Research progress on fractal microchannels for heat transfer process intensification

-

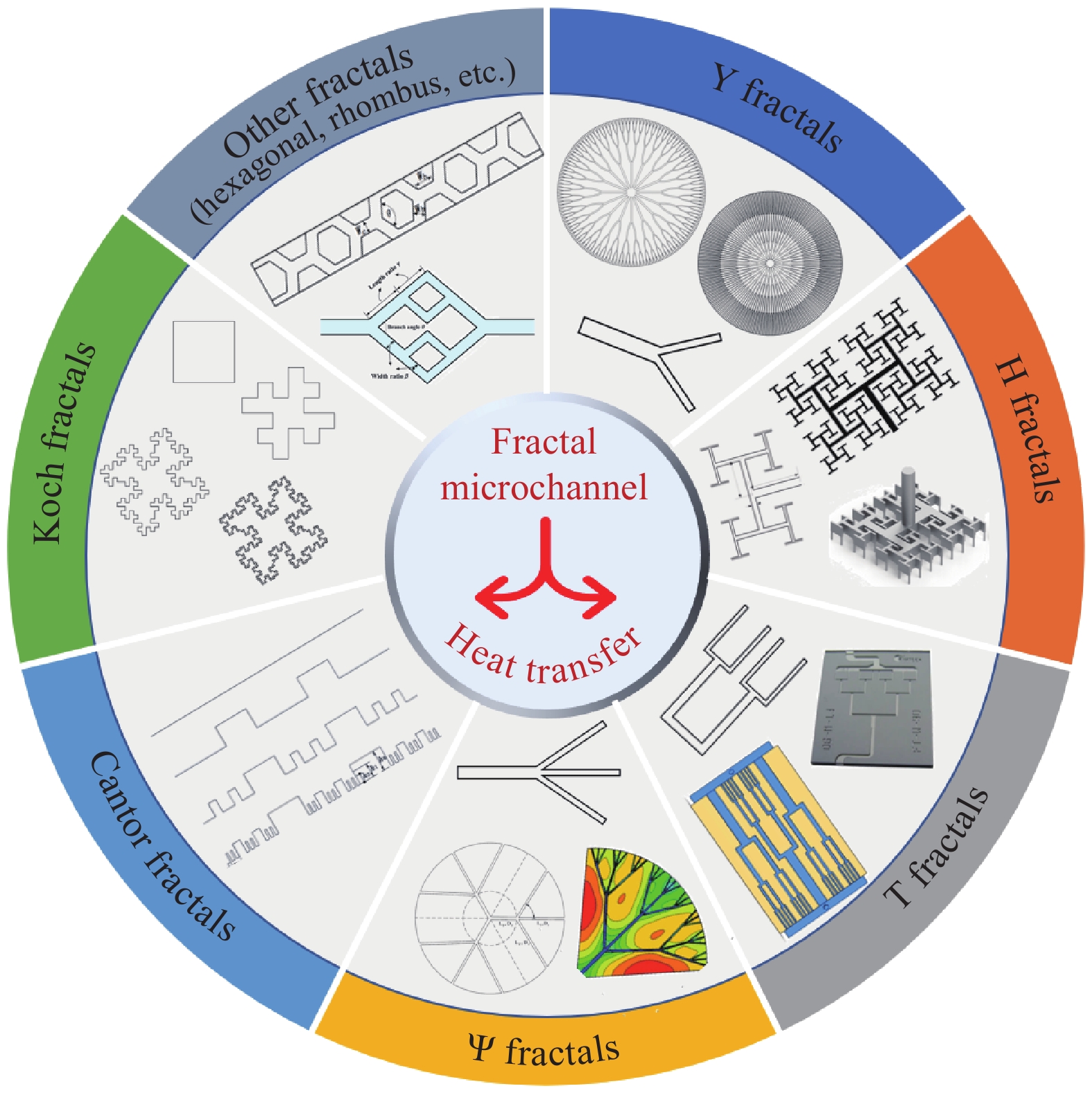

摘要: 隨著微納制造技術的快速發展,微電子芯片、微反應器和微燃料電池等微型器件受到了研究者越來越多的關注。微型器件的應用不僅對加工工藝和材料具有較高的要求,而且需要高效的熱管理來維持其性能。特別是對于高集成度和高頻化的高性能微電子芯片而言,超高的熱流密度不僅會嚴重制約芯片的性能,而且會顯著影響芯片的壽命和可靠性。鑒于傳統的風冷和液體單相對流換熱冷卻方式無法滿足散熱需求,具有高換熱系數的微通道換熱技術成為解決微型器件散熱問題的重要途徑。然而,常規的微通道換熱技術普遍存在著高流動阻力和非均溫性的難題,限制了該技術的實際規模化應用。近年來,研究者開發出一系列新型的分形微通道技術用于換熱過程強化。本文系統總結了不同類型的分形換熱微通道(包括Y、H、T、Ψ、康托、科赫等分形結構),并對各分形微通道的原理和性能進行了著重介紹,最后對分形微通道換熱的現存挑戰和未來發展方向分別進行了分析和展望,以期為換熱過程強化的發展提供新的研究思路。Abstract: With the rapid development of microscale/nanoscale manufacturing technology, electronic microchips, microreactors, and microscale fuel cells have attracted considerable attention. The practical applications of miniaturized devices require not only advanced fabrication procedures and materials but also efficient thermal management to maintain their performance. For electronic microchips with high integration and frequency, high heat flux not only significantly limits their performance but also considerably affects their lifetime and reliability. Given that conventional air cooling and single-phase liquid convection cooling methods cannot meet the heat dissipation requirements, microchannel heat transfer technology has become an important alternative to solve the heat transfer problem of miniaturized devices. However, conventional microchannel heat transfer methods usually face two major challenges, namely, microscale dimensions that result in high-pressure drop and high-pump power consumption and temperature increase along the microchannels that considerably affect stability and reliability. The resulting high flow resistance and temperature nonuniformity significantly limit the practical applications of microchannel heat sinks. In recent years, inspired by natural fractals, such as mountain ranges, rivers, leaf venations, plant roots, tree trunks, blood vessels, and lung bronchus, researchers have developed a series of new types of fractal microchannels for heat transfer process intensification. This review provides a comprehensive overview of state-of-the-art research on fractal microchannel heat sinks, such as Y-shaped, H-shaped, T-shaped, Ψ-shaped, Cantor, and Koch fractals. We highlight the principles of heat transfer fractal microchannels, discuss the theoretical and experimental research findings, and identify the current problems and future research directions. Although research on fractal heat sinks has already gained considerable progress, the following challenges should be carefully considered: most studies focus on numerical simulations; meanwhile, experimental studies are relatively limited because of the difficulties in device fabrication. Compared with Y-shaped fractals, the other types of fractal microchannels exhibited a better performance but have received significantly less attention. Both multilayer and hydrogel-assisted fractal microchannels have typically high heat transfer capacity; however, their fabrication process is complicated. There are still a few contradictory results concerning the impact of fractal structures on heat transfer enhancement that need in-depth theoretical modeling and experimental observations. This review can not only provide an in-depth understanding of fractal microchannels but also shed new light on the development of robust fractal heat sinks for intensifying heat transfer applications.

-

Key words:

- microchannel /

- fractal /

- heat transfer /

- process intensification /

- heat sink

-

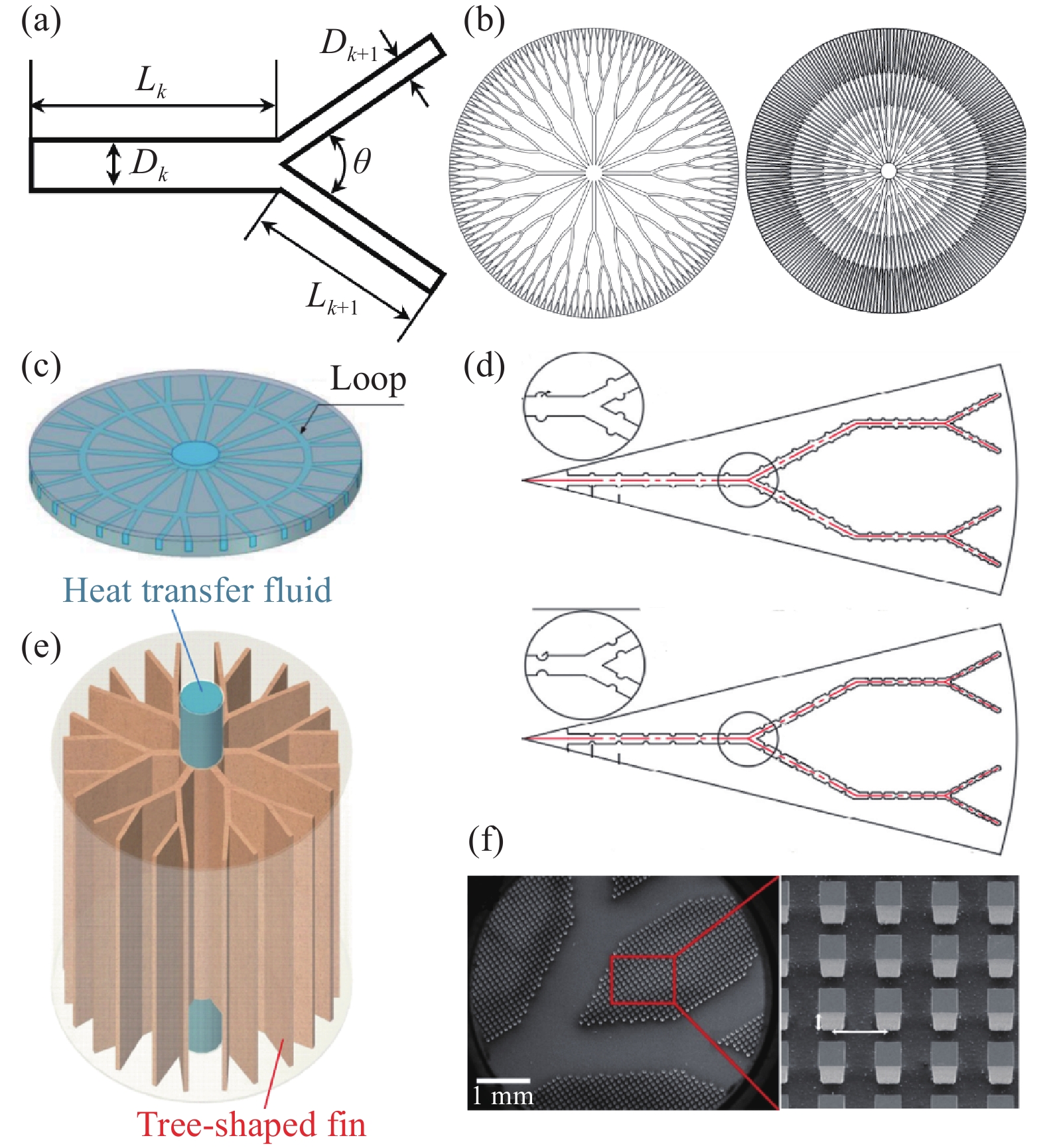

圖 2 Y形分形微通道熱沉結構. (a) Y形分形微通道結構設計示意圖;(b) 典型的通道長度逐漸降低(左)和通道長度逐漸增加(右)的Y形分形微通道網絡[10];(c) 環線連接的Y形分形微通道熱沉[11];(d) 具有凸起(上)和凹陷結構(下)的Y形分形微通道[12];(e) 三維Y形分形微通道換熱翅片[13];(f) 微型針翅陣列形成的Y形分形微通道網絡[14]

Figure 2. Y-shaped fractal microchannel heat sinks: (a) schematic diagram of the structural design of Y-shaped fractal microchannels; (b) typical Y-shaped fractal microchannel network with decreasing (left) and increasing (right) channel lengths[10]; (c) Y-shaped fractal microchannel heat sink with connected loops[11]; (d) Y-shaped fractal microchannels with ribs (top) and cavities (bottom)[12]; (e) 3D Y-shaped fractal microchannel fins[13]; (f) Y-shaped fractal microchannel network formed by specific microscale pin-fins[14]

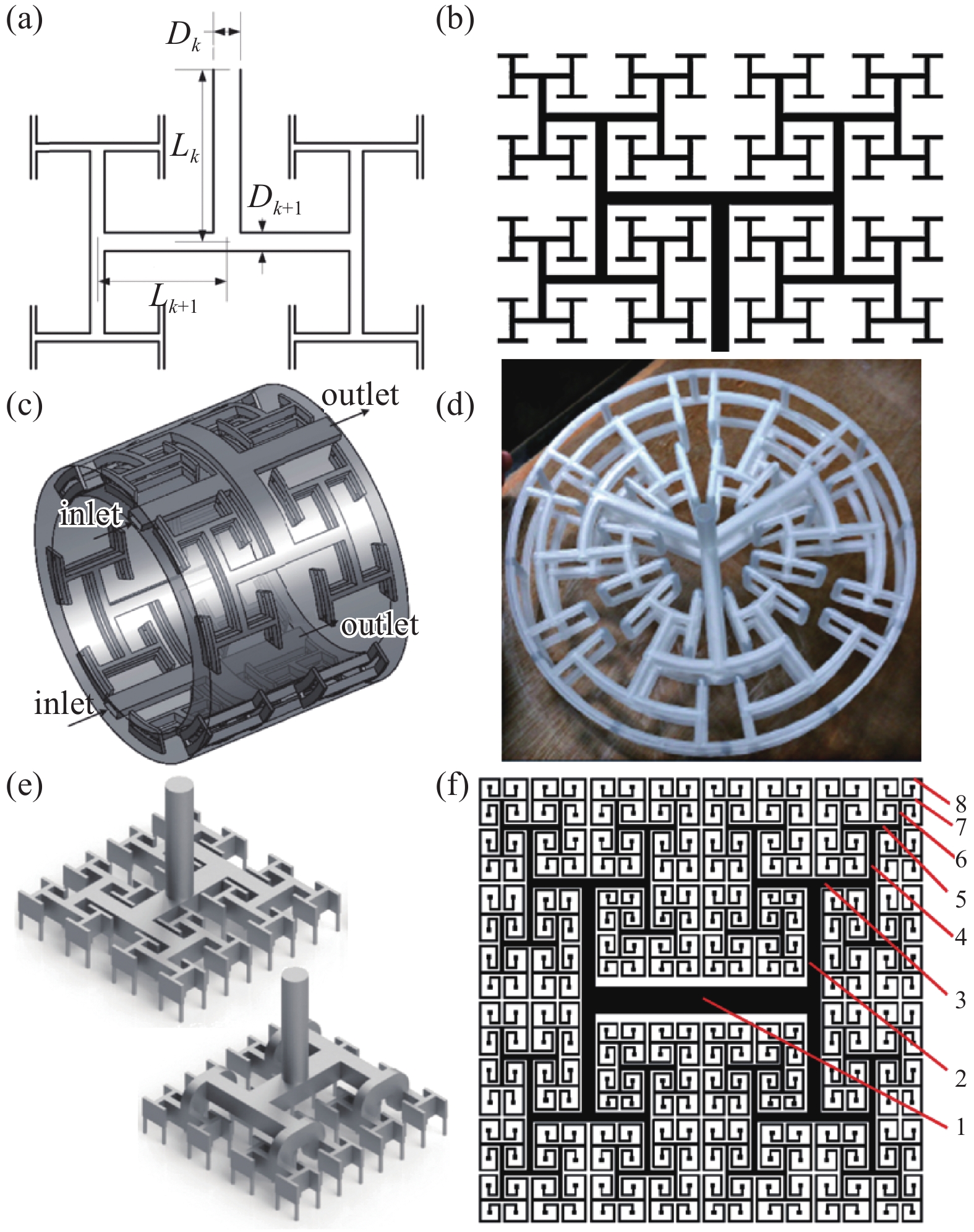

圖 3 H形分形微通道熱沉結構. (a) H形分形微通道結構設計示意圖[44];(b) 一種典型的H形分形微通道熱沉結構[42];(c) 圓筒狀分布H形分形微通道熱沉[44];(d) 3D打印扭曲H形分形微通道結構[45];(e) 共平面(左)與面外(右)H形分形微通道熱沉[46];(f) 末端為S形通道的H形分形微通道網絡(數字1~8為尺寸不斷遞減的分支通道)[47]

Figure 3. H-shaped fractal microchannel heat sinks: (a) schematic diagram of the structural design of H-shaped fractal microchannels[44]; (b) one kind of typical H-shaped fractal microchannel heat sink[42]; (c) cylindrical H-shaped fractal microchannel heat sink[44]; (d) distorted H-shaped fractal microchannels manufactured by 3D printing[45]; (e) coplanar (top) and out-of-plane (bottom) H-shaped fractal microchannel heat sink[46]; (f) modified H-shaped fractal microchannel network ending with serpentine channels (numbers 1–8 denote the size-reducing branch channels)[47]

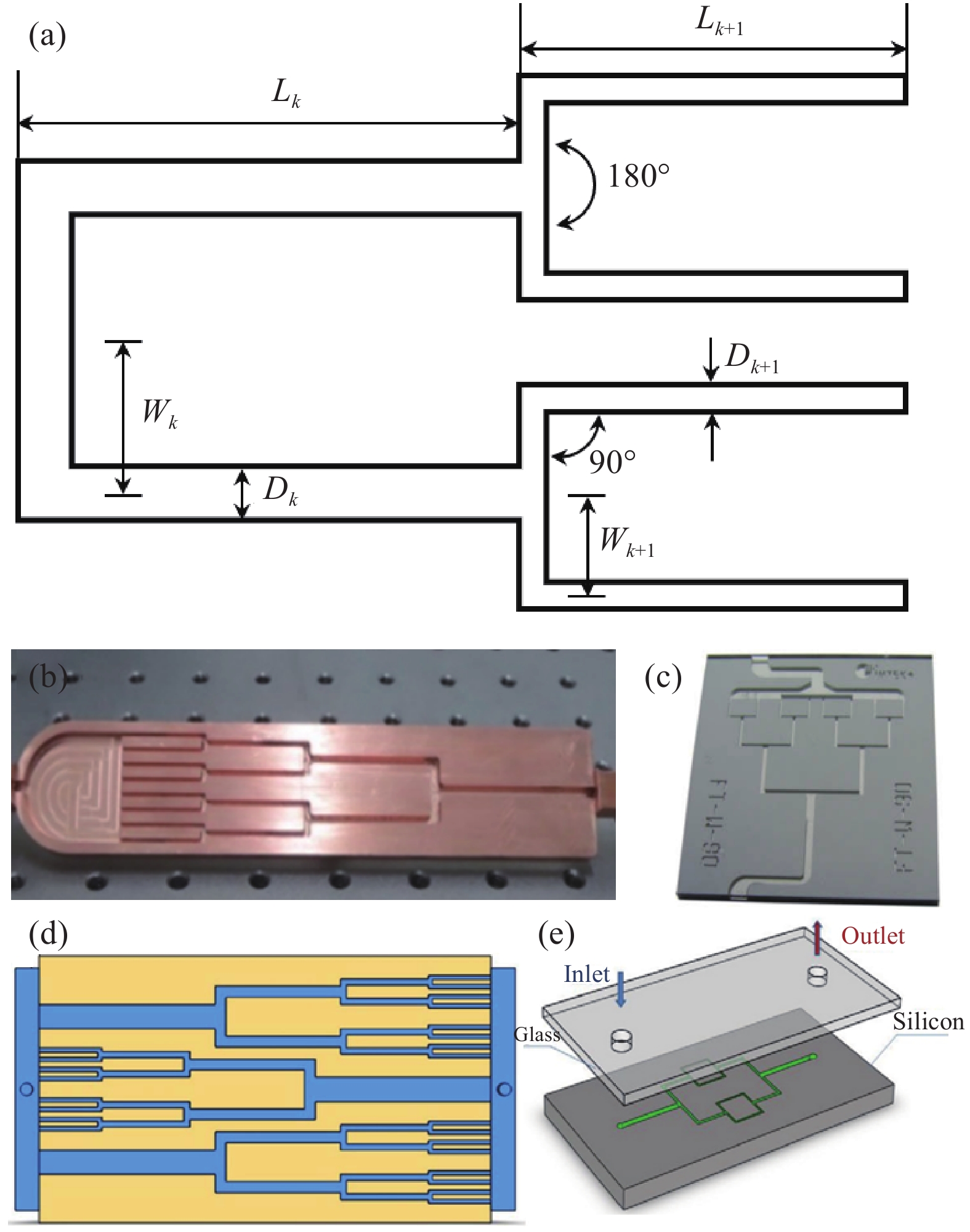

圖 4 T形分形微通道熱沉結構. (a) T形分形微通道結構設計示意圖;(b) 銅基底分形結構裝置[58];(c) 硅基底分形結構裝置[59];(d) 多簇T形分形微通道結構設計[61];(e) 基于T形分形結構的矩形微通道[63]

Figure 4. T-shaped fractal microchannel heat sinks: (a) schematic diagram of the structural design of T-shaped fractal microchannels; (b) T-shaped fractal microchannels on the copper substrate[58]; (c) T-shaped fractal microchannels on the silicon substrate[59]; (d) structural design of multiple T-shaped fractal microchannels[61]; (e) rectangular microchannels based on the T-shaped fractal structures[63]

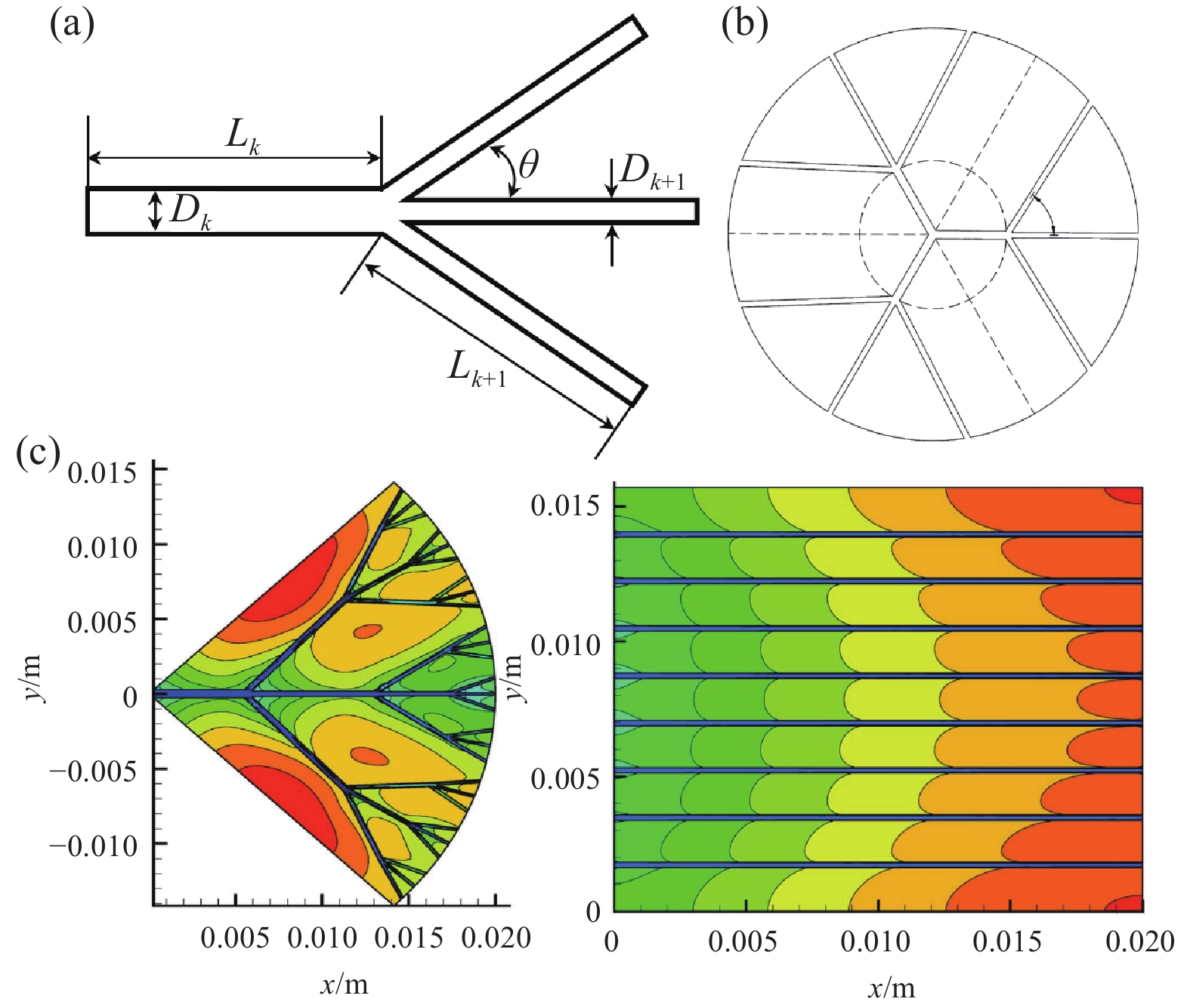

圖 5 Ψ形分形微通道熱沉結構. (a) Ψ形分形微通道結構設計示意圖;(b) 多簇Ψ形分形微通道結構設計[67];(c) Ψ形(左)和直形(右)微通道網絡的溫度分布[68]

Figure 5. Ψ-shaped fractal microchannel heat sinks: (a) schematic diagram of the structural design of Ψ-shaped fractal microchannels; (b) structural design of multiple Ψ-shaped fractal microchannels[67]; (c) temperature distribution of Ψ-shaped fractal microchannels (left) and straight parallel microchannels (right)[68]

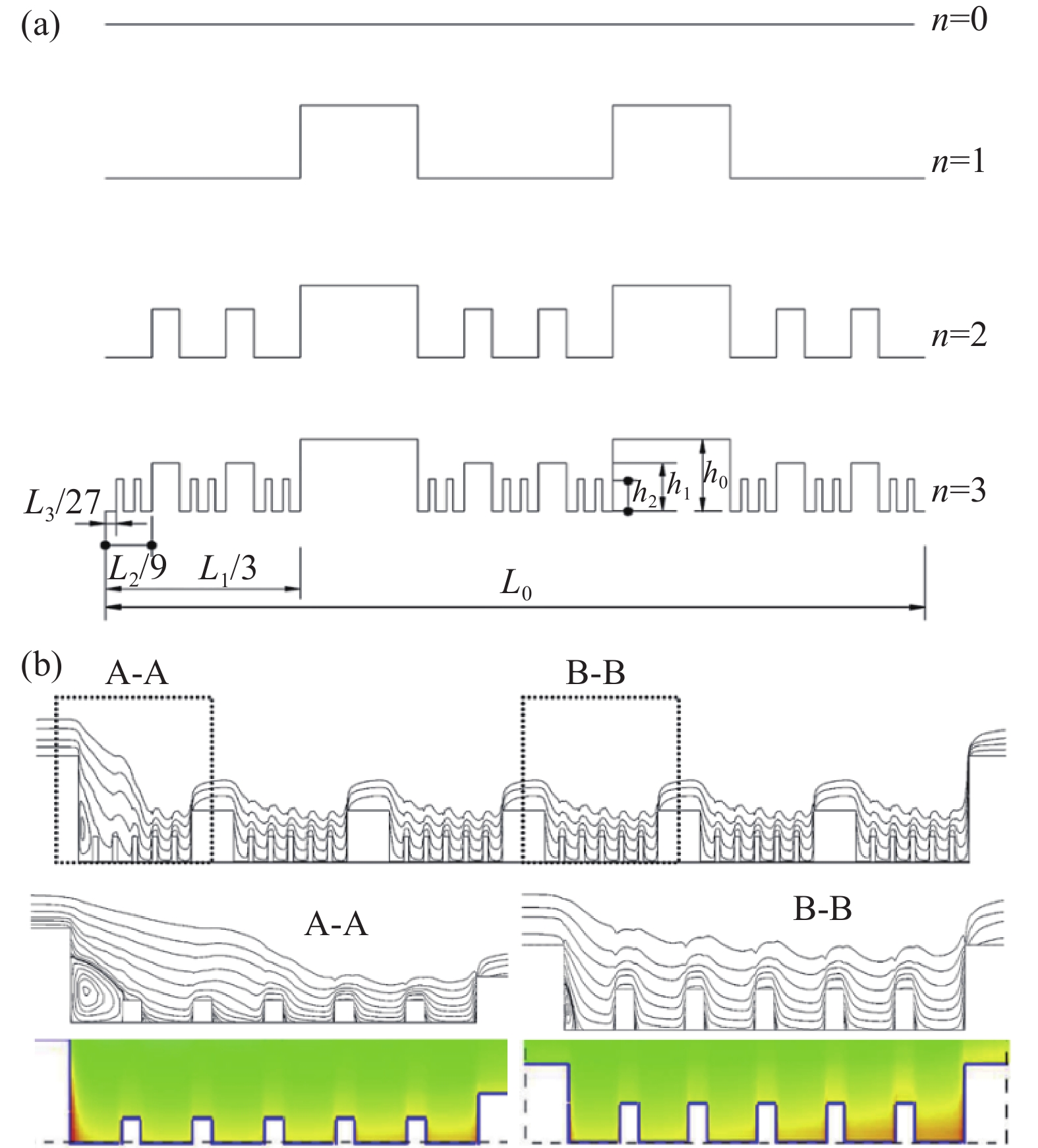

圖 6 康托分形微通道熱沉結構. (a) 康托分形微通道結構設計示意圖[71];(b) 康托分形微通道結構近壁區流線圖及溫度分布[72]

Figure 6. Cantor fractal microchannel heat sinks: (a) schematic diagram of the structural design of Cantor fractal microchannels[71]; (b) local streamlines and temperature profiles in the near-wall region of Cantor fractal microchannels[72]

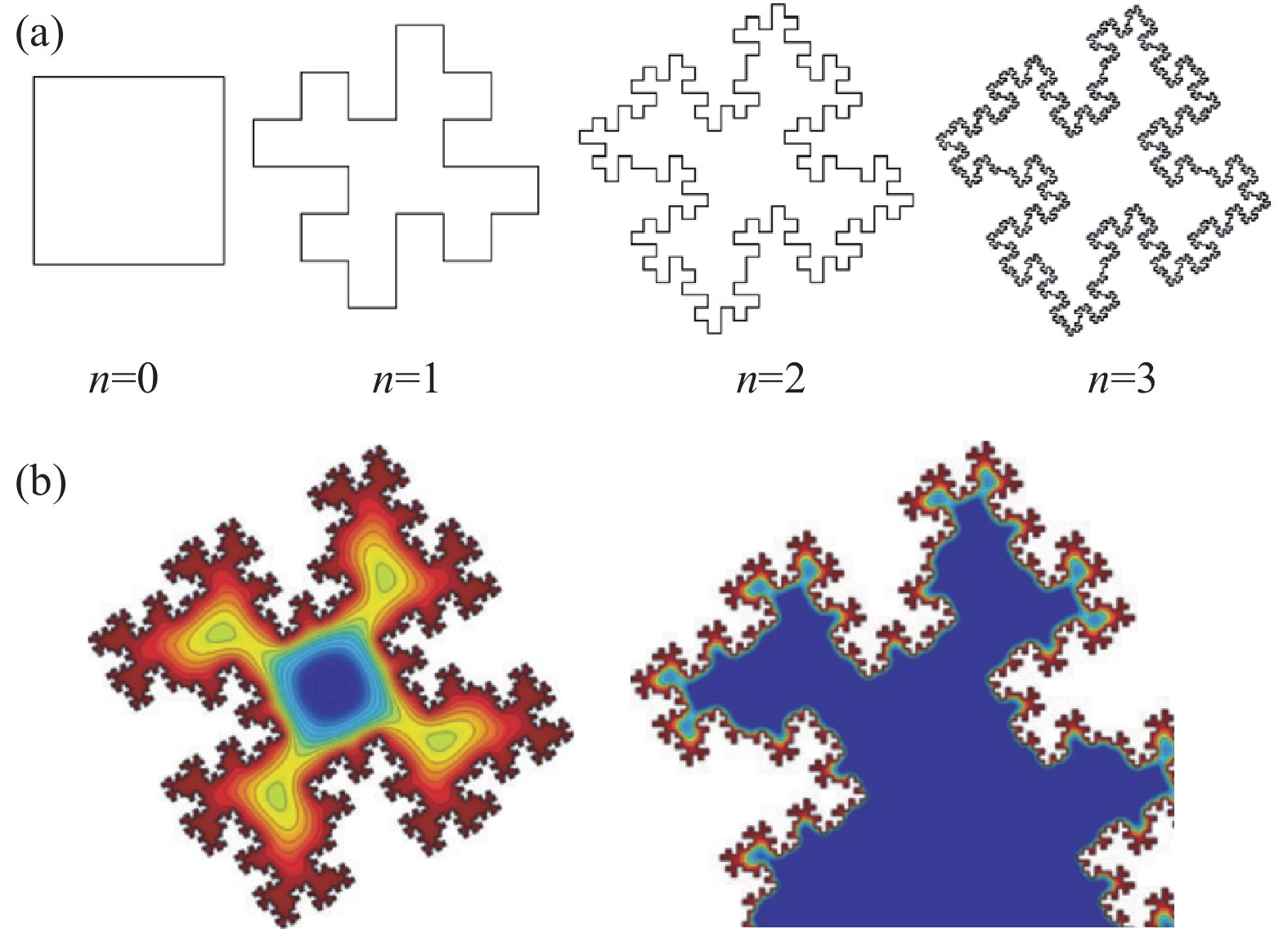

圖 7 科赫分形微通道熱沉結構. (a) 方形科赫分形結構設計示意圖[74];(b) 方形科赫分形微通道結構流速場(左)及溫度場(右)分布圖[75]

Figure 7. Koch fractal microchannel heat sinks: (a) schematic diagram of the structural design of quadratic Koch fractal microchannels[74]; (b) contour color plot of the velocity (left) and temperature (right) fields of quadratic Koch fractal microchannels[75]

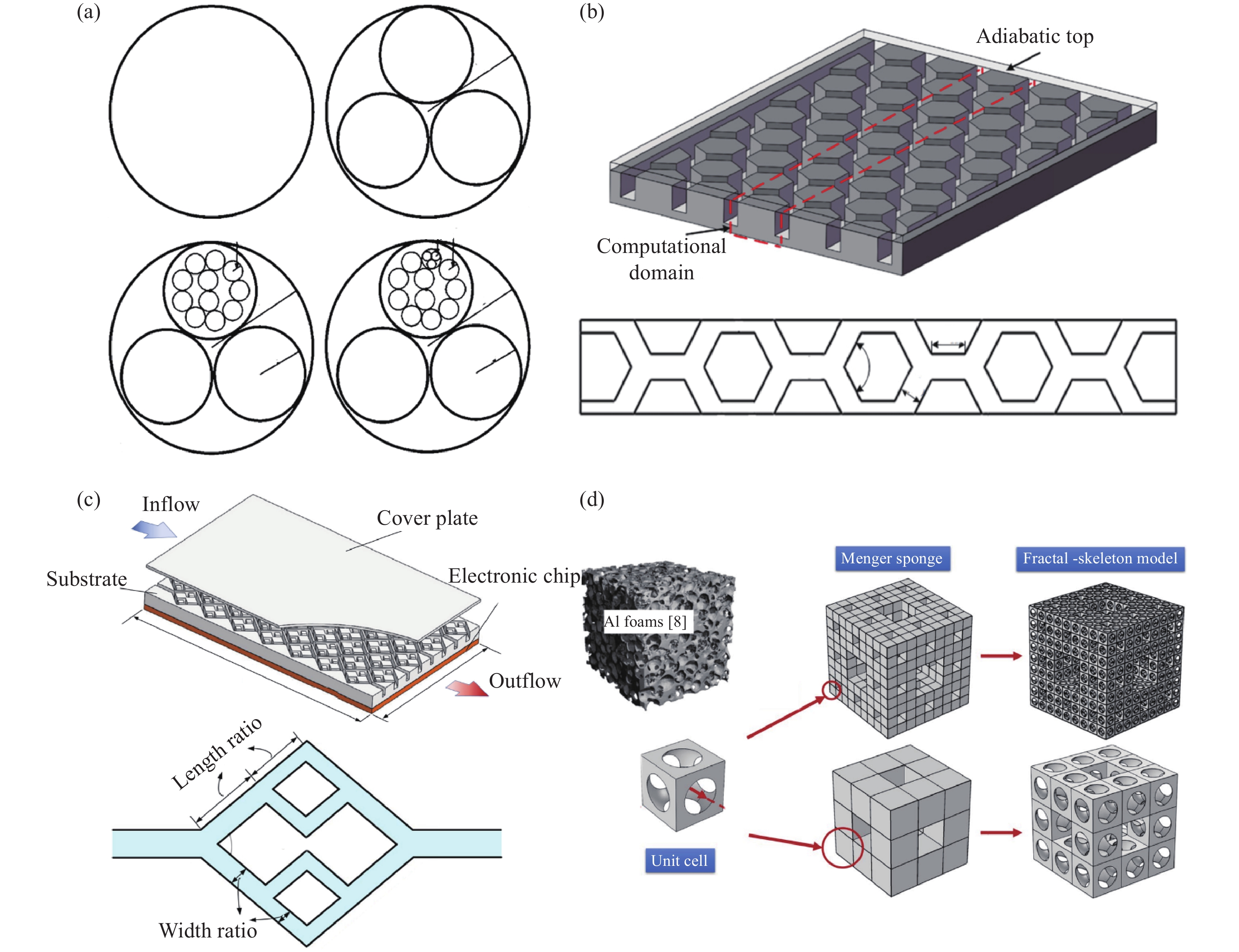

久色视频圖 8 其他類型分形微通道熱沉結構. (a) 羊毛纖維狀分形通道網絡[76];(b) 六邊形分形微通道換熱結構[77];(c) 菱形分形微通道熱沉[78];(d)分形骨架結構模擬孔狀鋁換熱過程[79]

Figure 8. Other types of fractal microchannel heat sinks: (a) fractal channel network of wool fiber [76]; (b) heat transfer platform with hexagonal fractal microchannels[77]; (c) microchannel heat sink with rhombus fractal structures[78]; (d) fractal skeleton structures to simulate the heat transfer process of porous aluminum[79]

-

參考文獻

[1] Wei J J, Zhang Y H. Review of enhanced boiling heat transfer over micro-pin-finned surfaces. CIESC J, 2016, 67(1): 97魏進家, 張永海. 柱狀微結構表面強化沸騰換熱研究綜述. 化工學報, 2016, 67(1):97 [2] Wei J J, Liu B, Zhang Y H. Progress in enhanced boiling heat transfer over microstructured surfaces under normal/microgravity. Chem Ind Eng Prog, 2019, 38(1): 14 doi: 10.16085/j.issn.1000-6613.2018-1133魏進家, 劉斌, 張永海. 常/微重力下微結構表面強化沸騰換熱研究進展. 化工進展, 2019, 38(1):14 doi: 10.16085/j.issn.1000-6613.2018-1133 [3] Ramesh K N, Sharma T K, Rao G A P. Latest advancements in heat transfer enhancement in the micro-channel heat sinks: A review. Arch Comput Methods Eng, 2021, 28(4): 3135 doi: 10.1007/s11831-020-09495-1 [4] Kumar S, Kumar A, Kothiyal A D, et al. A review of flow and heat transfer behaviour of nanofluids in micro channel heat sinks. Therm Sci Eng Prog, 2018, 8: 477 doi: 10.1016/j.tsep.2018.10.004 [5] Japar W M A A, Sidik N A C, Mat S. A comprehensive study on heat transfer enhancement in microchannel heat sink with secondary channel. Int Commun Heat Mass Transf, 2018, 99: 62 doi: 10.1016/j.icheatmasstransfer.2018.10.005 [6] Sidik N A C, Muhamad M N A W, Japar W M A A, et al. An overview of passive techniques for heat transfer augmentation in microchannel heat sink. Int Commun Heat Mass Transf, 2017, 88: 74 doi: 10.1016/j.icheatmasstransfer.2017.08.009 [7] Tuckerman D B, Pease R F W. High-performance heat sinking for VLSI. IEEE Electron Device Lett, 1981, 2(5): 126 doi: 10.1109/EDL.1981.25367 [8] Deng D X, Zeng L, Sun W. A review on flow boiling enhancement and fabrication of enhanced microchannels of microchannel heat sinks. Int J Heat Mass Transf, 2021, 175: 121332 doi: 10.1016/j.ijheatmasstransfer.2021.121332 [9] Chen X Y, Li T C, Shen J N, et al. Fractal design of microfluidics and nanofluidics—A review. Chemom Intell Lab Syst, 2016, 155: 19 doi: 10.1016/j.chemolab.2016.04.003 [10] Daniels B, Liburdy J A, Pence D V. Adiabatic flow boiling in fractal-like microchannels. Heat Transf Eng, 2007, 28(10): 817 doi: 10.1080/01457630701378218 [11] Yan Y F, Shen K M, Liu Y, et al. Thermal-hydraulic performance enhancement of miniature heat sinks using connected Y-shaped fractal micro-channels. Chem Eng Process Process Intensif, 2021, 166: 108487 doi: 10.1016/j.cep.2021.108487 [12] Huang P N, Dong G P, Zhong X N, et al. Numerical investigation of the fluid flow and heat transfer characteristics of tree-shaped microchannel heat sink with variable cross-section. Chem Eng Process Process Intensif, 2020, 147: 107769 doi: 10.1016/j.cep.2019.107769 [13] Zhang C B, Li J, Chen Y P. Improving the energy discharging performance of a latent heat storage (LHS) unit using fractal-tree-shaped fins. Appl Energy, 2020, 259: 114102 doi: 10.1016/j.apenergy.2019.114102 [14] Yuan B, Liu L, Cui C Y, et al. Micro-pin-finned surfaces with fractal treelike hydrophilic networks for flow boiling enhancement. ACS Appl Mater Interfaces, 2021, 13(40): 48189 doi: 10.1021/acsami.1c11250 [15] Pence D. Reduced pumping power and wall temperature in microchannel heat sinks with fractal-like branching channel networks. Microscale Thermophys Eng, 2003, 6(4): 319 doi: 10.1080/10893950290098359 [16] Alharbi A Y, Pence D V, Cullion R N. Fluid flow through microscale fractal-like branching channel networks. J Fluids Eng, 2003, 125(6): 1051 doi: 10.1115/1.1625684 [17] Alharbi A Y, Pence D V, Cullion R N. Thermal characteristics of microscale fractal-like branching channels. J Heat Transf, 2004, 126(5): 744 doi: 10.1115/1.1795236 [18] Heymann D, Pence D, Narayanan V. Optimization of fractal-like branching microchannel heat sinks for single-phase flows. Int J Therm Sci, 2010, 49(8): 1383 doi: 10.1016/j.ijthermalsci.2010.01.015 [19] Salakij S, Liburdy J A, Pence D V, et al. Modeling in situ vapor extraction during convective boiling in fractal-like branching microchannel networks. Int J Heat Mass Transf, 2013, 60: 700 doi: 10.1016/j.ijheatmasstransfer.2013.01.004 [20] Ghaedamini H, Salimpour M R, Mujumdar A S. The effect of svelteness on the bifurcation angles role in pressure drop and flow uniformity of tree-shaped microchannels. Appl Therm Eng, 2011, 31(5): 708 doi: 10.1016/j.applthermaleng.2010.10.005 [21] Wang S F, Yu B M. A fractal model for the starting pressure gradient for Bingham fluids in porous media embedded with fractal-like tree networks. Int J Heat Mass Transf, 2011, 54(21-22): 4491 doi: 10.1016/j.ijheatmasstransfer.2011.06.031 [22] Lyu Z J, Pourfattah F, Arani A A A, et al. On the thermal performance of a fractal microchannel subjected to water and kerosene carbon nanotube nanofluid. Sci Rep, 2020, 10: 7243 doi: 10.1038/s41598-020-64142-w [23] Niu Y T, Huang P N, Pan M Q. Study of heat and mass transfer by bionic fractal microchannel plates. Chem Eng Technol, 2021, 44(4): 741 doi: 10.1002/ceat.202000554 [24] Yan Y F, Yan H Y, Yin S Y, et al. Single/multi-objective optimizations on hydraulic and thermal management in micro-channel heat sink with bionic Y-shaped fractal network by genetic algorithm coupled with numerical simulation. Int J Heat Mass Transf, 2019, 129: 468 doi: 10.1016/j.ijheatmasstransfer.2018.09.120 [25] He Z Q, Yan Y F, Zhao T, et al. Multi-objective optimization and multi-factors analysis of the thermal/hydraulic performance of the bionic Y-shaped fractal heat sink. Appl Therm Eng, 2021, 195: 117157 doi: 10.1016/j.applthermaleng.2021.117157 [26] He Z Q, Yan Y F, Feng S, et al. Multi-objective optimizations on thermal and hydraulic performance of symmetric and asymmetric bionic Y-shaped fractal networks by genetic algorithm coupled with CFD simulation. Int Commun Heat Mass Transf, 2021, 124: 105261 doi: 10.1016/j.icheatmasstransfer.2021.105261 [27] Yan Y F, He Z Q, Wu G G, et al. Influence of hydrogels embedding positions on automatic adaptive cooling of hot spot in fractal microchannel heat sink. Int J Therm Sci, 2020, 155: 106428 doi: 10.1016/j.ijthermalsci.2020.106428 [28] Duan Z J, Xie G N, Shen H, et al. Thermal performance and entropy generation of single-layer and double-layer constructal Y-shaped bionic microchannel heat sinks. Int J Energy Res, 2021, 45(6): 9449 doi: 10.1002/er.6473 [29] Yan Y F, Yan H Y, Feng S, et al. Thermal-hydraulic performances and synergy effect between heat and flow distribution in a truncated doubled-layered heat sink with Y-shaped fractal network. Int J Heat Mass Transf, 2019, 142: 118337 doi: 10.1016/j.ijheatmasstransfer.2019.06.093 [30] Fang K, Xu S L. Microfludic and heat transfer performance of multilayer fractal-like microchannel network. Adv Mater Res, 2011, 422: 392 doi: 10.4028/www.scientific.net/AMR.422.392 [31] Pence D. The simplicity of fractal-like flow networks for effective heat and mass transport. Exp Therm Fluid Sci, 2010, 34(4): 474 doi: 10.1016/j.expthermflusci.2009.02.004 [32] Kwak Y, Pence D, Liburdy J, et al. Gas-liquid flows in a microscale fractal-like branching flow network. Int J Heat Fluid Flow, 2009, 30(5): 868 doi: 10.1016/j.ijheatfluidflow.2009.03.014 [33] Daniels B J, Liburdy J A, Pence D V. Experimental studies of adiabatic flow boiling in fractal-like branching microchannels. Exp Therm Fluid Sci, 2011, 35(1): 1 doi: 10.1016/j.expthermflusci.2010.07.016 [34] Xu S L, Wang W J, Fang K, et al. Heat transfer performance of a fractal silicon microchannel heat sink subjected to pulsation flow. Int J Heat Mass Transf, 2015, 81: 33 doi: 10.1016/j.ijheatmasstransfer.2014.10.002 [35] Xu S L, Li Y, Hu X L, et al. Characteristics of heat transfer and fluid flow in a fractal multilayer silicon microchannel. Int Commun Heat Mass Transf, 2016, 71: 86 doi: 10.1016/j.icheatmasstransfer.2015.12.024 [36] Huang J, Zhang J H, Wang S Y, et al. Analysis of the flow rate characteristics of valveless piezoelectric pump with fractal-like Y-shape branching tubes. Chin J Mech Eng, 2014, 27(3): 628 doi: 10.3901/CJME.2014.03.628 [37] Liang L X, Hou J B, Fang X J, et al. Flow characteristics and heat transfer performance in a Y-Fractal mini/microchannel heat sink. Case Stud Therm Eng, 2019, 15: 100522 doi: 10.1016/j.csite.2019.100522 [38] See Y S, Leong K C. Experimental study of flow boiling of FC-72 in fractal-like flow channels. Int J Therm Sci, 2019, 140: 184 doi: 10.1016/j.ijthermalsci.2019.02.042 [39] Wang X Q, Yap C, Mujumdar A S. Laminar heat transfer in constructal microchannel networks with loops. J Electron Packag, 2006, 128(3): 273 doi: 10.1115/1.2229228 [40] Xu P, Wang X Q, Mujumdar A S, et al. Thermal characteristics of tree-shaped microchannel nets with/without loops. Int J Therm Sci, 2009, 48(11): 2139 doi: 10.1016/j.ijthermalsci.2009.03.018 [41] Yan Y F, Zhang C H, Liu Y, et al. Numerical study on hotspots adaptive cooling and thermal-hydraulic performance enhancement of fractal microchannel heat sink embedded with hydrogels. Int J Therm Sci, 2022, 172: 107272 doi: 10.1016/j.ijthermalsci.2021.107272 [42] Liu S T, Zhang Y C, Liu P. Heat transfer and pressure drop in fractal microchannel heat sink for cooling of electronic chips. Heat Mass Transf, 2007, 44(2): 221 doi: 10.1007/s00231-007-0240-0 [43] Ge H, Hong F J, Zheng P. The application of tree-shaped microchannel network in microelectronic cooling. J Eng Thermophys, 2007, 28(Suppl 2): 41葛浩, 洪芳軍, 鄭平. 樹型微通道網絡在集成微電子冷卻中的應用. 工程熱物理學報, 2007, 28(增刊2): 41 [44] Xia C H, Fu J Z, Lai J T, et al. Conjugate heat transfer in fractal tree-like channels network heat sink for high-speed motorized spindle cooling. Appl Therm Eng, 2015, 90: 1032 doi: 10.1016/j.applthermaleng.2015.07.024 [45] Wang G, Gu Y, Zhao L, et al. Experimental and numerical investigation of fractal-tree-like heat exchanger manufactured by 3D printing. Chem Eng Sci, 2019, 195: 250 doi: 10.1016/j.ces.2018.07.021 [46] Paniagua-Guerra L E, Sehgal S, Gonzalez-Valle C U, et al. Fractal channel manifolds for microjet liquid-cooled heat sinks. Int J Heat Mass Transf, 2019, 138: 257 doi: 10.1016/j.ijheatmasstransfer.2019.04.039 [47] Hong F J, Cheng P, Wu H Y. Characterization on the performance of a fractal-shaped microchannel network for microelectronic cooling. J Micromech Microeng, 2011, 21(6): 065018 doi: 10.1088/0960-1317/21/6/065018 [48] Bejan A. Constructal-theory network of conducting paths for cooling a heat generating volume. Int J Heat Mass Transf, 1997, 40(4): 799 doi: 10.1016/0017-9310(96)00175-5 [49] Chen Y P, Cheng P. Heat transfer and pressure drop in fractal tree-like microchannel nets. Int J Heat Mass Transf, 2002, 45(13): 2643 doi: 10.1016/S0017-9310(02)00013-3 [50] Zhang C B, Chen Y P, Wu R, et al. Flow boiling in constructal tree-shaped minichannel network. Int J Heat Mass Transf, 2011, 54(1-3): 202 doi: 10.1016/j.ijheatmasstransfer.2010.09.051 [51] Chen Y P, Cheng P. An experimental investigation on the thermal efficiency of fractal tree-like microchannel nets. Int Commun Heat Mass Transf, 2005, 32(7): 931 doi: 10.1016/j.icheatmasstransfer.2005.02.001 [52] Chen Y P, Zhang C B, Shi M H, et al. Thermal and hydrodynamic characteristics of constructal tree-shaped minichannel heat sink. Aiche J, 2010, 56(8): 2018 [53] Senn S M, Poulikakos D. Laminar mixing, heat transfer and pressure drop in tree-like microchannel nets and their application for thermal management in polymer electrolyte fuel cells. J Power Sources, 2004, 130(1-2): 178 doi: 10.1016/j.jpowsour.2003.12.025 [54] Yu W, Xu L Y, Chen S J, et al. Numerical study on flow boiling in a tree-shaped microchannel. Fractals, 2019, 27(7): 1950111 doi: 10.1142/S0218348X19501111 [55] Ghodoossi L. Thermal and hydrodynamic analysis of a fractal microchannel network. Energy Convers Manag, 2005, 46(5): 771 doi: 10.1016/j.enconman.2004.05.008 [56] Escher W, Michel B, Poulikakos D. Efficiency of optimized bifurcating tree-like and parallel microchannel networks in the cooling of electronics. Int J Heat Mass Transf, 2009, 52(5-6): 1421 doi: 10.1016/j.ijheatmasstransfer.2008.07.048 [57] Hong F J, Cheng P, Ge H, et al. Conjugate heat transfer in fractal-shaped microchannel network heat sink for integrated microelectronic cooling application. Int J Heat Mass Transf, 2007, 50(25-26): 4986 doi: 10.1016/j.ijheatmasstransfer.2007.09.006 [58] Shui L Q, Huang B, Gao F, et al. Experimental and numerical investigation on the flow and heat transfer characteristics in a tree-like branching microchannel. J Mech Sci Technol, 2018, 32(2): 937 doi: 10.1007/s12206-018-0144-y [59] Haller D, Woias P, Kockmann N. Simulation and experimental investigation of pressure loss and heat transfer in microchannel networks containing bends and T-junctions. Int J Heat Mass Transf, 2009, 52(11-12): 2678 doi: 10.1016/j.ijheatmasstransfer.2008.09.042 [60] Yan W T, Li C, Ye W B. Numerical investigation of hydrodynamic and heat transfer performances of nanofluids in a fractal microchannel heat sink. Heat Trans Asian Res, 2019, 48(6): 2329 doi: 10.1002/htj.21494 [61] Ge Q M, Chen Z M. Numerical study on heat dissipation performance of fractal tree microchannel. Int J Fluid Dyn, 2021(3): 44葛秋明, 陳正明. 分形樹狀微通道散熱性能的數值研究. 流體動力學, 2021(3):44 [62] Wang X Q, Mujumdar A S, Yap C. Thermal characteristics of tree-shaped microchannel nets for cooling of a rectangular heat sink. Int J Therm Sci, 2006, 45(11): 1103 doi: 10.1016/j.ijthermalsci.2006.01.010 [63] Yu X F, Zhang C P, Teng J T, et al. A study on the hydraulic and thermal characteristics in fractal tree-like microchannels by numerical and experimental methods. Int J Heat Mass Transf, 2012, 55(25-26): 7499 doi: 10.1016/j.ijheatmasstransfer.2012.07.050 [64] Zhang C P, Lian Y F, Yu X F, et al. Numerical and experimental studies on laminar hydrodynamic and thermal characteristics in fractal-like microchannel networks. Part A: Comparisons of two numerical analysis methods on friction factor and Nusselt number. Int J Heat Mass Transf, 2013, 66: 930 [65] Zhang C P, Lian Y F, Hsu C H, et al. Investigations of thermal and flow behavior of bifurcations and bends in fractal-like microchannel networks: Secondary flow and recirculation flow. Int J Heat Mass Transf, 2015, 85: 723 doi: 10.1016/j.ijheatmasstransfer.2015.01.118 [66] Zhang C P, Lian Y F, Yu X F, et al. Numerical and experimental studies on laminar hydrodynamic and thermal characteristics in fractal-like microchannel networks. Part B: Investigations on the performances of pressure drop and heat transfer. Int J Heat Mass Transf, 2013, 66: 939 [67] Wechsatol W, Lorente S, Bejan A. Optimal tree-shaped networks for fluid flow in a disc-shaped body. Int J Heat Mass Transf, 2002, 45(25): 4911 doi: 10.1016/S0017-9310(02)00211-9 [68] Wang X Q, Mujumdar A S, Yap C. Numerical analysis of blockage and optimization of heat transfer performance of fractal-like microchannel nets. J Electron Packag, 2006, 128(1): 38 doi: 10.1115/1.2159007 [69] Rubio-Jimenez C A, Hernandez-Guerrero A, Cervantes J G, et al. CFD study of constructal microchannel networks for liquid-cooling of electronic devices. Appl Therm Eng, 2016, 95: 374 doi: 10.1016/j.applthermaleng.2015.11.037 [70] Wang M, Sun H Y, Cheng L. Investigation of convective heat transfer performance in nanochannels with fractal Cantor structures. Int J Heat Mass Transf, 2021, 171: 121086 doi: 10.1016/j.ijheatmasstransfer.2021.121086 [71] Chen Y P, Zhang C B, Fu P P, et al. Characterization of surface roughness effects on laminar flow in microchannels by using fractal cantor structures. J Heat Transf, 2012, 134(5): 051011 doi: 10.1115/1.4005701 [72] Chen Y P, Fu P P, Zhang C B, et al. Numerical simulation of laminar heat transfer in microchannels with rough surfaces characterized by fractal Cantor structures. Int J Heat Fluid Flow, 2010, 31(4): 622 doi: 10.1016/j.ijheatfluidflow.2010.02.017 [73] Zhang C B, Deng Z L, Chen Y P. Temperature jump at rough gas-solid interface in Couette flow with a rough surface described by Cantor fractal. Int J Heat Mass Transf, 2014, 70: 322 doi: 10.1016/j.ijheatmasstransfer.2013.10.080 [74] Meyer J P, van der Vyver H. Heat transfer characteristics of a quadratic Koch Island fractal heat exchanger. Heat Transf Eng, 2005, 26(9): 22 doi: 10.1080/01457630500205638 [75] Adrover A. Laminar convective heat transfer across fractal boundaries. Europhys Lett, 2010, 90(1): 14002 doi: 10.1209/0295-5075/90/14002 [76] Fan J, Liu Y. Heat transfer in fractal channel network of wool fibre. Mater Sci Technol, 2010, 26(11): 1320 doi: 10.1179/026708310X12798718274278 [77] Yang X, Wei L C, Cao F, et al. A parametric study of laminar convective heat transfer in fractal minichannels with hexagonal fins. Int J Energy Res, 2020, 44(12): 9382 doi: 10.1002/er.4942 [78] Zhuang D W, Yang Y F, Ding G L, et al. Optimization of microchannel heat sink with rhombus fractal-like units for electronic chip cooling. Int J Refrig, 2020, 116: 108 doi: 10.1016/j.ijrefrig.2020.03.026 [79] Yu H Y, Zhang H C, Xia X L. A fractal-skeleton model of high porosity macroporous aluminum and its heat transfer characterizes. J Therm Anal Calorim, 2020, 141(1): 351 doi: 10.1007/s10973-020-09535-9 -

下載:

下載: