. 基于一維CNN參數優化的壓縮振動信號故障診斷. 系統工程與電子技術, 2020, 42(9):1911 doi: 10.3969/j.issn.1001-506X.2020.09.05 [28] Zhao X Q, Zhang Y Z. Improved CNN-based fault diagnosis method for rolling bearings under variable working conditions. J Xi’an Jiaotong Univ, 2021, 55(12): 108 doi: 10.7652/xjtuxb202112013趙小強, 張亞洲. 利用改進卷積神經網絡的滾動軸承變工況故障診斷方法. 西安交通大學學報, 2021, 55(12):108 doi: 10.7652/xjtuxb202112013 -

下載:

下載: