Research progress in the preparation and application of graphene-based superhydrophobic materials

-

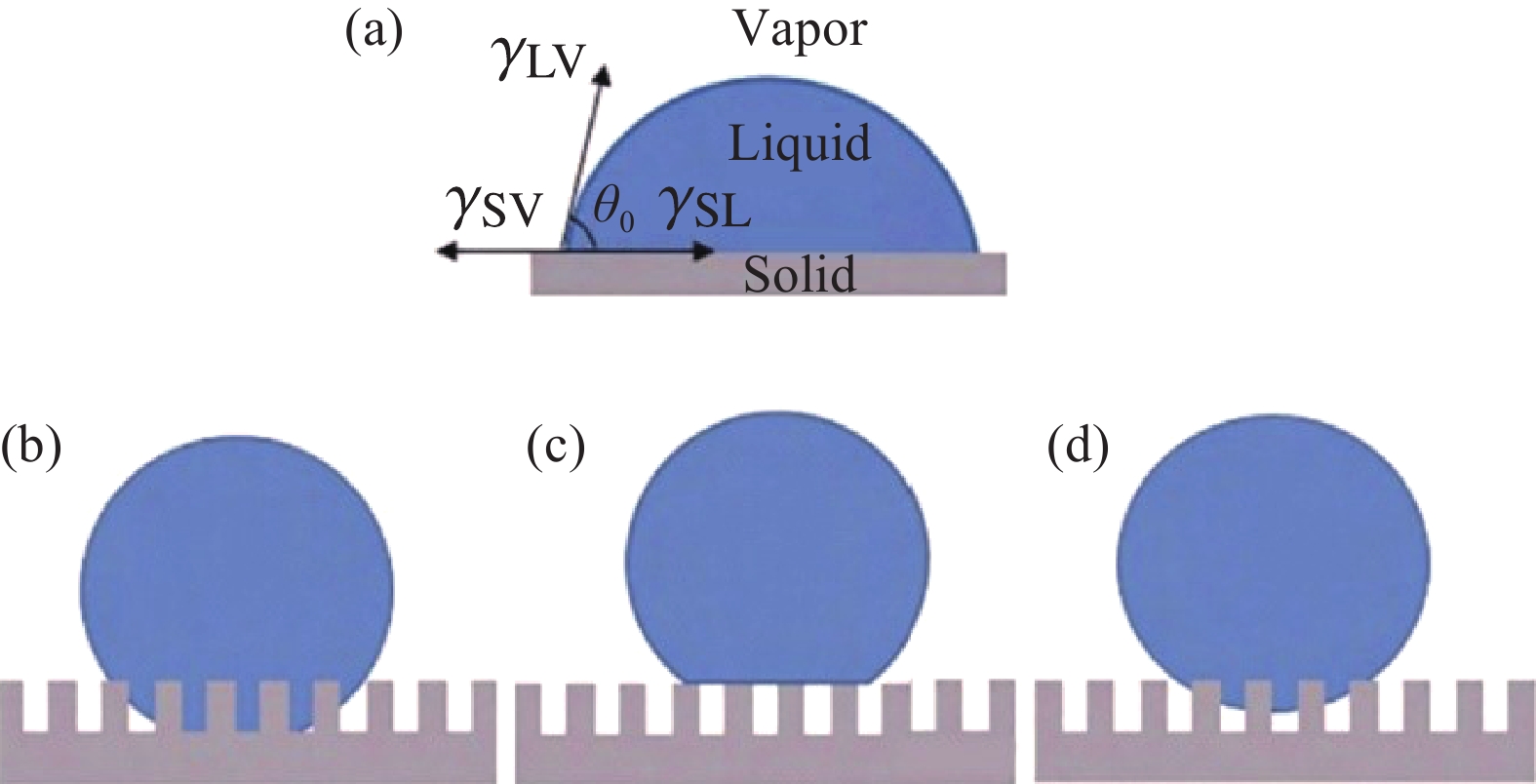

摘要: 超疏水表面是具有獨特性能的一類表面,本身就具有廣泛應用前景。石墨烯材料作為理化性質出眾的一類材料,由于其高電導率、高導熱系數、高比表面積、高透光率和有優異的機械性能,廣泛應用于航空航天、石油化工、海洋船舶等領域。目前,基于石墨烯材料構建超疏水表面,是超疏水表面研究中一個較新的方向。本文對超疏水表面的原理進行了概述,重點總結歸納了石墨烯基超疏水材料制備技術的研究現狀,包括表面修飾法、沉積改性法、激光誘導法、涂覆法、層層自組裝法等,簡要介紹了石墨烯超疏水材料在自清潔、油水分離、防覆冰、耐腐蝕、抗菌等領域的應用,并對石墨烯超疏水材料的下一步研究方向進行了展望。Abstract: Superhydrophobicity in the surface is a phenomenon in which the contact angle between the water and the corresponding surface is greater than 150° and the rolling angle is less than 10°. A superhydrophobic surface exhibits unique properties and has a wide range of application prospects in the field of self-cleaning, anti-corrosion, anti-icing, oil-water separation, and antibacterial agents. In addition to its unique self-cleaning properties, it can play a distinctive role in the fields of building maintenance, anti-biological corrosion in ship bodies, medical antibacterial agents, etc. At present, low-surface-energy materials commonly used to construct superhydrophobic materials mainly include alkane compounds, organosilicon compounds, and fluorine-containing compounds. However, these materials generally have problems of high production costs, large environmental pollution, and complex preparation processes, which severely restrict the industrial production and application of superhydrophobic coatings. Graphene is a two-dimensional honeycomb-structured material formed by the covalent bonding of carbon atoms through sp2 hybrid orbitals. It is the basic unit of graphite, and it is the thinnest two-dimensional material found so far. As a class of materials with outstanding physical and chemical properties, graphene materials have always received extensive attention because of its high electrical conductivity, high thermal conductivity, high specific surface area, high light transmittance, and excellent mechanical properties. Therefore, graphene has been considered a promising material in aerospace, petrochemical, marine ships, and other fields. The construction of superhydrophobic surfaces based on graphene is a relatively new direction in the research of superhydrophobic surfaces at present. Although graphene-based superhydrophobic materials have shown excellent performance in the laboratory, they have not been used on a large scale in industrial production. In this paper, the principles of superhydrophobic surfaces were summarized, focusing on the research status of graphene-based super-hydrophobic materials preparation technology, including surface modification, deposition modification, laser induction, dip-coating method, and layer-by-layer self-assembly. The applications of graphene-based super-hydrophobic materials in the fields of self-cleaning, oil-water separation, anti-icing, corrosion resistance, and anti- bacterial agents were also introduced. Finally, this paper presents the prospective future research directions of graphene-based super-hydrophobic materials.

-

Key words:

- graphene /

- super-hydrophobic /

- surface /

- preparation /

- application

-

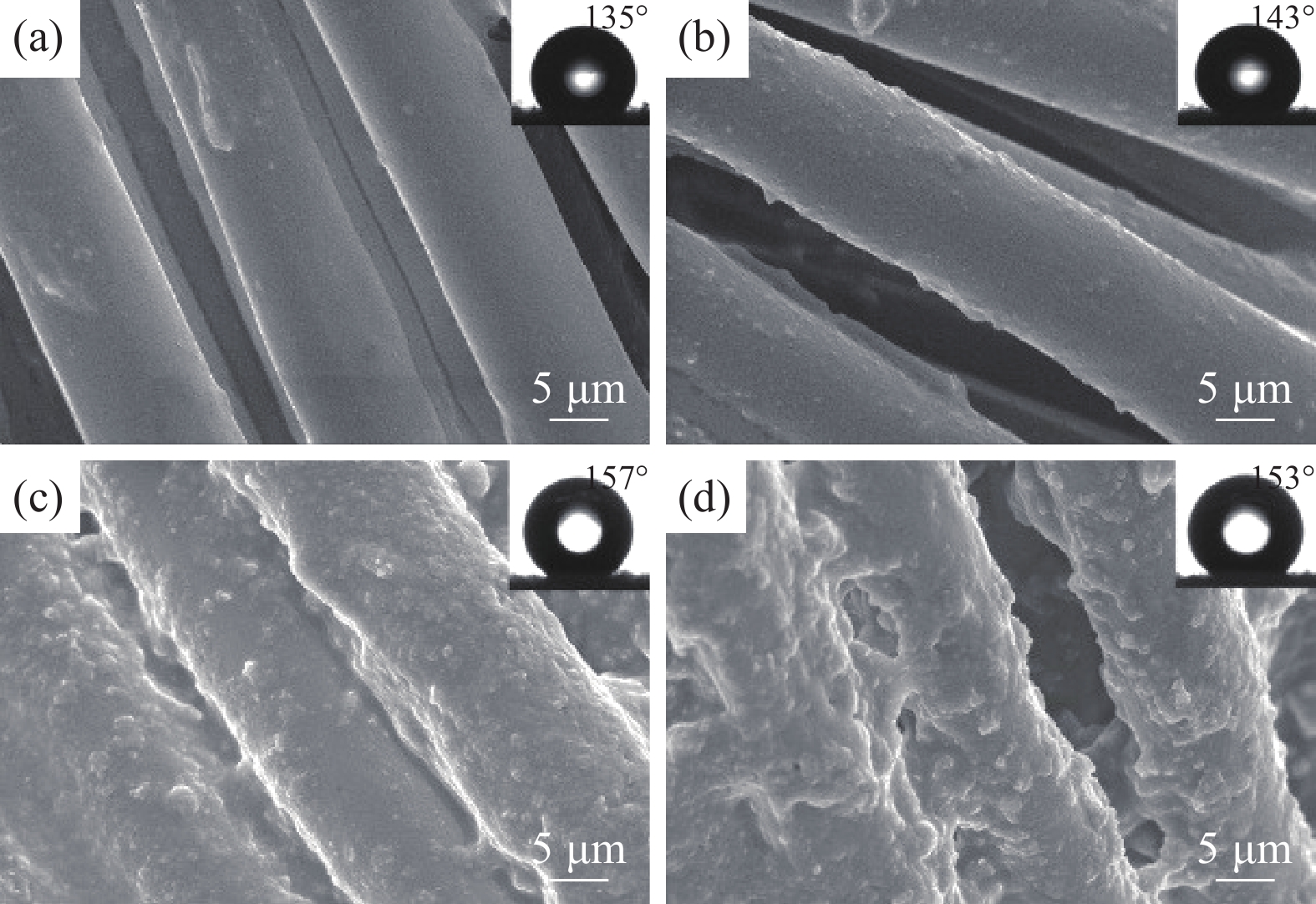

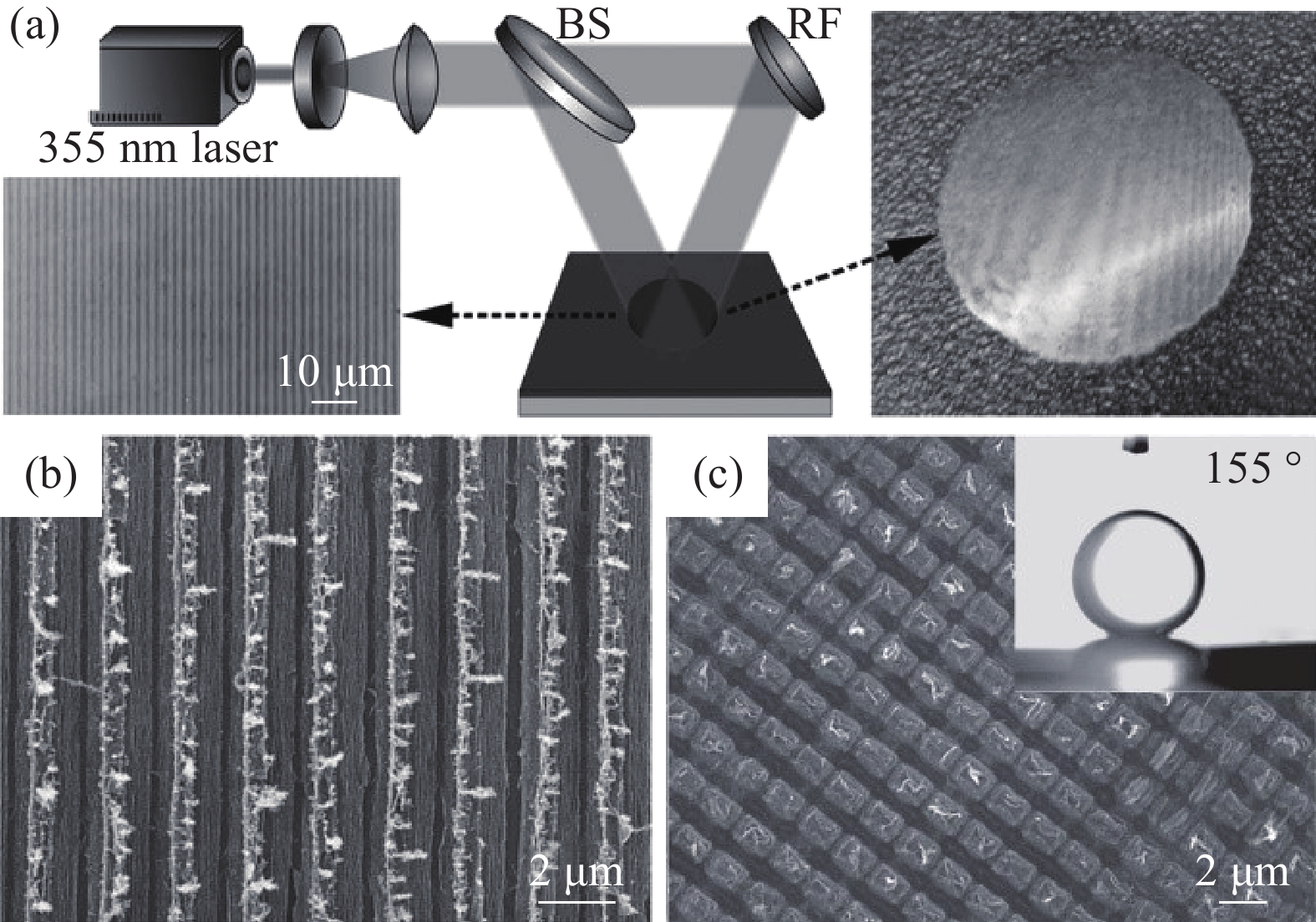

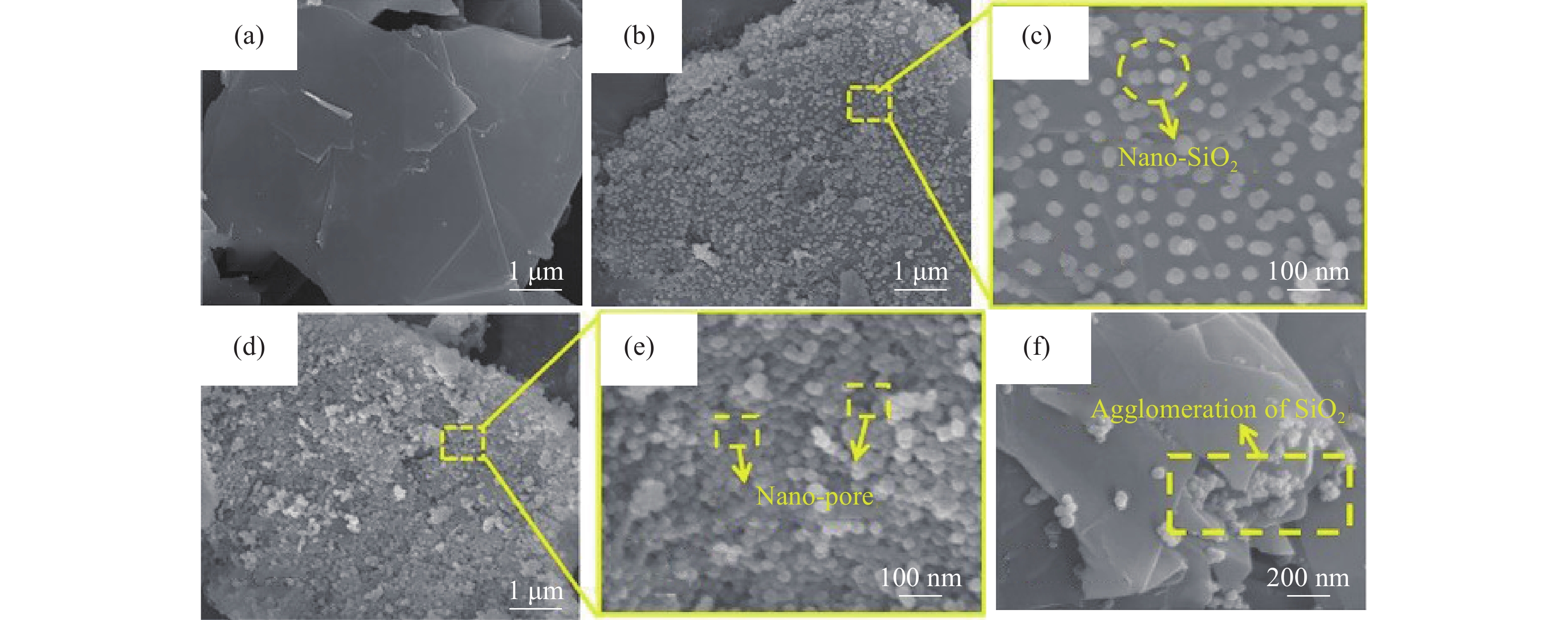

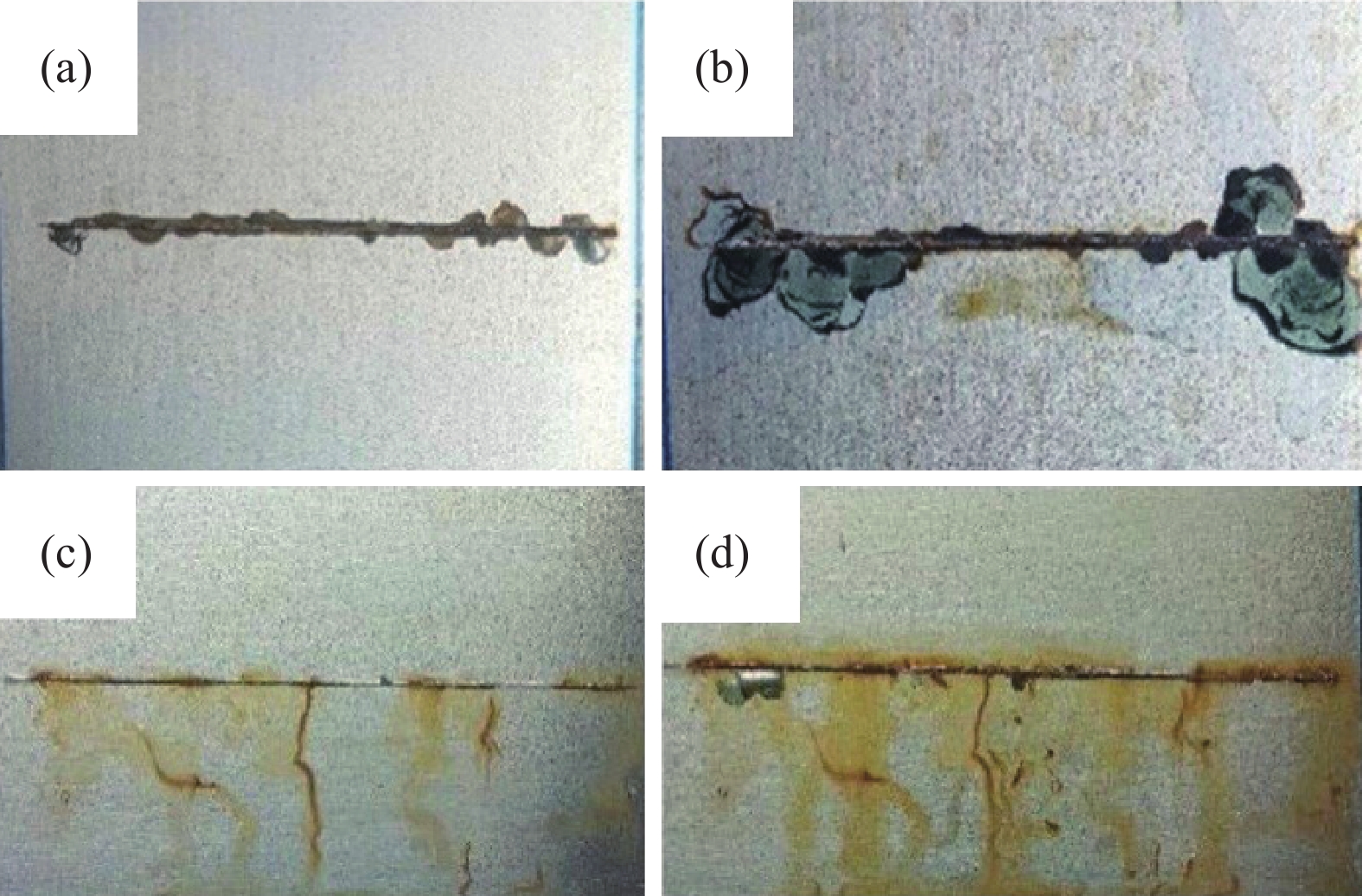

圖 4 (a)石墨烯沉積的不銹鋼網面;(b)石墨烯修飾不銹鋼網的掃描電鏡圖像[35];(c)松果狀石墨烯復合涂層;(d)松果狀石墨烯復合涂層放大圖[36];(e)花瓣形態石墨烯[41]

Figure 4. (a) Graphene-deposited stainless steel mesh; (b) SEM of graphene-modified stainless steel mesh[35]; (c) pinecone-like graphene composite coating; (d) magnified pinecone-like graphene composite coating[36]; (e) petal morphology graphene[41]

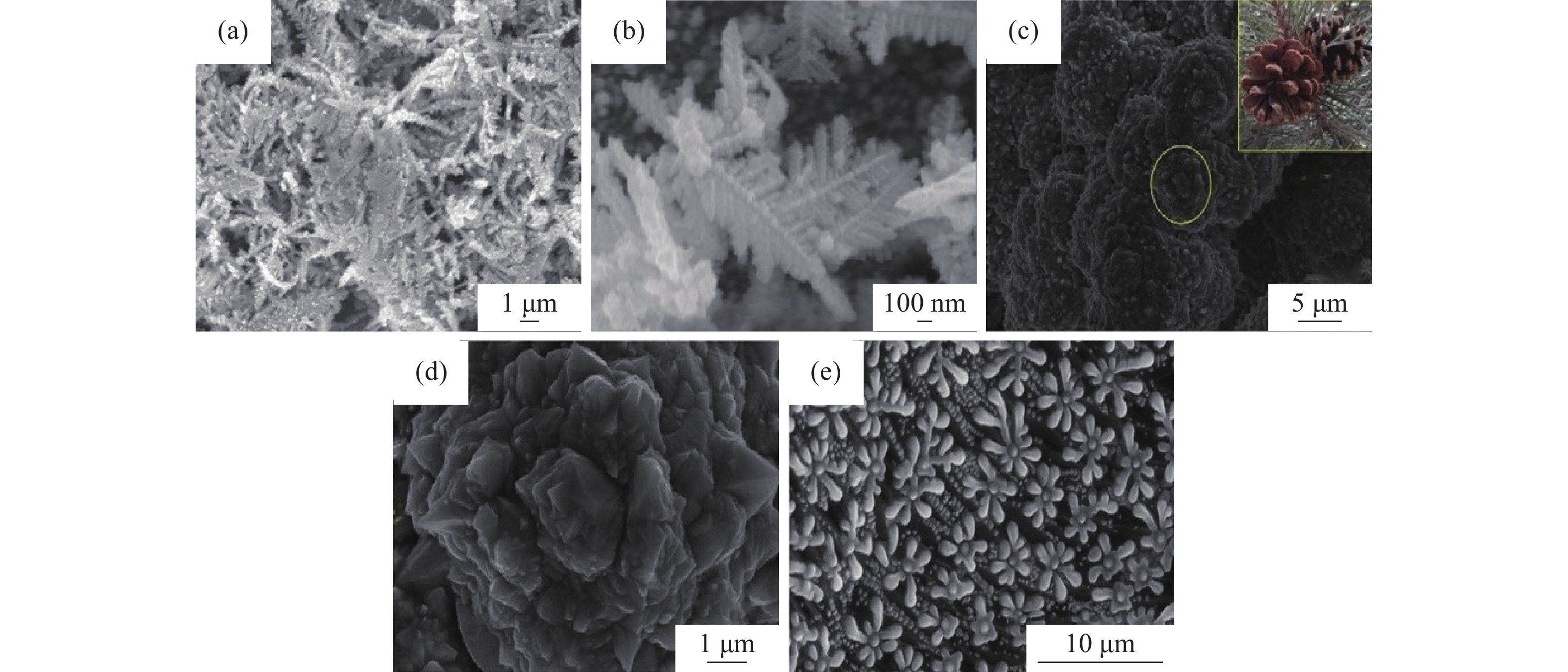

圖 5 簡要流程圖[46]。(a)激光誘導過程;(b)預碳化過程;(c)模型化誘導過程;(d)掃描激光束工作流程;(e)預碳化聚酰亞胺(PI)膜的光學圖;(f)經模型碳化的光學圖;(g)芋葉的掃描電鏡圖

Figure 5. Brief flow chart[46]: (a) laser induction process; (b) pre-carbonization process; (c) modeling induction process; (d) scanning laser beam workflow; (e) optical diagram of pre-carbonized PI film; (f) model carbonized optical image; (g) SEM image of taro leaf

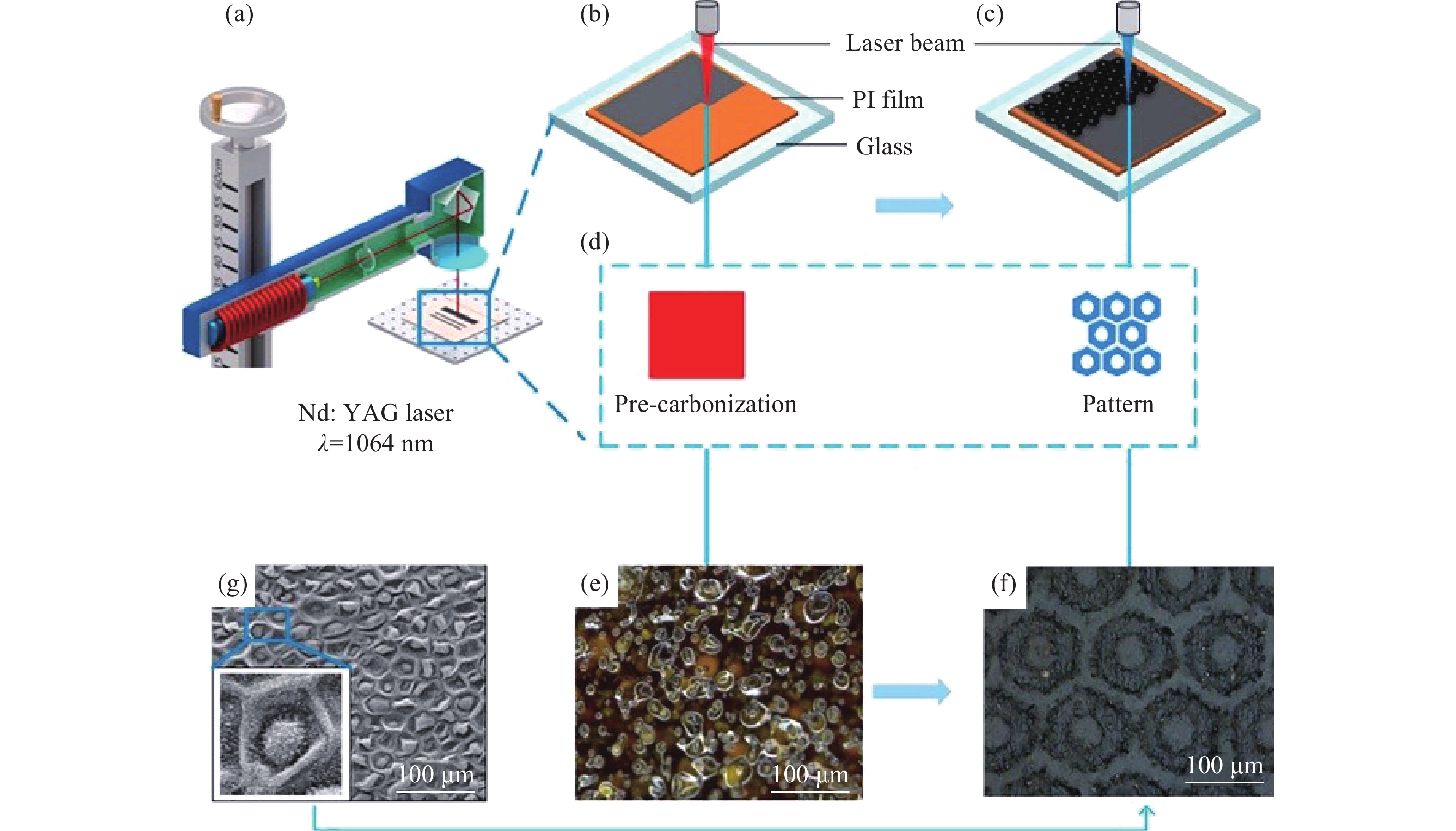

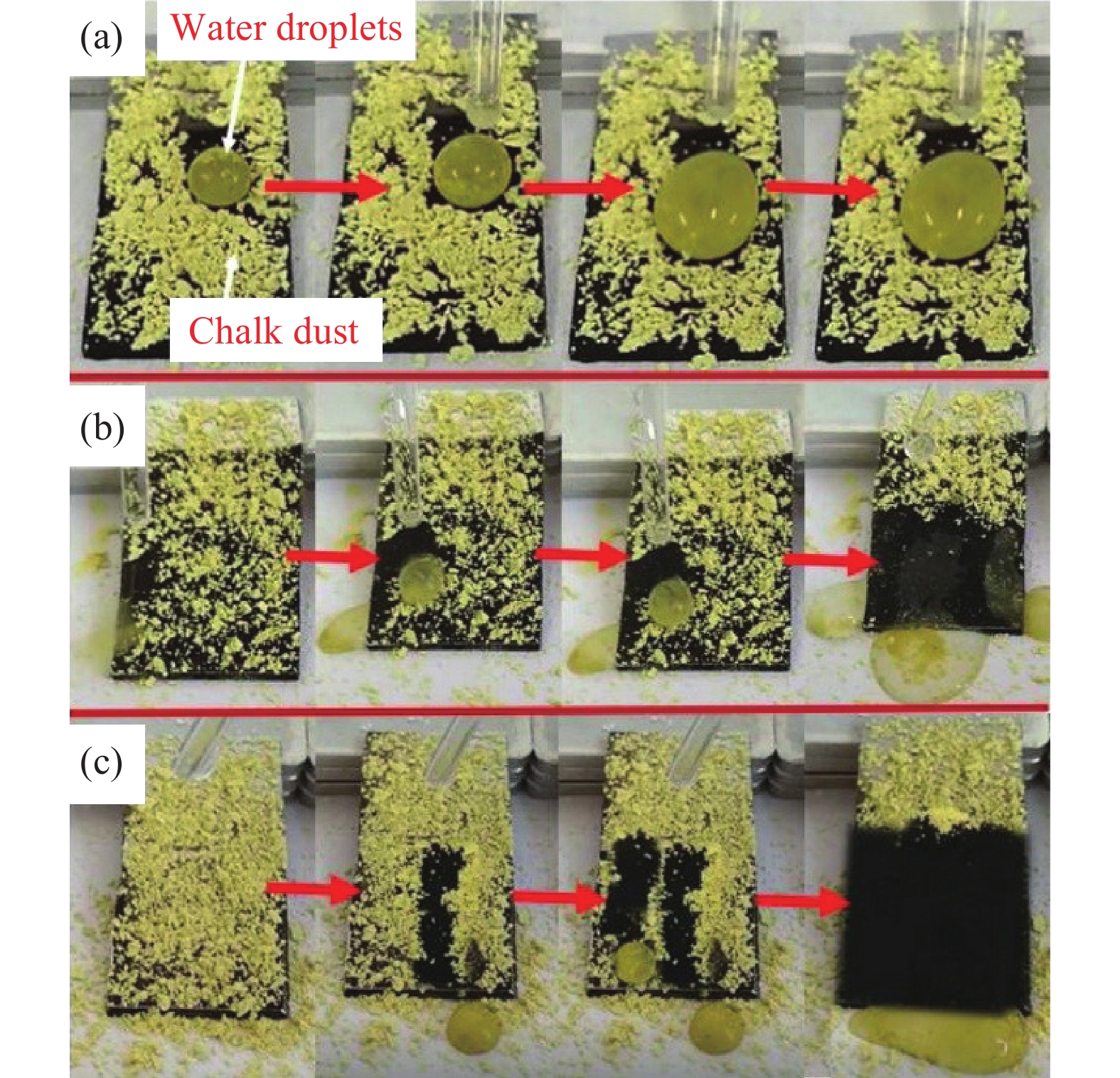

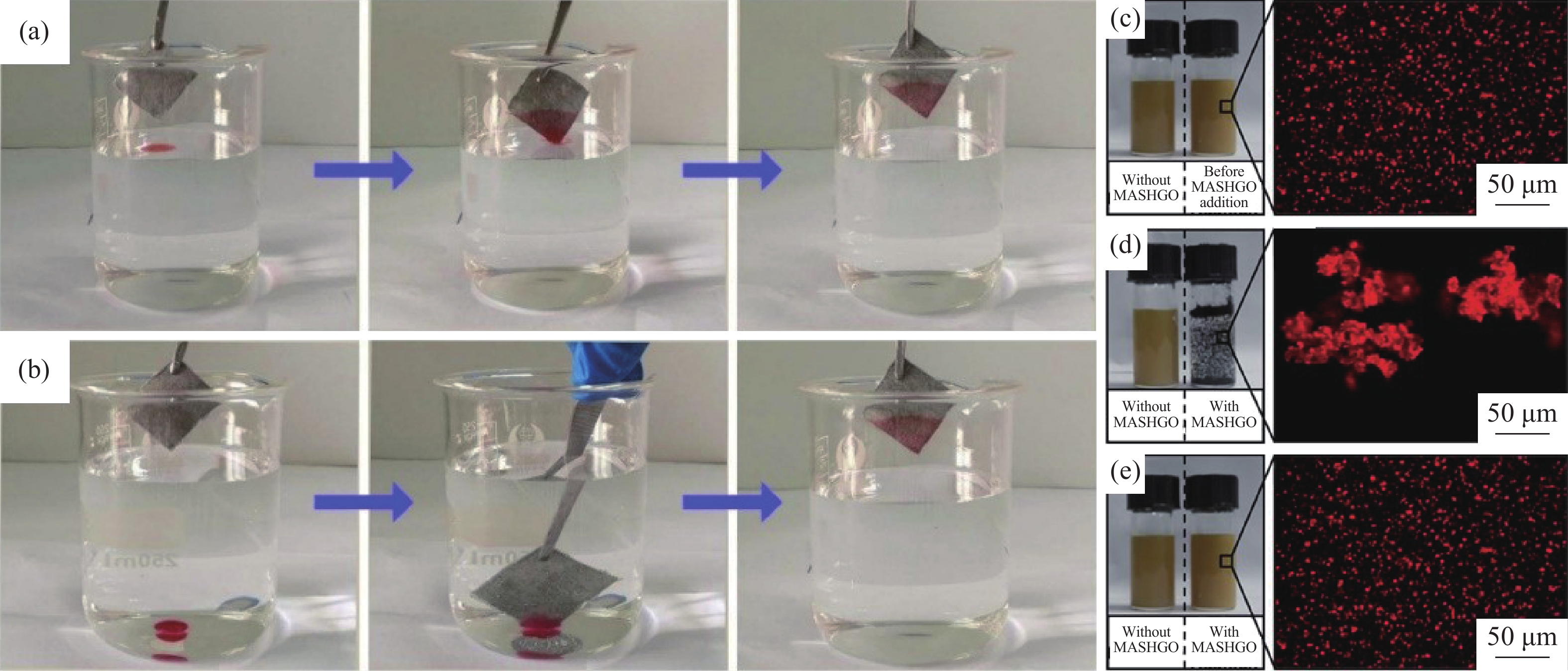

圖 11 石墨烯基超疏水聚氨酯材料油水分離測試圖。(a)輕油;(b)重油[32];(c~e)分別為MASHGO添加前、中、后的油水分離實驗圖及局部掃描電鏡圖[65]

Figure 11. Graphene-based super-hydrophobic polyurethane material oil?water separation test: (a) light oil; (b) heavy oil[32]; (c?e) are the oil-water separation experiment and partial SEM before, during, and after MASHGO addition[65]

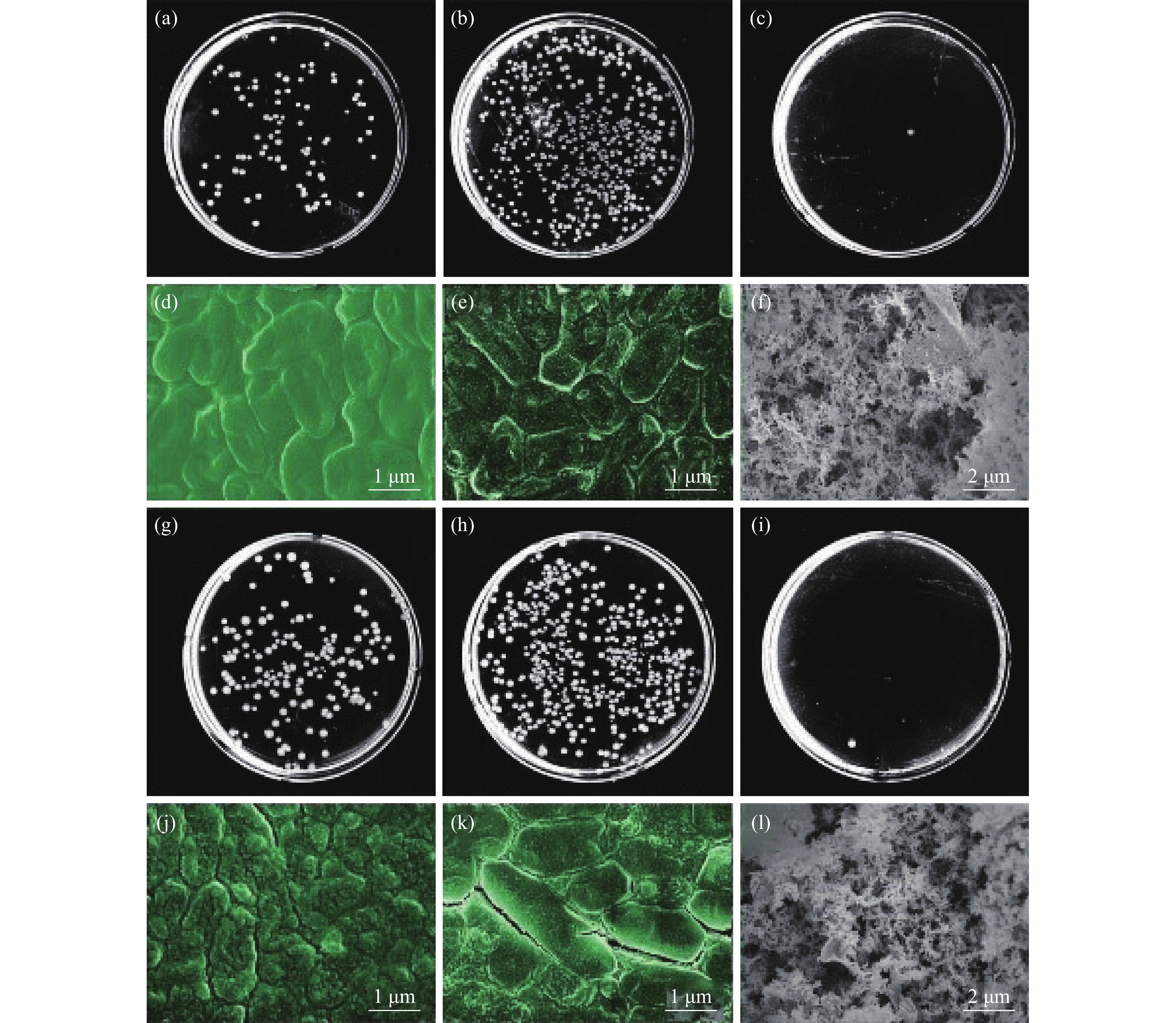

久色视频圖 13 大腸桿菌菌落圖及其掃描電鏡圖[69]. 未經陽光照射的PDMS(a,d),玻璃(b,e)和石墨烯涂層(c,f);經10 min陽光照射的PDMS(g,j);玻璃(h,k);石墨烯涂層(i,l)

Figure 13. Colony of Escherichia coli and its SEM[69]: PDMS (a,d), glass (b,e), and graphene-coated glass (c,f) without sunlight glass; PDMS (g,j), glass (h,k), and graphene-coated glass (i,l) after 10 minutes of sunlight glass

-

參考文獻

[1] Feng L, Li S H, Li Y S, et al. Super-hydrophobic surfaces: From natural to artificial. Adv Mater, 2002, 14(24): 1857 doi: 10.1002/adma.200290020 [2] Barthlott W, Neinhuis C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta, 1997, 202(1): 1 [3] Autumn K, Liang Y A, Hsieh S T, et al. Adhesive force of a single gecko foot-hair. Nature, 2000, 405(6787): 681 doi: 10.1038/35015073 [4] Parker A R, Lawrence C R. Water capture by a desert beetle. Nature, 2001, 414(6859): 33 doi: 10.1038/35102108 [5] Gao X F, Jiang L. Biophysics: water-repellent legs of water striders. Nature, 2004, 432(7013): 36 doi: 10.1038/432036a [6] Wen G, Guo Z G, Liu W M. Biomimetic polymeric superhydrophobic surfaces and nanostructures: From fabrication to applications. Nanoscale, 2017, 9(10): 3338 doi: 10.1039/C7NR00096K [7] Latthe S S, Sutar R S, Kodag V S, et al. Self-cleaning superhydrophobic coatings: Potential industrial applications. Prog Org Coat, 2019, 128: 52 doi: 10.1016/j.porgcoat.2018.12.008 [8] Bai X G, Shen Y Q, Tian H F, et al. Facile fabrication of superhydrophobic wood slice for effective water-in-oil emulsion separation. Sep Purif Technol, 2019, 210: 402 doi: 10.1016/j.seppur.2018.08.010 [9] Cui M K, Mu P, Shen Y Q, et al. Three-dimensional attapulgite with sandwich-like architecture used for multifunctional water remediation. Sep Purif Technol, 2020, 235: 116210 doi: 10.1016/j.seppur.2019.116210 [10] He Z K, Ma M, Xu X C, et al. Fabrication of superhydrophobic coating via a facile and versatile method based on nanoparticle aggregates. Appl Surf Sci, 2012, 258(7): 2544 doi: 10.1016/j.apsusc.2011.10.090 [11] Feng L B, Che Y H, Liu Y H, et al. Fabrication of superhydrophobic aluminium alloy surface with excellent corrosion resistance by a facile and environment-friendly method. Appl Surf Sci, 2013, 283: 367 doi: 10.1016/j.apsusc.2013.06.117 [12] Wang B, Guo Z G. Superhydrophobic copper mesh films with rapid oil/water separation properties by electrochemical deposition inspired from butterfly wing. Appl Phys Lett, 2013, 103(6): 063704 doi: 10.1063/1.4817922 [13] Liu Y, Yin X M, Zhang J J, et al. Biomimetic hydrophobic surface fabricated by chemical etching method from hierarchically structured magnesium alloy substrate. Appl Surf Sci, 2013, 280: 845 doi: 10.1016/j.apsusc.2013.05.072 [14] Liu F, Wang S L, Zhang M, et al. Improvement of mechanical robustness of the superhydrophobic wood surface by coating PVA/SiO2 composite polymer. Appl Surf Sci, 2013, 280: 686 doi: 10.1016/j.apsusc.2013.05.043 [15] Park E J, Sim J K, Jeong M G, et al. Transparent and superhydrophobic films prepared with polydimethylsiloxane-coated silica nanoparticles. RSC Adv, 2013, 3(31): 12571 doi: 10.1039/c3ra42402b [16] Liu X M, He J H. One-step hydrothermal creation of hierarchical microstructures toward superhydrophilic and superhydrophobic surfaces. Langmuir, 2009, 25(19): 11822 doi: 10.1021/la901426r [17] Zheng Y S, He Y, Qing Y Q, et al. Formation of SiO2/polytetrafluoroethylene hybrid superhydrophobic coating. Appl Surf Sci, 2012, 258(24): 9859 doi: 10.1016/j.apsusc.2012.06.043 [18] Ji S, Ramadhianti P A, Nguyen T B, et al. Simple fabrication approach for superhydrophobic and superoleophobic Al surface. Microelectron Eng, 2013, 111: 404 doi: 10.1016/j.mee.2013.04.010 [19] Tong W, Xiong D S. Bioinspired superhydrophobic materials: Progress and functional application. J Inorg Mater, 2019, 34(11): 1133佟威, 熊黨生. 仿生超疏水表面的發展及其應用研究進展. 無機材料學報, 2019, 34(11):1133 [20] Geim A K. Graphene: status and prospects. Science, 2009, 324(5934): 1530 doi: 10.1126/science.1158877 [21] Young T. An essay on the cohesion of fluids. Philos Trans R Soc London, 1805, 95: 65 doi: 10.1098/rstl.1805.0005 [22] Wenzel R N. Resistance of solid surfaces to wetting by water. Trans Faraday Soc, 1936, 28(8): 988 [23] Oner D, McCarthy T J. Ultrahydrophobic surfaces: Effects of topography and length scales on wettability. Langmuir, 2000, 16(20): 7777 doi: 10.1021/la000598o [24] Li H J, Wang X B, Song Y L, et al. Super-"Amphiphobic" aligned carbon nanotube films. Angew Chem, 2001, 113(9): 1793 doi: 10.1002/1521-3757(20010504)113:9<1793::AID-ANGE17930>3.0.CO;2-I [25] A J, S Jayan J S, Saritha A, et al. Superhydrophobic graphene-based materials with self-cleaning and anticorrosion performance: An appraisal of neoteric advancement and future perspectives. Colloids Surf A, 2020, 606: 125395 doi: 10.1016/j.colsurfa.2020.125395 [26] Chen Z X, Dong L, Yang D, et al. Superhydrophobic graphene-based materials: Surface construction and functional applications. Adv Mater, 2013, 25(37): 5352 doi: 10.1002/adma.201302804 [27] Nguyen-Tri P, Tran H N, Plamondon C O, et al. Recent progress in the preparation, properties and applications of superhydrophobic nano-based coatings and surfaces: A review. Prog Org Coat, 2019, 132: 235 doi: 10.1016/j.porgcoat.2019.03.042 [28] Hooda A, Goyat M S, Pandey J K, et al. A review on fundamentals, constraints and fabrication techniques of superhydrophobic coatings. Prog Org Coat, 2020, 142: 105557 doi: 10.1016/j.porgcoat.2020.105557 [29] Dalawai S P, Aly M A S, Latthe S S, et al. Recent advances in durability of superhydrophobic self-cleaning technology A critical review. Prog Org Coat, 2020, 138: 105381 doi: 10.1016/j.porgcoat.2019.105381 [30] Liu H D, Ying Q, Jia F, et al. Preparation and characterization of surperhydrophobic foam modified by graphene oxide. Poly Mater Sci Eng, 2016, 32(4): 115劉海東, 應琴, 賈飛, 等. 石墨烯改性聚氨酯超疏水泡沫的制備與表征. 高分子材料科學與工程, 2016, 32(4):115 [31] Mo Z H, Luo Z, Huang Q, et al. Superhydrophobic hybrid membranes by grafting arc-like macromolecular bridges on graphene sheets: Synthesis, characterization and properties. Appl Surf Sci, 2018, 440: 359 doi: 10.1016/j.apsusc.2017.12.268 [32] Liao X F, Li H Q, Zhang L, et al. Superhydrophobic mGO/PDMS hybrid coating on polyester fabric for oil/water separation. Prog Org Coat, 2018, 115: 172 doi: 10.1016/j.porgcoat.2017.12.001 [33] He S J, Zhan Y Q, Zhao S M, et al. Design of stable super-hydrophobic/super-oleophilic 3D carbon fiber felt decorated with Fe3O4 nanoparticles: Facial strategy, magnetic drive and continuous oil/water separation in harsh environments. Appl Surf Sci, 2019, 494: 1072 doi: 10.1016/j.apsusc.2019.07.258 [34] Saharudin K A, Karim M A, Sreekantan S. Preparation of a polydimethylsiloxane (PDMS)/graphene-based super-hydrophobic coating. Mater Today Proc, 2019, 17: 752 doi: 10.1016/j.matpr.2019.06.359 [35] Tang W J, Sun D, Liu S H, et al. One step electrochemical fabricating of the biomimetic graphene skins with superhydrophobicity and superoleophilicity for highly efficient oil-water separation. Sep Purif Technol, 2020, 236: 116293 doi: 10.1016/j.seppur.2019.116293 [36] Bai Z G, Zhang B. Fabrication of superhydrophobic reduced-graphene oxide/nickel coating with mechanical durability, self-cleaning and anticorrosion performance. Nano Mater Sci, 2020, 2(2): 151 doi: 10.1016/j.nanoms.2019.05.001 [37] Ding S B, Xiang T F, Li C, et al. Fabrication of self-cleaning super-hydrophobic nickel/graphene hybrid film with improved corrosion resistance on mild steel. Mater Des, 2017, 117: 280 doi: 10.1016/j.matdes.2016.12.084 [38] Liang J F, Wu X W, Ling Y H, et al. Trilaminar structure hydrophobic graphene oxide decorated organosilane composite coatings for corrosion protection. Surf Coat Technol, 2018, 339: 65 doi: 10.1016/j.surfcoat.2018.02.002 [39] Zhu X B, Zhou S G, Yan Q Q, et al. Ternary graphene/amorphous carbon/nickel nanocomposite film for outstanding superhydrophobicity. Chem Phys, 2018, 505: 19 doi: 10.1016/j.chemphys.2018.03.008 [40] Jena G, Thinaharan C, George R P, et al. Robust nickel-reduced graphene oxide-myristic acid superhydrophobic coating on carbon steel using electrochemical codeposition and its corrosion resistance. Surf Coat Technol, 2020, 397: 125942 doi: 10.1016/j.surfcoat.2020.125942 [41] Yoon J C, Yoon C S, Lee J S, et al. Lotus leaf-inspired CVD grown graphene for a water repellant flexible transparent electrode. Chem Commun, 2013, 49(90): 10626 doi: 10.1039/c3cc46156d [42] Zheng Z H, Liu Y, Bai Y, et al. Fabrication of biomimetic hydrophobic patterned graphene surface with ecofriendly anti-corrosion properties for Al alloy. Colloids Surf A, 2016, 500: 64 doi: 10.1016/j.colsurfa.2016.04.008 [43] Ong C C, Saheed M S M, Mohamed N M, et al. Highly hydrophobic 3D graphene-carbon nanotubes composite film for oil absorption. Mater Today Proc, 2019, 16: 1772 doi: 10.1016/j.matpr.2019.06.048 [44] Li Y L, Luong D X, Zhang J B, et al. Laser-induced graphene in controlled atmospheres: from superhydrophilic to superhydrophobic surfaces. Adv Mater, 2017, 29(27): 1700496 doi: 10.1002/adma.201700496 [45] Nasser J, Lin J J, Zhang L S, et al. Laser induced graphene printing of spatially controlled super-hydrophobic/hydrophilic surfaces. Carbon, 2020, 162: 570 doi: 10.1016/j.carbon.2020.03.002 [46] Wu W B, Liang R X, Lu L S, et al. Preparation of superhydrophobic laser-induced graphene using taro leaf structure as templates. Surf Coat Technol, 2020, 393: 125744 doi: 10.1016/j.surfcoat.2020.125744 [47] Wang J N, Shao R Q, Zhang Y L, et al. Biomimetic graphene surfaces with superhydrophobicity and iridescence. Chem Asian J, 2012, 7(2): 301 doi: 10.1002/asia.201100882 [48] Song Y Y, Liu Y, Jiang H B, et al. Biomimetic super hydrophobic structured graphene on stainless steel surface by laser processing and transfer technology. Surf Coat Technol, 2017, 328: 152 doi: 10.1016/j.surfcoat.2017.08.031 [49] Wan Y L, Cui P, Xu L N, et al. Anti-icing performance of micro-nano composite texture based on image processing technology. Surf Technol, 2019, 48(8): 54彎艷玲, 崔普, 徐麗寧, 等. 基于圖像處理技術界定微納復合織構防覆冰性能. 表面技術, 2019, 48(8):54 [50] Jiang H B, Zhang Y L, Han D D, et al. Bioinspired fabrication of superhydrophobic graphene films by two-beam laser interference. Adv Funct Mater, 2014, 24(29): 4720 doi: 10.1002/adfm.201470194 [51] Shateri-Khalilabad M, Yazdanshenas M E. Preparation of superhydrophobic electroconductive graphene-coated cotton cellulose. Cellulose, 2013, 20(2): 963 doi: 10.1007/s10570-013-9873-y [52] Zhang X T, Liu D Y, Ma Y L, et al. Super-hydrophobic graphene coated polyurethane (GN@PU) sponge with great oil-water separation performance. Appl Surf Sci, 2017, 422: 116 doi: 10.1016/j.apsusc.2017.06.009 [53] Peng M, Chen G Q, Zeng G M, et al. Superhydrophobic kaolinite modified graphene oxide-melamine sponge with excellent properties for oil-water separation. Appl Clay Sci, 2018, 163: 63 doi: 10.1016/j.clay.2018.07.008 [54] Lü C J, Wang H Y, Liu Z J, et al. Fabrication of durable fluorine-free polyphenylene sulfide/silicone resin composite superhydrophobic coating enhanced by carbon nanotubes/graphene fillers. Prog Org Coat, 2019, 134: 1 doi: 10.1016/j.porgcoat.2019.04.042 [55] Uzoma P C, Liu F C, Xu L, et al. Superhydrophobicity, conductivity and anticorrosion of robust siloxane-acrylic coatings modified with graphene nanosheets. Prog Org Coat, 2019, 127: 239 doi: 10.1016/j.porgcoat.2018.11.018 [56] Zhang X G, Liu Z J, Li Y, et al. Robust superhydrophobic epoxy composite coating prepared by dual interfacial enhancement. Chem Eng J, 2019, 371: 276 doi: 10.1016/j.cej.2019.04.040 [57] Wang P, Yao T, Sun B, et al. A cost-effective method for preparing mechanically stable anti-corrosive superhydrophobic coating based on electrochemically exfoliated graphene. Colloids Surf A, 2017, 513: 396 doi: 10.1016/j.colsurfa.2016.11.002 [58] Liu Y, Zhang J J, Li S Y, et al. Fabrication of a superhydrophobic graphene surface with excellent mechanical abrasion and corrosion resistance on an aluminum alloy substrate. RSC Adv, 2014, 4(85): 45389 doi: 10.1039/C4RA06051B [59] Chen N N, Wang Y H, Zhong L, et al. Anticorrosion performance of super-hydrophobic complex film of graphene/stearic acid on AZ91 Mg-alloy. J Mater Res, 2017, 31(10): 751 doi: 10.11901/1005.3093.2016.617陳寧寧, 王燕華, 鐘蓮, 等. 石墨烯/硬脂酸超疏水復合膜層的防腐性能. 材料研究學報, 2017, 31(10):751 doi: 10.11901/1005.3093.2016.617 [60] Wang Y, Yu Y, Hu X B, et al. p-phenylenediamine strengthened graphene oxide for the fabrication of superhydrophobic surface. Mater Des, 2017, 127: 22 doi: 10.1016/j.matdes.2017.04.033 [61] Zhang Y Q, He S J, Hu J X, et al. Robust super-hydrophobic/super-oleophilic sandwich-like UIO-66-F4@rGO composites for efficient and multitasking oil/water separation applications. J Hazard Mater, 2020, 388: 121752 doi: 10.1016/j.jhazmat.2019.121752 [62] Sin Y Y, Huang C C, Lin C N, et al. Ultrastrong adhesion of fluorinated graphene on a substrate: In situ electrochemical conversion to ionic-covalent bonding at the interface. Carbon, 2020, 169: 248 doi: 10.1016/j.carbon.2020.07.067 [63] Wang P, Yao T, Li Z Q, et al. A superhydrophobic/electrothermal synergistically anti-icing strategy based on graphene composite. Compos Sci Technol, 2020, 198: 108307 doi: 10.1016/j.compscitech.2020.108307 [64] Akhtar N, Anemone G, Farias D, et al. Fluorinated graphene provides long lasting ice inhibition in high humidity. Carbon, 2019, 141: 451 doi: 10.1016/j.carbon.2018.09.008 [65] Das A, Maji K, Naskar S, et al. Facile optimization of hierarchical topography and chemistry on magnetically active graphene oxide nanosheets. Chem Sci, 2020, 11(25): 6556 doi: 10.1039/D0SC00517G [66] Sadeghian Z, Hadidi M R, Salehzadeh D, et al. Hydrophobic octadecylamine-functionalized graphene/TiO2 hybrid coating for corrosion protection of copper bipolar plates in simulated proton exchange membrane fuel cell environment. Int J Hydrogen Energy, 2020, 45(30): 15380 doi: 10.1016/j.ijhydene.2020.04.015 [67] Asaldoust S, Hosseini M S, Ramezanzadeh B, et al. Construction of a unique anti-corrosion nanocomposite based on graphene oxide@Zn3PO4/epoxy; experimental characterization and detailed-theoretical quantum mechanics (QM) investigations. Constr Build Mater, 2020, 256: 119439 doi: 10.1016/j.conbuildmat.2020.119439 [68] Ouadil B, Amadine O, Essamlali Y, et al. A new route for the preparation of hydrophobic and antibacterial textiles fabrics using Ag-loaded graphene nanocomposite. Colloids Surf A, 2019, 579: 123713 doi: 10.1016/j.colsurfa.2019.123713 [69] Jiang N, Wang Y L, Chan K C, et al. Additive manufactured graphene coating with synergistic photothermal and superhydrophobic effects for bactericidal applications. Global Challenges, 2019, 4(1): 1900054 -

下載:

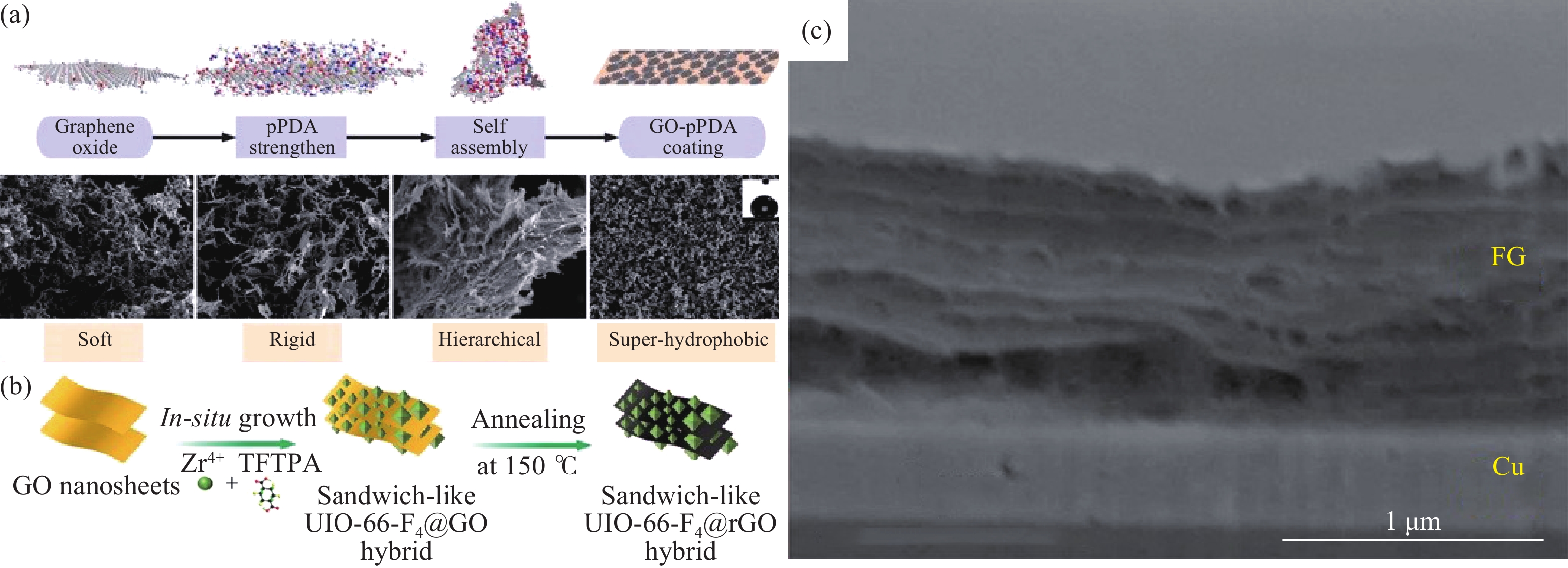

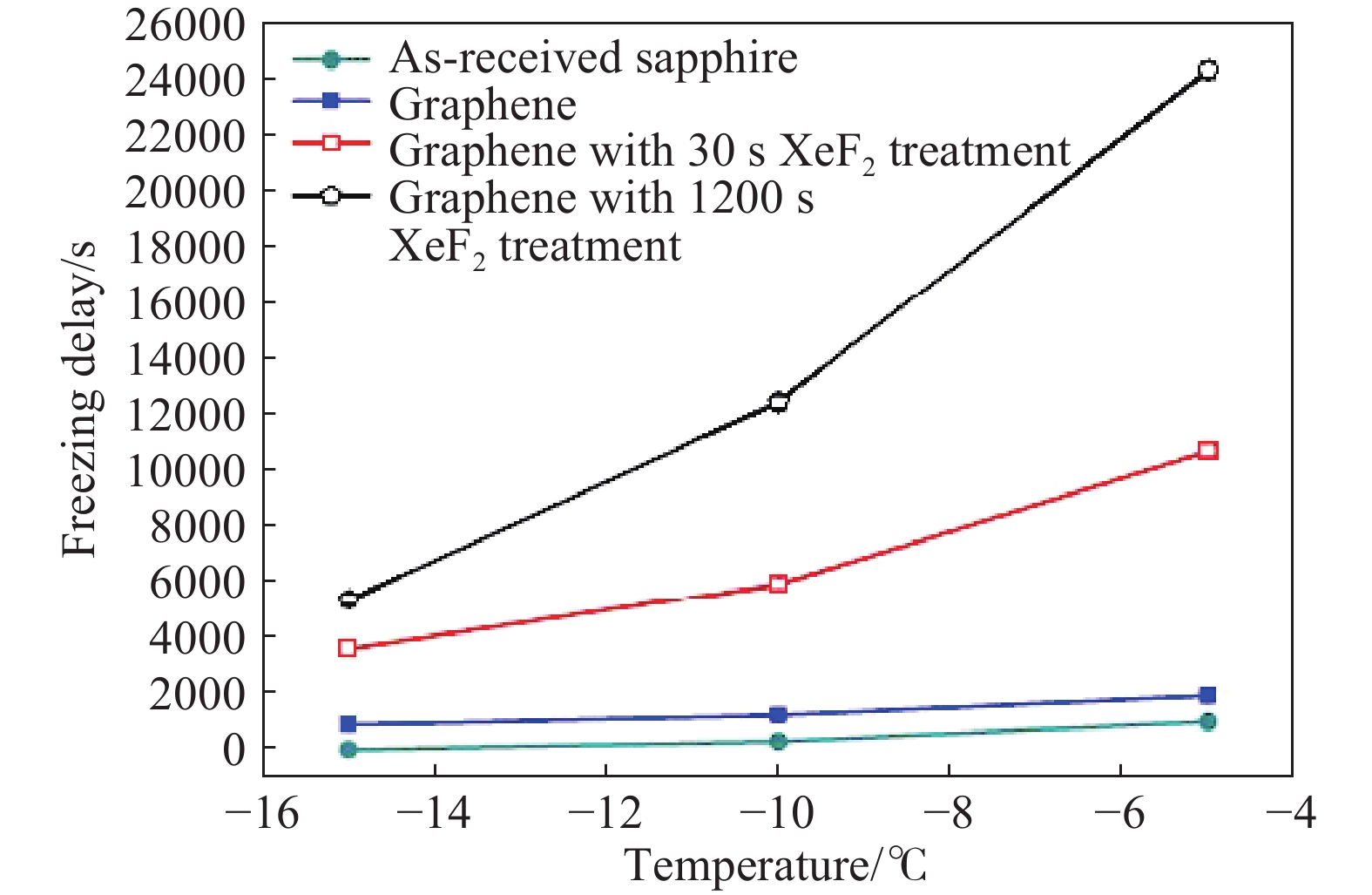

下載: