Research on the mathematical relationship between mud height and underflow concentration of deep cone thickener based on effective stress

-

摘要: 首先,從Terzaghi有效應力原理定義出發,證明了有效應力原理在深錐濃密機泥層壓力分析中的適用性。其次,以壓縮系數

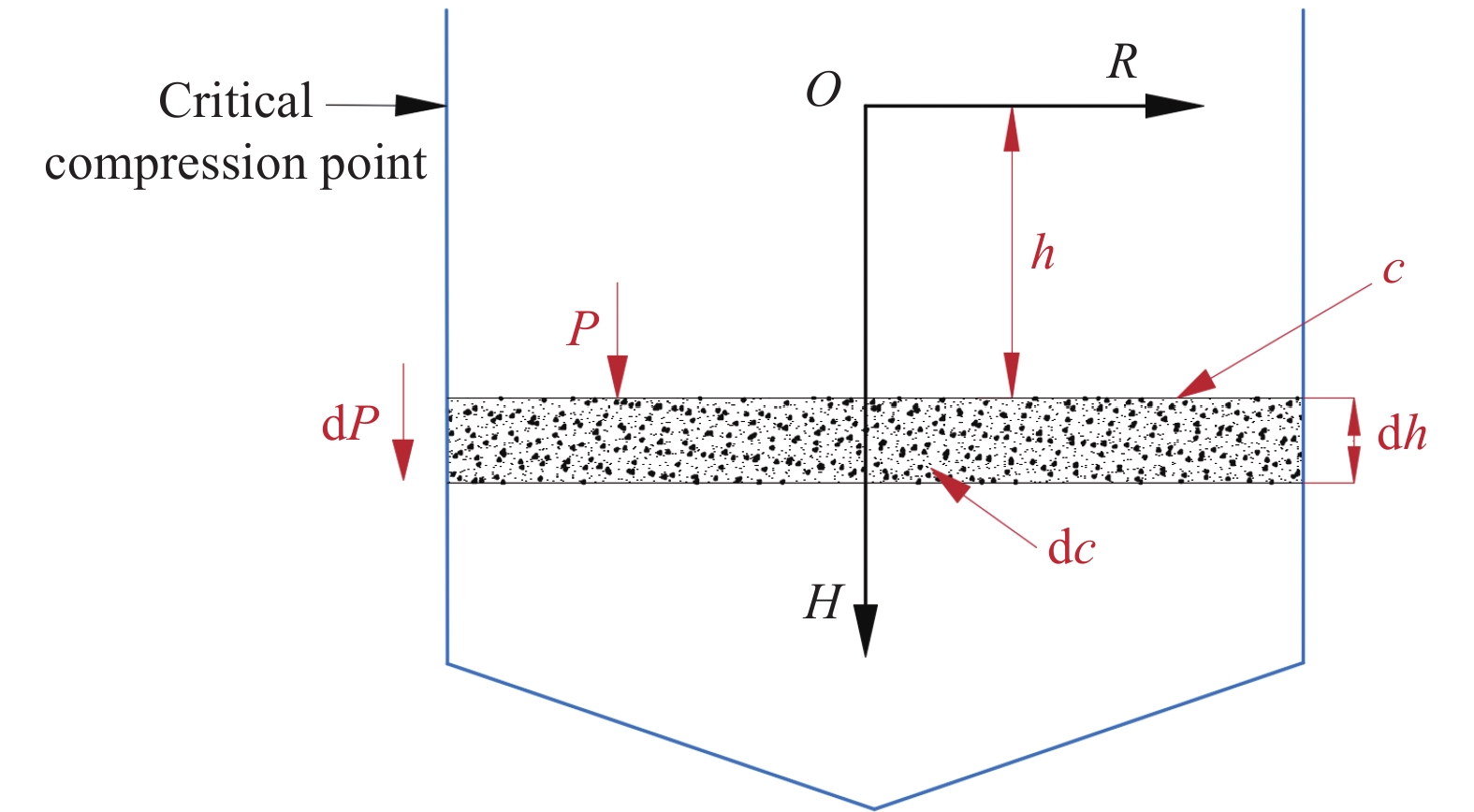

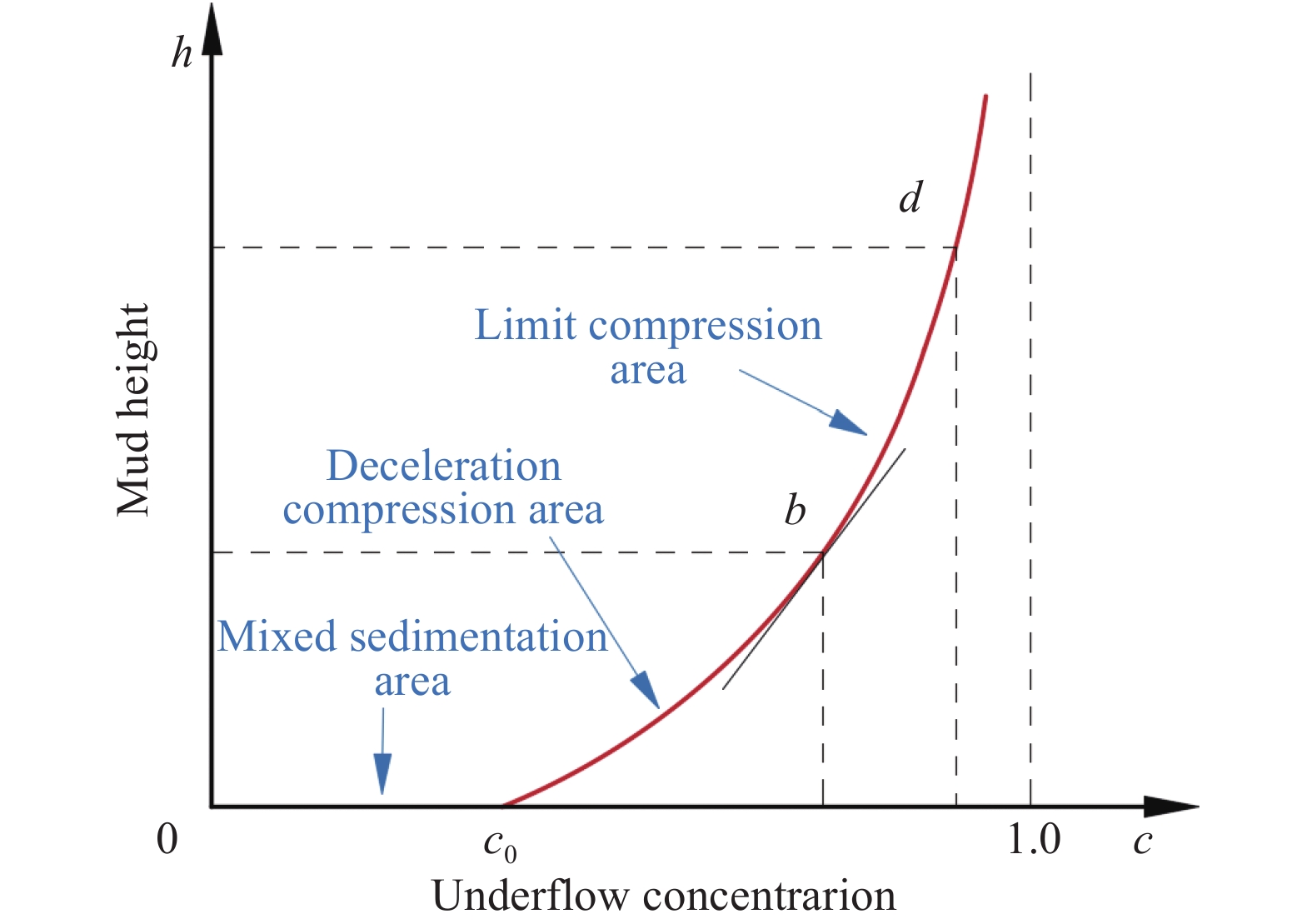

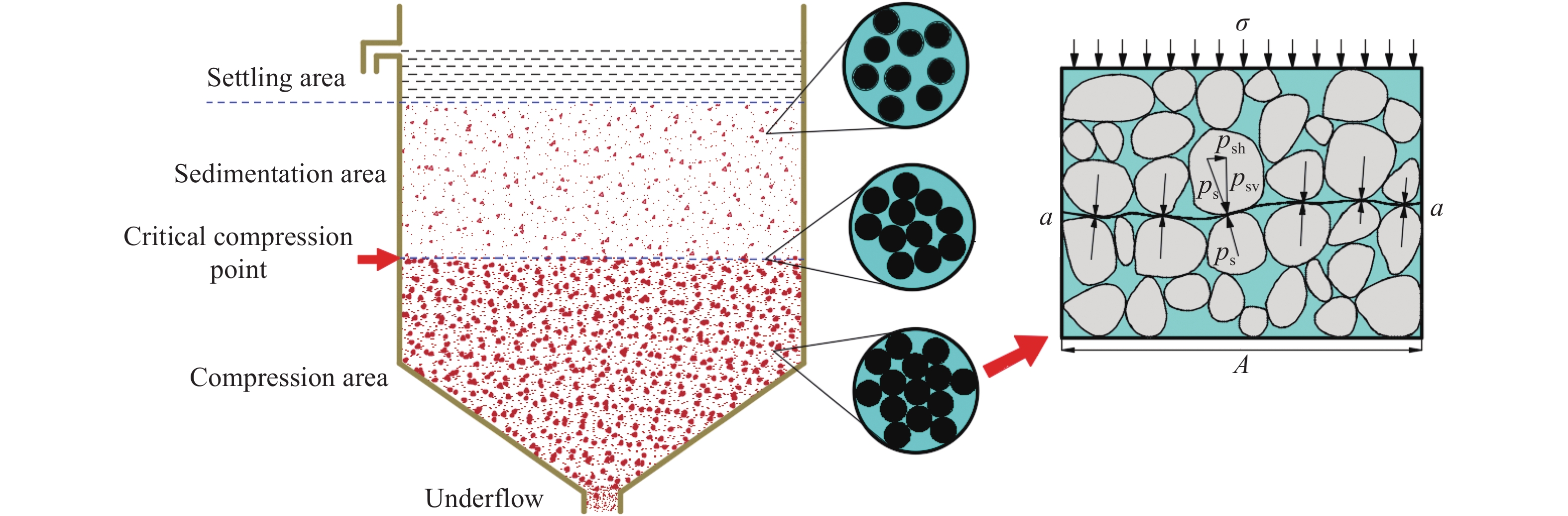

$ \alpha $ 與泥層壓力之間的關系為紐帶,建立了不同情況($ \alpha $ 為常數和$ \alpha $ 為變量)下泥層高度和底流濃度數學模型。然后,結合礦山實例對數學模型進行工業應用和差異性分析,研究結果表明:兩種情況下泥層高度與底流濃度均呈冪函數關系;在$ \alpha $ 為常數時,隨泥層高度增加,泥層高度變化率(dh/dc)逐漸減少,并且泥層高度為29.4 m時底流濃度就達到100%,與現實不符;在$ \alpha $ 為變量時,隨泥層高度增加,dh/dc逐漸增加,泥層越來越不容易被壓縮,該模型與現實相符合。最后,根據數學模型表達式及實際應用,將深錐濃密機中尾礦劃分為混合沉降區、減速壓縮區和極限壓縮區。泥層高度與底流濃度關系的揭示對實際生產中底流濃度的精準控制具有較好的指導意義。Abstract: Low grade is one of the three characteristics of mineral resources in China. With the exploitation of a large number of mineral resources, more tailings will inevitably be produced in the concentrator, and transporting them to the goaf is the best way to deal with tailings. The tailings are compacted by a deep cone thickener (DCT) to prepare a paste. The mud height and underflow concentration are the key parameters to ensure the filling efficiency and quality. To explore the relationship between mud height and underflow concentration of the DCT, mathematical models of mud height and underflow concentration under different conditions were established based on the Terzaghi effective stress principle and the relationship between compressibility$ \alpha $ and mud pressure. Taking a mine as an example, the industrial application and difference analysis of the mathematical model are conducted. Results show that the relationship between mud height and underflow concentration is a power function. When$ \alpha $ is constant, dh/dc decreases gradually with the increase of mud height, and the underflow concentration reaches 100% when the mud height is 29.4 m, which is inconsistent with reality. When$ \alpha $ varies, dh/dc increases gradually with the increase of mud height, and the mud layer becomes difficult to compress. This model is consistent with reality. Moreover, for this mine, the mud height is 5.79 m when the underflow concentration of the DCT increases from 60% to 65% and 11.22 m when the underflow concentration increases from 70% to 75%; the mud height required by the latter is approximately 1.94 times that of the former. The physical significance of the mathematical model is that the effective stress and intergranular porosity vary at different mud heights. As the height of the upper mud layer increases, the tailings particles at the bottom are rearranged and combined under pressure, the water between the pores is discharged, and the particles are compressed more densely. That is, the higher the mud height is, the smaller the intergranular porosity and the higher the underflow concentration. Notably, the mathematical model is applicable to both dynamic and static operations of the DCT from two perspectives, that is, compaction mechanism and effective stress; however, it cannot be generalized. Finally, according to the mathematical model expression and practical application, the mud layer in the DCT is divided into mixed sedimentation, deceleration compression, and limit compression areas. -

表 1 尾礦物理性質參數表

Table 1. Physical property parameters of tailings

Dry density/

(g·cm?3)Density/

(g·cm?3)Loose density/

(g·cm?3)Dense porosity/% Loose porosity/% 2.970 1.568 1.001 47.20 66.28 久色视频表 2 數學模型關鍵參數表

Table 2. Key parameters of the mathematical model

Critical compression concentration/% Underflow concentration/% Maximum mud height/m Compressibility/MPa?1 Correction factor 60.18 70.0 13.7 6.87 0.18 -

參考文獻

[1] Wang Y, Wu A X, Wang H J, et al. Dynamic thickening characteristics and mathematical model of total tailings. Rock Soil Mech, 2014, 35(Suppl 2): 168王勇, 吳愛祥, 王洪江, 等. 全尾膏體動態壓密特性及其數學模型. 巖土力學, 2014, 35(增刊2): 168 [2] Cihangir F, Ercikdi B, Kesimal A, et al. Paste backfill of high-sulphide mill tailings using alkali-activated blast furnace slag: Effect of activator nature, concentration and slag properties. Miner Eng, 2015, 83: 117 doi: 10.1016/j.mineng.2015.08.022 [3] Yilmaz E, Benzaazoua M, Bussière B, et al. Influence of disposal configurations on hydrogeological behaviour of sulphidic paste tailings: A field experimental study. Int J Miner Process, 2014, 131: 12 doi: 10.1016/j.minpro.2014.08.004 [4] Chen H J, Liu Q J. Harms and resource-like treatment of the solid wastes from metal mines. Met Mine, 2009(4): 154 doi: 10.3321/j.issn:1001-1250.2009.04.043陳華君, 劉全軍. 金屬礦山固體廢物危害及資源化處理. 金屬礦山, 2009(4):154 doi: 10.3321/j.issn:1001-1250.2009.04.043 [5] Wang H J, Peng Q S. Yang Y, et al. Research status and prospect of thickening technology for metal tailings. Chinese J Chin Eng,https://doi.org/10.13374/j.issn2095-9389.2021.01.11.001王洪江, 彭青松, 楊瑩, 等. 金屬礦尾砂濃密技術研究現狀與展望. 工程科學學報, https://doi.org/10.13374/j.issn2095-9389.2021.01.11.001 [6] Tao D, Parekh B K, Zhao Y M, et al. Pilot-scale demonstration of deep cone? paste thickening process for phosphatic clay/sand disposal. Sep Sci Technol, 2010, 45(10): 1418 doi: 10.1080/01496391003652783 [7] Liu X H, Wu A X, Wang H J, et al. A primary discussion on the thickening law of paste-filling. Met Mine, 2009(9): 38 doi: 10.3321/j.issn:1001-1250.2009.09.007劉曉輝, 吳愛祥, 王洪江, 等. 膏體充填尾礦濃密規律初探. 金屬礦山, 2009(9):38 doi: 10.3321/j.issn:1001-1250.2009.09.007 [8] Gu Z J. Application of the biggest deep cone paste thickener in domestic copper-molybdenum mine. Gold, 2010, 31(11): 43 doi: 10.3969/j.issn.1001-1277.2010.11.012谷志君. 最大型深錐膏體濃密機在中國銅鉬礦山的應用. 黃金, 2010, 31(11):43 doi: 10.3969/j.issn.1001-1277.2010.11.012 [9] Farrow J B, Johnston R R M, Simic K, et al. Consolidation and aggregate densification during gravity thickening. Chem Eng J, 2000, 80(1-3): 141 doi: 10.1016/S1383-5866(00)00083-6 [10] Zhou X, Jin X G, Liu P Z, et al. Prediction model for underflow concentration of deep cone thickener based on dynamic thickening experimentation. Met Mine, 2017(12): 39 doi: 10.3969/j.issn.1001-1250.2017.12.008周旭, 金曉剛, 劉培正, 等. 基于動態濃密試驗的深錐濃密機底流濃度預測模型. 金屬礦山, 2017(12):39 doi: 10.3969/j.issn.1001-1250.2017.12.008 [11] Wang H, Liu T, Cao Y N, et al. Underflow concentration prediction model of deep-cone thickener based on data-driven. J China Univ Posts Telecommun, 2019, 26(6): 63 [12] Fang C Y, He D K, Li K, et al. Image-based thickener mud layer height prediction with attention mechanism-based CNN. ISA Trans,https://doi.org/10.1016/j.isatra.2021.11.004 [13] Wang Y, Wang H J, Wu A X. Mathematical model of deep cone thickener underflow concentration based on the height to diameter ratio. J Wuhan Univ Technol, 2011, 33(8): 113 doi: 10.3963/j.issn.1671-4431.2011.08.025王勇, 王洪江, 吳愛祥. 基于高徑比的深錐濃密機底流濃度數學模型. 武漢理工大學學報, 2011, 33(8):113 doi: 10.3963/j.issn.1671-4431.2011.08.025 [14] Wu A X, Yang Y, Wang Y M, et al. Mathematical modelling of underflow concentration in a deep cone thickener and analysis of the dynamic compaction mechanism. Chin J Eng, 2018, 40(2): 152吳愛祥, 楊瑩, 王貽明, 等. 深錐濃密機底流濃度模型及動態壓密機理分析. 工程科學學報, 2018, 40(2):152 [15] Wang X M, Zhang G Q, Zhao J W, et al. Underflow concentration prediction and external structure parameter optimization of deep cone thickener. J Chongqing Univ, 2015, 38(6): 1 doi: 10.11835/j.issn.1000-582X.2015.06.001王新民, 張國慶, 趙建文, 等. 深錐濃密機底流濃度預測與外部結構參數優化. 重慶大學學報, 2015, 38(6):1 doi: 10.11835/j.issn.1000-582X.2015.06.001 [16] Du J H, Mcloughlin R, Smart R S C. Improving thickener bed density by ultrasonic treatment. Int J Miner Process, 2014, 133: 91 doi: 10.1016/j.minpro.2014.10.003 [17] Jiao H Z, Wu Y C, Wang H, et al. Micro-scale mechanism of sealed water seepage and thickening from tailings bed in rake shearing thickener. Miner Eng, 2021, 173: 107043 doi: 10.1016/j.mineng.2021.107043 [18] Hunter T N, Usher S P, Biggs S, et al. Characterization of bed densification in a laboratory scale thickener, by novel application of an acoustic backscatter system. Procedia Eng, 2015, 102: 858 doi: 10.1016/j.proeng.2015.01.206 [19] Shao L T, Guo X X, Zheng G F. Intergranular stress, soil skeleton stress and effective stress. Chin J Geotech Eng, 2015, 37(8): 1478 doi: 10.11779/CJGE201508017邵龍潭, 郭曉霞, 鄭國鋒. 粒間應力、土骨架應力和有效應力. 巖土工程學報, 2015, 37(8):1478 doi: 10.11779/CJGE201508017 [20] Li G X. On soil skeleton and seepage force. Chin J Geotech Eng, 2016, 38(8): 1522 doi: 10.11779/CJGE201608021李廣信. 論土骨架與滲透力. 巖土工程學報, 2016, 38(8):1522 doi: 10.11779/CJGE201608021 [21] Lu D C, Du X L, Xu C S. Analytical solutions to principle of effective stress. Chin J Geotech Eng, 2013, 35(Suppl 1): 146路德春, 杜修力, 許成順. 有效應力原理解析. 巖土工程學報, 2013, 35(增刊1): 146 [22] Yang J. Study on Compression and Strength Properties of Compacted Loess-Like Backfill [Dissertation]. Taiyuan: Taiyuan University of Technology, 2014楊晶. 黃土狀壓實填土壓縮和強度特性研究[學位論文] 太原: 太原理工大學, 2014 [23] Zhan H H, Yang X S, Cai M H. Compression process and related calculation in thickener. Met Mine, 1989(11): 45湛含輝, 楊小生, 蔡明華. 濃密機中壓縮過程及其有關計算. 金屬礦山, 1989(11):45 [24] Fang Y L, Ren J W, Li Y P, et al. Empirical relationship between compression coefficient and pore ratio of soil in Kaifeng area. J Yellow River Cnserv Tech Inst, 2004, 16(1): 43 doi: 10.3969/j.issn.1008-486X.2004.01.016方永倫, 任建偉, 李亞平, 等. 開封地區土的壓縮系數和孔隙比的經驗關系. 黃河水利職業技術學院學報, 2004, 16(1):43 doi: 10.3969/j.issn.1008-486X.2004.01.016 [25] Wang H J, Wang Y, Wu A X, et al. Dynamic compaction and static compaction mechanism of fine unclassified tailings. J Univ Sci Technol Beijing, 2013, 35(5): 566王洪江, 王勇, 吳愛祥等. 細粒全尾動態壓密與靜態壓密機理. 北京科技大學學報, 2013, 35(5):566 -

下載:

下載: