Progress and trend of bulk utilization technology of metallurgical solid wastes in China

-

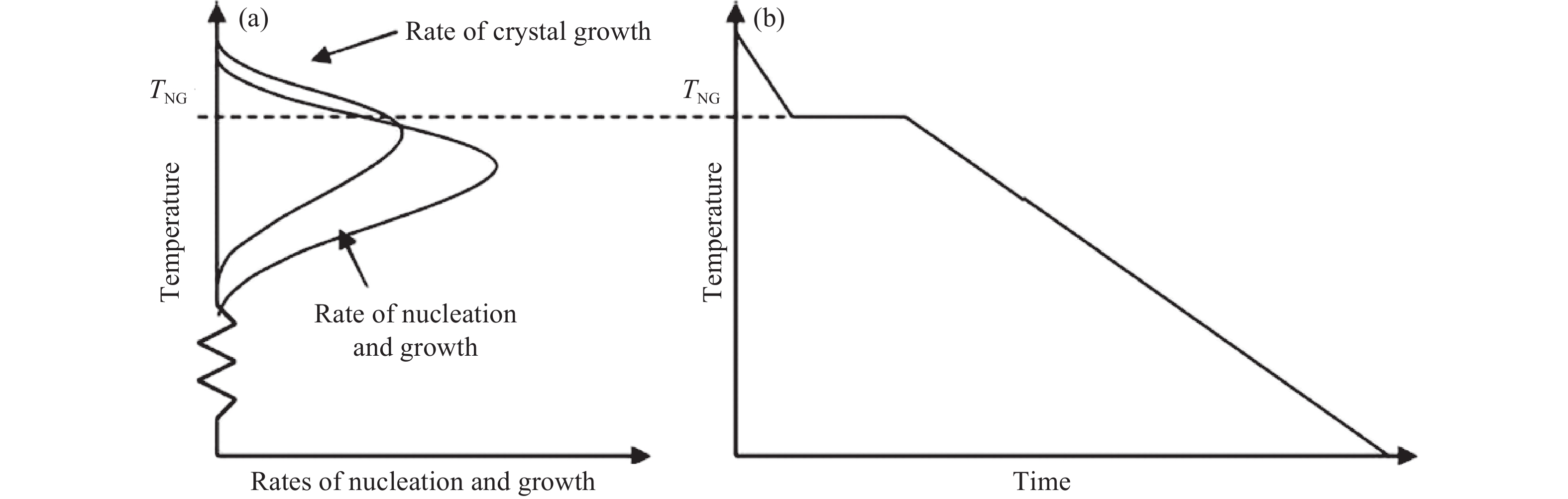

摘要: 我國鋼渣、赤泥、銅渣和部分鐵合金渣年排放量在千萬噸甚至億噸級,難以大量用于傳統的水泥、混凝土或道路工程領域,是難利用的大宗冶金固廢。本文分析了以上典型冶金固廢大宗資源化利用的現狀,指出了制約大宗資源化利用的瓶頸問題;進一步提出砂石骨料、陶瓷材料、人造石材在我國具有年億噸級乃至百億噸級的市場需求,適合作為冶金固廢利用的大宗量出口,并綜述了這一領域冶金渣低成本制備燒結陶粒、冶金渣制備陶瓷和燒結磚、熔渣調質制備骨料以及熔渣人造石材制備等方面研究取得的進展,包括在新建年10萬噸基于帶式焙燒機原理的固廢陶粒生產線上進行了赤泥摻加質量分數50%~65%的燒結陶粒工業化生產試驗;分別摻入質量分數40%~60%的赤泥,30%~50%的鋼渣,50%~80%的銅渣,先后完成了陶瓷磚和燒結磚的工業化中試以及工業化生產實驗;加入質量分數12.96%的砂子對熔融電爐渣進行調質并制備砂石骨料、基于“Petrurgic”工藝的利用熔渣制備石材技術也完成了工業化和中試試驗。在此基礎上提出了固廢的大宗量利用、協同利用、節能減碳利用和與智能化結合的資源化利用是這一領域技術發展的主要趨勢。Abstract: In China, the annual discharge of steel slag, red mud, copper slag, and most ferroalloy slag has reached 10–100 million tons; these slags are difficult to be resued due to poor utilization in the fields of cement, concrete, or road pavement. The difficult reusing of these wastes requires new theory and technology, particularly due to the huge scale and concentration in their distribution in China. This study analyzed the current situation of the bulk utilization of the abovementioned typical metallurgical solid wastes and summarized the causes of the problems hindering the utilization, including harmful components, low cementitious reactivity, fine particle size, instability in composition, and huge discharge amount in China, distribution concentrated in several areas for a kind of metallurgical solid waste. Owing to a huge market of 100 million tons or even 10 billion tons per year in China, aggregates, ceramic materials, and artificial stones are suitable for the bulk utilization of solid wastes. Relative research progresses in the low-cost preparation of sintered ceramsite from metallurgical slags, slag-based ceramic tiles and fired bricks, modification of molten slags for producing aggregates, and artificial stones directly converted from molten slags were reviewed. During these researches, an experiment on the industrial production of sintered ceramsite with mass fraction of 50%–65% red mud in its raw materials was conducted in a new 100-thousand tons production line. Ceramic tiles and sintered bricks with mass fraction of 40%–60% red mud or 30%–50% steel slag, or 50%–80% copper slag were respectively produced in the pilot-scale experiment and industry line. The direct conversion of molten slag into building materials is an energy-saving and carbon-reducing technology. An industrial experiment for modification of a molten electric arc furnace slag with mass fraction of 12.96% sand added during its discharge process without any energy supply was completed, and the modified slag was further converted into an artificial aggregate with qualified volume stability properties. A casting stone with low production cost was prepared directly from the modified molten slag in small-scale experiments using the “Petrurgic” heat treatment method. Finally, main trends of the utilization technology for the metallurgical slag were further put forward, including the large-scale utilization technologies, synergistic utilization technology for different solid wastes, energy-saving or recovery and carbon reduction technologies during the utilization process, and intelligent technologies integrated into the resource’s utilization process. Besides these four aspects, the change and improvement of approach toward solid wastes, management of solid wastes, and promotion of new technology applications for people in the production, treatment, and management departments in the metallurgical industry are especially important.

-

Key words:

- metallurgical solid waste /

- bulk utilization technology /

- steel slag /

- red mud /

- copper slag /

- ferroalloy slag

-

表 1 典型鐵合金渣的成分(質量分數)

Table 1. Composition of typical ferroalloy slags

% Slags SiO2 Al2O3 CaO MgO Fe2O3 Cr2O3 MnO other Silicon manganese slag 42.17 20.71 16.07 3.68 0.12 0.01 11.38 5.86 Ferrochrome slag 34.96 23.27 2.44 26.79 2.74 7.36 0.25 2.19 Nickel-iron slag of blast furnace 28.92 22.81 31.55 10.69 1.24 0.23 0.22 4.34 Nickel-iron slag for electric furnace 49.47 4.20 2.17 28.33 12.23 1.08 0.5 2.02 久色视频表 2 我國大宗建筑材料的用量及價格

Table 2. Amounts and costs of bulk building materials in China

Building materials Annual consumption/t Price of products/

(¥·t?1)Sand and gravel material More than 20 billion 50–200 for product Concrete Nearly 10 billion 30–300 for admixture Cement Nearly 2 billion 30–300 for admixture Sintered brick 10–20 billion 10–100 for raw materials Ceramic tile About 300 million 60–300 for raw materials Nature Stone More than 100 million 1000–3500 for rough stone -

參考文獻

[1] World Steel Association. World steel statistics 2021 [EB/OL]. Intennet Online (2021-4-26) [2021-09-10].https://www.worldsteel.org/zh/dam/jcr:976723ed-74b3-47b4-92f6-81b6a452b86e/WSIF_2021_CN.pdf [2] The International Aluminium Institute. Alumina production [EB/OL]. Intennet Online (2021-5-26) [2021-09-10].https://www.world-aluminium.org/statistics/alumina-production/#data [3] National Bureau of Statistics of the People's Republic of China. Ferroalloy output [EB/OL]. Intennet Online [2021-09-10].https://data.stats.gov.cn/easyquery.htm?cn=A01&zb=A02091B&sj=202105 [4] Lai X S, Huang H J. Current status of the comprehensive utilization technology of copper slag. Met Mine, 2017(11): 205 doi: 10.3969/j.issn.1001-1250.2017.11.040賴祥生, 黃紅軍. 銅渣資源化利用技術現狀. 金屬礦山, 2017(11):205 doi: 10.3969/j.issn.1001-1250.2017.11.040 [5] Xi B D, Li R F, Zhao X Y, et al. Constraints and opportunities for the recycling of growing ferronickel slag in China. Resour Conserv Recycl, 2018, 139: 15 doi: 10.1016/j.resconrec.2018.08.002 [6] Miao X W, Bai Z T, Lu G H, et al. Review of comprehensive utilization of typical ferroalloy slags. Chin J Eng, 2020, 42(6): 663苗希望, 白智韜, 盧光華, 等. 典型鐵合金渣的資源化綜合利用研究現狀與發展趨勢. 工程科學學報, 2020, 42(6):663 [7] Liu C B, Peng B, Xia C, et al. The research progress of steel slag utilization and stabilization technology. Conserv Util Miner Resour, 2018(6): 145劉長波, 彭犇, 夏春, 等. 鋼渣利用及穩定化技術研究進展. 礦產保護與利用, 2018(6):145 [8] Vaverka J, Sakurai K. Quantitative determination of free lime amount in steelmaking slag by X-ray diffraction. ISIJ Int, 2014, 54(6): 1334 doi: 10.2355/isijinternational.54.1334 [9] Cui X W, Ni W, Ren C. Hydration mechanism of all solid waste cementitious materials based on steel slag and blast furnace slag. Chin J Mater Res, 2017, 31(9): 687 doi: 10.11901/1005.3093.2016.741崔孝煒, 倪文, 任超. 鋼渣礦渣基全固廢膠凝材料的水化反應機理. 材料研究學報, 2017, 31(9):687 doi: 10.11901/1005.3093.2016.741 [10] Manso J M, Polanco J A, Losa?ez M, et al. Durability of concrete made with EAF slag as aggregate. Cem Concr Compos, 2006, 28(6): 528 doi: 10.1016/j.cemconcomp.2006.02.008 [11] Zhang S, Zhang L L. Research progress of steel slag as road base material // The 6th National Advanced Concrete Technology and Engineering Application Conference. Guangzhou, 2018: 7張碩, 張亮亮. 鋼渣作道路基層材料的研究進展. 第六屆“全國先進混凝土技術及工程應用”研討會論文集. 廣州, 2018: 7 [12] Li C, Chen Z W, Xie J, et al. A technological and applicational review on steel slag asphalt mixture. Mater Rev, 2017, 31(3): 86李超, 陳宗武, 謝君, 等. 鋼渣瀝青混凝土技術及其應用研究進展. 材料導報, 2017, 31(3):86 [13] Albertsson G J. Investigations of Stabilization of Cr in Spinel Phase in Chromium-Containing Slags [Dissertation]. Sweden: KTH Royal Institute of Technology, 2011 [14] National Bureau of Statistics of People's Republic of China. China Statistical Yearbook. Beijing: China Statistics Press, 2020中華人民共和國國家統計局. 中國統計年鑒. 北京: 中國統計出版社, 2020 [15] Tangshan City Transportation Bureau. Tangshan highway mileage has reached 19, 000 kilometers [EB/OL]. Intennet Online (2020-07-08) [2021-09-10]. http://jtysj.tangshan.gov.cn/jiaotong/jiaotongdongtaia/ 20200708/940654.html唐山市交通運輸局. 唐山公路通車里程已達1.9萬公里[EB/OL]. (2020-07-08) [2021-09-10]. http://jtysj.tangshan.gov.cn/jiaotong/jiaotongdongtaia/20200708/940654.html [16] Bureau of Transportation Statistics. National transportation statistics [EB/OL]. Intennet Online [2021-09-10].https://www.bts.gov/content/highway-profile [17] Statistics Bureau of Japan. Japan statistical yearbook 2021 [EB/OL]. Intennet Online [2021-09-10]. http://www.stat.go.jp/english/data/nenkan/70nenkan/1431-13.html [18] USGS. Mcs2021-Cement [EB/OL]. Intennet Online [2021-09-10]. https://pubs.usgs.gov/periodicals/mcs2021/mcs2021-cement.pdf [19] Tangshan Cement Network. Tangshan's annual cement production in 2020 was 34.543 million tons, up 19.76% year on year [EB/OL]. Intennet Online (2021-1-19) [2021-09-10]. http://www.tssnw.com/news/2362.html唐山水泥網. 唐山市2020年全年生產水泥3454.3萬噸同比增長19.76% [EB/OL]. 網絡在線(2021-1-19) [2021-10-21]. http://www.tssnw.com/news/2362.html [20] Xue S G, Zhu F, Kong X F, et al. A review of the characterization and revegetation of bauxite residues (red mud). Environ Sci Pollut Res, 2016, 23(2): 1120 doi: 10.1007/s11356-015-4558-8 [21] Kong X F, Li M, Xue S G, et al. Acid transformation of bauxite residue: Conversion of its alkaline characteristics. J Hazard Mater, 2017, 324: 382 doi: 10.1016/j.jhazmat.2016.10.073 [22] Zhu X B, Li W, Guan X M. An active dealkalization of red mud with roasting and water leaching. J Hazard Mater, 2015, 286: 85 doi: 10.1016/j.jhazmat.2014.12.048 [23] Fang Y G. Study on High Alkaline Red Mud as Resoures and Its Application [Dissertation]. Wuhan: Wuhan University of Technology, 2010房永廣. 高堿赤泥資源化研究及其應用[學位論文]. 武漢: 武漢理工大學, 2010 [24] Liu X M, Tang B W, Yin H F, et al. Durability and environmental performance of Bayer red mud-coal gangue-based road base material. Chin J Eng, 2018, 40(4): 438劉曉明, 唐彬文, 尹海峰, 等. 赤泥—煤矸石基公路路面基層材料的耐久與環境性能. 工程科學學報, 2018, 40(4):438 [25] Zhang N, Li H X, Liu X M. Hydration mechanism and leaching behavior of bauxite-calcination-method red mud-coal gangue based cementitious materials. J Hazard Mater, 2016, 314: 172 doi: 10.1016/j.jhazmat.2016.04.040 [26] Bayat A, Hassani A, Yousefi A A. Effects of red mud on the properties of fresh and hardened alkali-activated slag paste and mortar. Constr Build Mater, 2018, 167: 775 doi: 10.1016/j.conbuildmat.2018.02.105 [27] Wang D Q, Wang Q, Huang Z X. Reuse of copper slag as a supplementary cementitious material: Reactivity and safety. Resour Conserv Recycl, 2020, 162: 105037 doi: 10.1016/j.resconrec.2020.105037 [28] Xie R Q, Huang R, Zhao S F, et al. Research progress on resource utilization of copper slag. Conserv Util Miner Resour, 2020, 40(6): 149謝仁齊, 黃潤, 趙世翻, 等. 銅渣資源化利用研究進展. 礦產保護與利用, 2020, 40(6):149 [29] Zhang X F, Ni W, Wu J Y, et al. Hydration mechanism of a cementitious material prepared with Si?Mn slag. Int J Miner Metall Mater, 2011, 18(2): 234 doi: 10.1007/s12613-011-0428-7 [30] Wang Q, Zhou Y Q, Zhang Z Q, et al. New Mineral Admixtures for Green Concrete. Beijing: China Building Industry Press, 2018王強, 周予啟, 張增起, 等 綠色混凝土用新型礦物摻合料. 北京: 中國建筑工業出版社, 2018 [31] Ju L P, Chen Y H, Zhu Y B, et al. Environmental risk study on utilization of Ferro-nickel slag in concrete. Nonferrous Met (Extr Metall) , 2020(9): 106鞠麗萍, 陳彥虎, 祝怡斌, 等. 鎳鐵渣在混凝土綜合利用中的環境風險研究. 有色金屬(冶煉部分), 2020(9):106 [32] Liu L B, Zhang L H, Tang K J. Comprehensive Utilization Technology of High Carbon Ferrochrome Metallurgical Slag. Beijing: China Building Materials Industry Press, 2021劉來寶, 張禮華, 唐凱靖. 高碳鉻鐵冶金渣資源化綜合利用技術. 北京: 中國建材工業出版社, 2021 [33] Huang W, Luo B, Li B, et al. Experiment on flexural behavior of green concrete composite slab with different structural forms. J Hunan Univ (Nat Sci) , 2019, 46(7): 35黃煒, 羅斌, 李斌, 等. 不同構造形式綠色混凝土疊合板受彎性能試驗. 湖南大學學報(自然科學版), 2019, 46(7):35 [34] Department of Raw material Industry. Publicly solicit opinions on the "Several opinions on promoting the high-quality development of the sand and stone industry of the mechanism (draft for comments). Ministry of Industry and Information Technology of the People’s Republic of China. (2019-01-30) [2021-9-10]. https://www.miit.gov.cn/jgsj/ycls/jzcl/art/2020/art_42e1a6c63b65490daaf1a9155b844909.html原材料工業司. 公開征求對《關于推進機制砂石行業高質量發展的若干意見(征求意見稿)》的意見. 中華人民共和國工業和信息化部. (2019-01-30) [2021-9-10].https://www.miit.gov.cn/jgsj/ycls/jzcl/art/2020/art_42e1a6c63b65490daaf1a9155b844909.html [35] The price of machine-made sand has soared, and governments all over the country have strengthened regulation. Commercial Concrete Periodical, 2018(10): 21 [36] China Aggregates Association. Sand" shortage! The price of C25 concrete in the Pearl River Delta rose to 520 yuan per square. China Aggresgate Website. (2018-07-31) [2021-9-10]. http://www.zgss.org.cn/gongqiuxinxi/2018/5575.html中國砂石協會. “砂”荒!后日起珠三角C25砼價漲至520元每方. 中國沙石骨料網. (2018-07-31) [2021-9-10]. http://www.zgss.org.cn/gongqiuxinxi/2018/5575.html [37] China Aggregates Website. 185 yuan/ton of imported sand has arrived [EB/OL]. Intennet Online (2018-9-6) [2021-10-30]. http://www.zgss.org.cn/zixun/zhuti/5884.html [38] Xiang X D, Tang W J, Jiang X W, et al. Experimental investigation of the characteristics of steel slag ceramsite. Multipurp Util Miner Resour, 2018(1): 96 doi: 10.3969/j.issn.1000-6532.2018.01.021向曉東, 唐衛軍, 江新衛, 等. 高強鋼渣陶粒特性試驗研究. 礦產綜合利用, 2018(1):96 doi: 10.3969/j.issn.1000-6532.2018.01.021 [39] Yue D T. Preparation of Innovative Porous Ceramsite by Sewage Sludge, Red Mud and Steel Slag and the Research of Its Expansion Mechanism [Dissertation]. Jinan: Shandong University, 2014岳東亭. 利用污泥/赤泥/鋼渣等固體廢物制備新型多孔陶粒的膨脹機理研究[學位論文]. 濟南: 山東大學, 2014 [40] Gao M L. Experimental Research on Ceramsite Prepared by Using Steel Slag [Dissertation]. Shenyang: Northeastern University, 2010高明磊. 利用鋼渣制備陶粒的實驗研究[學位論文]. 沈陽: 東北大學, 2010 [41] Fu Y, Ma Z. Experimental study on ceramsite preparation by using red mud, bauxite tailings and sludge. China Energy Environ Prot, 2017, 39(4): 48符勇, 馬喆. 基于赤泥、鋁土尾礦和污泥三大工業廢物的陶粒制備實驗研究. 能源與環保, 2017, 39(4):48 [42] Wan J, Liu H B, Song M, et al. Tests on utilization of red mud to prepare high-strength ceramisite. Min Metall Eng, 2011, 31(5): 111 doi: 10.3969/j.issn.0253-6099.2011.05.030萬軍, 劉恒波, 宋美, 等. 利用赤泥制備高強陶粒的試驗研究. 礦冶工程, 2011, 31(5):111 doi: 10.3969/j.issn.0253-6099.2011.05.030 [43] Zhao J X, Wang L J, Xie X L. Preparation of sintering-expanded haydite with red mud from bayer process. Multipurp Util Miner Resour, 2009(4): 41 doi: 10.3969/j.issn.1000-6532.2009.04.012趙建新, 王林江, 謝襄漓. 利用拜耳法赤泥制備燒脹陶粒的研究. 礦產綜合利用, 2009(4):41 doi: 10.3969/j.issn.1000-6532.2009.04.012 [44] Zhao L H, Li Y, Zhang L L, et al. Effects of CaO and Fe2O3 on the microstructure and mechanical properties of SiO2–CaO–MgO–Fe2O3 ceramics from steel slag. ISIJ Int, 2017, 57(1): 15 doi: 10.2355/isijinternational.ISIJINT-2016-064 [45] Pei D J, Li Y, Cang D Q. In?situ XRD study on sintering mechanism of SiO2?Al2O3?CaO?MgO ceramics from red mud. Mater Lett, 2019, 240: 229 doi: 10.1016/j.matlet.2019.01.019 [46] Wang Y Z. Study on Preparation of Ceramic Sintered Bricks and Water Permeable Bricks by Steel Slag [Dissertation]. Beijing: University of Science and Technology Beijing, 2018王耀忠. 利用鋼渣制備陶瓷燒結磚和透水磚的研究[學位論文]. 北京: 北京科技大學, 2018 [47] Wang X C, Zhi N, Hu J. Technology of fly ash ceramsite. Brick-Tile, 2018(12): 74 doi: 10.3969/j.issn.1001-6945.2018.12.019王小超, 支楠, 胡杰. 淺談粉煤灰陶粒工藝技術. 磚瓦, 2018(12):74 doi: 10.3969/j.issn.1001-6945.2018.12.019 [48] Li S D, Zhi N, Qin X J. Analysis and improvement measures of heat consumption of ceramsite produced by rotary kiln in China. Brick-Tile, 2007(5): 39 doi: 10.3969/j.issn.1001-6945.2007.05.014李壽德, 支楠, 秦仙景. 我國回轉窯生產陶粒熱耗解析及改進措施. 磚瓦, 2007(5):39 doi: 10.3969/j.issn.1001-6945.2007.05.014 [49] Huang S C, Chang F C, Lo S L, et al. Production of lightweight aggregates from mining residues, heavy metal sludge, and incinerator fly ash. J Hazard Mater, 2007, 144(1-2): 52 doi: 10.1016/j.jhazmat.2006.09.094 [50] Deng H W. Preparation of High-Strength Lightweight Lytag and Its Concrete Performance [Dissertation]. Harbin: Harbin Institute of Technology, 2009鄧宏衛. 輕質高強粉煤灰陶粒的制備及其混凝土性能[學位論文]. 哈爾濱: 哈爾濱工業大學, 2009 [51] Li Y, Yao C Q. Kiln System and Method for Firing Ceramsite Containing Calorific Value Raw Materials and Producing Waste Heat as Byproduct: China Patent, CN112880394A. 2021-06-01李宇, 姚長青. 一種利用含熱值原料的陶粒燒制及副產余熱的窯爐系統及方法: 中國專利, CN112880394A. 2021-06-01 [52] Yao C Q, Li Y, Zheng L Q, et al. Tunnel Kiln System for Firing Ceramsite and Ceramsite Firing Method: China Patent, CN112050631A. 2020-12-08姚長青, 李宇, 鄭靈棋, 等. 一種燒制陶粒的隧道窯系統及陶粒燒制方法: 中國專利, CN112050631A. 2020-12-08 [53] Badiee H, Maghsoudipour A, Dehkordi B R. Use of Iranian steel slag for production of ceramic floor tiles. Adv Appl Ceram, 2008, 107(2): 111 doi: 10.1179/174367608X263377 [54] Furlani E, Tonello G, Maschio S. Recycling of steel slag and glass cullet from energy saving lamps by fast firing production of ceramics. Waste Manag, 2010, 30(8-9): 1714 doi: 10.1016/j.wasman.2010.03.030 [55] Zhao L H, Li Y, Zhou Y Y, et al. Preparation of novel ceramics with high CaO content from steel slag. Mater Des, 2014, 64: 608 doi: 10.1016/j.matdes.2014.08.015 [56] Ai X B, Liu X M, GU X M, et al. Effect of steel slag content on the performance of traditional ceramics system // 2013 International Conference on Renewable Energy and Environmental Materials. Chengdu, 2013: 602 [57] Pei D J, Li Y, Cang D Q. Na+-solidification behavior of SiO2?Al2O3?CaO?MgO (10wt%) ceramics prepared from red mud. Ceram Int, 2017, 43(18): 16936 doi: 10.1016/j.ceramint.2017.09.098 [58] Xu X H, Song J, Li Y, et al. The microstructure and properties of ceramic tiles from solid wastes of Bayer red muds. Constr Build Mater, 2019, 212: 266 doi: 10.1016/j.conbuildmat.2019.03.280 [59] He H T, Yue Q Y, Qi Y F, et al. The effect of incorporation of red mud on the properties of clay ceramic bodies. Appl Clay Sci, 2012, 70: 67 doi: 10.1016/j.clay.2012.09.022 [60] Su Q, Xie H B, Chen Z, et al. Study on preparation of ceramic tiles by co-mixing nickel-iron slag and tin tailings. Guangdong Build Mater, 2020, 36(3): 1 doi: 10.3969/j.issn.1009-4806.2020.03.002蘇青, 謝紅波, 陳哲, 等. 鎳鐵渣和錫尾礦共摻制備陶瓷磚的研究. 廣東建材, 2020, 36(3):1 doi: 10.3969/j.issn.1009-4806.2020.03.002 [61] Li Y, Ren Y P, Pei D J. Ferro-Nickel Slag Ceramic and Preparation Method There: China Patent, CN107935555B. 2020-08-07李宇, 任育鵬, 裴德健. 一種鎳鐵渣陶瓷及其制備方法: 中國專利, CN107935555B. 2020-08-07 [62] Li Y, Ren Y P, Pei D J, et al. Mechanism of pore formation in novel porous permeable ceramics prepared from steel slag and bauxite tailings. ISIJ Int, 2019, 59(9): 1723 doi: 10.2355/isijinternational.ISIJINT-2018-782 [63] Pei D J. Study on the Mechanism and Application of Si-Ca Multicomponent Ceramics Prepared from Metallurgical Slags [Dissertation]. Beijing: University of Science and Technology Beijing, 2019裴德健. 利用冶金渣制備硅鈣基多元體系陶瓷的機理及應用研究[學位論文]. 北京: 北京科技大學, 2019 [64] Dai X T, Qi Y H, Zhang C X. Development of molten slag dry granulation and heat recovery in steel industry. J Iron Steel Res, 2008, 20(7): 1戴曉天, 齊淵洪, 張春霞. 熔融鋼鐵渣干式粒化和顯熱回收技術的進展. 鋼鐵研究學報, 2008, 20(7):1 [65] Wang H F, Zhang C X, Qi Y H, et al. Present situation and development trend of blast furnace slag treatment. Iron Steel, 2007, 42(6): 83 doi: 10.3321/j.issn:0449-749X.2007.06.019王海風, 張春霞, 齊淵洪, 等. 高爐渣處理技術的現狀和新的發展趨勢. 鋼鐵, 2007, 42(6):83 doi: 10.3321/j.issn:0449-749X.2007.06.019 [66] Qin Y L, Lü X, Bai C G, et al. Waste heat recovery from blast furnace slag by chemical reactions. JOM, 2012, 64(8): 997 doi: 10.1007/s11837-012-0392-3 [67] Li Y, Cang D Q. Preparing high value-added materials directly from melting slag // The 27th International Conference on Solid Waste Technology and Management. Philadelphia, 2012(3): 2A14 [68] Li Y, Dai W B. Modifying hot slag and converting it into value-added materials: A review. J Clean Prod, 2018, 175: 176 doi: 10.1016/j.jclepro.2017.11.171 [69] Drissen P, Ehrenberg A, Kühn M, et al. Recent development in slag treatment and dust recycling. Steel Res Int, 2009, 80(10): 737 [70] Lu X, Li Y, Ma S, et al. Thermal equilibrium analysis and experiment of molten slag modification by use of its sensible heat. Chin J Eng, 2016, 38(10): 1386盧翔, 李宇, 馬帥, 等. 利用顯熱對熔渣進行直接改質的熱平衡分析及試驗驗證. 工程科學學報, 2016, 38(10):1386 [71] Ma S, Li Y, Zhang L L, et al. Effects of EAF slag basicity on its recovery rate of iron components. Iron Steel, 2017, 52(4): 78馬帥, 李宇, 張玲玲, 等. 堿度變化對電爐渣含鐵組分回收率的影響規律. 鋼鐵, 2017, 52(4):78 [72] Huang S S, Guo M, Zhang M. Modification of converter slag with acidic oxides. J Iron Steel Res, 2015, 27(11): 38黃世爍, 郭敏, 張梅. 酸性氧化物對轉爐鋼渣的改性作用. 鋼鐵研究學報, 2015, 27(11):38 [73] Li Y, Meng X Y, Chen K Y, et al. Crystallization behaviors of spinel during cooling process of modified EAF slag. Metall Mater Trans B, 2020, 51(3): 1027 doi: 10.1007/s11663-020-01802-2 [74] Mudersbach D, Drissen P, Motz H. Improved slag qualities by liquid slag treatment // The 2nd International Slag Valorization Symposium. Leuven, 2011: 299 [75] Mudersbach D, Kühn M, Geisler J, et al. Chrome immobilisation in EAF-slags from high-alloy steelmaking: tests at FEhS institute and development of an operational slag treatment process // Proceedings of the 1st International Slag Valorisation Symposium. Leuven, 2009: 101 [76] Dai W B, Li Y, Cang D Q, et al. Research on a novel modifying furnace for converting hot slag directly into glass-ceramics. J Clean Prod, 2018, 172: 169 doi: 10.1016/j.jclepro.2017.10.039 [77] Pioro L S, Pioro I L. Reprocessing of metallurgical slag into materials for the building industry. Waste Manag, 2004, 24(4): 371 doi: 10.1016/S0956-053X(03)00071-0 [78] Wang Q T, Huang Y R, Li Y H, et al. Thermal Refining Method of Blast Furnace Hot Slags: China Patent, CN103555874A. 2014-02-05王清濤, 黃幼榕, 李要輝, 等. 高爐熱態熔渣的調質處理方法: 中國專利, CN103555874A. 2014-02-05 [79] Zhang W T, He F, Xie J L, et al. Crystallization mechanism and properties of glass ceramics from modified molten blast furnace slag. J Non Cryst Solids, 2018, 502: 164 doi: 10.1016/j.jnoncrysol.2018.08.024 [80] Cheng J S, Tang L Y, Wang Q, et al. Investigation of a slag glass-ceramics. J Wuhan Univ Technol, 1995, 17(4): 1程金樹, 湯李纓, 王全, 等. 鋼渣微晶玻璃的研究. 武漢工業大學學報, 1995, 17(4):1 [81] Zhao G Z, Li Y, Dai W B, et al. Crystallization mechanism and properties of high basicity steel slag-derived glass-ceramics. J Ceram Soc Japan, 2016, 124(3): 247 doi: 10.2109/jcersj2.15218 [82] Li Y, Yi Y D, Chen K Y, et al. Optimization of performance and composition for glass ceramics prepared from mixing molten slags. Chin J Eng, 2019, 41(10): 1288李宇, 伊耀東, 陳奎元, 等. 冶金熔渣混合制備微晶玻璃的組成及性能優化. 工程科學學報, 2019, 41(10):1288 [83] Jia B Z, Chang Y Y, Ren K M, et al. Technical research on making cast stone with manganese slag. Ferro-Alloys, 2010, 41(5): 33 doi: 10.3969/j.issn.1001-1943.2010.05.010賈寶志, 常原勇, 任康民, 等. 錳渣制作鑄石的工藝研究. 鐵合金, 2010, 41(5):33 doi: 10.3969/j.issn.1001-1943.2010.05.010 [84] Chen K Y, Li Y, Meng L, et al. Preparation of glass-ceramic from titanium-bearing blast furnace slag by “petrurgic” method // TMS 2018 Annual Meeting & Exhibition. Phoenix, 2018: 415 [85] Francis A A, Rawlings R D, Boccaccini A R. Glass-ceramics from mixtures of coal ash and soda-lime glass by the petrurgic method. J Mater Sci Lett, 2002, 21(12): 975 doi: 10.1023/A:1016094211224 [86] Bisio G. Energy recovery from molten slag and exploitation of the recovered energy. Energy, 1997, 22(5): 501 doi: 10.1016/S0360-5442(96)00149-1 [87] Barati M, Esfahani S, Utigard T A. Energy recovery from high temperature slags. Energy, 2011, 36(9): 5440 doi: 10.1016/j.energy.2011.07.007 -

下載:

下載: