Reasonable coal pillar setting and roadway surrounding rock control technology in close-distance coal seam working face

-

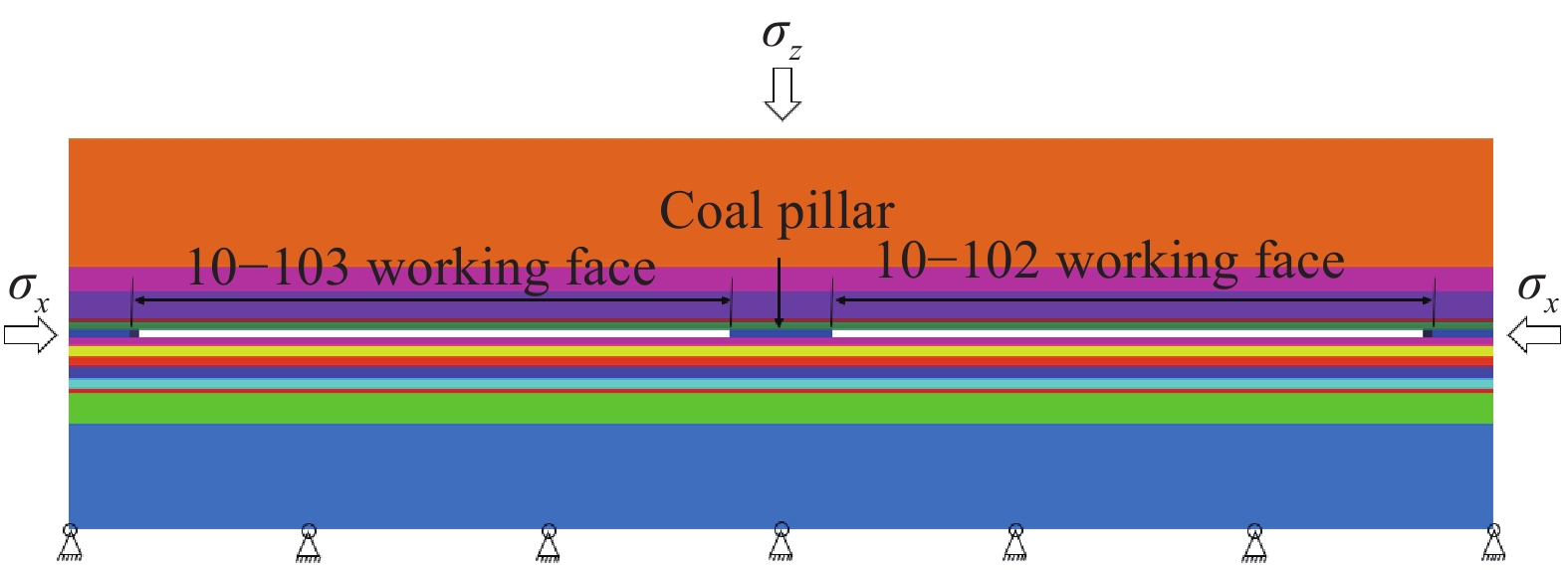

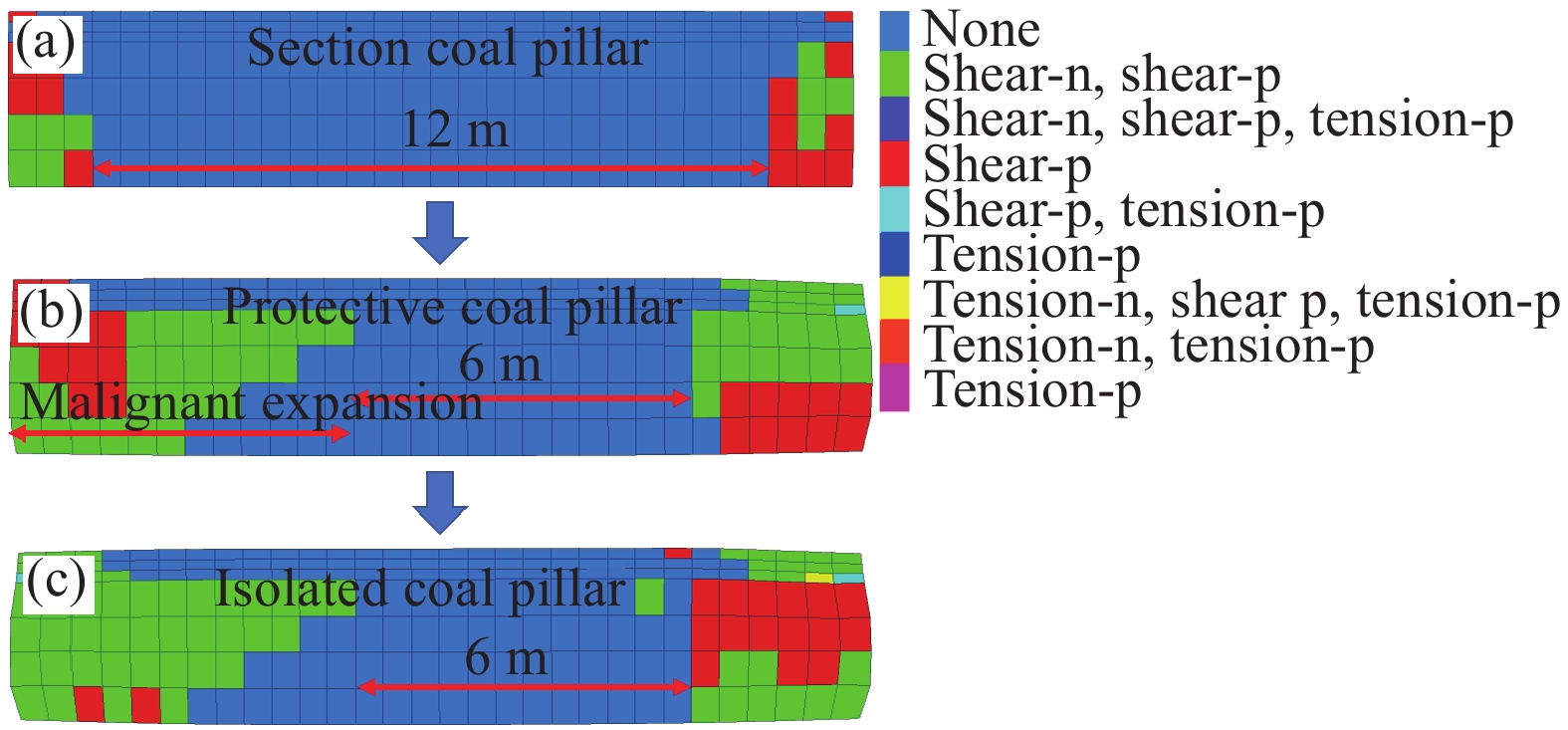

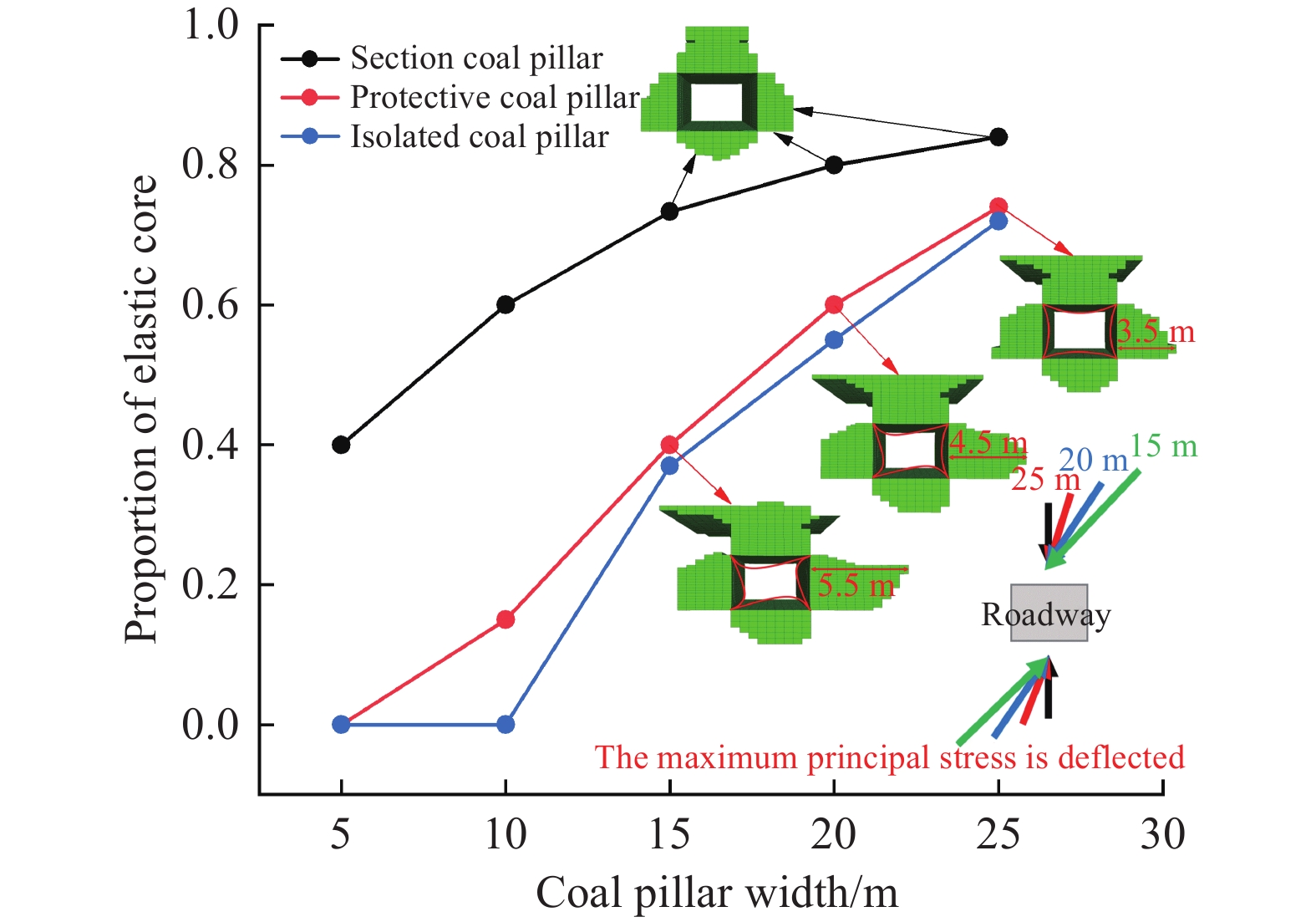

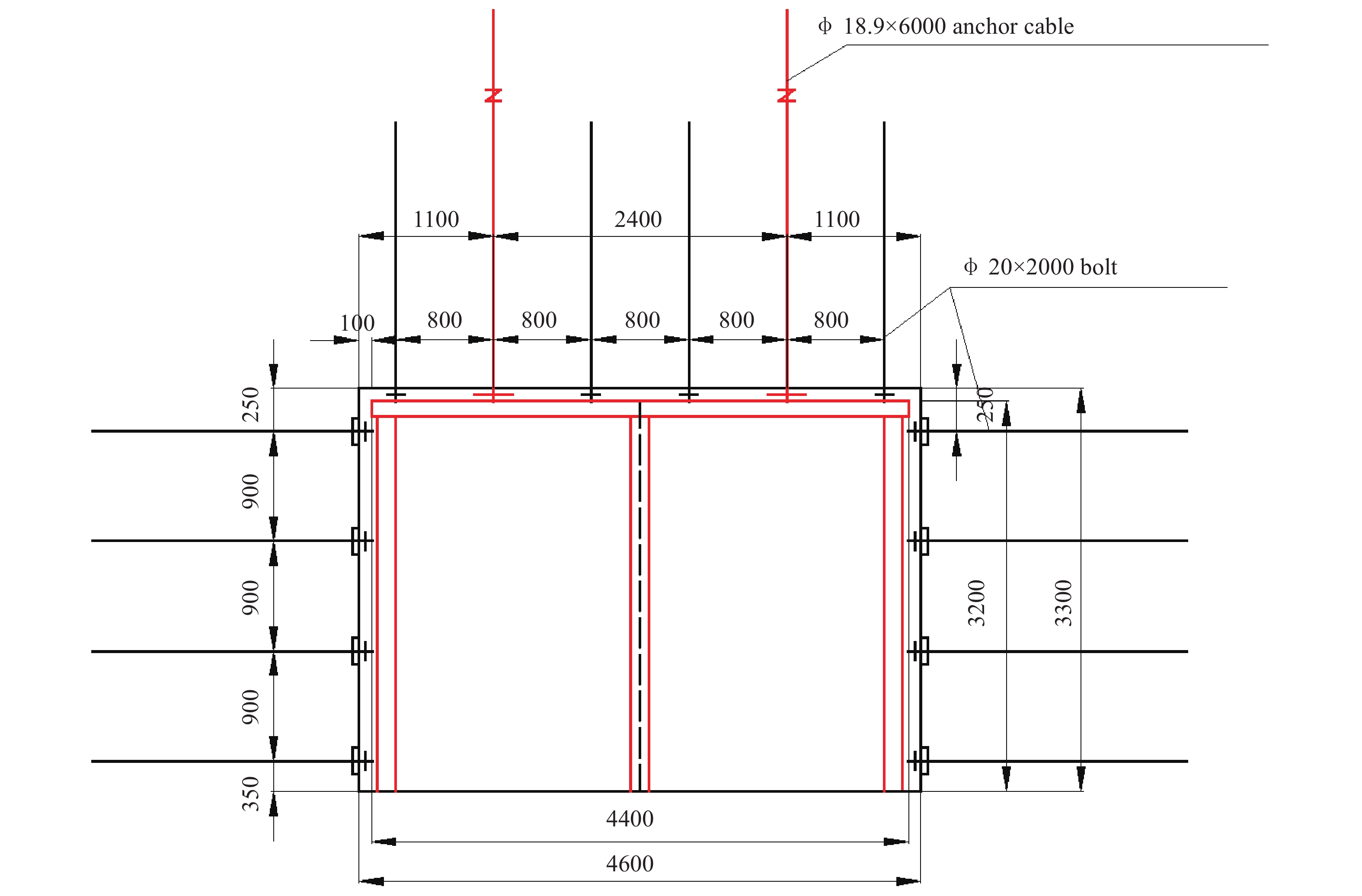

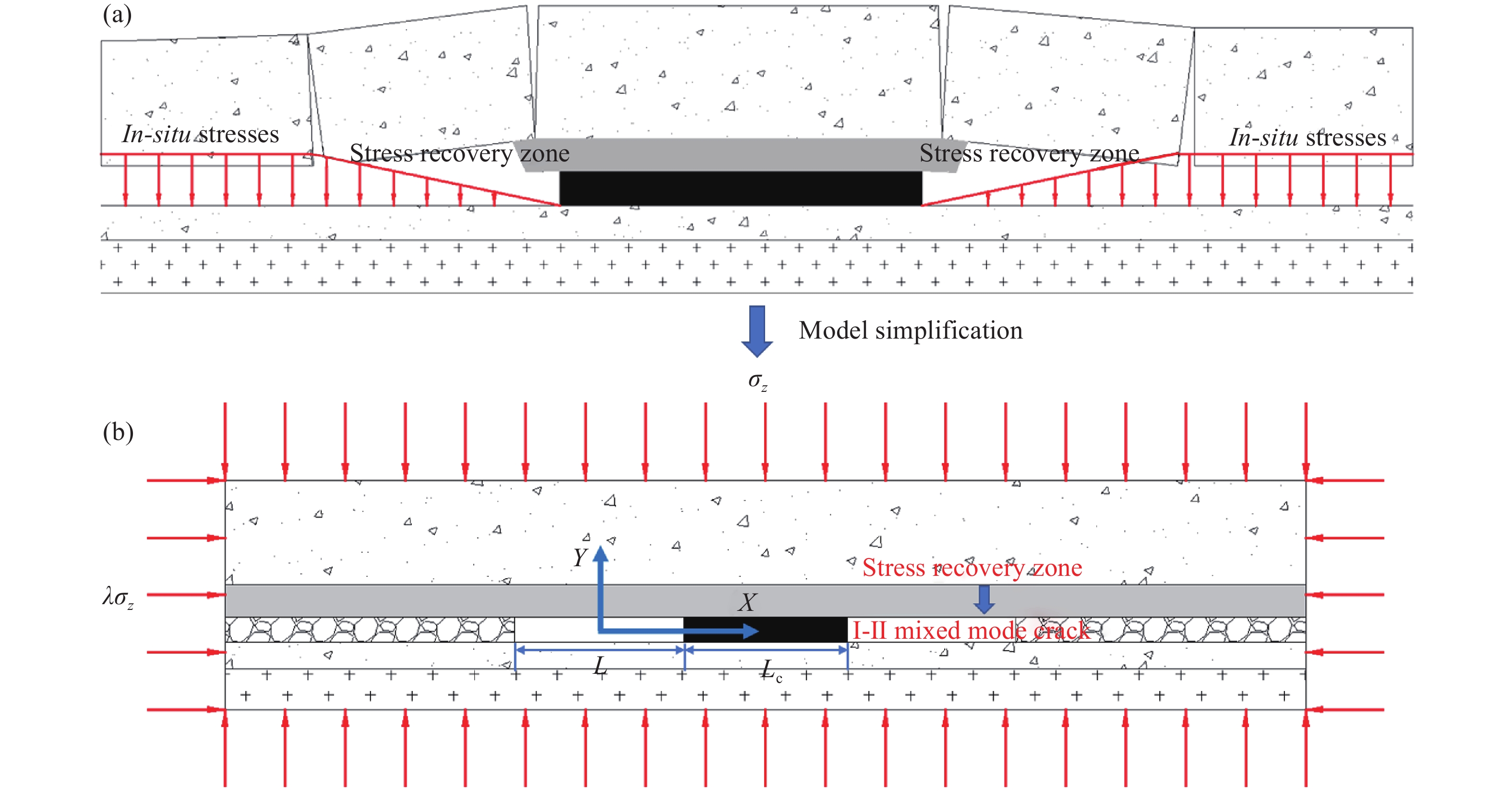

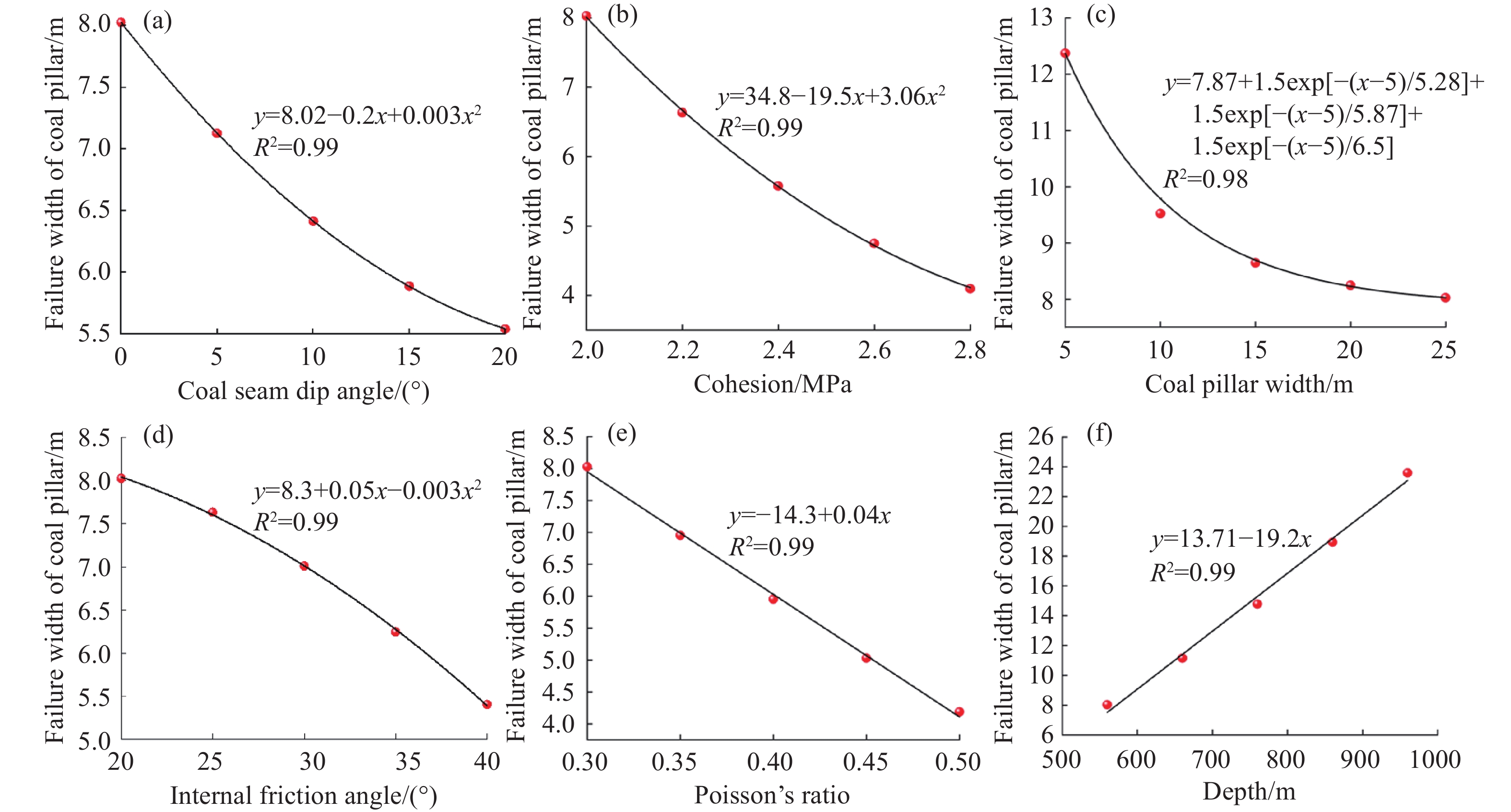

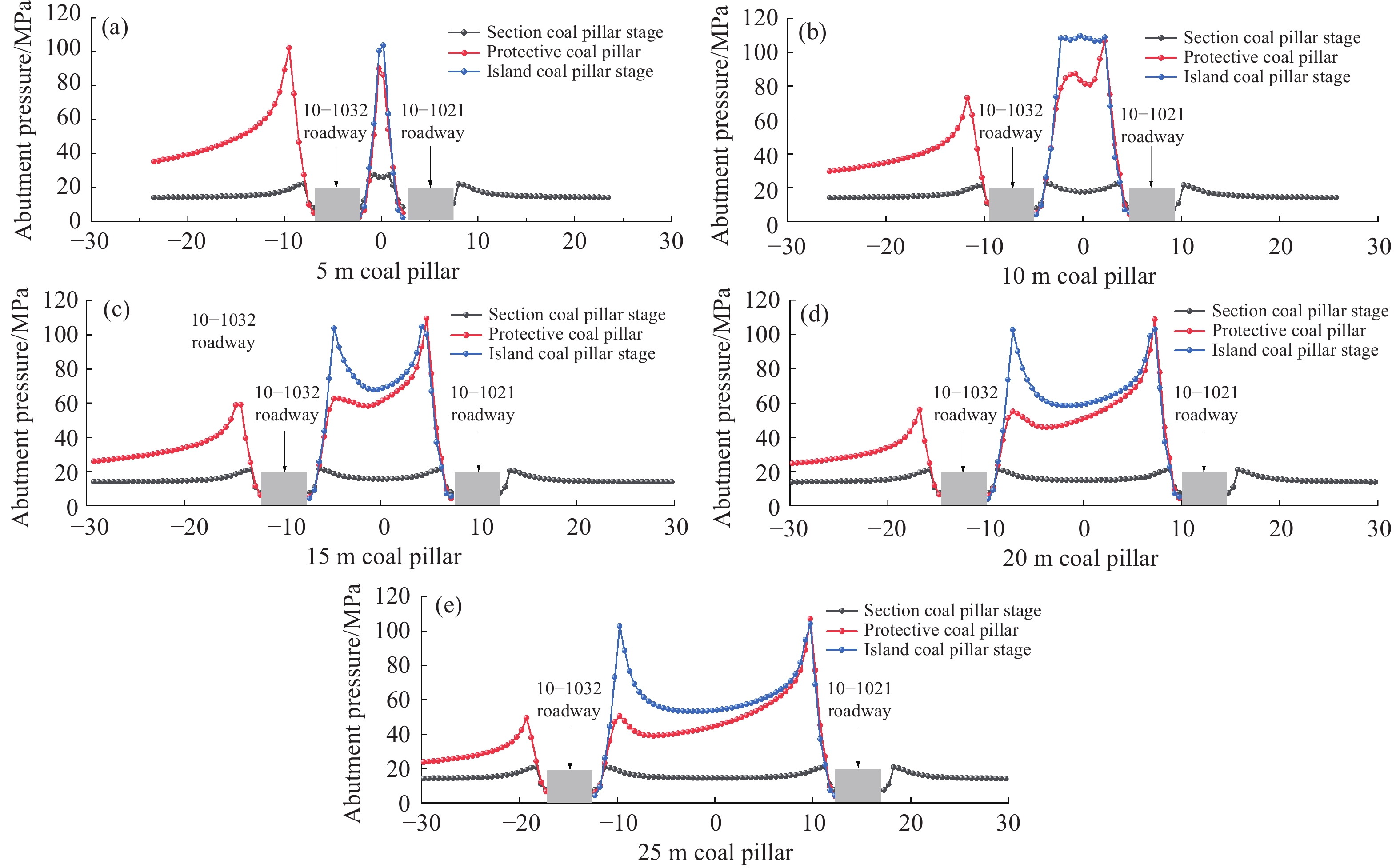

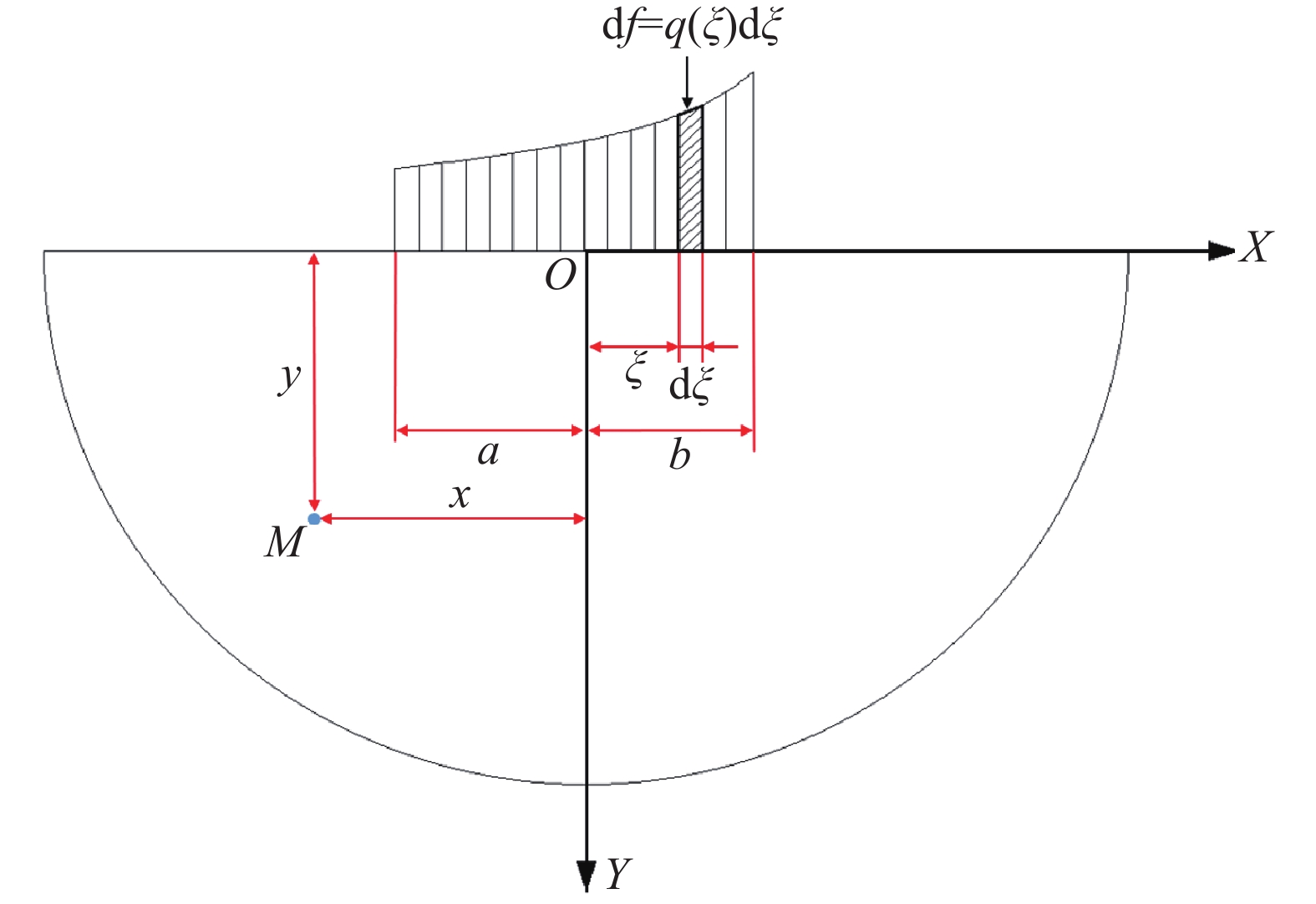

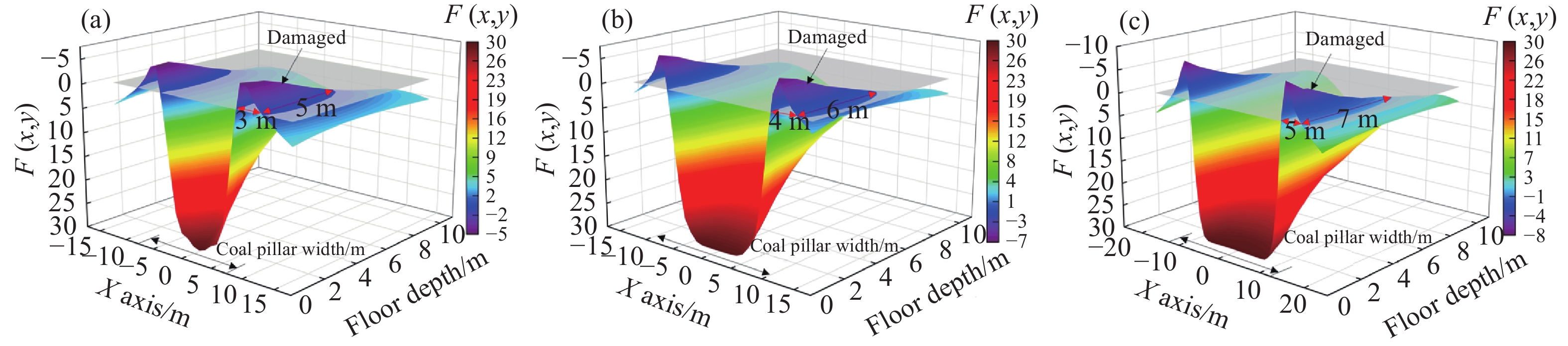

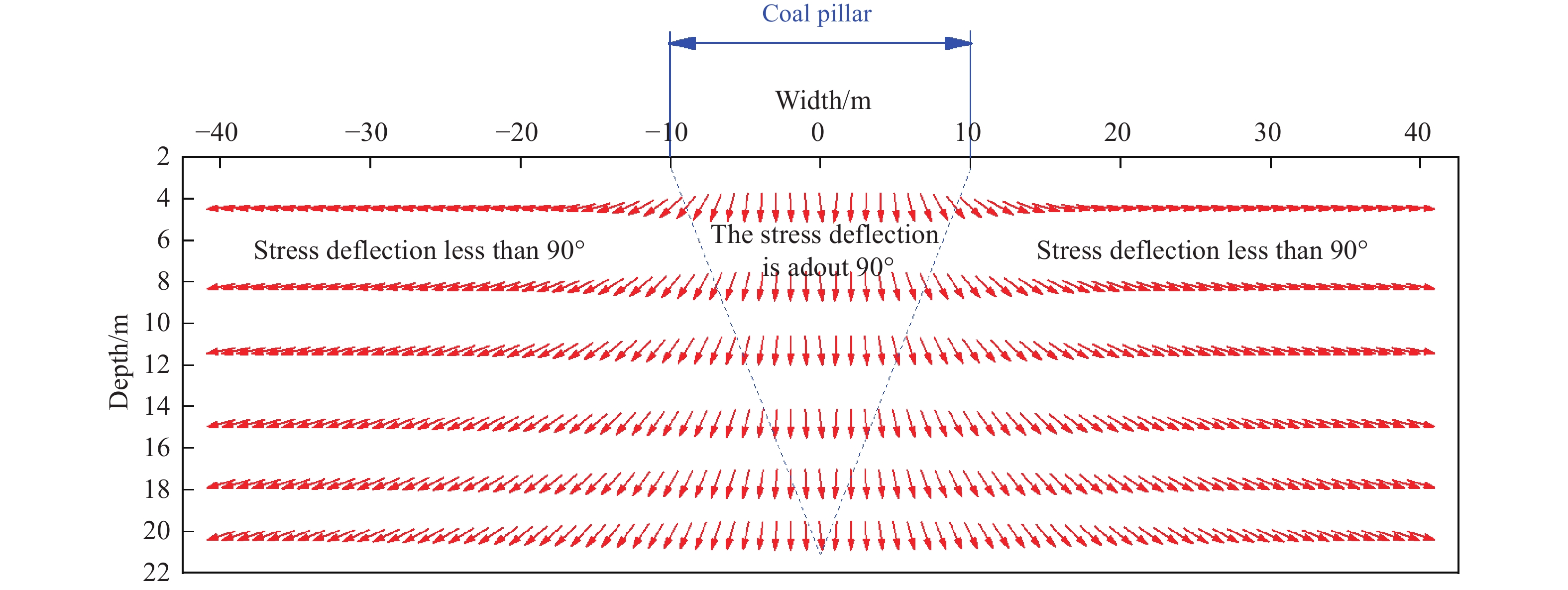

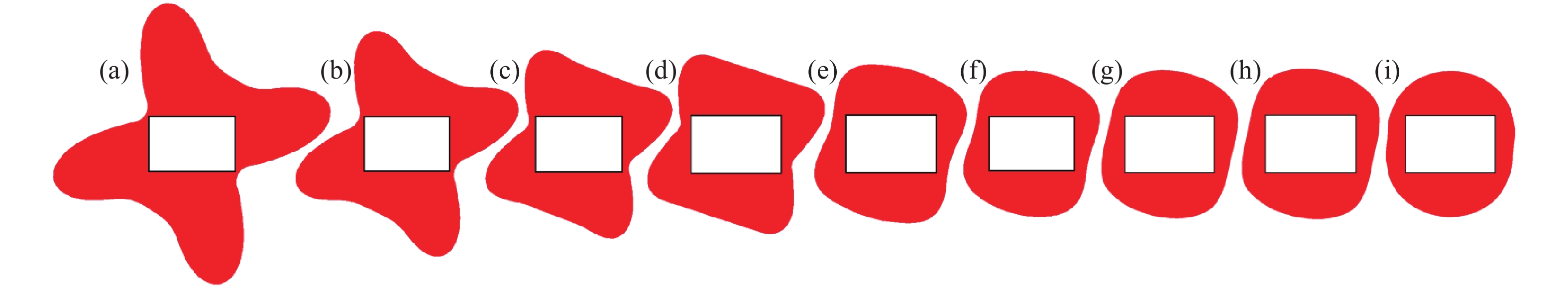

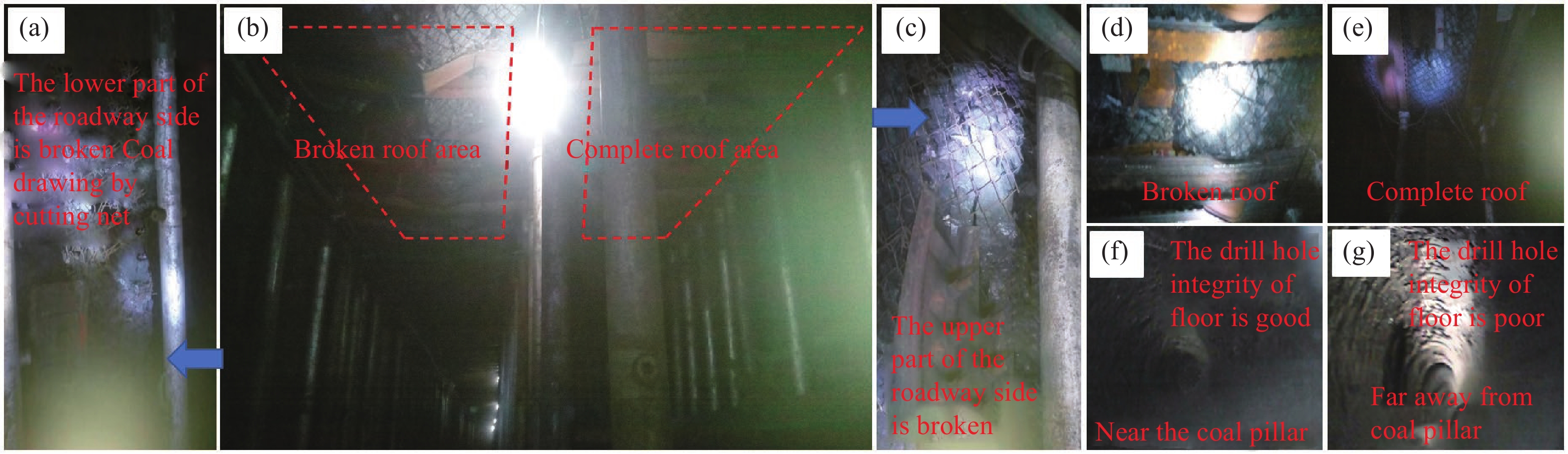

摘要: 為探究近距離煤層工作面煤柱合理留設寬度以及回采巷道圍巖控制技術,以回坡底煤礦近距離煤層開采為工程背景,通過數值模擬、理論分析、現場實踐等技術手段對不同寬度條件下煤柱破壞演化過程、影響因素、底板破壞范圍以及11號煤層回采巷道圍巖控制技術進行了深入研究。研究結果表明:(1)煤柱在預留煤柱時期、區段煤柱時期、保護煤柱時期、孤島煤柱時期四個階段過程中,煤柱破壞范圍逐漸增大;煤柱彈性核占比均隨煤柱寬度的增加而增加,本煤層回采巷道隨煤柱寬度的增加從非對稱性破壞逐漸演化為對稱性破壞。煤柱破壞寬度與煤層傾角、黏聚力、煤柱寬度、內摩擦角和泊松比等因素成反比關系,只與埋深成正比關系。(2)隨著煤柱寬度增大,煤柱底板破壞寬度與深度會發生變化,且底板破壞集中在煤柱邊緣側,煤柱正下方底板破壞區域較小。(3)煤柱應力集中作用致底板下方最大主應力發生偏轉,底板任意一點與煤柱中心線的距離越大,最大主應力偏轉角度越小;隨著11號煤層巷道與煤柱邊緣距離的增大,巷道圍巖塑性區由傾斜的“X”形分布轉變為傾斜的“8”形分布,再轉化為傾斜的“O”形分布,最終轉化為橢圓形分布;離煤柱距離較近時,巷道往往出現非對稱性破壞,支護也要采取非對稱支護形式。Abstract: To explore the reasonable width of the coal pillar and surrounding rock control technology of the mining roadway in a close-distance coal seam working face, this paper took the mining of No.10 and No.11 coal seams of the Huipodi coal mine as the engineering background. Through numerical simulation, theoretical analysis, field practice, and other technical means, the evolution of the coal pillar failure, influencing factors, and damage range of floor under different widths were analyzed. The surrounding rock control technology of the mining roadway was studied in depth. Results show that: (1) During the four stages of reserved, section, protective, and isolated coal pillars, the damage scope of the coal pillar gradually increased. The proportion of the elastic core of the coal pillar increased with the increase of the coal pillar width. The mining roadway in this coal seam evolves from asymmetric failure to symmetrical failure. The failure width of the coal pillar is directly proportional to the buried depth and inversely proportional to the coal seam dip angle, cohesion, coal pillar width, internal friction angle, and Poisson’s ratio. (2) With the increase in coal pillar width, the width and depth of the coal pillar floor failure will change. Moreover, the floor failure concentrated on the side of the coal pillar edge, and the damaged floor area under the coal pillar is observed to be small. (3) The maximum principal stress under the floor deflects owing to the concentrated stress of the coal pillar. The larger is the distance between any point of the floor and the centerline of the coal pillar, the smaller is the deflection angle of the maximum principal stress. With the increase in the distance between the roadway and coal pillar edge, the plastic zone of the roadway surrounding rock initially changes from an inclined X-shaped distribution to an inclined 8-shaped distribution, which then changes to an inclined O-shaped distribution and finally to an elliptical distribution. When the distance from the coal pillar is close, the roadway often shows an asymmetric failure, and the support should also take the form of asymmetric support.

-

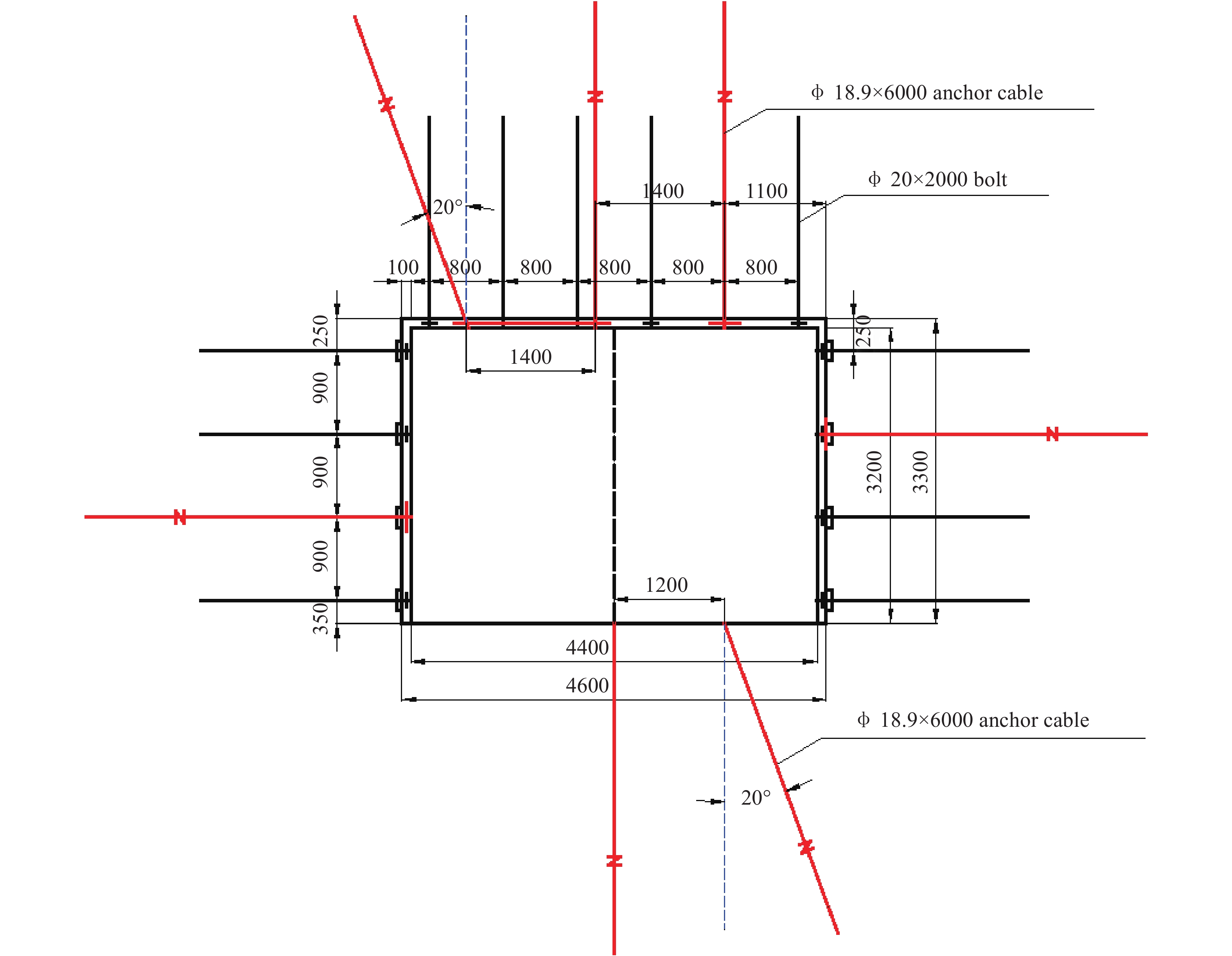

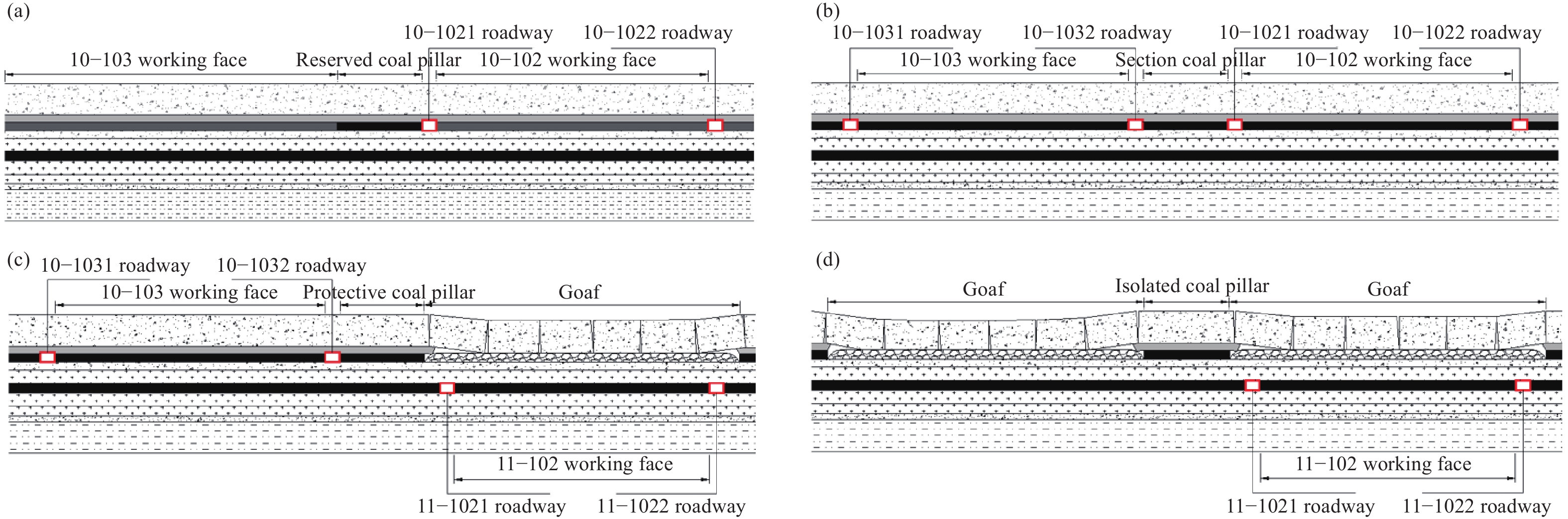

圖 1 巷道開挖、工作面回采與煤柱演化過程. (a)預留煤柱時期; (b)區段煤柱時期; (c)保護煤柱時期; (d)孤島煤柱時期

Figure 1. Roadway excavation, working face mining, and coal pillar evolution process: (a) period of the reserved coal pillar; (b) period of the section coal pillar; (c) period of the protection coal pillar; (d) period of the isolated coal pillar

圖 12 距煤柱邊緣不同距離下巷道圍巖塑性區分布形態. (a)4 m; (b)6 m; (c)8 m; (d)10 m; (e)12 m; (f)14 m; (g)16 m; (h)18 m; (i)30 m

Figure 12. Plastic zone distribution of the roadway surrounding rock in different distances from the coal pillar edge: (a) 4 m; (b) 6 m; (c) 8 m; (d) 10 m; (e) 12 m; (f) 14 m; (g) 16 m; (h) 18 m; (i) 30 m

圖 13 11-1021巷圍巖破壞情況. (a)靠近煤柱側巷幫; (b)巷道頂板; (c)遠離煤柱側巷幫; (d)靠近煤柱側頂板; (e)遠離煤柱側頂板; (f)靠近煤柱側底板鉆孔; (g)遠離煤柱側底板鉆孔

Figure 13. Surrounding rock failure of 11-1021 roadway: (a) roadway side near the coal pillar; (b) roadway roof; (c) roadway side far away from coal pillar; (d) roof near the coal pillar side; (e) roof far away from the coal pillar; (f) floor drilling hole near the coal pillar side; (g) floor drilling hole away from pillar side

久色视频表 1 巖層物理力學參數

Table 1. Rock’s physical and mechanical parameters

Rock stratum Thickness /m Density/

(kg·m?3)Bulk/

GPaShear/

GPaCohesion/

MPaCohesion /MPa Angle of internal friction /(°) Overlying strata 46 2460 10.83 8.13 7.8 5.4 38 Siltstone 8 2680 5.6 4.2 5.2 1.4 29 K2 limestone 8.9 2800 5.57 4.53 5.4 3.8 27 No.9 coal 1 1400 2.08 0.54 1.2 0.64 20 Mudstone 2.3 2600 2.91 1.5 2 2.1 32 No.10 coal 2.65 1420 2.50 1.72 2 1 21 Siltstone 2.82 2680 5.6 4.2 5.1 1.4 29 Mudstone 3.8 2461 6.08 3.47 3 0.6 28 No.11 coal 3.2 1423 2.50 1.72 2.4 1.2 29 Aluminous mudstone 0.8 2100 2.6 1.8 2.65 2 25 Mudstone 3 2461 6.08 3.47 3 0.6 28 Siltstone 2.53 2680 5.6 4.2 5.1 1.4 29 Aluminous mudstone 3 2981 2.17 1 2.4 0.9 25 Quartz sandstone 2 2650 3.05 1.92 4.3 1.6 27 Siltstone 10 2680 5.57 4.2 5.1 1.4 29 Overlying strata 35 2680 5.6 4.18 5.2 1.5 30 -

參考文獻

[1] Yu Y, Shen W L, Gao J. Deformation mechanism and control of lower seam roadway of contiguous seams. J Min Saf Eng, 2016, 33(1): 49于洋, 神文龍, 高杰. 極近距離煤層下位巷道變形機理及控制. 采礦與安全工程學報, 2016, 33(1):49 [2] Hao D Y, Wu Y Z, Chen H J, et al. Instability mechanism and prevention technology of roadway in close distance and extra thick coal seam under goaf. J China Coal Soc, 2019, 44(9): 2682郝登云, 吳擁政, 陳海俊, 等. 采空區下近距離特厚煤層回采巷道失穩機理及其控制. 煤炭學報, 2019, 44(9):2682 [3] Cao S G, Zou D J, Bai Y J, et al. Surrounding rock control of mining roadway in the thin coal seam group with short distance and “three soft”. J Min Saf Eng, 2011, 28(4): 524 doi: 10.3969/j.issn.1673-3363.2011.04.005曹樹剛, 鄒德均, 白燕杰, 等. 近距離“三軟”薄煤層群回采巷道圍巖控制. 采礦與安全工程學報, 2011, 28(4):524 doi: 10.3969/j.issn.1673-3363.2011.04.005 [4] Zheng B S, Xie W B, Dou L M, et al. A surrounding rock controlling technique of roadway affected by dynamic stress in “islet face” of adjacent coal seam. J China Univ Min Technol, 2006, 35(4): 483 doi: 10.3321/j.issn:1000-1964.2006.04.012鄭百生, 謝文兵, 竇林名, 等. 近距離孤島工作面動壓影響巷道圍巖控制. 中國礦業大學學報, 2006, 35(4):483 doi: 10.3321/j.issn:1000-1964.2006.04.012 [5] Peng G Y, Gao M Z, Lü Y C, et al. Investigation on mining mechanics behavior of deep close distance seam group. J China Coal Soc, 2019, 44(7): 1971彭高友, 高明忠, 呂有廠, 等. 深部近距離煤層群采動力學行為探索. 煤炭學報, 2019, 44(7):1971 [6] Wang L F, Chang Z C, Yang Z B, et al. Combined support technology of roadway under mined gob of ultra-distance seams in deep mine. J Min Saf Eng, 2018, 35(4): 686王龍飛, 常澤超, 楊戰標, 等. 深井近距離煤層群采空區下回采巷道聯合支護技術. 采礦與安全工程學報, 2018, 35(4):686 [7] Fang X Q, Guo M J, Lu Z Q. Instability mechanism and prevention of roadway under close-distance seam group mining. Chin J Rock Mech Eng, 2009, 28(10): 2059 doi: 10.3321/j.issn:1000-6915.2009.10.013方新秋, 郭敏江, 呂志強. 近距離煤層群回采巷道失穩機制及其防治. 巖石力學與工程學報, 2009, 28(10):2059 doi: 10.3321/j.issn:1000-6915.2009.10.013 [8] Lu Y, Gao J, Liu C Y, et al. Study on the optimal layout of roadways of contiguous seams by simultaneous mining. J Min Saf Eng, 2012, 29(6): 797魯巖, 高杰, 劉長友, 等. 近距煤層同采巷道優化布置研究. 采礦與安全工程學報, 2012, 29(6):797 [9] Ma Z Q, Jiang Y D, Yang Y M, et al. Floor roadway stability in repeated mining of close distance coal seams in Luling coal mine. Chin J Rock Mech Eng, 2015, 34(Suppl 1): 3320馬振乾, 姜耀東, 楊英明, 等. 蘆嶺礦近距離煤層重復開采下底板巷道穩定性研究. 巖石力學與工程學報, 2015, 34(增刊1): 3320 [10] Wang R, Yan S, Bai J B, et al. Theoretical analysis of the destabilization mechanism and the damaged width of rib pillar in open-pit highwall mining. Rock Soil Mech, 2019, 40(8): 3167王瑞, 閆帥, 柏建彪, 等. 端幫開采下煤柱破壞寬度計算及失穩機制研究. 巖土力學, 2019, 40(8):3167 [11] Xu Z L. A Concise Course in Elasticity. 4th Ed. Beijing: Higher Education Press, 2013徐芝綸. 彈性力學簡明教程. 4版. 北京: 高等教育出版社, 2013 [12] Meng X R, Xu C H, Gao Z N, et al. Stress distribution and damage mechanism of mining floor. J China Coal Soc, 2010, 35(11): 1832孟祥瑞, 徐鋮輝, 高召寧, 等. 采場底板應力分布及破壞機理. 煤炭學報, 2010, 35(11):1832 [13] Zhu S Y, Jiang Z Q, Yao P, et al. Application of analytic method in calculating floor stress of a working face. J Min Saf Eng, 2007, 24(2): 191 doi: 10.3969/j.issn.1673-3363.2007.02.015朱術云, 姜振泉, 姚普, 等. 采場底板巖層應力的解析法計算及應用. 采礦與安全工程學報, 2007, 24(2):191 doi: 10.3969/j.issn.1673-3363.2007.02.015 [14] Lu H F, Yao D X. Stress distribution and failure depths of layered rock mass of mining floor. Chin J Rock Mech Eng, 2014, 33(10): 2030魯海峰, 姚多喜. 采動底板層狀巖體應力分布規律及破壞深度研究. 巖石力學與工程學報, 2014, 33(10):2030 [15] Lu H F, Yao D X, Liang X Y, et al. Analytical solution of stress in a transversely isotropic floor rock mass under mining. Chin J Undergr Space Eng, 2013, 9(5): 1050魯海峰, 姚多喜, 梁修雨, 等. 采動底板橫觀各向同性巖體應力解析解. 地下空間與工程學報, 2013, 9(5):1050 [16] Song W C, Liang Z Z, Liu W T, et al. Theoretical analysis and experimental investigation on failure characteristics and stability of stope floors. Chin J Rock Mech Eng, 2019, 38(11): 2208宋文成, 梁正召, 劉偉韜, 等. 采場底板破壞特征及穩定性理論分析與試驗研究. 巖石力學與工程學報, 2019, 38(11):2208 [17] Zhang H L, Wang L G. Computation of mining induced floor additional stress and its application. J Min Saf Eng, 2011, 28(2): 288 doi: 10.3969/j.issn.1673-3363.2011.02.023張華磊, 王連國. 采動底板附加應力計算及其應用研究. 采礦與安全工程學報, 2011, 28(2):288 doi: 10.3969/j.issn.1673-3363.2011.02.023 [18] Peng W H, Dong Z Z, Li S C. Boundary integral formula of semi-plane elasticity problem and its application. J China Univ Min Technol, 2005, 34(3): 400 doi: 10.3321/j.issn:1000-1964.2005.03.028彭維紅, 董正筑, 李順才. 半平面體彈性問題的邊界積分公式及應用. 中國礦業大學學報, 2005, 34(3):400 doi: 10.3321/j.issn:1000-1964.2005.03.028 [19] Wang M, Niu Y H, Yu Y J, et al. Experimental research on characteristics of deformation and failure of surrounding rock of roadway in deep mine under influence of principal stress evolution. Chin J Geotech Eng, 2016, 38(2): 237 doi: 10.11779/CJGE201602006王猛, 牛譽賀, 于永江, 等. 主應力演化影響下的深部巷道圍巖變形破壞特征試驗研究. 巖土工程學報, 2016, 38(2):237 doi: 10.11779/CJGE201602006 [20] Yin G Z, Lu J, Li X, et al. Stability and plastic zone characteristics of surrounding rock under true triaxial stress conditions. J China Coal Soc, 2018, 43(10): 2709尹光志, 魯俊, 李星, 等. 真三軸應力條件下鉆孔圍巖穩定性及塑性區特性. 煤炭學報, 2018, 43(10):2709 [21] Yin G Z, Lu J, Zhang D M, et al. Study on plastic zone and permeability-increasing radius of borehole surrounding rock under true triaxial stress conditions. Rock Soil Mech, 2019, 40(Suppl 1): 1尹光志, 魯俊, 張東明, 等. 真三軸應力條件下鉆孔圍巖塑性區及增透半徑研究. 巖土力學, 2019, 40(增刊1): 1 [22] Zhao H B, Cheng H, Li J Y, et al. Study on asymmetric deformation mechanism of surrounding rock of roadway under the effect of isolated coal pillar. Chin J Rock Mech Eng, 2020, 39(Suppl 1): 2771趙洪寶, 程輝, 李金雨, 等. 孤島煤柱影響下巷道圍巖非對稱性變形機制研究. 巖石力學與工程學報, 2020, 39(增刊1): 2771 [23] Zhang G, Wu J G, Yang L J. Determination of the sealing length of upward long crossing boreholes for gas drainage under unequal stress fields. Chin J Rock Mech Eng, 2018, 37(Suppl 1): 3422章光, 吳金剛, 楊龍杰. 非等壓應力場上向長距離穿層瓦斯抽采鉆孔密封長度研究. 巖石力學與工程學報, 2018, 37(增刊1): 3422 [24] Wang W J, Dong E Y, Yuan C. Boundary equation of plastic zone of circular roadway in non-axisymmetric stress and its application. J China Coal Soc, 2019, 44(1): 105王衛軍, 董恩遠, 袁超. 非等壓圓形巷道圍巖塑性區邊界方程及應用. 煤炭學報, 2019, 44(1):105 [25] Liu L Y, Ji H G, Wang T, et al. Mechanism of country rock damage and failure in deep shaft excavation under high pore pressure and asymmetric geostress. Chin J Eng, 2020, 42(6): 715劉力源, 紀洪廣, 王濤, 等. 高滲透壓和不對稱圍壓作用下深豎井圍巖損傷破裂機理. 工程科學學報, 2020, 42(6):715 [26] Ma N J, Guo X F, Zhao Z Q, et al. Occurrence mechanisms and judging criterion on circular tunnel butterfly rock burst in homogeneous medium. J China Coal Soc, 2016, 41(11): 2679馬念杰, 郭曉菲, 趙志強, 等. 均質圓形巷道蝶型沖擊地壓發生機理及其判定準則. 煤炭學報, 2016, 41(11):2679 [27] Zhao H B, Cheng H, Ji D L, et al. Study of the mechanism and evolution law of unsymmetrical failure of the mining roadway in close distance coal seam. Chin J Geotech Eng, 2021, 50(6): 1029趙洪寶, 程輝, 吉東亮, 等. 近距離煤層回采巷道非對稱性破壞機理與演化規律研究. 中國礦業大學學報, 2021, 50(6):1029 [28] Zhao H B, Cheng H, Wang L, et al. Distribution characteristics of deviatoric stress field and failure law of roadway surrounding rock under non-hydrostatic pressure. J China Coal Soc, 2021, 46(2): 370趙洪寶, 程輝, 王磊, 等. 非靜水壓力條件下巷道圍巖偏應力場分布特征與圍巖破壞規律. 煤炭學報, 2021, 46(2):370 -

下載:

下載: