Effect of cleavage characteristics of mineral grains on the failure process of hard rock based on UDEC-GBM modeling

-

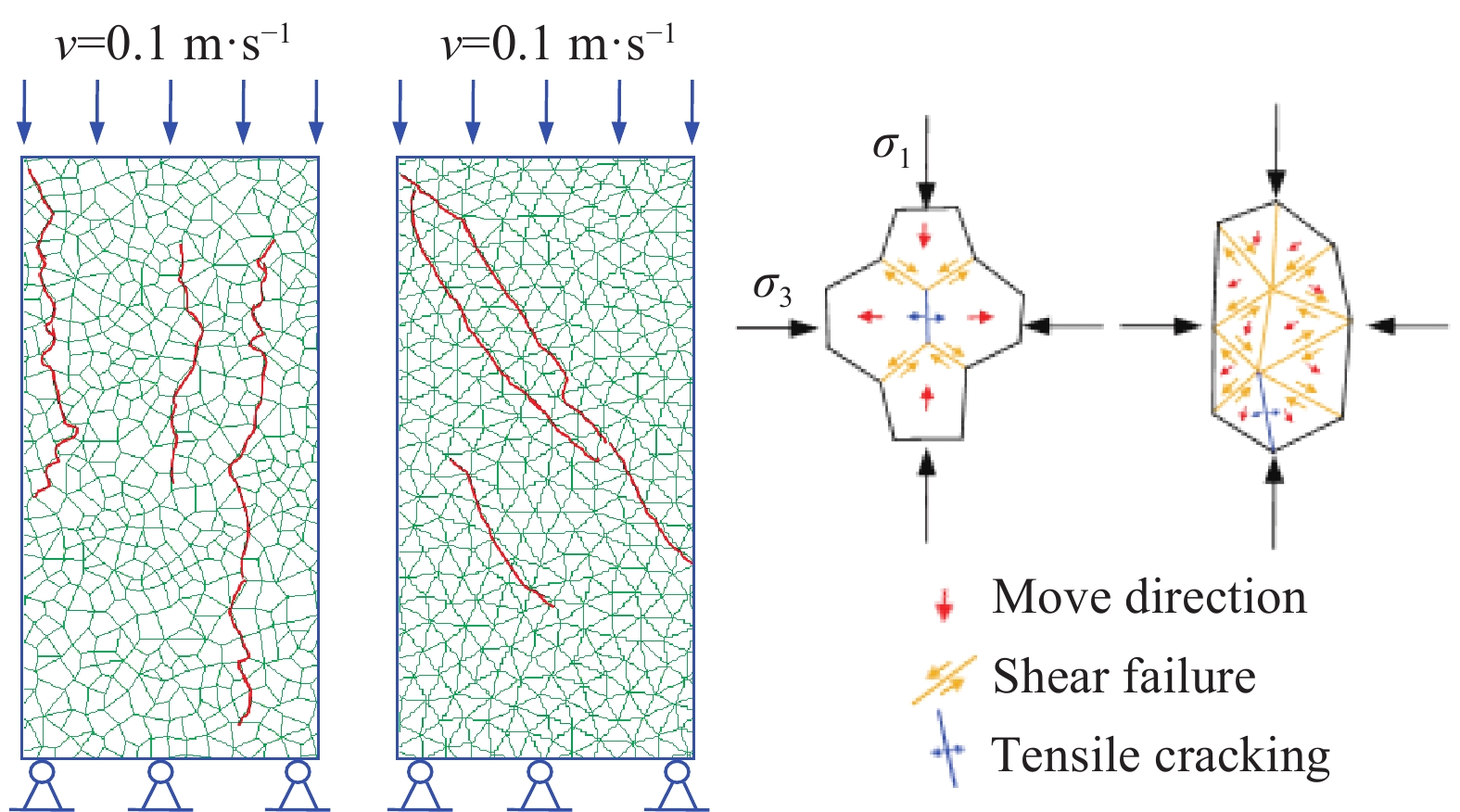

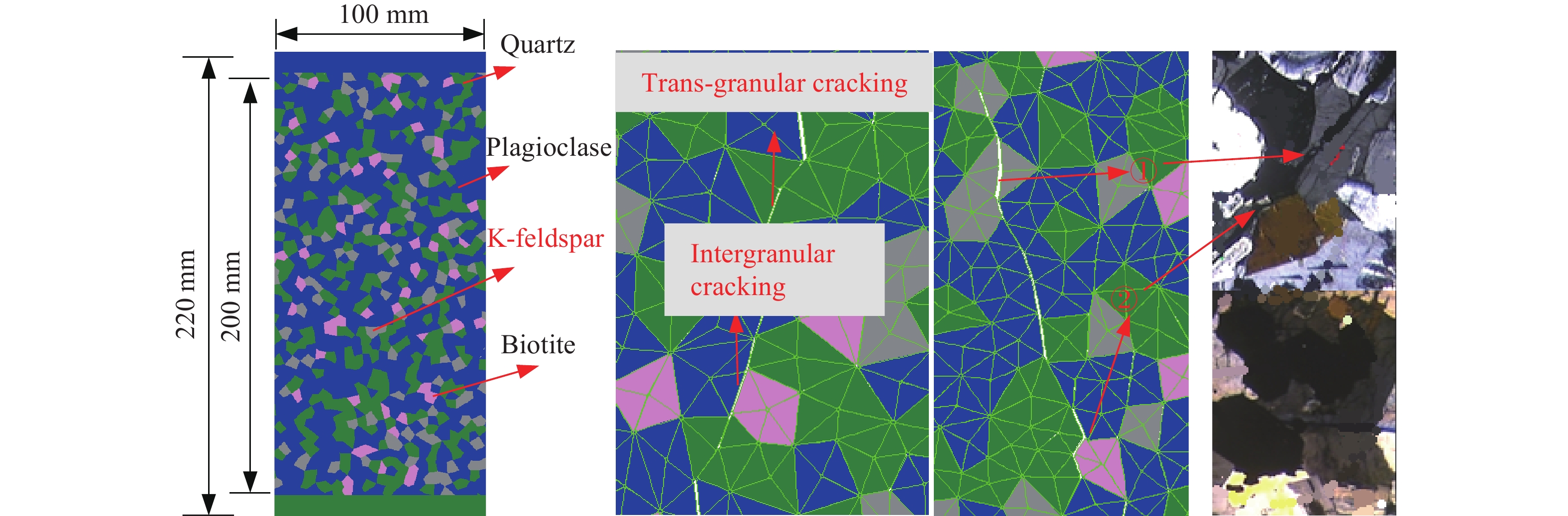

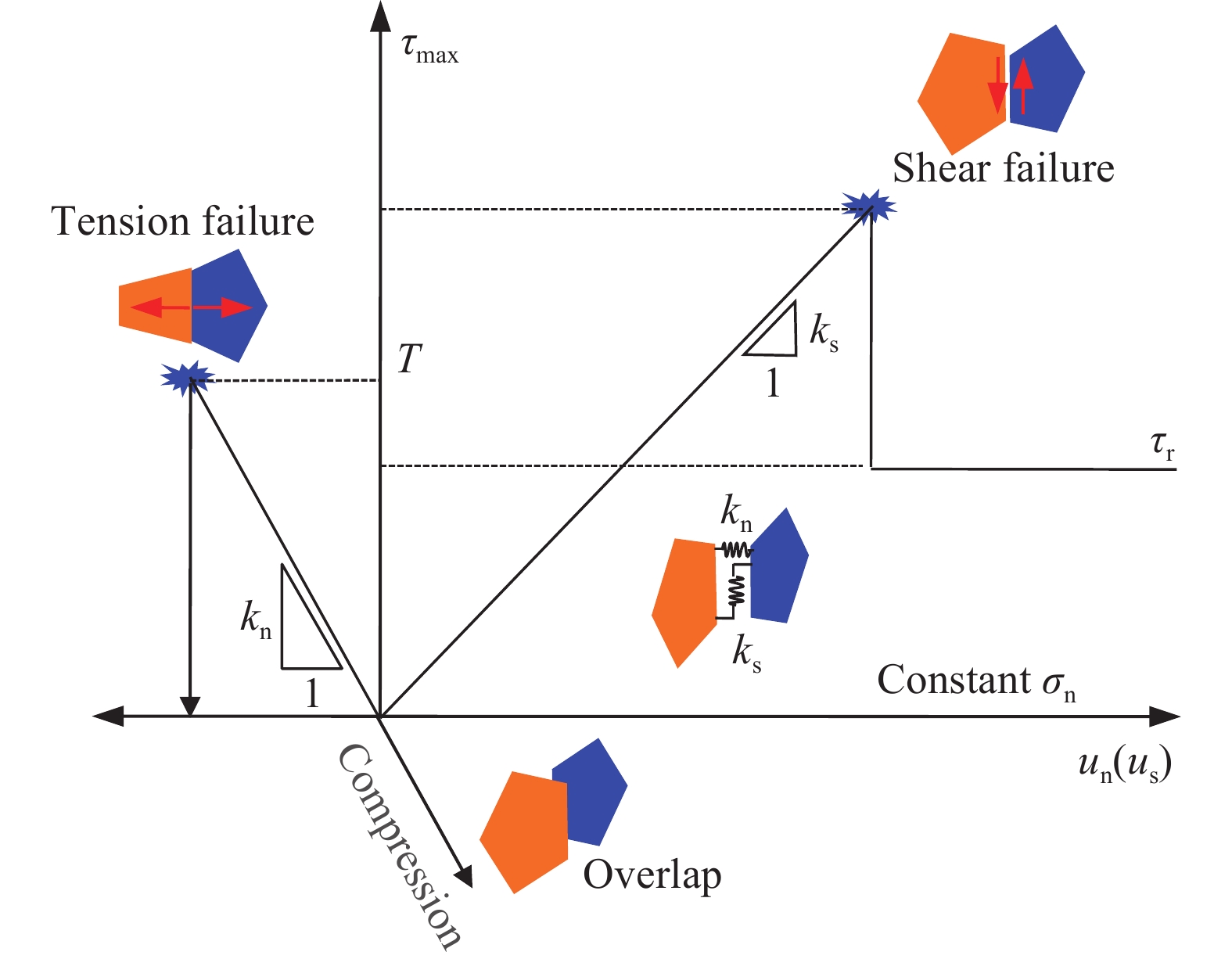

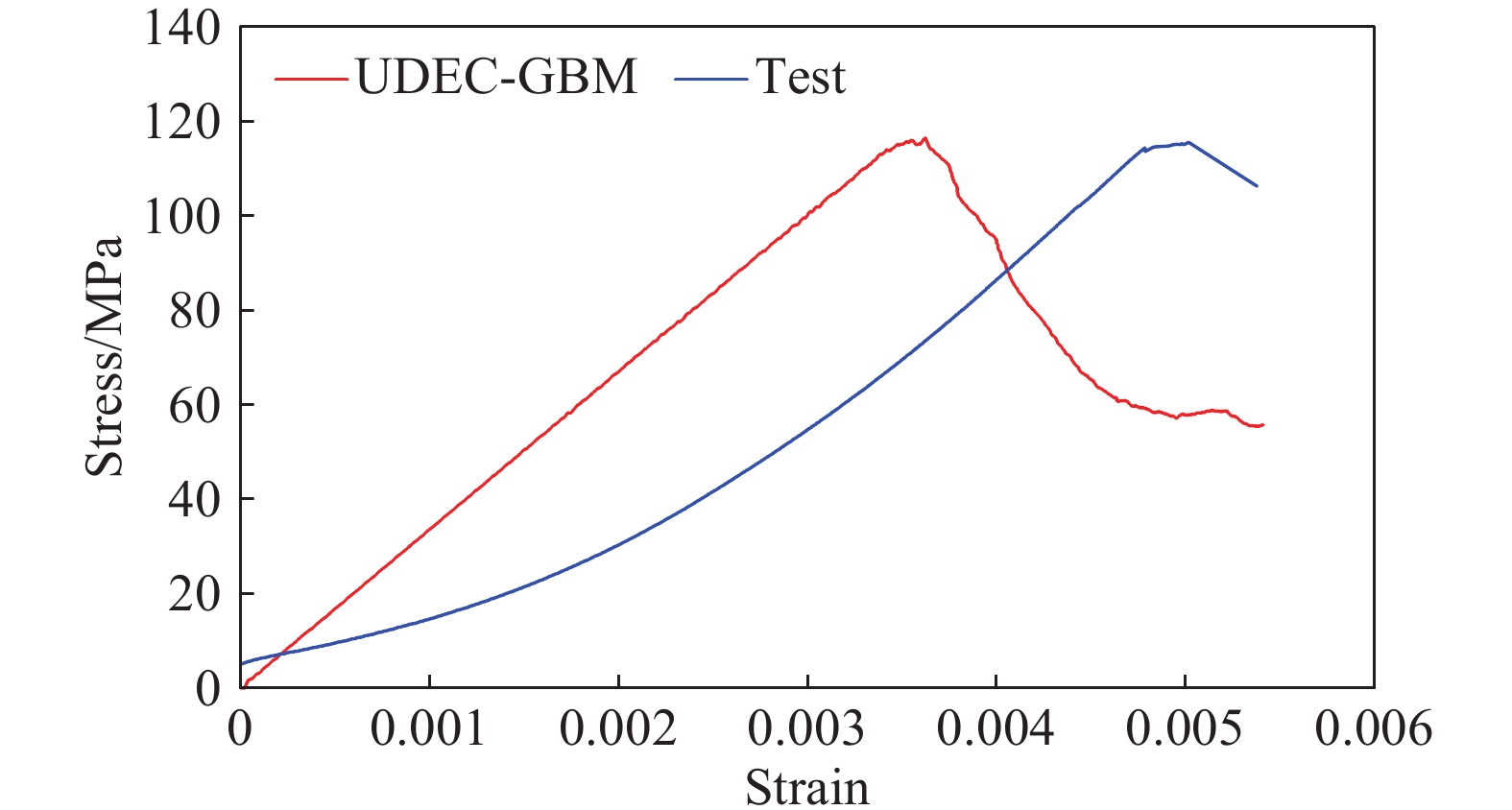

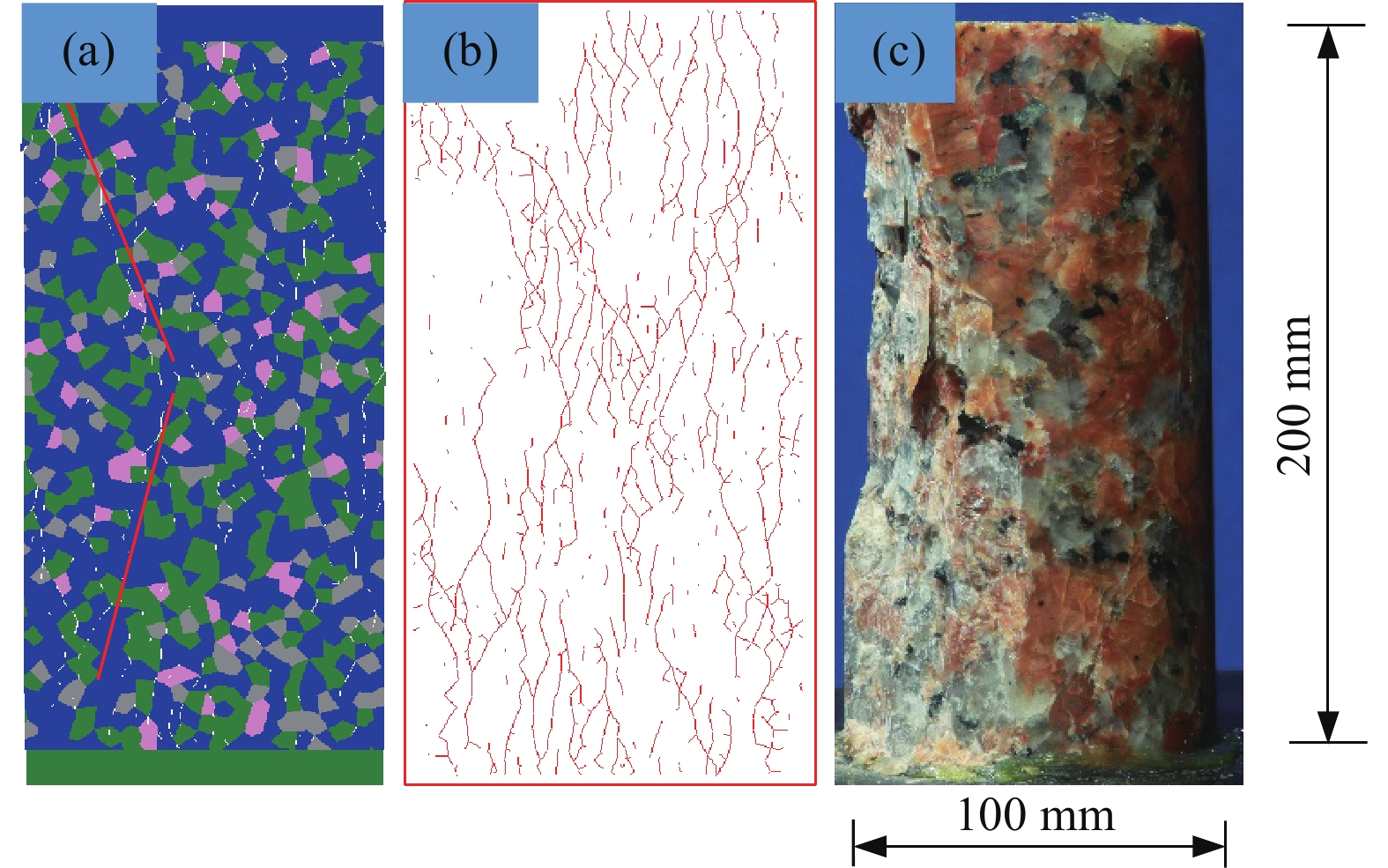

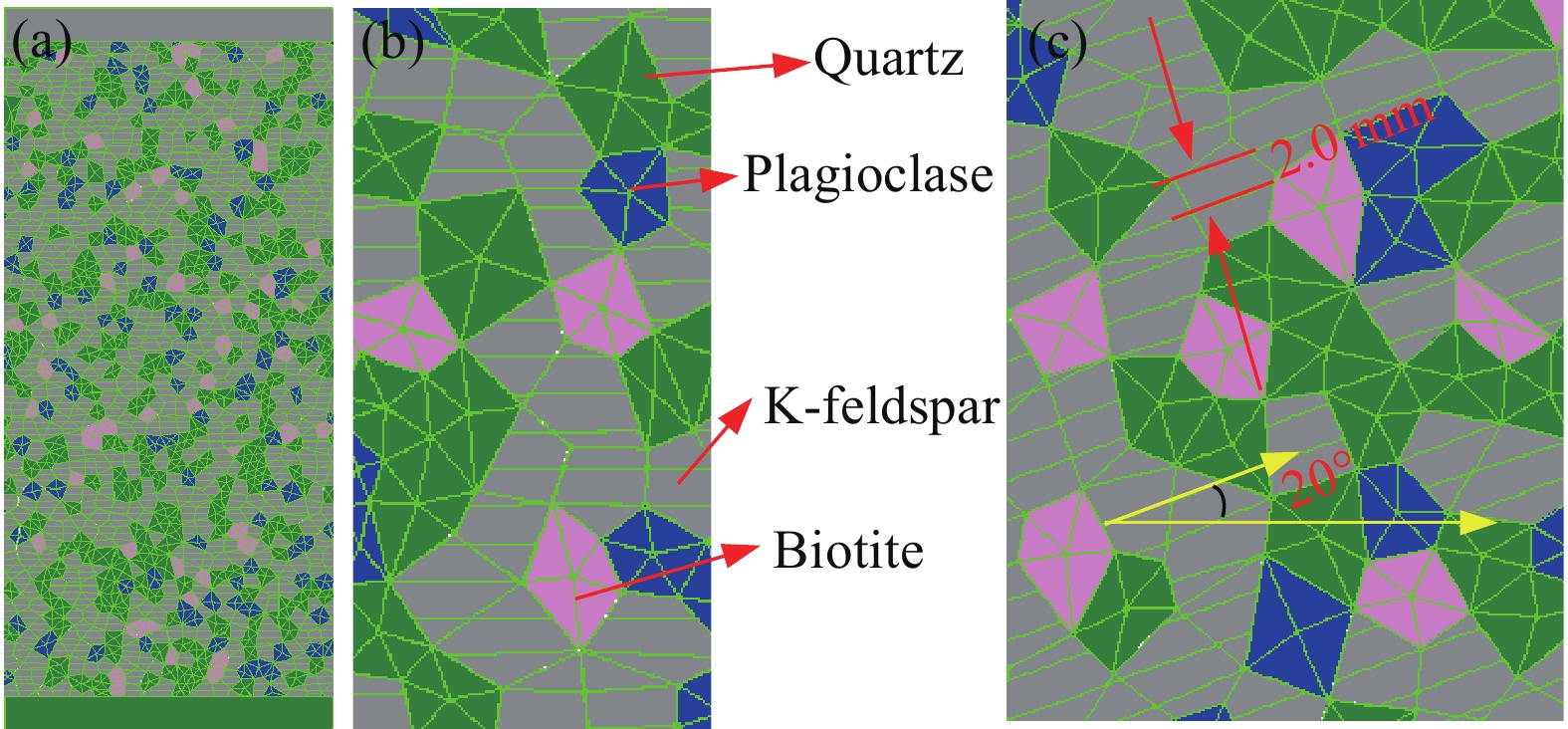

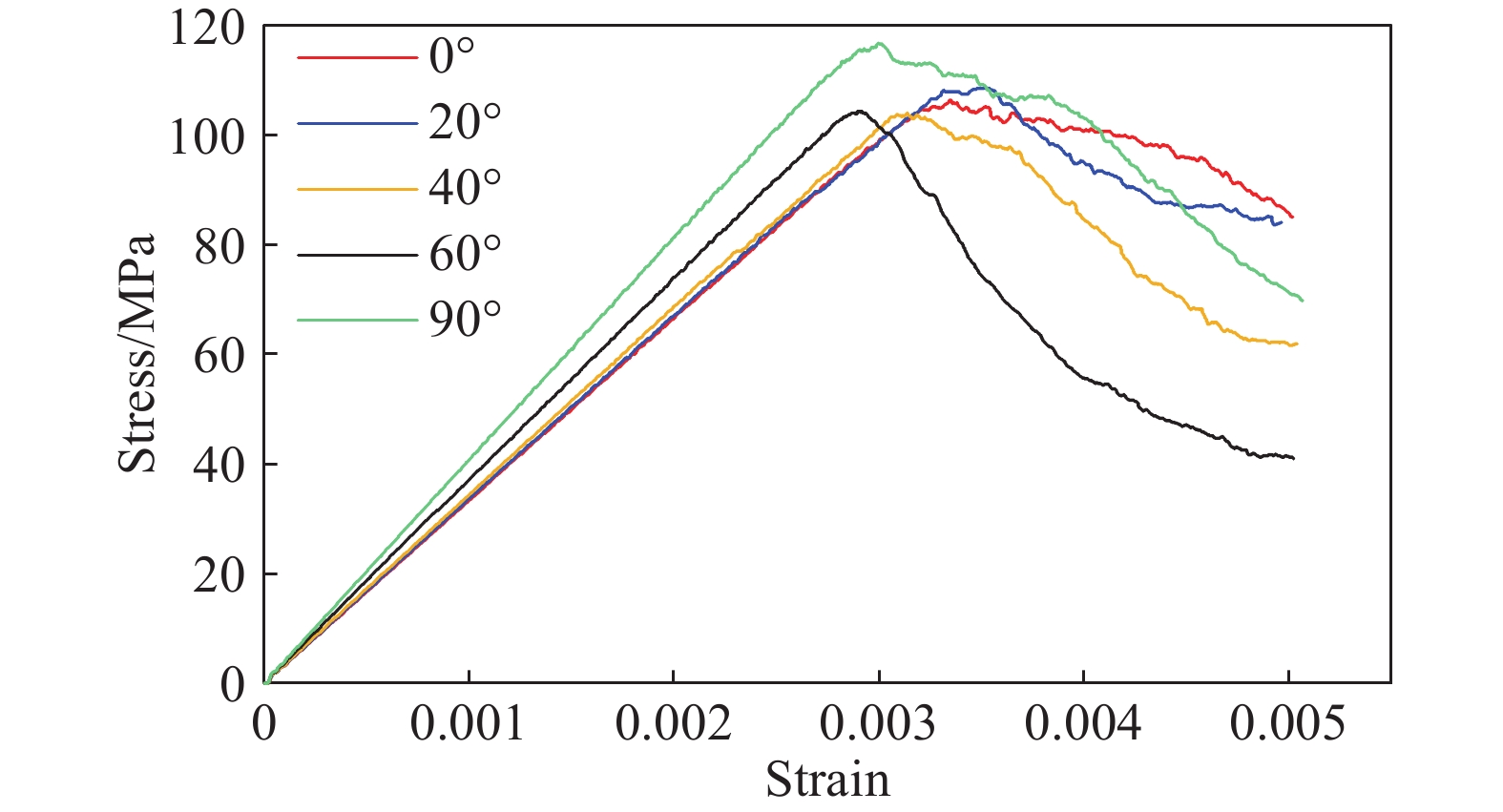

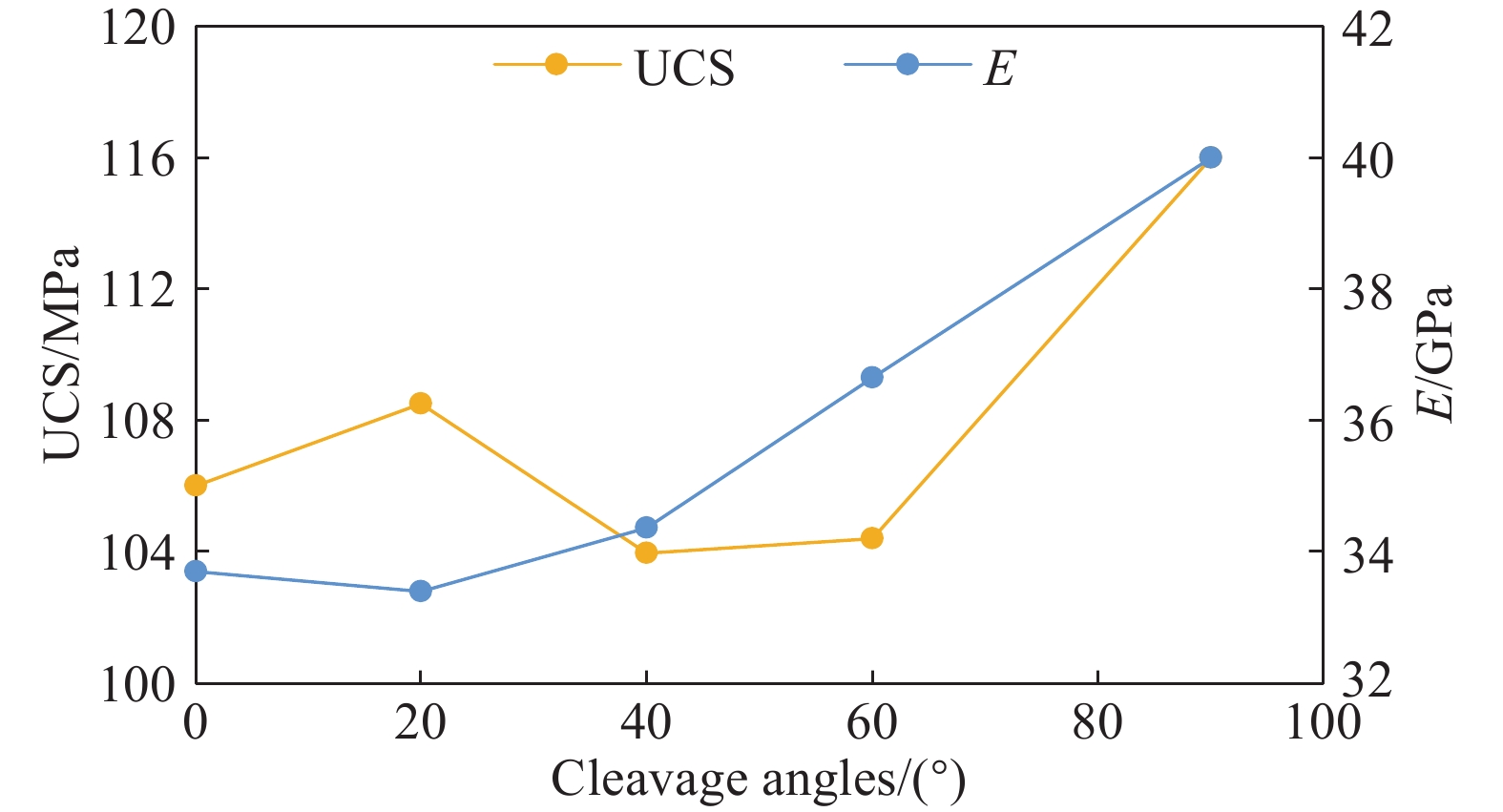

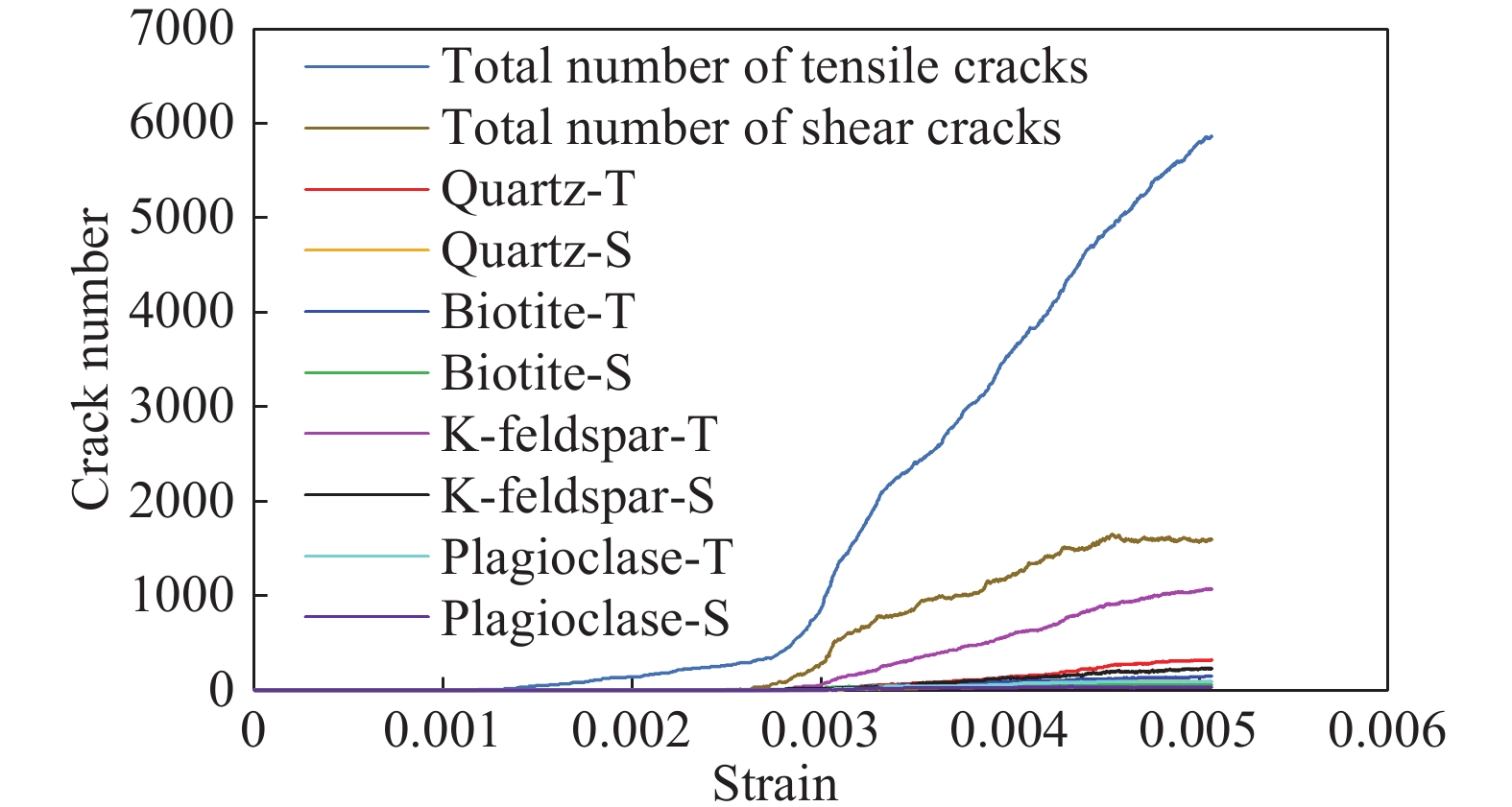

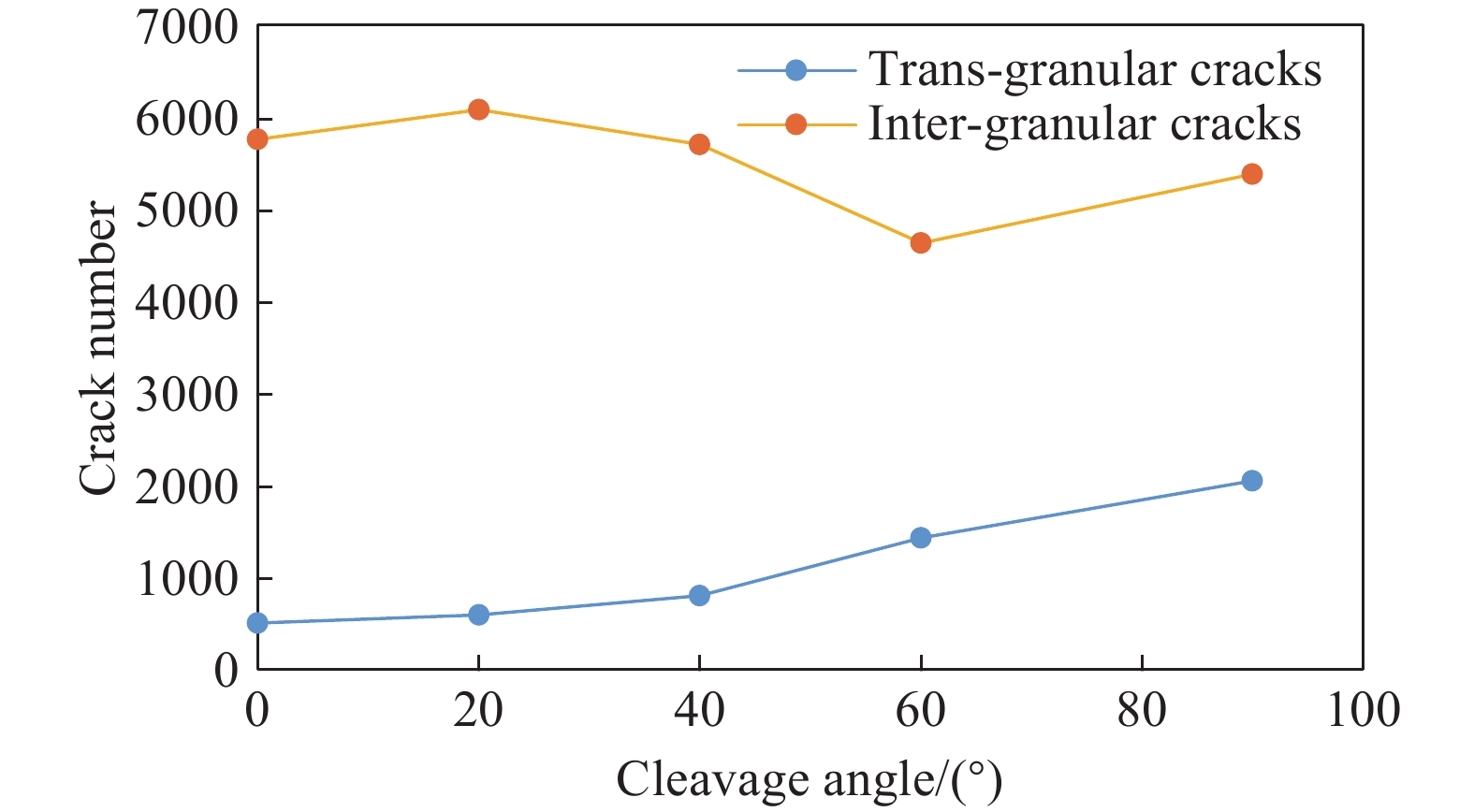

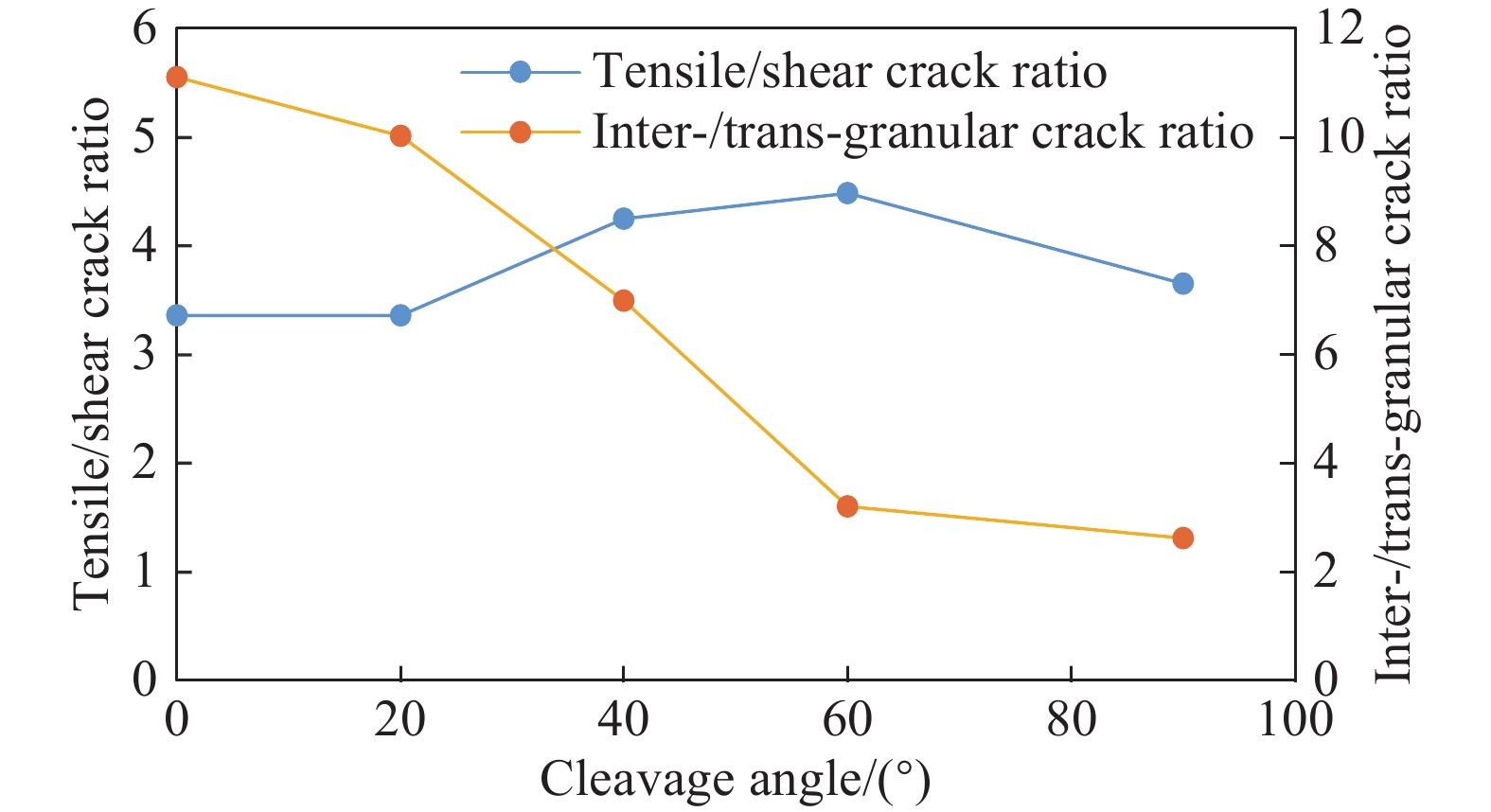

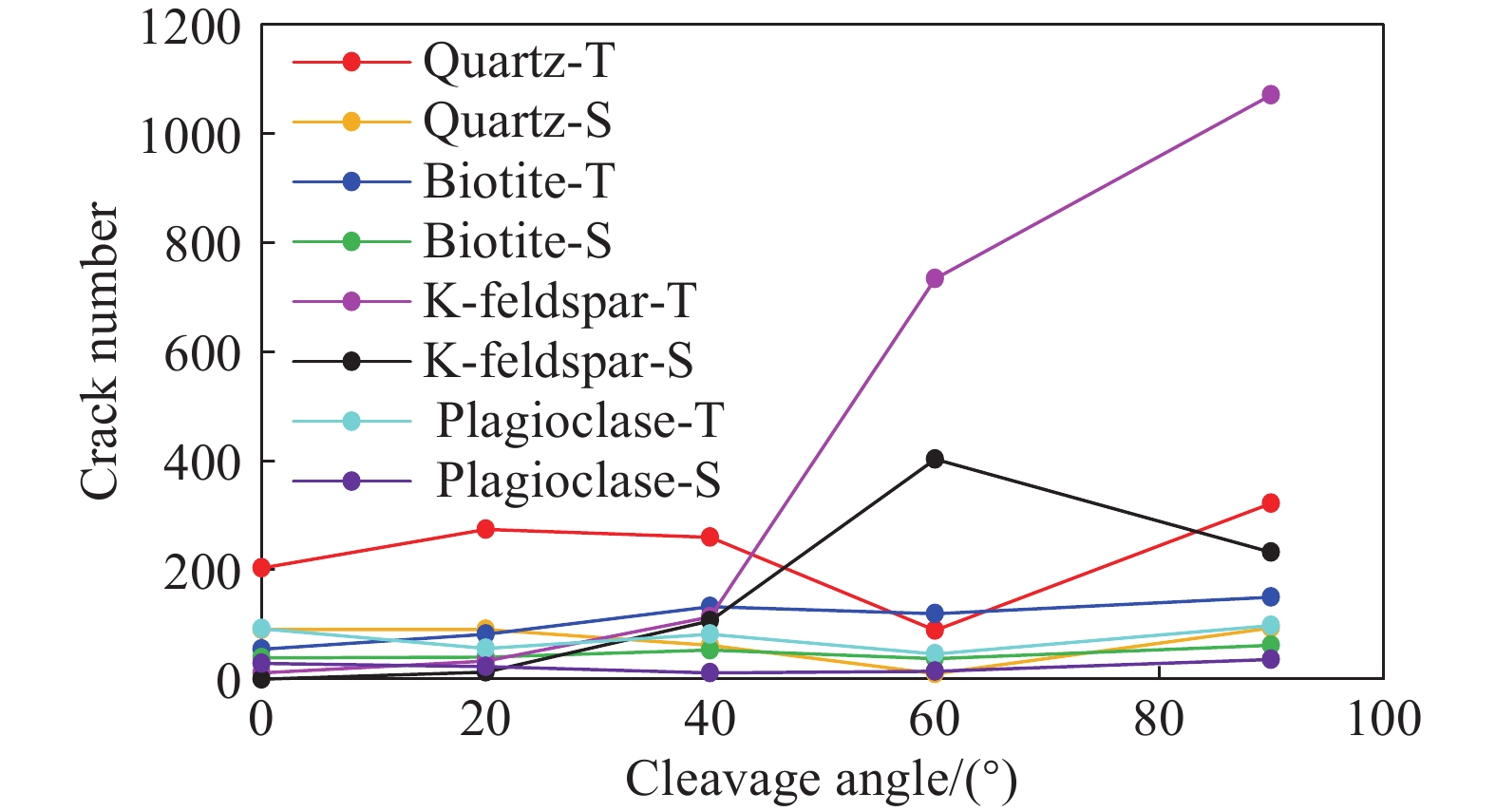

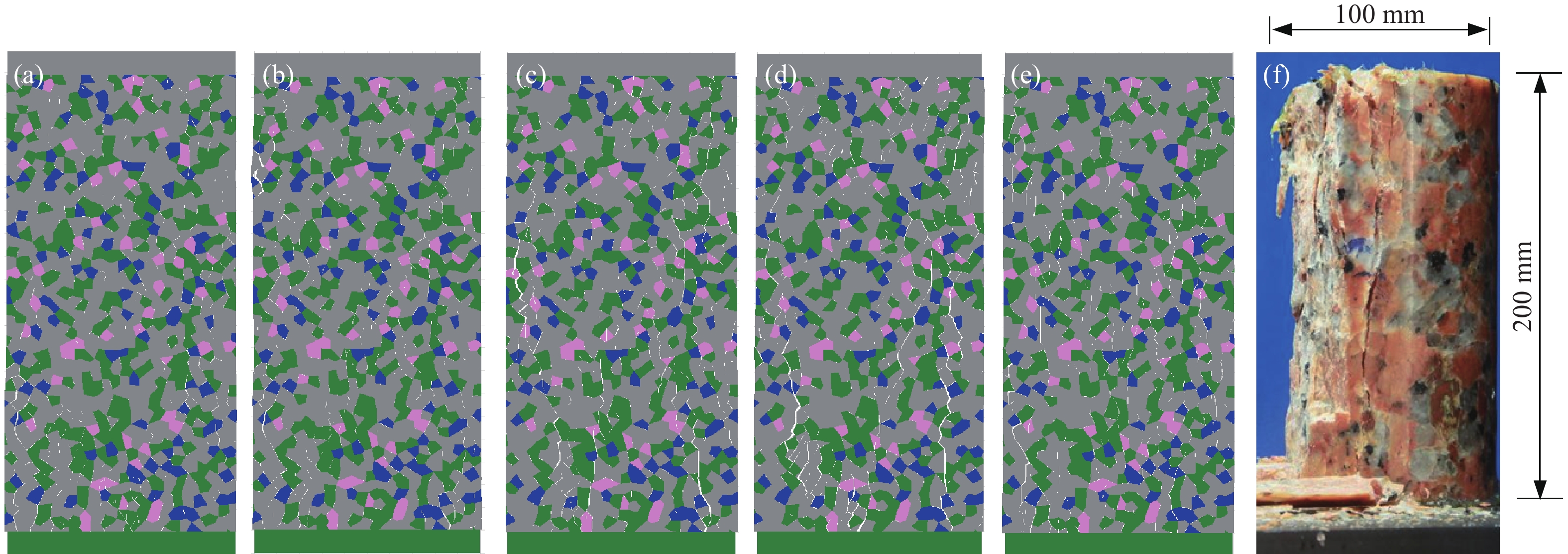

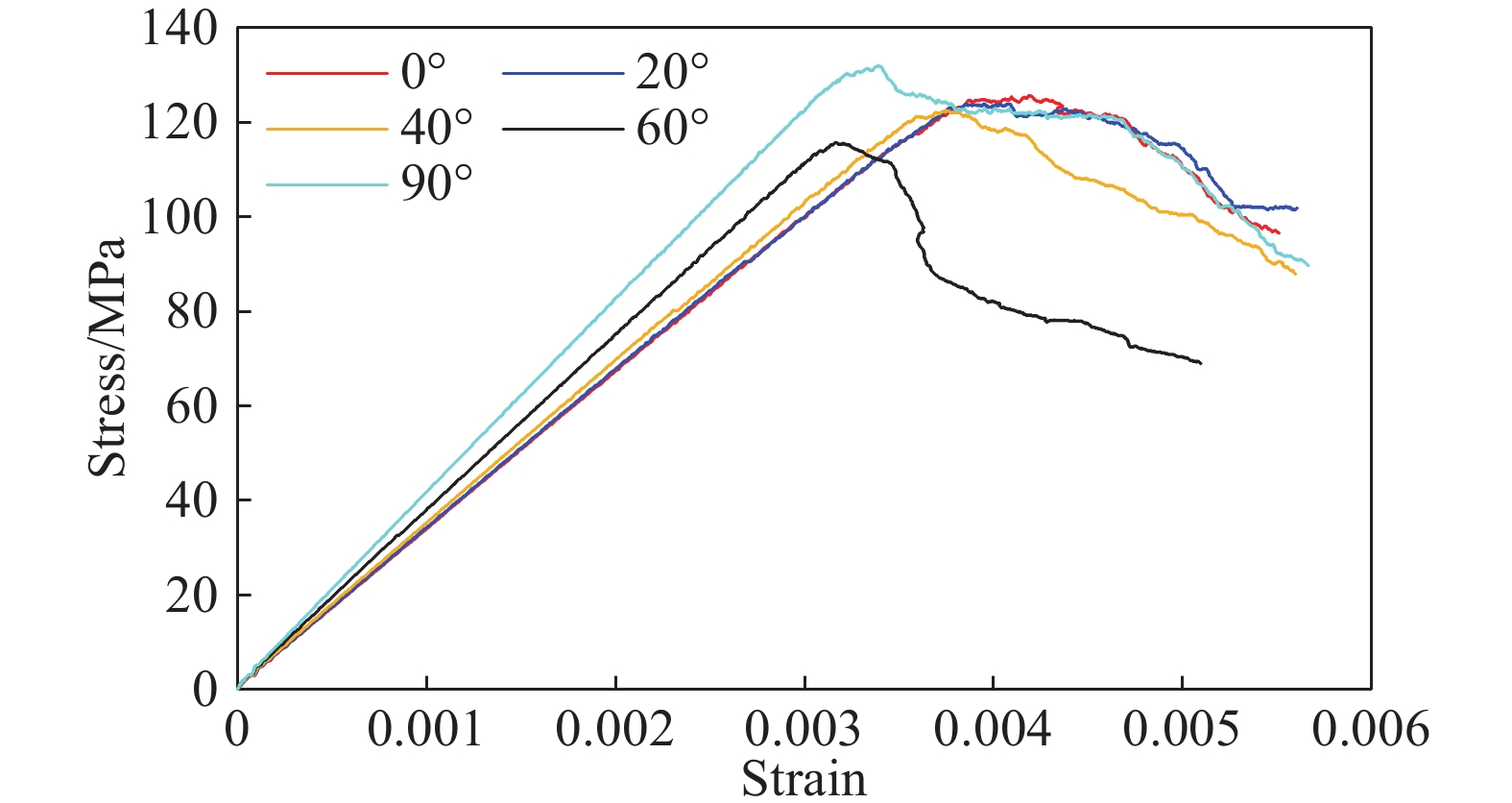

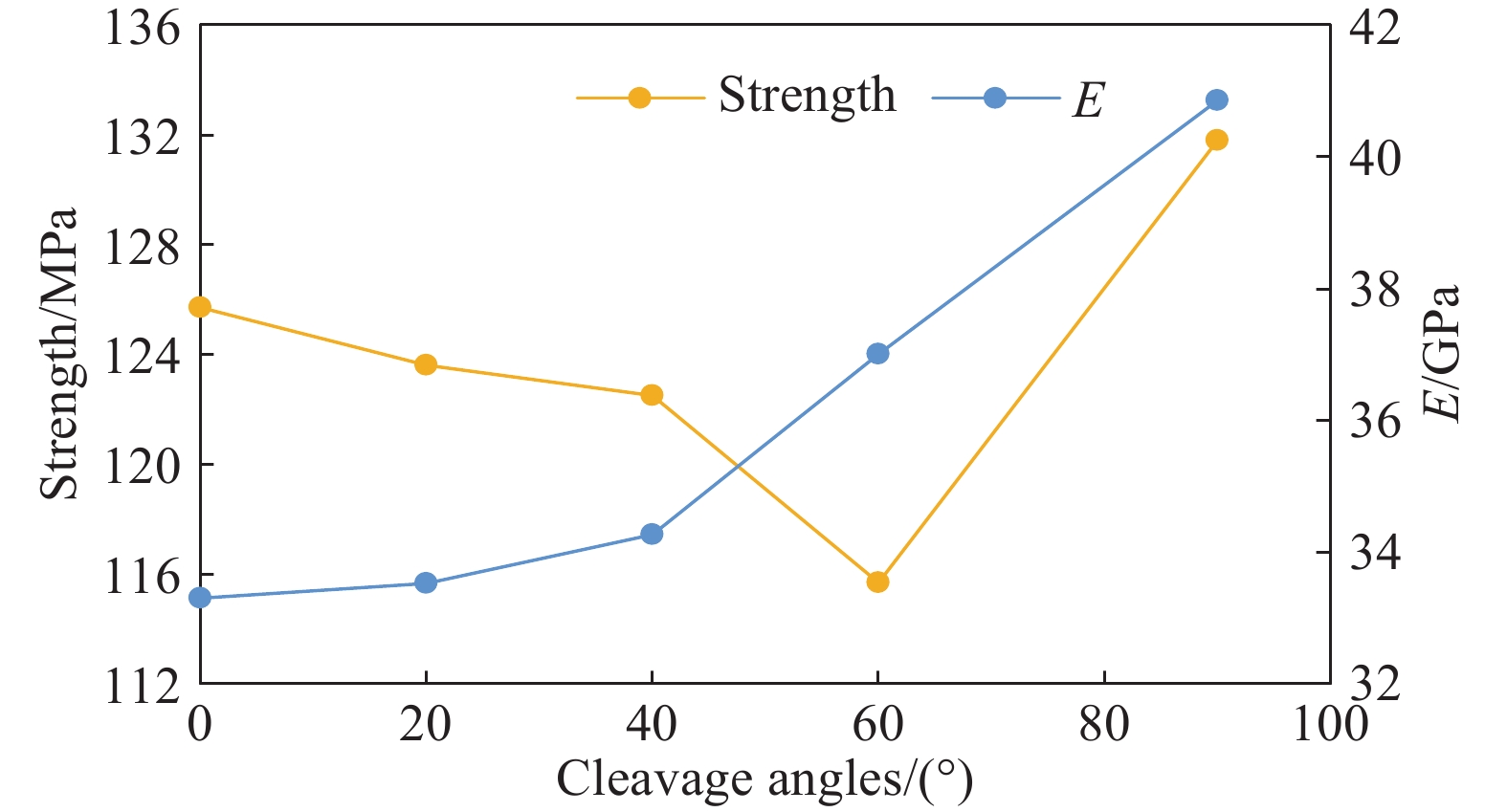

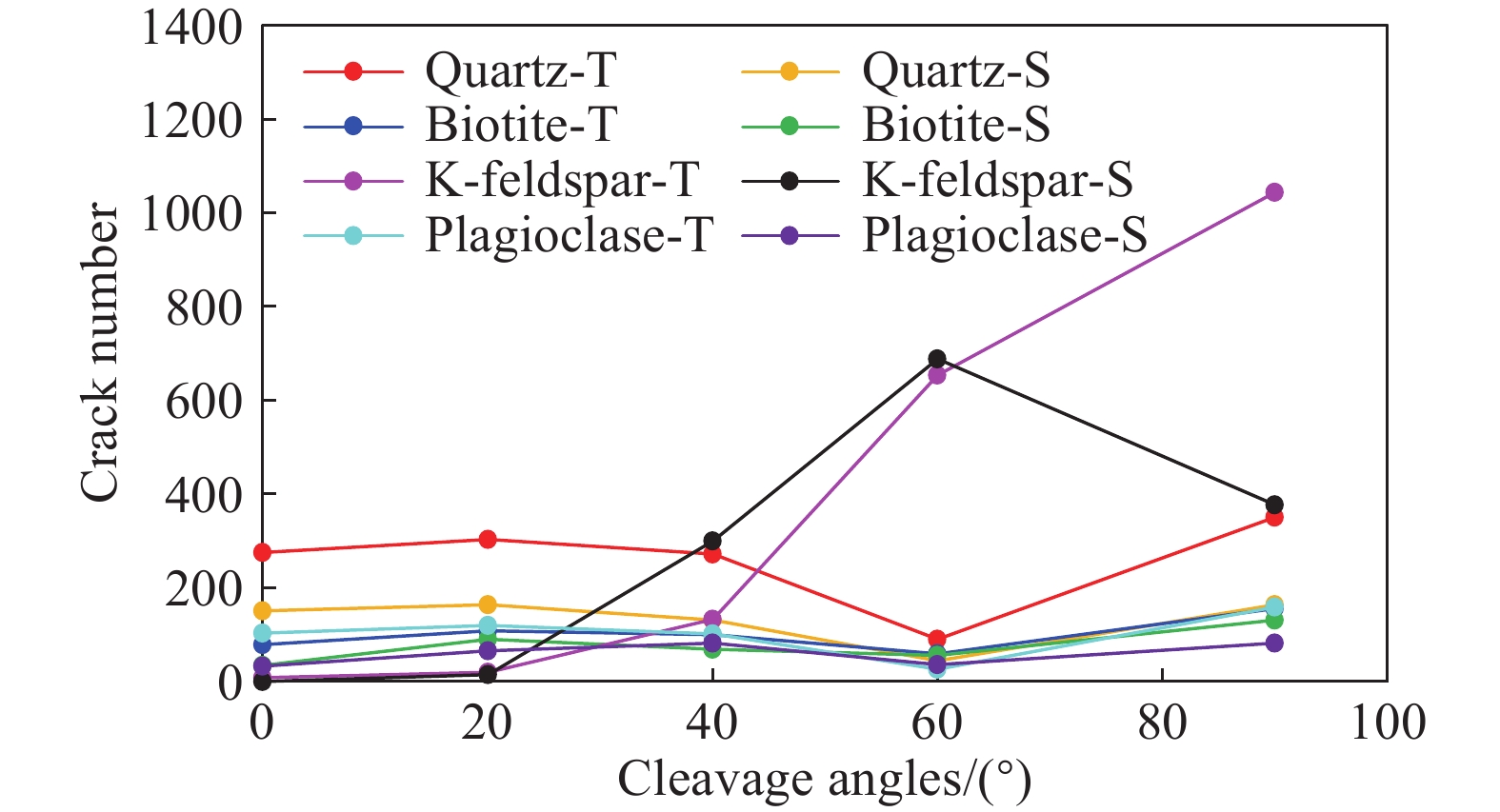

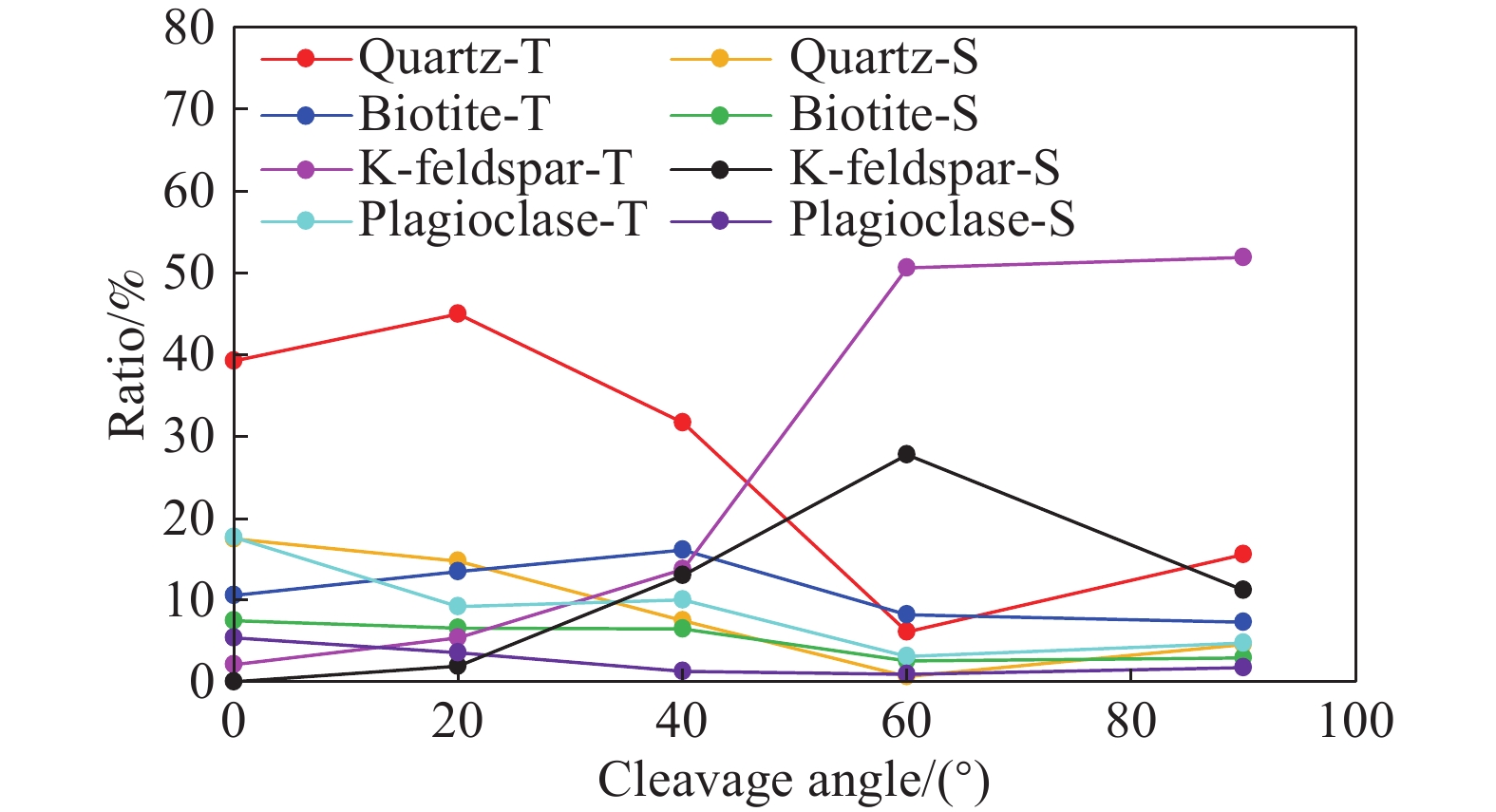

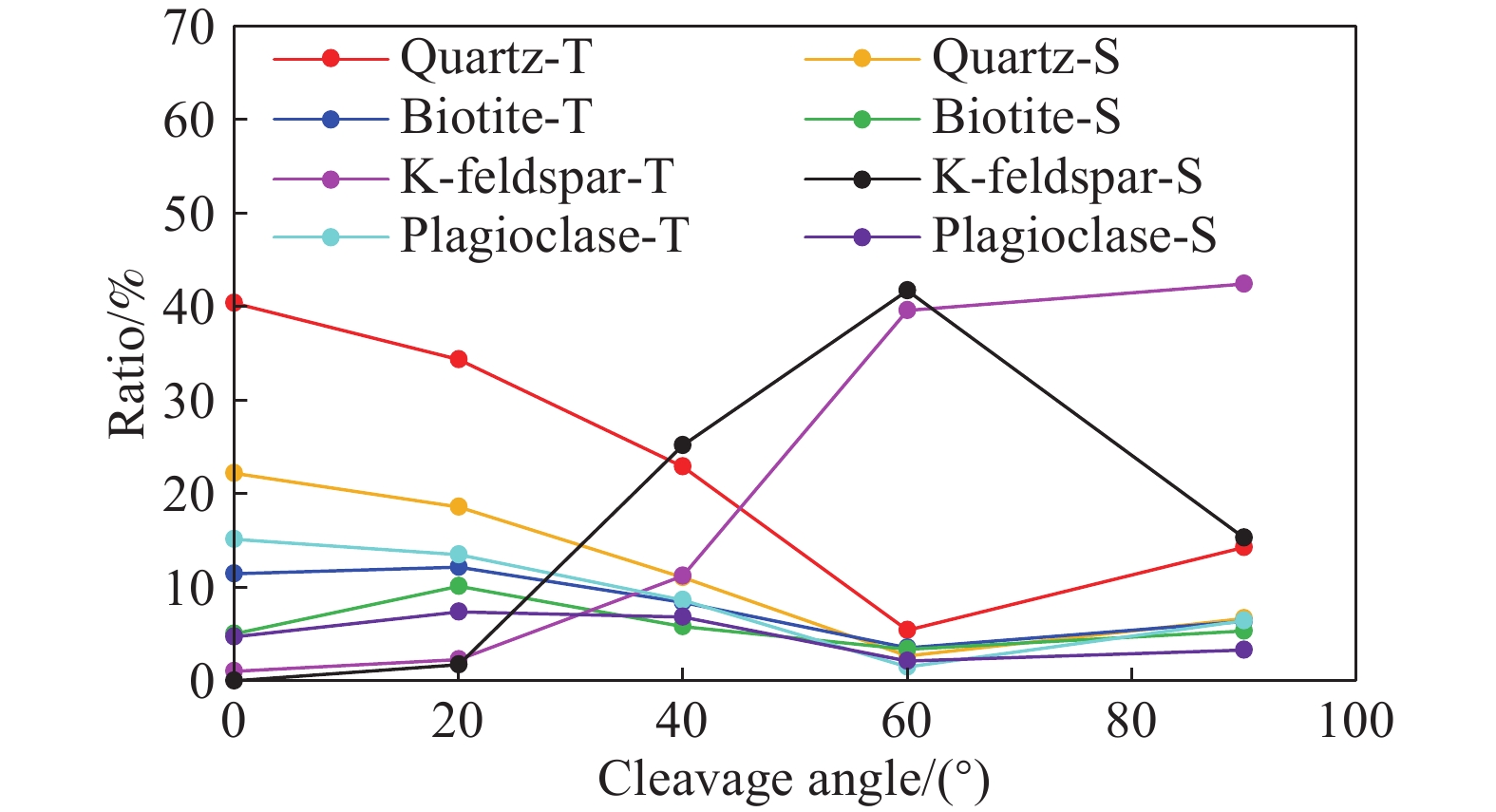

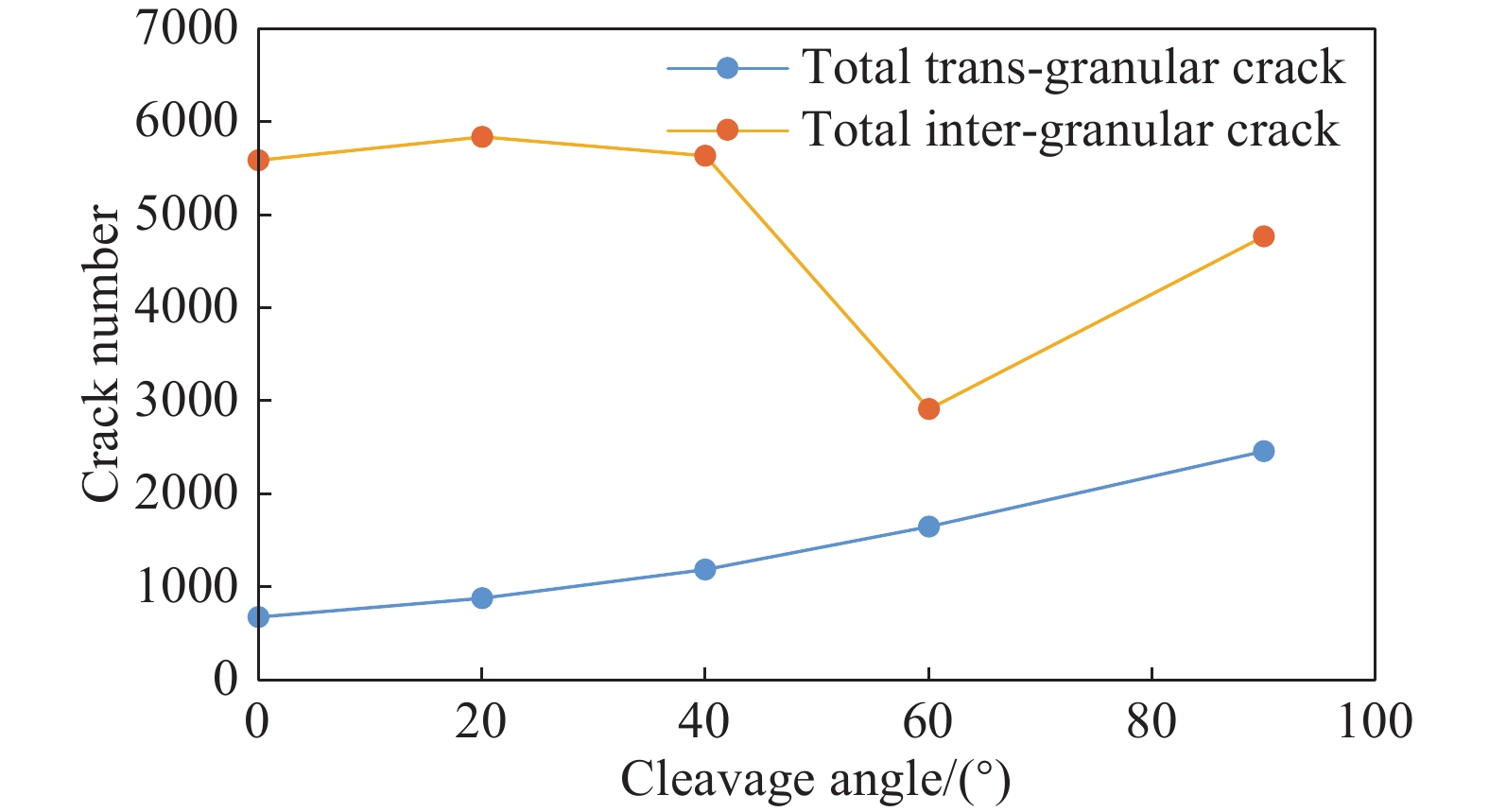

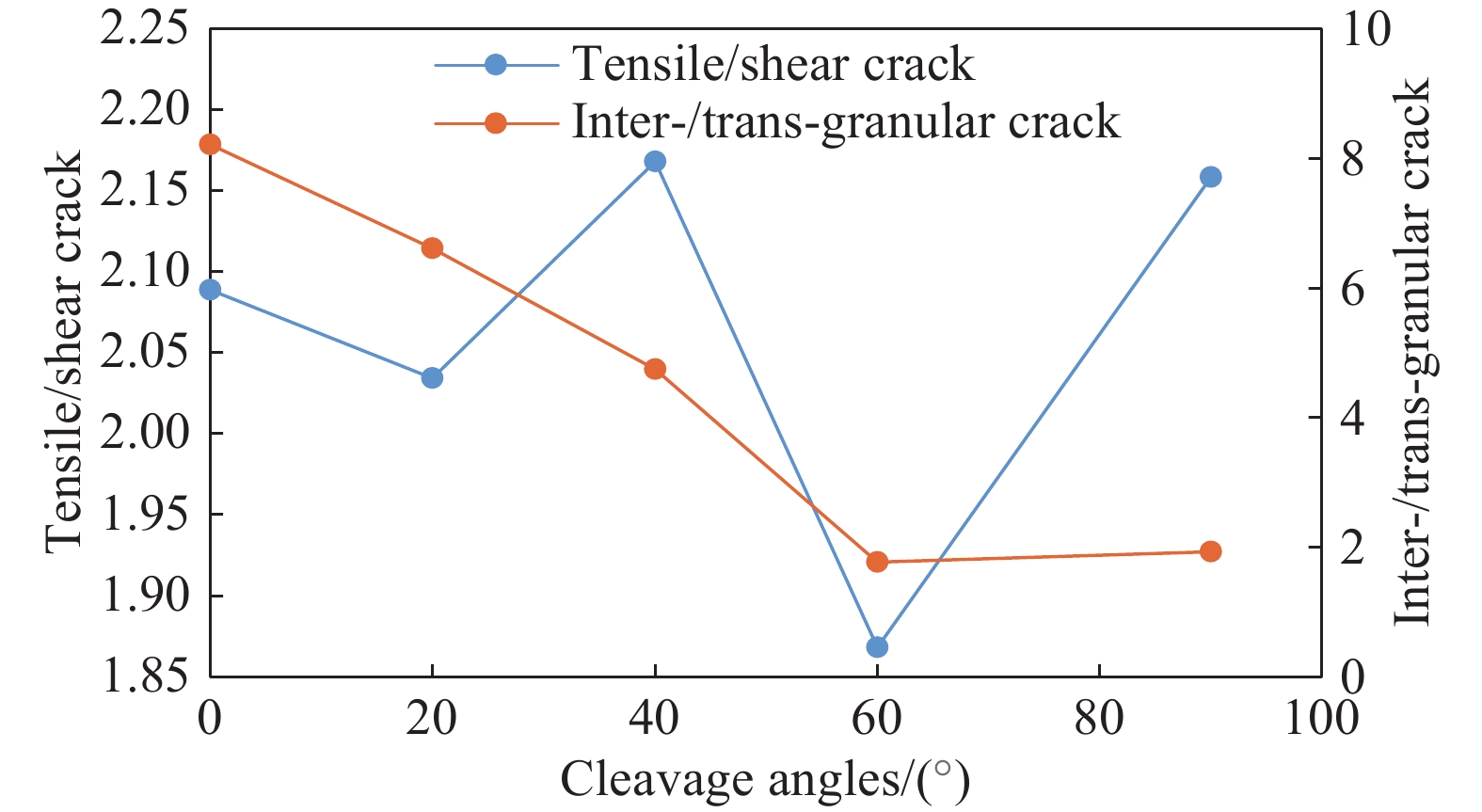

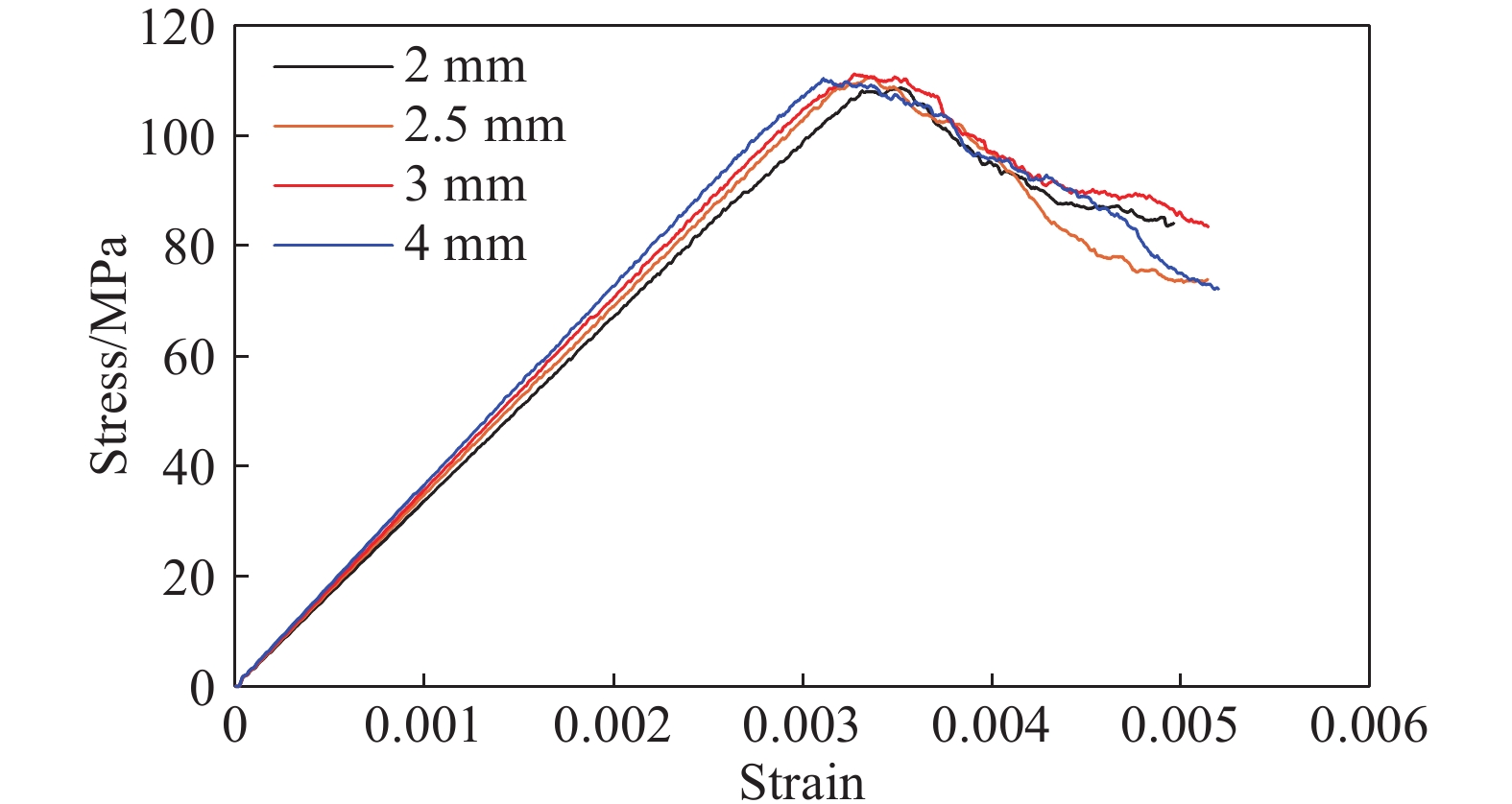

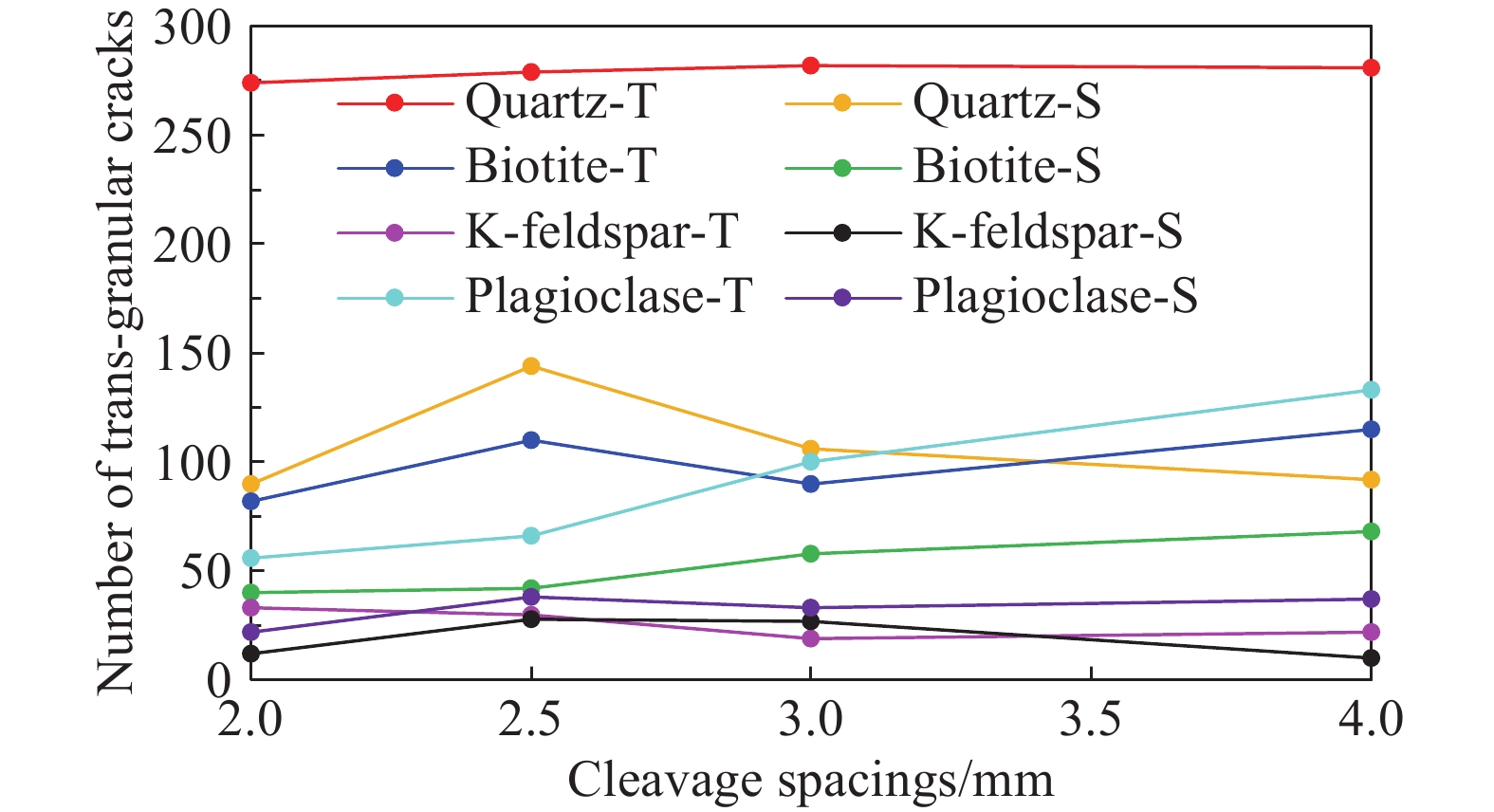

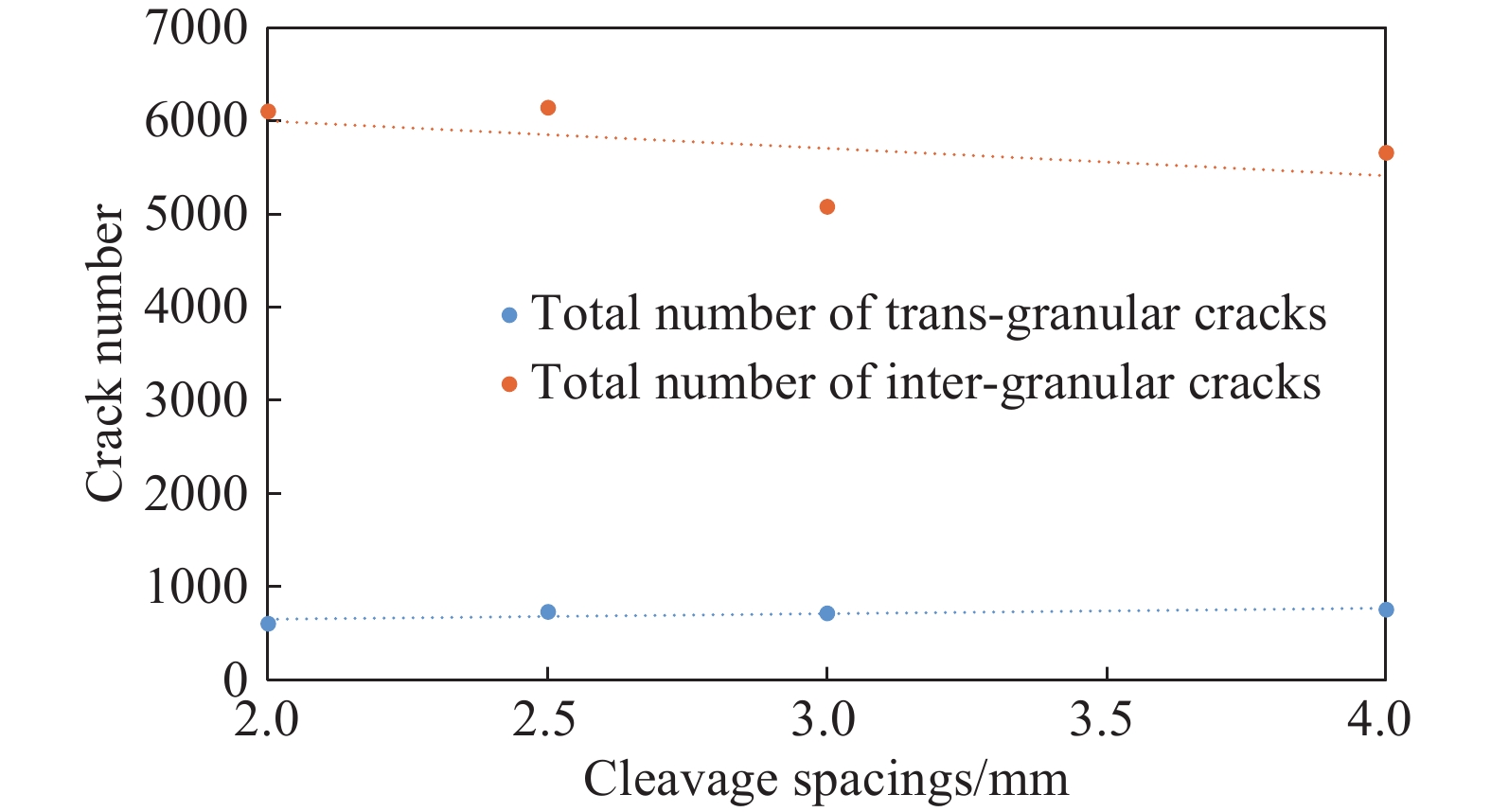

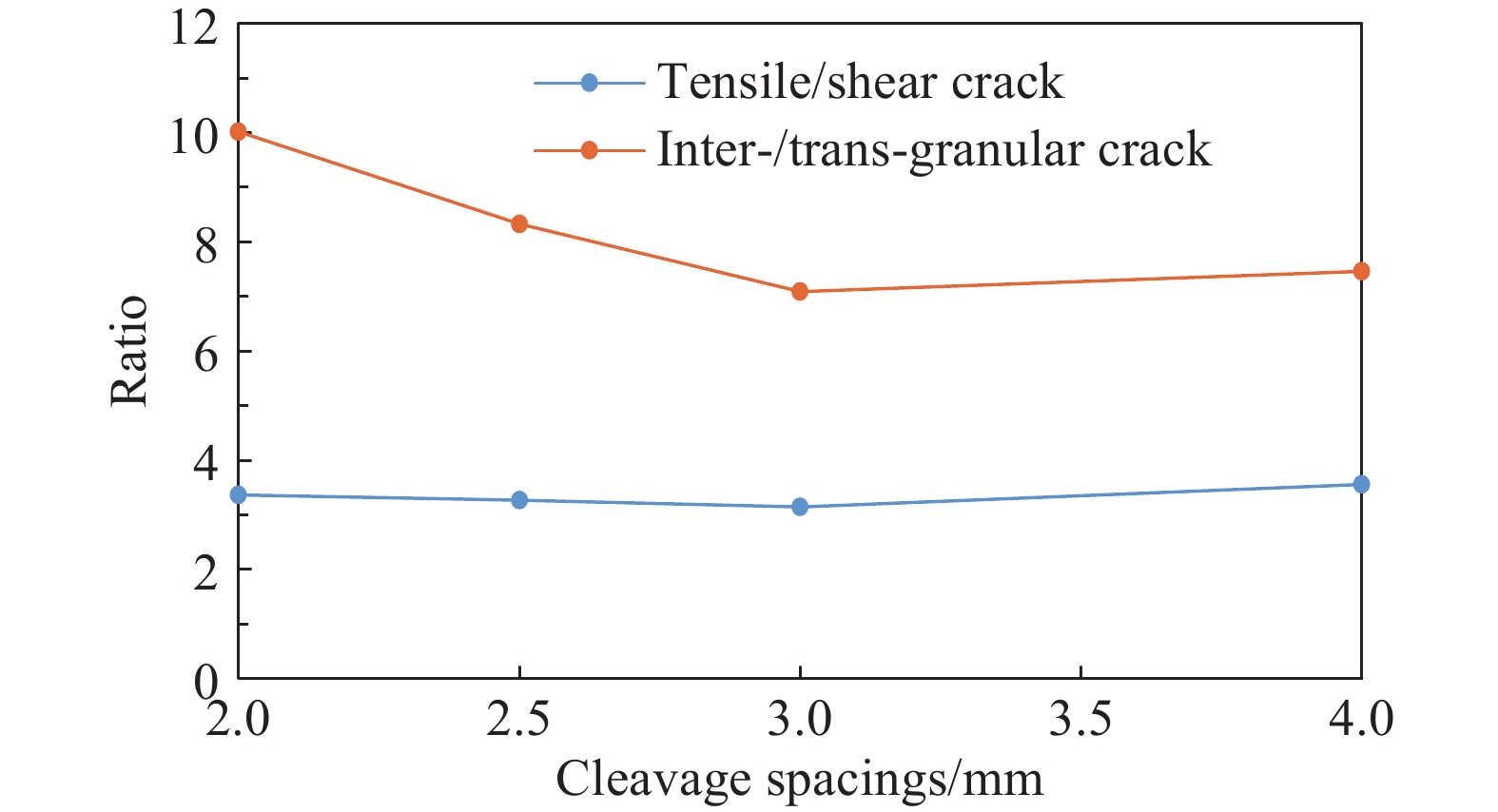

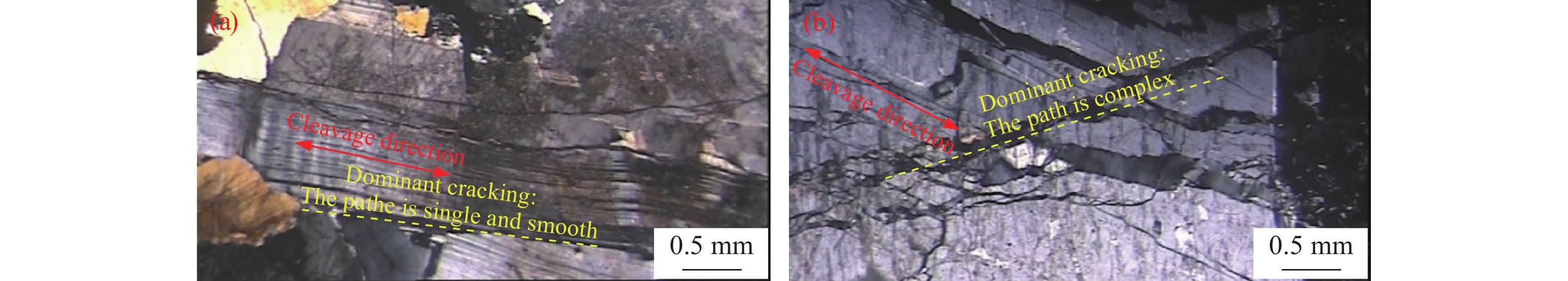

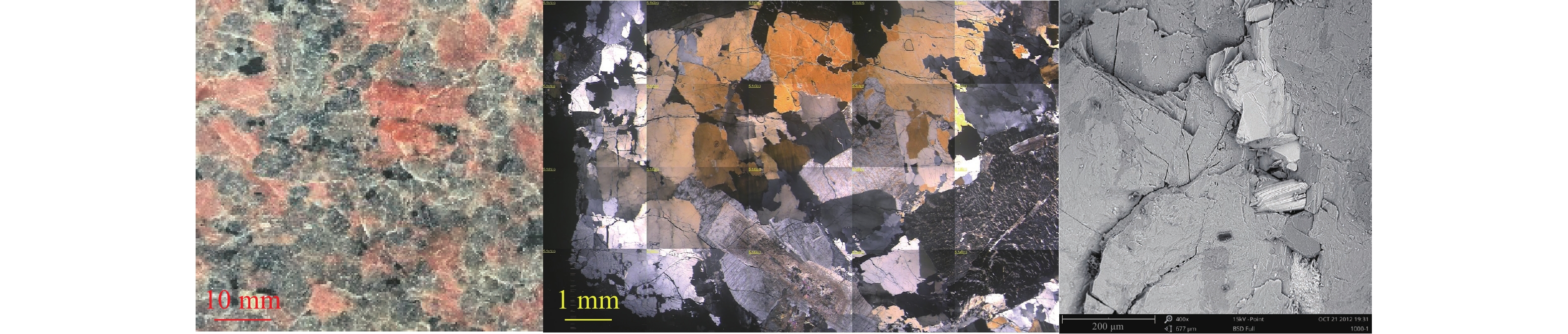

摘要: 基于塊體離散單元數值模擬方法(UDEC-GBM),以鉀長石礦物顆粒為例,詳細研究了礦物晶粒解理傾角、解理傾角圍壓效應及解理間距對硬質巖石力學性質、微觀開裂過程及機理的影響,并探討了解理特征在工程實際中可能帶來的影響。數值研究結果表明:(1)晶粒解理具有明顯傾角效應,當解理傾角由0°增加到90°時,巖石的彈性模量、單軸壓縮強度及峰后脆延特征都會發生變化,穿晶總裂紋數受影響明顯,主要體現在鉀長石張拉穿晶裂紋顯著增加,鉀長石剪切裂紋數量在60°增加到最大值后減少,石英穿晶張拉裂紋數量也有明顯變化,總體而言不斷增加,而沿晶裂紋數量呈減少趨勢,整個開裂過程仍以張拉沿晶主導;(2)晶粒解理傾角效應受圍壓影響,圍壓會導致沿晶裂紋和穿晶裂紋數量和二者比值發生變化,但不同傾角下圍壓對沿晶裂紋和穿晶裂紋數量和比值變化影響不一樣;(3)當解理間距由2 mm增加到4 mm時,穿晶裂紋數量有增加趨勢,而沿晶裂紋數量減少,總剪切和張拉裂紋數量比值不變,對巖石微觀張拉、剪切破壞機制無明顯影響。此外,具有解理結構的礦物晶粒含量較高且礦物晶粒本身性質對巖石性質及響應影響顯著時,解理特征對板裂、巖爆等破壞的影響應給予重視。Abstract: Based on the UDEC (Universal distinct element code) modeling and grain-based model (UDEC-GBM), the effects of mineral’s (e.g., feldspar) cleavage angle, the confining effect of the cleavage angle and cleavage spacing on mechanical properties, microcracking process and mechanism of hard rocks, and the resulting problems in engineering were investigated in the present study. Numerical results show that: (1) Mineral cleavage has a considerable angle effect. As the cleavage angle increases from 0° to 90°, the elastic modulus, uniaxial compressive strength, and post-peak characteristics of the rock are affected. The total number of transgranular cracks is obviously affected, which is mainly reflected by the increase in the number of feldspar tensile cracks and the number of feldspar shear cracks increases to a maximum at 60° and then decreases, and the number of quartz tensile cracks changes considerably. In general, the number of transgranular cracks increases, while the number of intergranular cracks decreases. However, tensile and intergranular cracking dominate the cracking process. (2) The cleavage effect is affected by the confining pressure. The confining pressure will cause the number and proportion of intergranular cracks and transgranular cracks to change. However, the confining pressure at different angles has different effects on the number and proportion of intergranular cracks and transgranular cracks. (3) As the cleavage spacing increases from 2 to 4 mm, the number of transgranular cracks increases and the number of intergranular cracks decreases. However, the ratio of the total shear and tensile cracks remains constant, indicating that microscopic tensile and shear cracking mechanisms are almost unaffected. In addition, when the proportion of minerals with cleavage characteristics is high and the type of mineral has a considerable influence on the rock properties, the influence of cleavage characteristics on rock failures, such as spalling and rockburst, should be given attention.

-

表 1 基本物理與力學參數

Table 1. Basic physical and mechanical parameters

Density/

(kg·m?3)Uniaxial compressive

strength/MPaElastic modulus/

GPaP, wave

velocity/(km·s?1)2687 115 32.2 4.5 表 2 礦物晶粒物理、力學參數

Table 2. Physical and mechanical parameters of grains

Grain type Percentage/% ρ/(g·cm–3) Sh/GPa Bu/GPa υ Q 27 2,650 44.0 37.0 0.08 B 5 2,850 12.4 41.1 0.36 K 58 2,560 27.2 53.7 0.28 P 10 2,630 29.3 50.8 0.26 Note: Q, B, K and P represent quartz, biotite, K-feldspar and plagioclase respectively; υ represents Poisson's ratio; Bu, Sh and ρ represent bulk modulus, shear plane modulus and density respectively. 表 3 加載鋼板參數

Table 3. Properties of the loading platens

Bu/GPa Sh/GPa ρ/(kg·m?3) 15715 11785 7800 表 4 接觸微觀參數

Table 4. Microparameter of contacts

Contact type Microparameter of contacts kn/

(GPa·m–1)ks/

(GPa·m–1)cp/

MPaφp/

(o)$ {\tau _{{\text{max}}}} $/MPa Q-Q 72000 36000 80 35 48 B-B 41740 20870 52 35 35 K-K 52175 26087 70 35 40 P-P 62610 31305 75 35 44 Intergranular contact 34870 17392 50 42 14 Note: Intergranular parameters are uniformly set between grains, and different parameters are set inside grains (such as Q-Q); the residual cohesion, friction angle and tensile strength of intracrystalline and intergranular contact are set to 0. 久色视频表 5 參數校核結果

Table 5. Calibrated results of properties

Item E/GPa UCS/MPa σT σci/UCS σcd/UCS υ UDEC-GBM 33.5 116.5 — 0.36 0.86 0.25 Tests 32.7 115.4 6.7 — — 0.24 Error/% 2.45% 0.95% — — — 4.17% Note: E, UCS σT, σci and σcd represent the elastic modulus, uniaxial compressive strength, crack initiation stress and damage stress of granite specimens respectively. -

參考文獻

[1] Qian Q H. Challenges faced by underground projects construction safety and countermeasures. Chin J Rock Mech Eng, 2012, 31(10): 1945 doi: 10.3969/j.issn.1000-6915.2012.10.001錢七虎. 地下工程建設安全面臨的挑戰與對策. 巖石力學與工程學報, 2012, 31(10):1945 doi: 10.3969/j.issn.1000-6915.2012.10.001 [2] Cai M, Kaiser P K, Tasaka Y, et al. Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int J Rock Mech Min Sci, 2004, 41(5): 833 doi: 10.1016/j.ijrmms.2004.02.001 [3] Martin C D, Christiansson R, S?derh?ll J. Rock Stability Considerations for Siting and Constructing a KBS-3 Repository: Based on Experiences from Aespoe HRL, AECL's URL, Tunnelling and Mining. Stockholm: Swedish Nuclear Fuel and Waste Management Co., 2001 [4] Martin C D, Chandler N A. The progressive fracture of Lac du Bonnet granite. Int J Rock Mech Min Sci Geomech Abstr, 1994, 31(6): 643 doi: 10.1016/0148-9062(94)90005-1 [5] Feng X T, Chen B R, Zhang C Q, et al. Mechanism, Warning and Dynamic Control of Rockburst Development Processes. Beijing: Science Press, 2013馮夏庭, 陳炳瑞, 張傳慶, 等. 巖爆孕育過程的機制、預警與動態調控. 北京: 科學出版社, 2013 [6] Diederichs M S, Kaiser P K, Eberhardt E. Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int J Rock Mech Min Sci, 2004, 41(5): 785 doi: 10.1016/j.ijrmms.2004.02.003 [7] Potyondy D. A grain-based model for rock: approaching the true microstructure // Proceedings of Rock Mechanics in the Nordic Countries. Kongsberg, 2010: 9 [8] Jiang M J, Bai R P, Liu J D, et al. Experimental study of inter-granular particles bonding behaviors for rock microstructure. Chin J Rock Mech Eng, 2013, 32(6): 1121 doi: 10.3969/j.issn.1000-6915.2013.06.005蔣明鏡, 白閏平, 劉靜德, 等. 巖石微觀顆粒接觸特性的試驗研究. 巖石力學與工程學報, 2013, 32(6):1121 doi: 10.3969/j.issn.1000-6915.2013.06.005 [9] Peng J, Wong L N Y, Teh C I. Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks. J Geophys Res Solid Earth, 2017, 122(2): 1054 doi: 10.1002/2016JB013469 [10] Gao F Q, Stead D. The application of a modified Voronoi logic to brittle fracture modelling at the laboratory and field scale. Int J Rock Mech Min Sci, 2014, 68: 1 doi: 10.1016/j.ijrmms.2014.02.003 [11] He J. Clastic Rock Flake Identification Guide. Beijing: Petroleum Industry Press, 2019賀靜. 碎屑巖薄片鑒定指南. 北京: 石油工業出版社, 2019 [12] Lim S S, Martin C D, ?kesson U. In-situ stress and microcracking in granite cores with depth. Eng Geol, 2012, 147-148: 1 doi: 10.1016/j.enggeo.2012.07.006 [13] Wang X, Cai M. A comprehensive parametric study of grain-based models for rock failure process simulation. Int J Rock Mech Min Sci, 2019, 115: 60 doi: 10.1016/j.ijrmms.2019.01.008 [14] Haimson B, Chang C. A new true triaxial cell for testing mechanical properties of rock, and its use to determine rock strength and deformability of Westerly granite. Int J Rock Mech Min Sci, 2000, 37(1-2): 285 doi: 10.1016/S1365-1609(99)00106-9 [15] Tao M, Wang J, Li Z W, et al. Meso-and micro-experimental research on the fracture of granite spallation under impact loads. Chin J Rock Mech Eng, 2019, 38(11): 2172陶明, 汪軍, 李占文, 等. 沖擊荷載下花崗巖層裂斷口細–微觀試驗研究. 巖石力學與工程學報, 2019, 38(11):2172 [16] Abdelaziz A, Zhao Q, Grasselli G. Grain based modelling of rocks using the combined finite-discrete element method. Comput Geotech, 2018, 103: 73 doi: 10.1016/j.compgeo.2018.07.003 [17] Itasca Consulting Group Inc. UDEC (niversal Distinct Element Code). Version 6.0. Mineapolis, Itasca, 2014 [18] Wang X, Cai M. Modeling of brittle rock failure considering inter- and intra-grain contact failures. Comput Geotech, 2018, 101: 224 doi: 10.1016/j.compgeo.2018.04.016 [19] Gao F Q, Stead D, Elmo D. Numerical simulation of microstructure of brittle rock using a grain-breakable distinct element grain-based model. Comput Geotech, 2016, 78: 203 doi: 10.1016/j.compgeo.2016.05.019 [20] Cho N, Martin C D, Sego D C. A clumped particle model for rock. Int J Rock Mech Min Sci, 2007, 44(7): 997 doi: 10.1016/j.ijrmms.2007.02.002 [21] Yoon J. Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int J Rock Mech Min Sci, 2007, 44(6): 871 doi: 10.1016/j.ijrmms.2007.01.004 [22] Liang Z Z, Tang C A, Li H X, et al. A numerical study on failure process of transversely isotropic rock subjected to uniaxial compression. Rock Soil Mech, 2005, 26(1): 57 doi: 10.3969/j.issn.1000-7598.2005.01.012梁正召, 唐春安, 李厚祥, 等. 單軸壓縮下橫觀各向同性巖石破裂過程的數值模擬. 巖土力學, 2005, 26(1):57 doi: 10.3969/j.issn.1000-7598.2005.01.012 [23] Gong F Q, Luo Y, Li X B, et al. Experimental simulation investigation on rockburst induced by spalling failure in deep circular tunnels. Tunn Undergr Space Technol, 2018, 81: 413 doi: 10.1016/j.tust.2018.07.035 [24] Duan K, Kwok C Y, Ma X. DEM simulations of sandstone under true triaxial compressive tests. Acta Geotech, 2017, 12(3): 495 doi: 10.1007/s11440-016-0480-6 [25] Chen W Z, Lu S P, Guo X H, et al. Research on unloading confining pressure tests and rockburst criterion based on energy theory. Chin J Rock Mech Eng, 2009, 28(8): 1530 doi: 10.3321/j.issn:1000-6915.2009.08.003陳衛忠, 呂森鵬, 郭小紅, 等. 基于能量原理的卸圍壓試驗與巖爆判據研究. 巖石力學與工程學報, 2009, 28(8):1530 doi: 10.3321/j.issn:1000-6915.2009.08.003 [26] Hu X C, Su G S, Chen G Y, et al. Experimental study on slabbing process of hard rock in deep tunnels. Chin J Geotech Eng, 2020, 42(12): 2271胡小川, 蘇國韶, 陳冠言, 等. 深埋隧洞硬巖板裂化過程試驗研究. 巖土工程學報, 2020, 42(12):2271 -

下載:

下載: