Influence of particle loss on the seepage characteristics of tuff in the fault fracture zone under triaxial stress

-

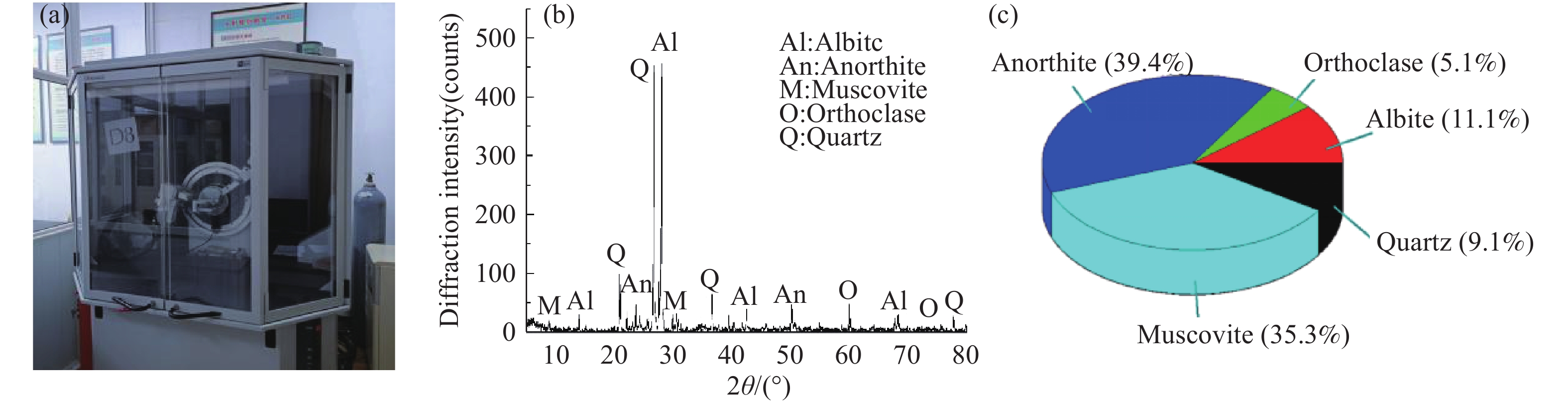

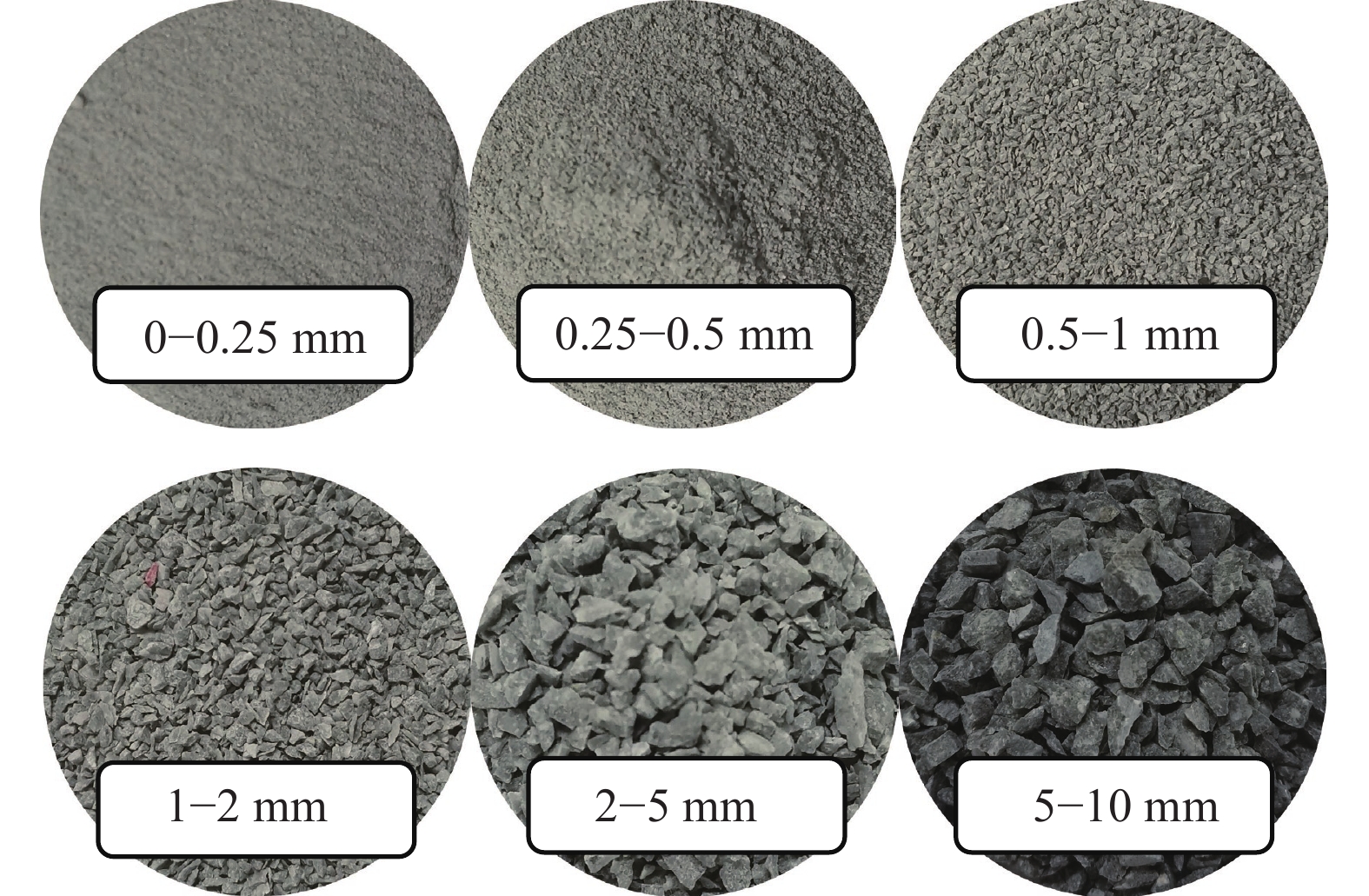

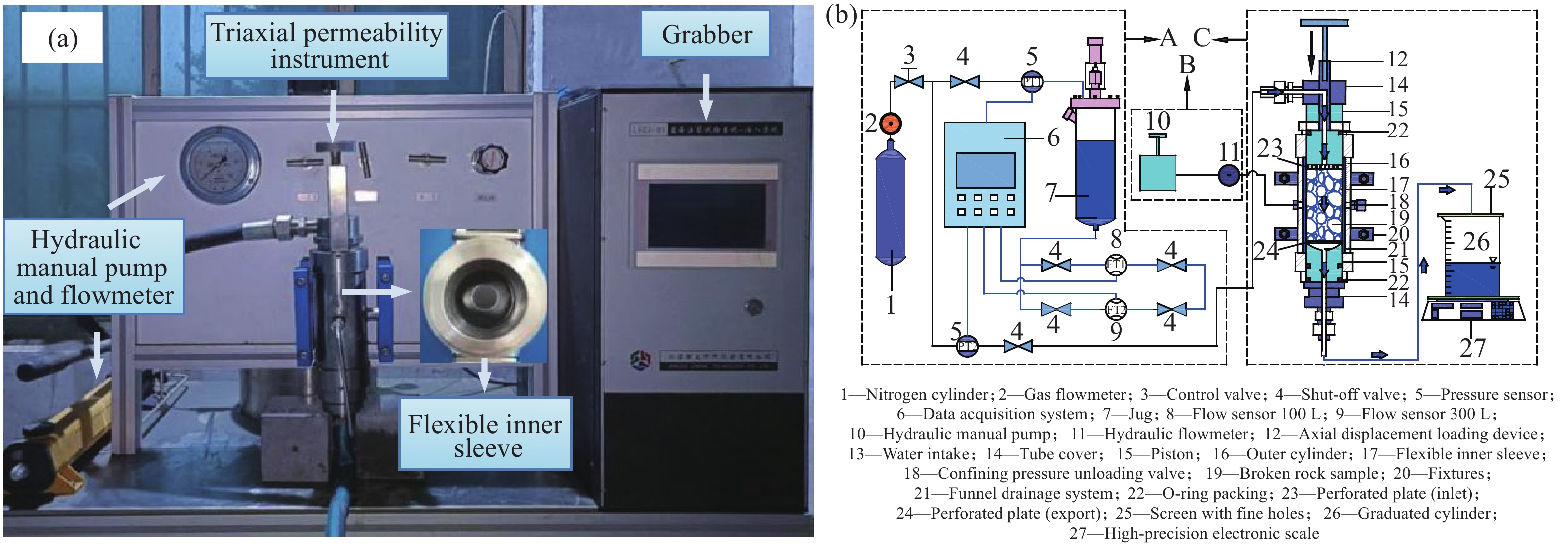

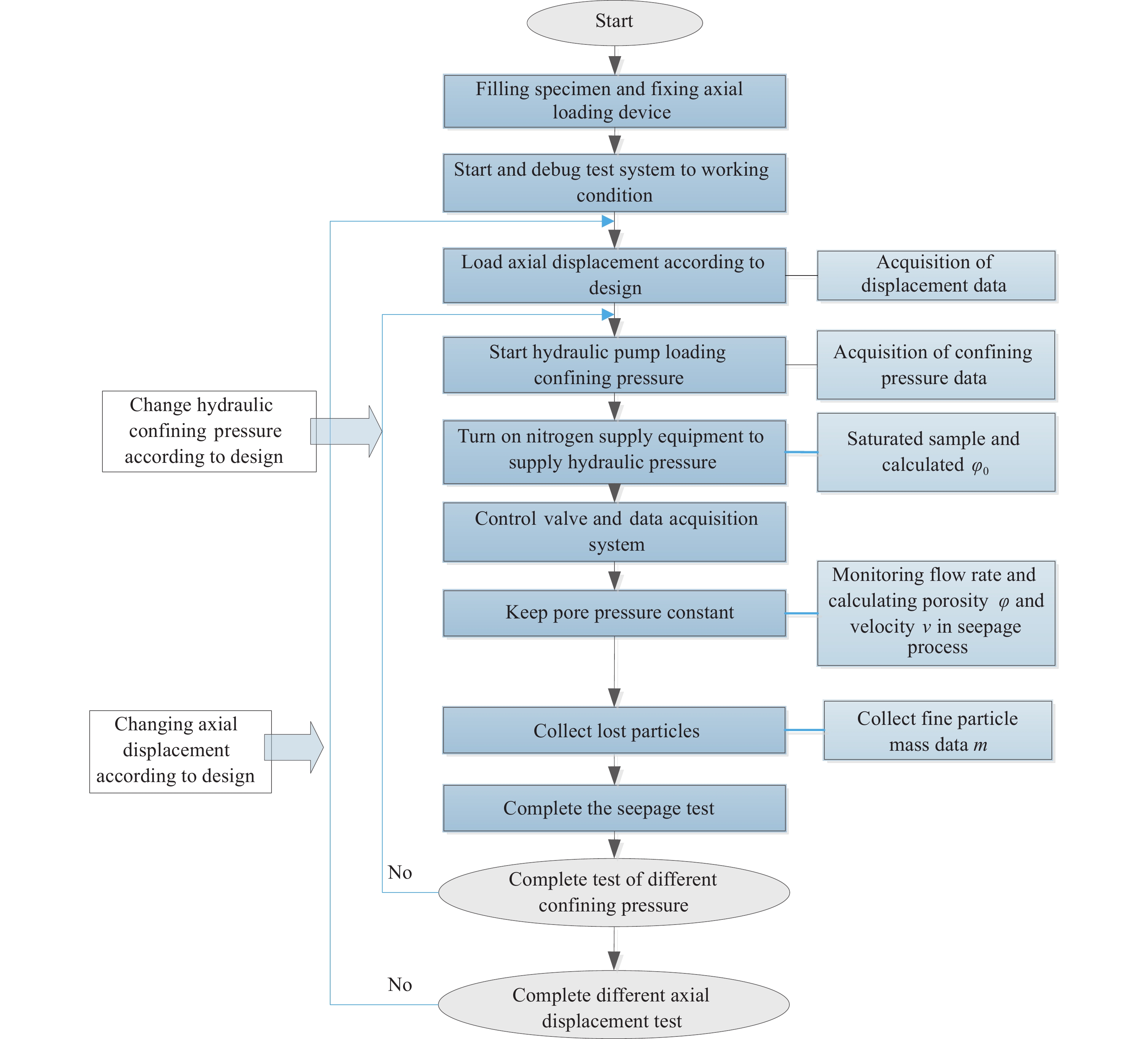

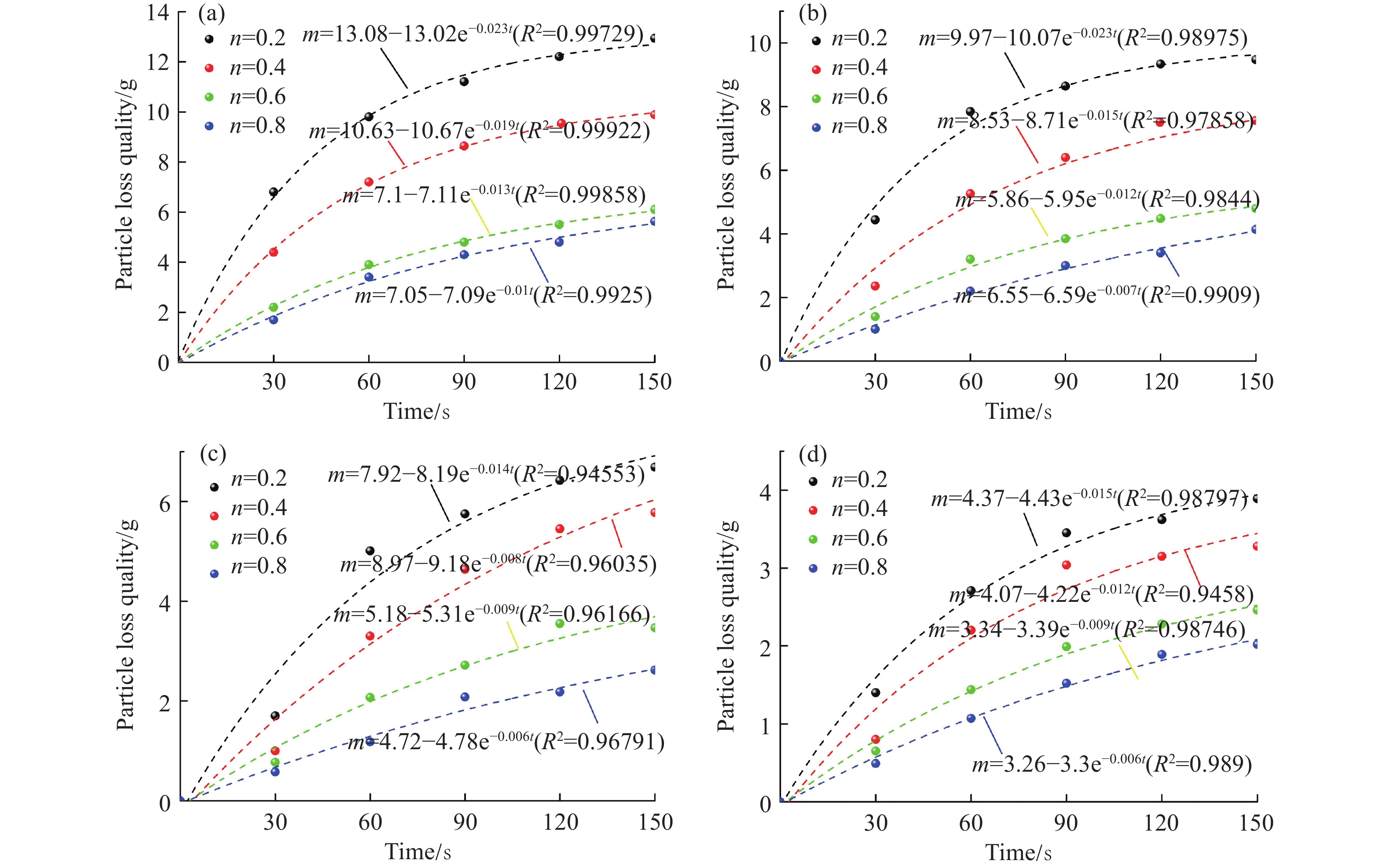

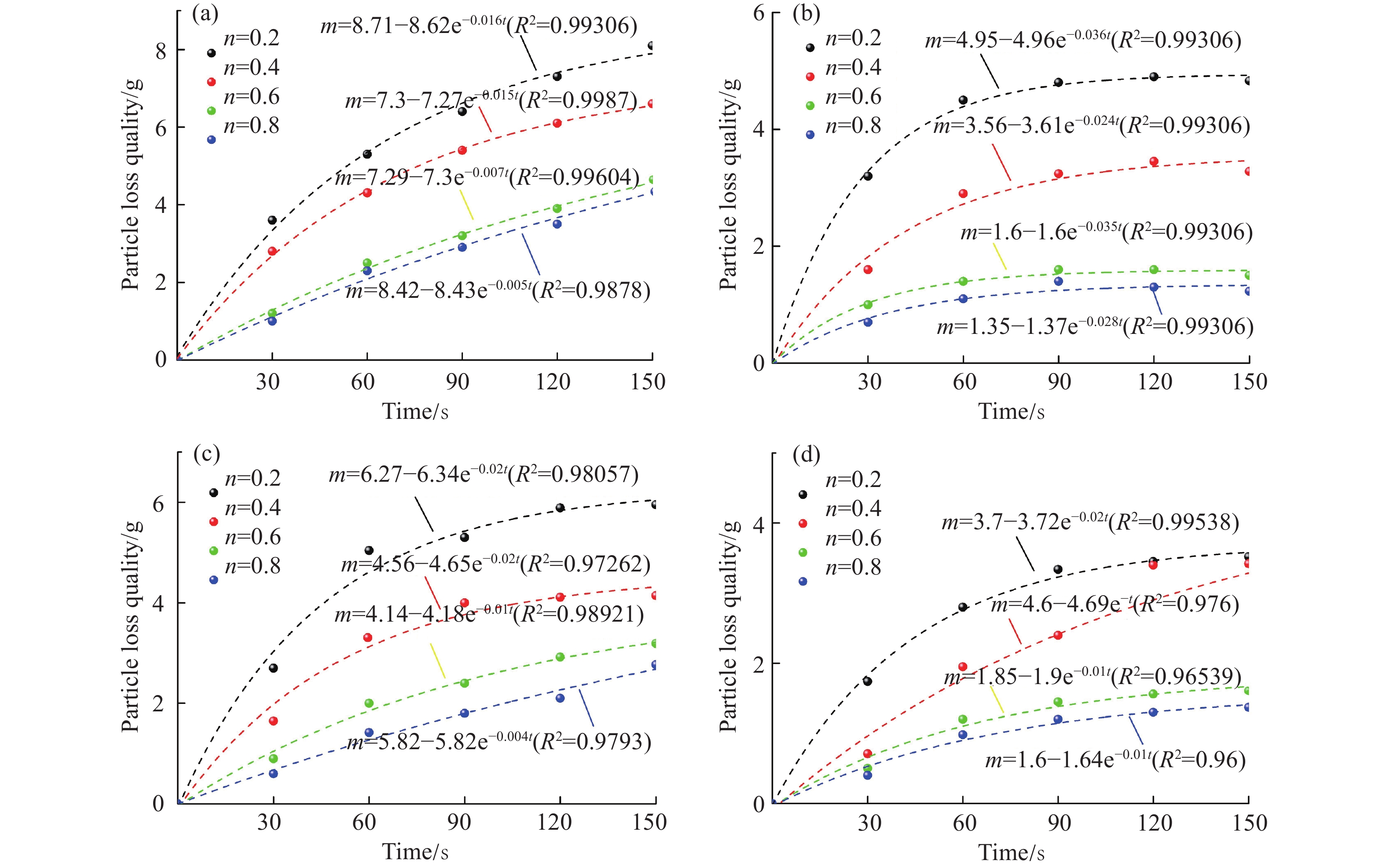

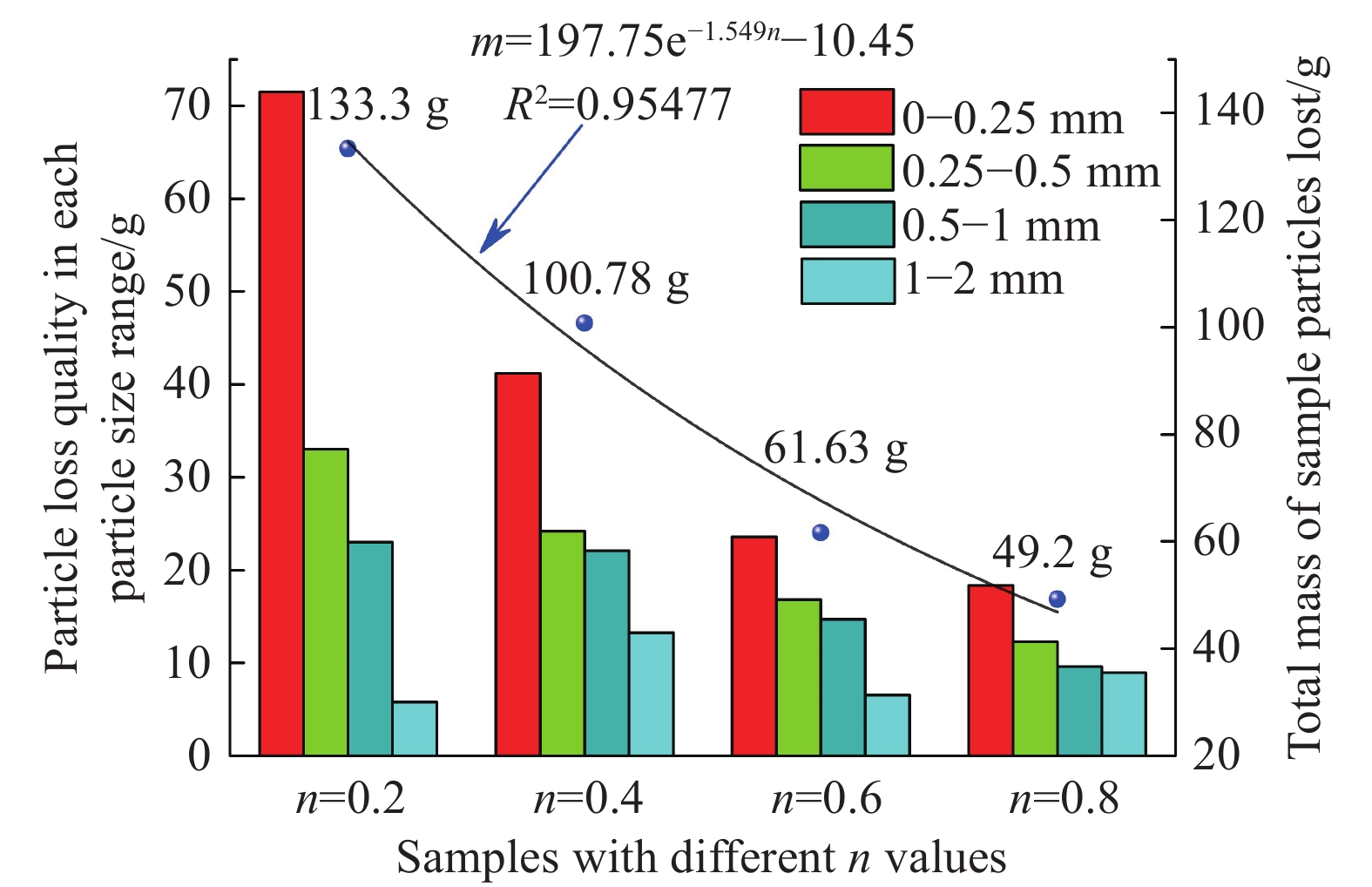

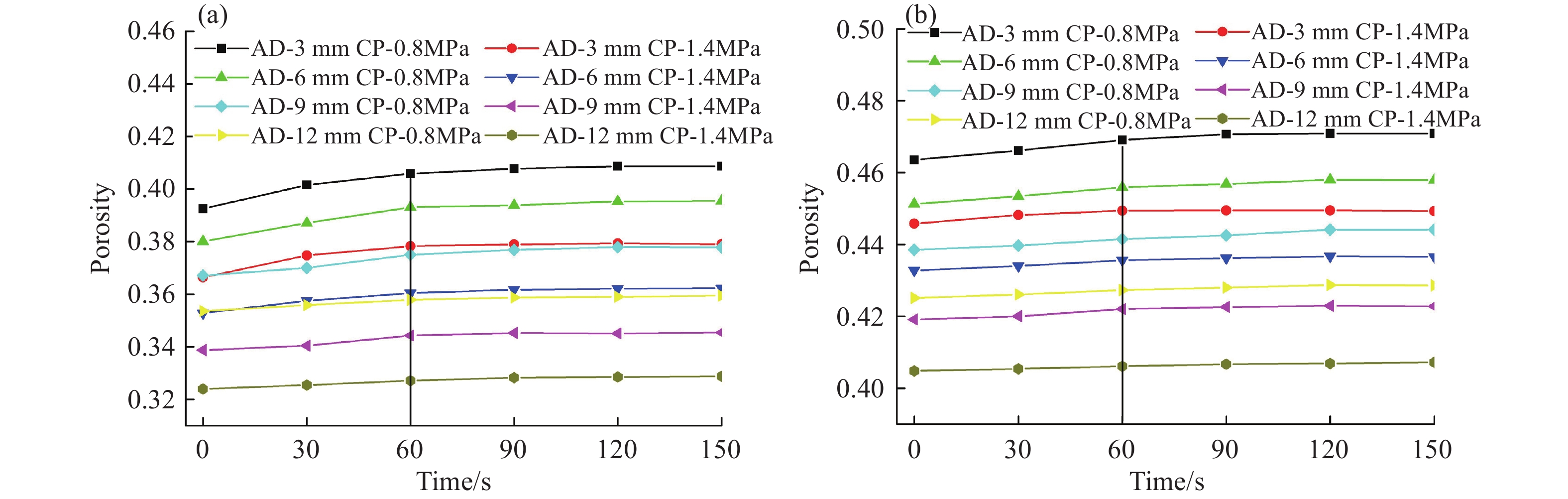

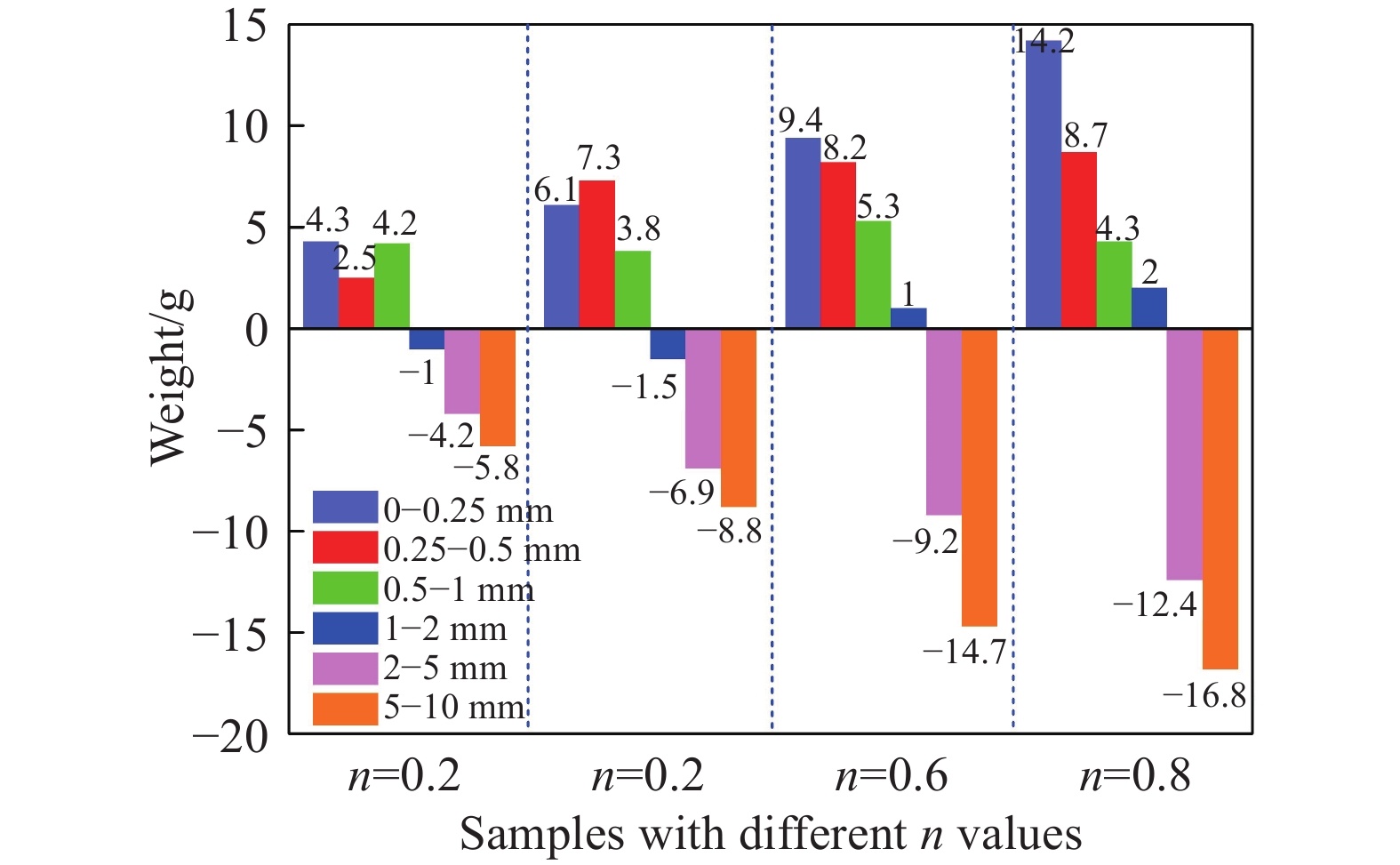

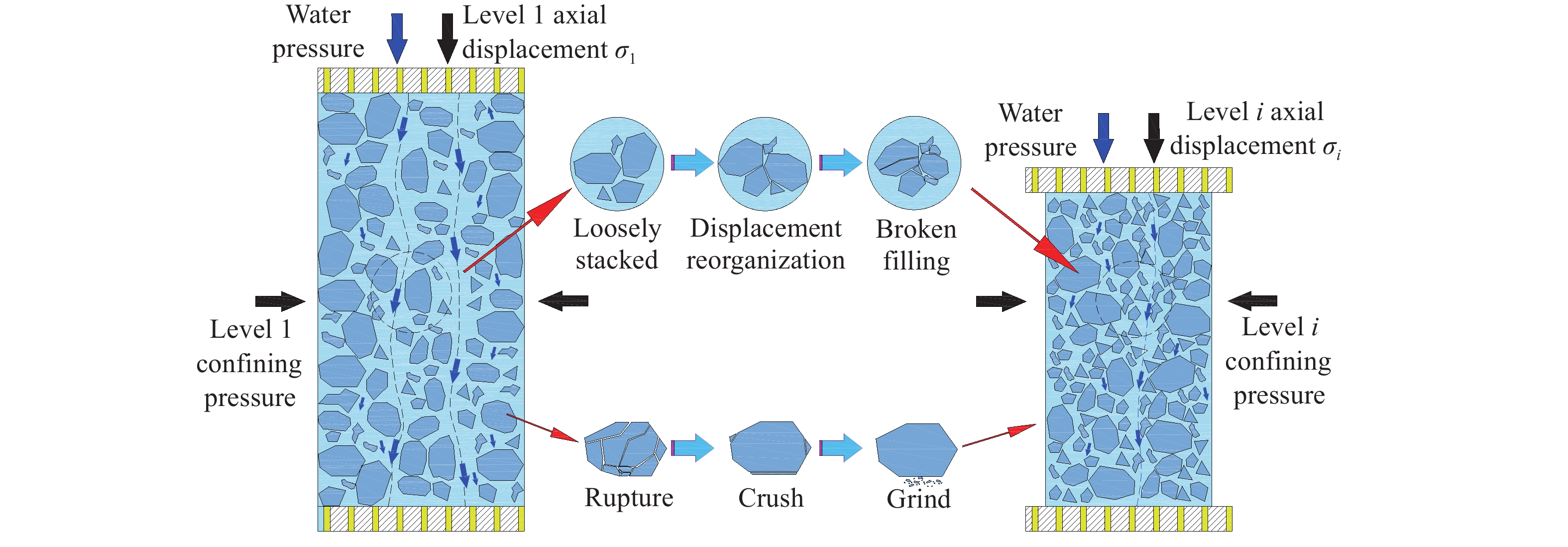

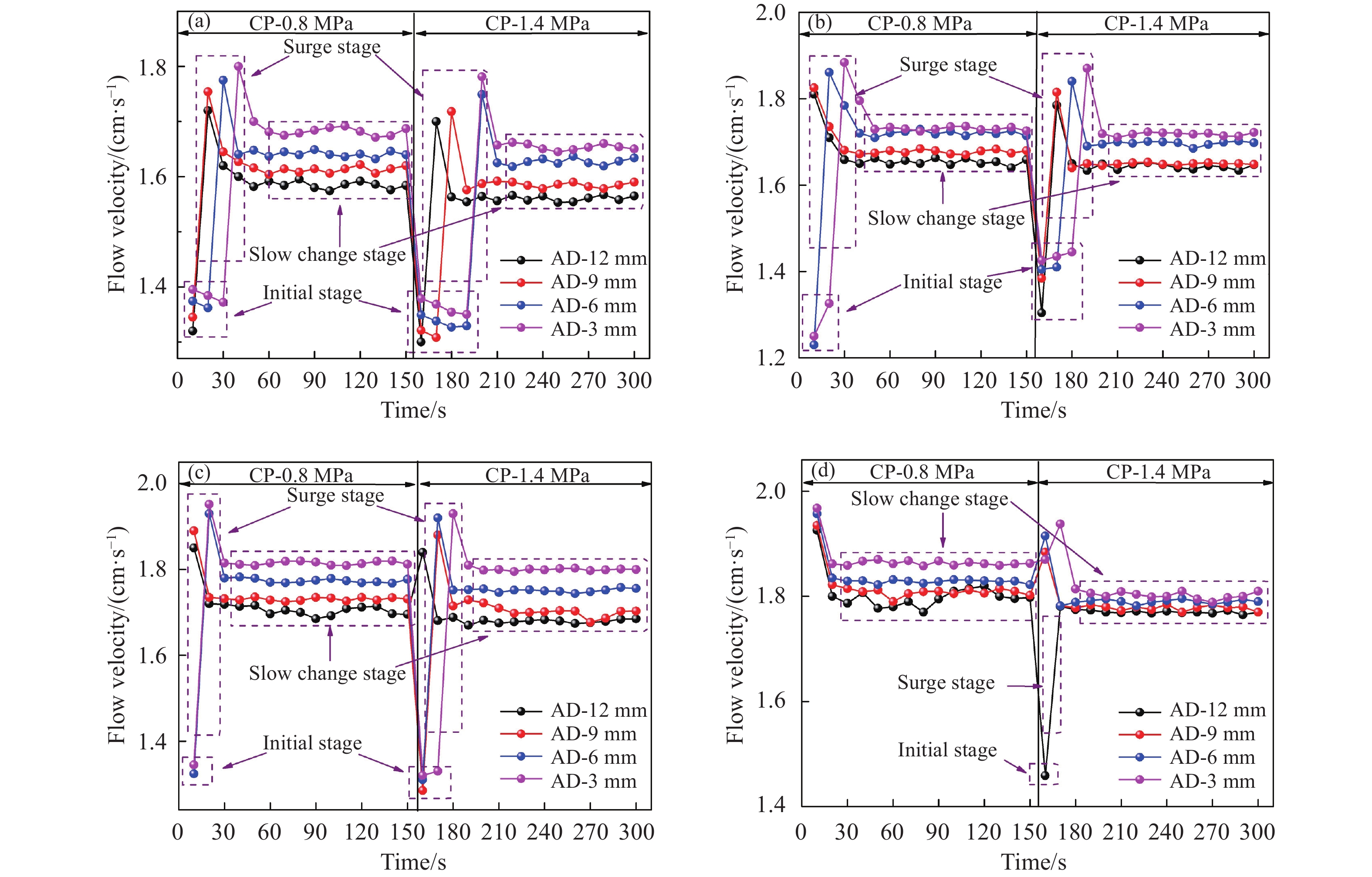

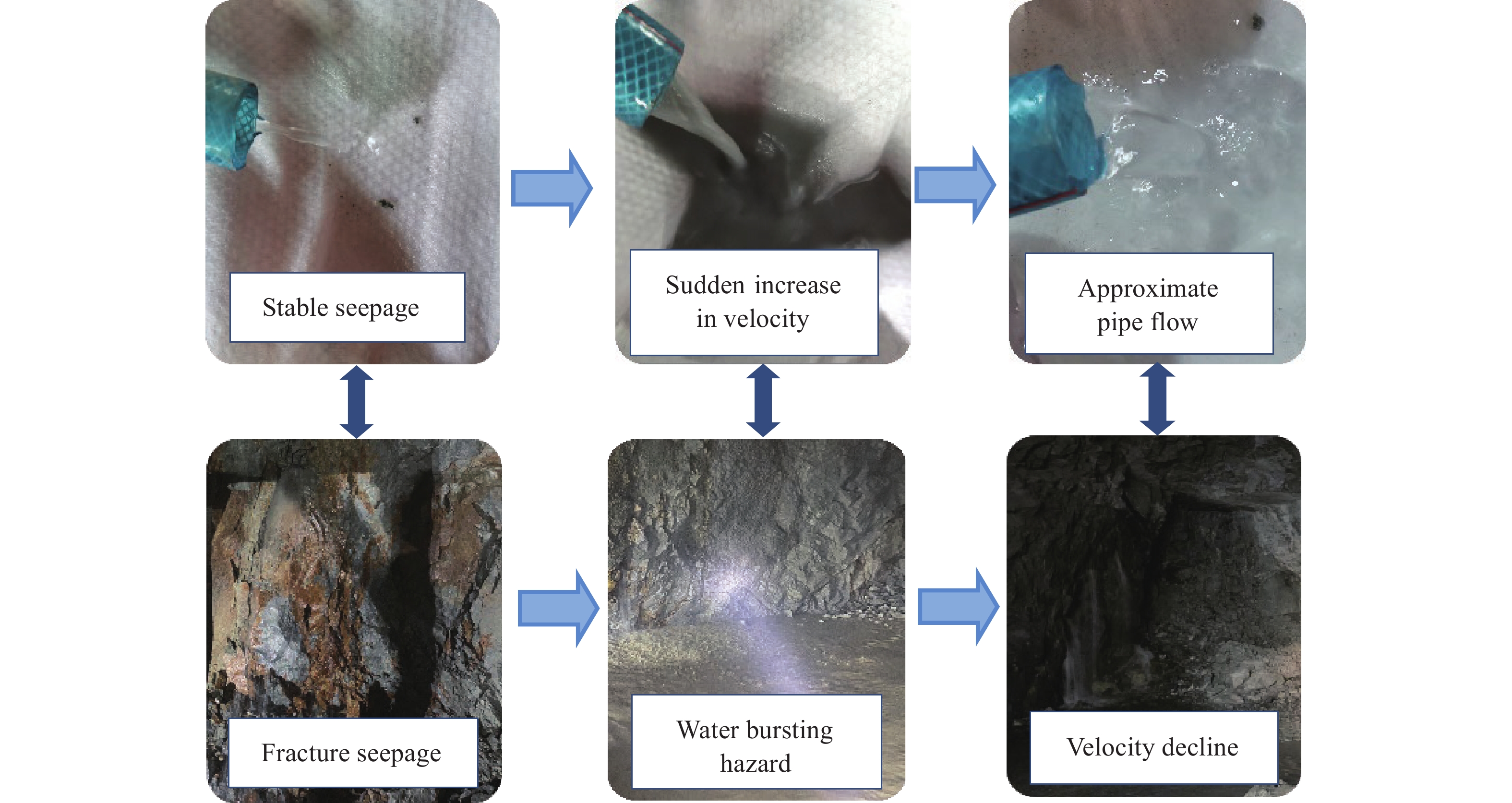

摘要: 地下工程施工過程中,處于三向應力狀態的斷層破碎帶凝灰巖在流固耦合作用下發生顆粒流失,繼而誘發斷層帶破碎巖石結構失穩,最終導致斷層突水災害發生。基于此,開展現場斷層取樣,利用破碎巖石三軸滲透試驗系統,研究三軸荷載下不同粒徑級配試樣顆粒流失規律,進而分析顆粒流失對孔隙結構與滲流流速時變演化規律的影響。研究結果表明:(1)不同三軸應力下,破碎凝灰巖顆粒流失質量與時間滿足指數型函數關系,兩者間相關系數不低于94%。顆粒流失質量與軸壓和圍壓成反比,且軸向位移越大,顆粒流失質量隨圍壓減小的幅度越小;(2)滲透過程中0~60 s間的孔隙率增長較快,孔隙結構的滲流演變過程與粒徑級配有關,隨著n (Talbot冪指數) 值的增大,孔隙率整體增大,n值相同時,孔隙率隨軸向位移與圍壓的增大而減小,且孔隙率量級為0.33~0.52;(3)由于試樣內部顆粒規律性流失,破碎凝灰巖滲流流速時變演化過程可劃分為“平穩滲流、滲流流速突增和近似管流”三個階段,圍壓為0.8 MPa時各階段流速整體大于圍壓為1.4 MPa時對應階段的流速。平穩滲流階段歷時短,流速低,其發生次數隨n值增加而減少;滲流流速突增階段流速猛增達到峰值;近似管流階段保持較高流速,雖然偶爾產生波動,但整體相對平穩。研究成果可為斷層突水災害演化規律研究提供理論依據。Abstract: In the process of underground engineering construction, tuff in the fault fracture zone under a three-dimensional stress state loses particles under the action of fluid–solid coupling, causing the structural instability of the fault fracture rock. Finally, fault water inrush disaster occurs. Based on this, the field fault sampling has been conducted, and the broken rock triaxial seepage test system has been used to investigate the phenomenon of particle loss in samples with various particle sizes under triaxial load, as well as the effect of particle loss on pore structure and the time-varying evolution of seepage velocity. The following are the results: (1) The quality and time of the particle loss of broken tuff satisfy the exponential nonlinear relationship under different levels of triaxial stress, with a correlation coefficient of not less than 94%. Particle loss quality is inversely related to axial pressure and confining pressure, indicating that the higher the axial displacement, the smaller the decrease in particle loss mass with confining pressure. (2) The porosity increases rapidly between 0 and 60 s during the infiltration process. The seepage evolution process of the pore structure is related to the particle size gradation; that is, the overall porosity increases as the value of n (Talbot power exponent) increases. In the case of the same value of n, the porosity, which ranges from 0.33 to 0.52, decreases as the axial displacement and confining pressure increase. (3) Owing to the regular loss of particles in the sample, the time-varying evolution process of the seepage velocity of fractured tuff can be divided into three stages: stable seepage, sudden increase of seepage velocity, and approximate pipe flow. When the confining pressure is 0.8 MPa, each stage’s flow velocity is higher than that of the corresponding stage when the confining pressure is 1.4 MPa. The stable seepage stage has a short duration and low flow rate, and its occurrence times decrease as the n value increases. In the stage of seepage velocity surge, velocity surges to a peak value. The approximate pipe flow stage maintains a relatively stable and high flow velocity despite occasional fluctuations. The research results can offer a theoretical basis for studying the evolution law of fault water inrush disaster.

-

Key words:

- shattered fault zone /

- tuff /

- triaxial stress /

- particle loss /

- pore structure

-

圖 7 不同圍壓下流失顆粒質量?時間擬合曲線. (a) 軸向位移為3 mm,圍壓為0.8 MPa; (b) 軸向位移為3 mm,圍壓為1.4 MPa; (c) 軸向位移為6 mm,圍壓為0.8 MPa; (d) 軸向位移為6 mm,圍壓為1.4 MPa

Figure 7. Lost particles mass–time fitting curve under different confining pressures: (a) axial displacement is 3 mm, confining pressure is 0.8 MPa; (b) axial displacement is 3 mm, confining pressure is 1.4 MPa; (c) axial displacement is 6 mm, confining pressure is 0.8 MPa; (d) axial displacement is 6 mm, confining pressure is 1.4 MPa

圖 13 不同n值級配試樣滲透試驗中流速?時間試驗結果(圖中AD指軸向位移, CP指圍壓). (a) n=0.2; (b) n=0.4; (c) n=0.6; (d) n=0.8

Figure 13. Flow velocity–time test results of different Talbot power exponent gradation samples in penetration test (AD means axial displacement, CP means confining pressure): (a) n=0.2; (b) n=0.4; (c) n=0.6; (d) n=0.8

久色视频表 1 不同Talbot冪指數n值下的巖石顆粒質量

Table 1. Rock particle mass under different n

Rock grain size/mm Particle mass/g n=0.2 n=0.4 n=0.6 n=0.8 0?0.25 114.76 54.88 26.24 12.55 0.25?0.5 17.07 17.53 13.53 9.30 0.5?1 19.60 23.14 20.52 16.19 1?2 22.52 30.52 31.09 28.19 2?5 34.98 55.82 66.96 71.61 5?10 31.07 58.11 81.66 102.16 -

參考文獻

[1] Li S C, Xu Z H, Huang X, et al. Classification, geological identification, hazard mode and typical case studies of hazard-causing structures for water and mud inrush in tunnels. Chin J Rock Mech Eng, 2018, 37(5): 1041李術才, 許振浩, 黃鑫, 等. 隧道突水突泥致災構造分類、地質判識、孕災模式與典型案例分析. 巖石力學與工程學報, 2018, 37(5):1041 [2] Li X Z, Zhang P X, He Z C, et al. Identification of geological structure which induced heavy water and mud inrush in tunnel excavation: A case study on Lingjiao tunnel. Tunn Undergr Space Technol, 2017, 69: 203 doi: 10.1016/j.tust.2017.06.014 [3] Li S C, Chen Z Q, Miao X X, et al. Experimental study on the properties of time-dependent deformation-seepage in water-saturated broken sandstone. J Mini Saf Eng, 2011, 28(4): 542 doi: 10.3969/j.issn.1673-3363.2011.04.008李順才, 陳占清, 繆協興, 等. 飽和破碎砂巖隨時間變形?滲流特性試驗研究. 采礦與安全工程學報, 2011, 28(4):542 doi: 10.3969/j.issn.1673-3363.2011.04.008 [4] Miu X X, Liu W Q, Chen Z Q. Seepage Theory of Mining Rock Mass. Beijing: Science Press, 2004繆協興, 劉衛群, 陳占清. 采動巖體滲流理論. 北京: 科學出版社, 2004 [5] Chen Z Q, Li S C, Mao X B, et al. Experimental on the porosity changing of water-saturated granular limestone during its creep. J China Coal Soc, 2006, 31(1): 26 doi: 10.3321/j.issn:0253-9993.2006.01.006陳占清, 李順才, 茅獻彪, 等. 飽和含水石灰巖散體蠕變過程中孔隙度變化規律的試驗. 煤炭學報, 2006, 31(1):26 doi: 10.3321/j.issn:0253-9993.2006.01.006 [6] Sun M G, Huang X W, Li T Z, et al. Seepage properties of non-Darcy flow in complete failure process of limestone. Chin J Rock Mech Eng, 2006, 25(3): 484 doi: 10.3321/j.issn:1000-6915.2006.03.008孫明貴, 黃先伍, 李天珍, 等. 石灰巖應力?應變全過程的非Darcy流滲透特性. 巖石力學與工程學報, 2006, 25(3):484 doi: 10.3321/j.issn:1000-6915.2006.03.008 [7] Wang W, Xu W Y, Wang R B, et al. Permeability of dense rock under triaxial compression. Chin J Rock Mech Eng, 2015, 34(1): 40王偉, 徐衛亞, 王如賓, 等. 低滲透巖石三軸壓縮過程中的滲透性研究. 巖石力學與工程學報, 2015, 34(1):40 [8] Du F, Li Z H, Jiang G H, et al. Types and mechanism of water-sand inrush disaster in west coal mine. J China Coal Soc, 2017, 42(7): 1846杜鋒, 李振華, 姜廣輝, 等. 西部礦區突水潰沙類型及機理研究. 煤炭學報, 2017, 42(7):1846 [9] Yao B H. Research on Variable on Variable Mass Fluid-Solid Coupling Dynamic Theory of Broken Rockmass and Application [Dissertation]. Xuzhou: China University of Mining and Technology, 2012姚邦華. 破碎巖體變質量流固耦合動力學理論及應用研究[學位論文]. 徐州: 中國礦業大學, 2012 [10] Liu W Q, Fei X D, Fang J N. Rules for confidence intervals of permeability coefficients for water flow in over-broken rock mass. Int J Min Sci Technol, 2012, 22(1): 29 doi: 10.1016/j.ijmst.2011.06.003 [11] Ma D, Miao X X, Chen Z Q, et al. Experimental investigation of seepage properties of fractured rocks under different confining pressures. Rock Mech Rock Eng, 2013, 46(5): 1135 [12] Ma D, Rezania M, Yu H S, et al. Variations of hydraulic properties of granular sandstones during water inrush: Effect of small particle migration. Eng Geol, 2017, 217: 61 doi: 10.1016/j.enggeo.2016.12.006 [13] Ma D, Duan H Y, Liu J F, et al. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci Total Environ, 2019, 664: 436 doi: 10.1016/j.scitotenv.2019.02.059 [14] Zhang T J, Shang H B, Li S G, et al. Permeability characteristics of broken sandstone and its stability analysis under step loading. J China Coal Soc, 2016, 41(5): 1129張天軍, 尚宏波, 李樹剛, 等. 分級加載下破碎砂巖滲透特性試驗及其穩定性分析. 煤炭學報, 2016, 41(5):1129 [15] Zhang T J, Shang H B, Li S G, et al. Permeability tests of fractured sandstone with different sizes of fragments under three-dimensional stress states. Rock Soil Mech, 2018, 39(7): 2361張天軍, 尚宏波, 李樹剛, 等. 三軸應力下不同粒徑破碎砂巖滲透特性試驗. 巖土力學, 2018, 39(7):2361 [16] Zhang T J, Zhang X F, Pang M K, et al. Effect of particle loss on the pore structure and emergent behavior of karst column fills. J China Coal Soc, 2021, 46(10): 3245張天軍, 張秀鋒, 龐明坤, 等. 顆粒流失對陷落柱充填物孔隙結構及突水行為的影響. 煤炭學報, 2021, 46(10):3245 [17] Zhang B Y, Bai H B, Zhang K. Experimental research on seepage mutation mechanism of collapse column medium. Rock Soil Mechs, 2016, 37(3): 745張勃陽, 白海波, 張凱. 類陷落柱介質滲流突變機制試驗研究. 巖土力學, 2016, 37(3):745 [18] Zhang B Y, Lin Z B, Wu J Y, et al. Seepage characteristics of broken rock inside collapse column under application of lateral limited uniaxial compression. J Min Saf Eng, 2020, 37(5): 1045張勃陽, 林志斌, 吳疆宇, 等. 側限條件下陷落柱破碎巖體的滲流特性研究. 采礦與安全工程學報, 2020, 37(5):1045 [19] Feng M M, Wu J Y, Ma D, et al. Experimental investigation on the seepage property of saturated broken red sandstone of continuous gradation. Bull Eng Geol Environ, 2018, 77(3): 1167 doi: 10.1007/s10064-017-1046-z [20] Yang B, Xu Z H, Yang T H, et al. Experimental study of non-linear water flow through unconsolidated porous media under condition of high hydraulic gradient. Rock Soil Mech, 2018, 39(11): 4017楊斌, 徐曾和, 楊天鴻, 等. 高水力梯度條件下顆粒堆積型多孔介質滲流規律試驗研究. 巖土力學, 2018, 39(11):4017 [21] Yu B Y, Chen Z Q, Yu L L. Water-resisting ability of cemented broken rocks. Int J Min Sci Technol, 2016, 26(3): 449 doi: 10.1016/j.ijmst.2016.02.013 [22] Liu W T, Du Y H, Yu S J, et al. Research on permeability and acoustic emission characteristics of karst collapsed column skeleton sandstone under triaxial compression. Chin J Rock Mech Eng, 2021, 40(8): 1580劉偉韜, 杜衍輝, 于師建, 等. 陷落柱骨架砂巖三軸壓縮滲流特性及聲發射特征試驗研究. 巖石力學與工程學報, 2021, 40(8):1580 [23] Wasantha P L P, Ranjith P G. Water-weakening behavior of Hawkesbury sandstone in brittle regime. Eng Geol, 2014, 178: 91 doi: 10.1016/j.enggeo.2014.05.015 [24] Zhao J H, Yin L M, Guo W J. Stress-seepage coupling of cataclastic rock masses based on digital image technologies. Rock Mech Rock Eng, 2018, 51(8): 2355 doi: 10.1007/s00603-018-1474-5 [25] Li Y S, Yang Y J, Yang S Q, et al. Deformation and acoustic emission behaviors of coal under triaxial compression and pore water pressure. J Univ Sci Technol Beijing, 2011, 33(6): 658李玉壽, 楊永杰, 楊圣奇, 等. 三軸及孔隙水作用下煤的變形和聲發射特性. 北京科技大學學報, 2011, 33(6):658 [26] Yan B Q, Ren F H, Cai M F, et al. Research review of rock mechanics experiment and numerical simulation under THMC multi-field coupling. Chin J Eng, 2021, 43(1): 47顏丙乾, 任奮華, 蔡美峰, 等. THMC多場耦合作用下巖石力學實驗與數值模擬研究進展. 工程科學學報, 2021, 43(1):47 [27] Li S C, Miao X X, Chen Z Q, et al. Experimental study on seepage properties of non-Darcy flow in confined broken rocks. Eng Mech, 2008, 25(4): 85李順才, 繆協興, 陳占清, 等. 承壓破碎巖石非Darcy滲流的滲透特性試驗研究. 工程力學, 2008, 25(4):85 [28] Ma D, Duan H Y, Zhang J X, et al. Experimental investigation of creep-erosion coupling mechanical properties of water inrush hazards in fault fracture rock masses. Chin J Rock Mech Eng, 2021, 40(9): 1751馬丹, 段宏宇, 張吉雄, 等. 斷層破碎帶巖體突水災害的蠕變?沖蝕耦合力學特性試驗研究. 巖石力學與工程學報, 2021, 40(9):1751 [29] Wu J Y, Han G S, Feng M M, et al. Mass-loss effects on the flow behavior in broken argillaceous red sandstone with different particle-size distributions. Comptes Rendus Mécanique, 2019, 347(6): 504 [30] Feng M M, Wu J Y, Chen Z Q, et al. Experimental study on the compaction of saturated broken rock of continuous gradation. J China Coal Soc, 2016, 41(9): 2195馮梅梅, 吳疆宇, 陳占清, 等. 連續級配飽和破碎巖石壓實特性試驗研究. 煤炭學報, 2016, 41(9):2195 [31] Xie H P, Gao F, Zhou H W, et al. Fractal fracture and fragmentation in rocks. J Disas Prev Mitig Eng, 2003, 23(4): 1謝和平, 高峰, 周宏偉, 等. 巖石斷裂和破碎的分形研究. 防災減災工程學報, 2003, 23(4):1 [32] Yu J, Lü X B, Qin Y J. Experimental study on concrete beams without web reinforcement based on fractal theory. Chin J Eng, 2021, 43(10): 1385于江, 呂旭濱, 秦擁軍. 基于分形理論無腹筋混凝土梁的受剪性能. 工程科學學報, 2021, 43(10):1385 [33] Zhang G T, Chen Y, Lu H B, et al. Fractal characteristics of fiber lithium slag concrete cracks under sulfate attack. Chin J Eng, 2022, 44(2): 208張廣泰, 陳勇, 魯海波, 等. 硫酸鹽侵蝕作用下纖維鋰渣混凝土裂縫的分形特征. 工程科學學報, 2022, 44(2):208 [34] Zhu S, Wang Y M, Weng H Y. Study of scale effect of density of coarse-grained dam materials. Chin J Rock Mech Eng, 2011, 30(2): 348朱晟, 王永明, 翁厚洋. 粗粒筑壩材料密實度的縮尺效應研究. 巖石力學與工程學報, 2011, 30(2):348 [35] Yin S H, Chen X, Liu C, et al. Effects of ore size distribution on the pore structure characteristics of packed ore beds. Chin J Eng, 2020, 42(8): 972尹升華, 陳勛, 劉超, 等. 礦石顆粒級配對堆浸體系三維孔隙結構的影響. 工程科學學報, 2020, 42(8):972 [36] Xie D S, Cai H, Wei Y Q, et al. Scaling principle and method in seepage tests on coarse materials. Chin J Geotech Eng, 2015, 37(2): 369 doi: 10.11779/CJGE201502023謝定松, 蔡紅, 魏迎奇, 等. 粗粒土滲透試驗縮尺原則與方法探討. 巖土工程學報, 2015, 37(2):369 doi: 10.11779/CJGE201502023 [37] Wu J Y, Feng M M, Mao X B, et al. Particle size distribution of aggregate effects on mechanical and structural properties of cemented rockfill: Experiments and modeling. Constr Build Mater, 2018, 193: 295 doi: 10.1016/j.conbuildmat.2018.10.208 [38] Zhu G S, Zhang J F, Chen J S, et al. Study of size and wall effects in seepage test of broadly graded coarse materials. Rock Soil Mech, 2012, 33(9): 2569朱國勝, 張家發, 陳勁松, 等. 寬級配粗粒土滲透試驗尺寸效應及邊壁效應研究. 巖土力學, 2012, 33(9):2569 [39] Liu M S, Luo Q, Jiang L W, et al. Boundary pore characteristics and optimal treatment thickness in seepage test of coarse grained soil. Rock Soil Mech, 2019, 40(5): 1787劉孟適, 羅強, 蔣良濰, 等. 粗粒土滲透試驗邊壁孔隙特征及處理層最優厚度研究. 巖土力學, 2019, 40(5):1787 [40] Yu B Y, Chen Z Q, Wu J Y, et al. Experimental study of compaction and fractal properties of grain size distribution of saturated crushed mudstone with different gradations. Rock Soil Mech, 2016, 37(7): 1887郁邦永, 陳占清, 吳疆宇, 等. 飽和級配破碎泥巖壓實與粒度分布分形特征試驗研究. 巖土力學, 2016, 37(7):1887 -

下載:

下載: