| [1] |

Norhasri M S M, Hamidah M S, Fadzil A M. Applications of using nano material in concrete: a review. Constr Build Mater, 2017, 133:91

|

| [2] |

Dai Y J, Li Y W, Xu X F, et al. Fracture behaviour of magnesia refractory materials in tension with the Brazilian test. J Eur Ceram Soc, 2019, 39(16): 5433 doi: 10.1016/j.jeurceramsoc.2019.07.026

|

| [3] |

Wang E H, Chen J H, Hou X M. Design, preparation, and application of new function refractories. Chin J Eng, 2019, 41(12): 1520王恩會, 陳俊紅, 侯新梅. 功能化新型耐火材料的設計、制備及應用. 工程科學學報, 2019, 41(12):1520

|

| [4] |

Dai Y J, Li Y W, Jin S L, et al. Mechanical and fracture investigation of magnesia refractories with acoustic emission-based method. J Eur Ceram Soc, 2020, 40(1): 181 doi: 10.1016/j.jeurceramsoc.2019.09.010

|

| [5] |

Roy J, Chandra S, Maitra S. Nanotechnology in castable refractory. Ceram Int, 2019, 45(1): 19 doi: 10.1016/j.ceramint.2018.09.261

|

| [6] |

Yao H B, Yao S Z, Luo C, et al. Current research and developing trend of MgO–C bricks. Chin J Eng, 2018, 40(3): 253姚華柏, 姚蘇哲, 駱昶, 等. 鎂碳磚的研究現狀與發展趨勢. 工程科學學報, 2018, 40(3):253

|

| [7] |

Bag M, Adak S, Sarkar R. Study on low carbon containing MgO–C refractory: use of nano carbon. Ceram Int, 2012, 38(3): 2339 doi: 10.1016/j.ceramint.2011.10.086

|

| [8] |

Luz A P, Souza T M, Pagliosa C, et al. In situ hot elastic modulus evolution of MgO–C refractories containing Al, Si or Al–Mg antioxidants. Ceram Int, 2016, 42(8): 9836 doi: 10.1016/j.ceramint.2016.03.080

|

| [9] |

Xiao J L, Chen J F, Wei Y W, et al. Oxidation behaviors of MgO–C refractories with different Si/SiC ratio in the 1100–1500 ℃ range. Ceram Int, 2019, 45(17): 21099 doi: 10.1016/j.ceramint.2019.07.086

|

| [10] |

Bag M, Adak S, Sarkar R. Nano carbon containing MgO–C refractory: effect of graphite content. Ceram Int, 2012, 38(6): 4909 doi: 10.1016/j.ceramint.2012.02.082

|

| [11] |

Ding D H, Chong X C, Xiao G Q, et al. Combustion synthesis of B4C/Al2O3/C composite powders and their effects on properties of low carbon MgO–C refractories. Ceram Int, 2019, 45(13): 16433 doi: 10.1016/j.ceramint.2019.05.174

|

| [12] |

Zhu T B, Li Y W, Sang S B, et al. Effect of nanocarbon sources on microstructure and mechanical properties of MgO–C refractories. Ceram Int, 2014, 40(3): 4333 doi: 10.1016/j.ceramint.2013.08.101

|

| [13] |

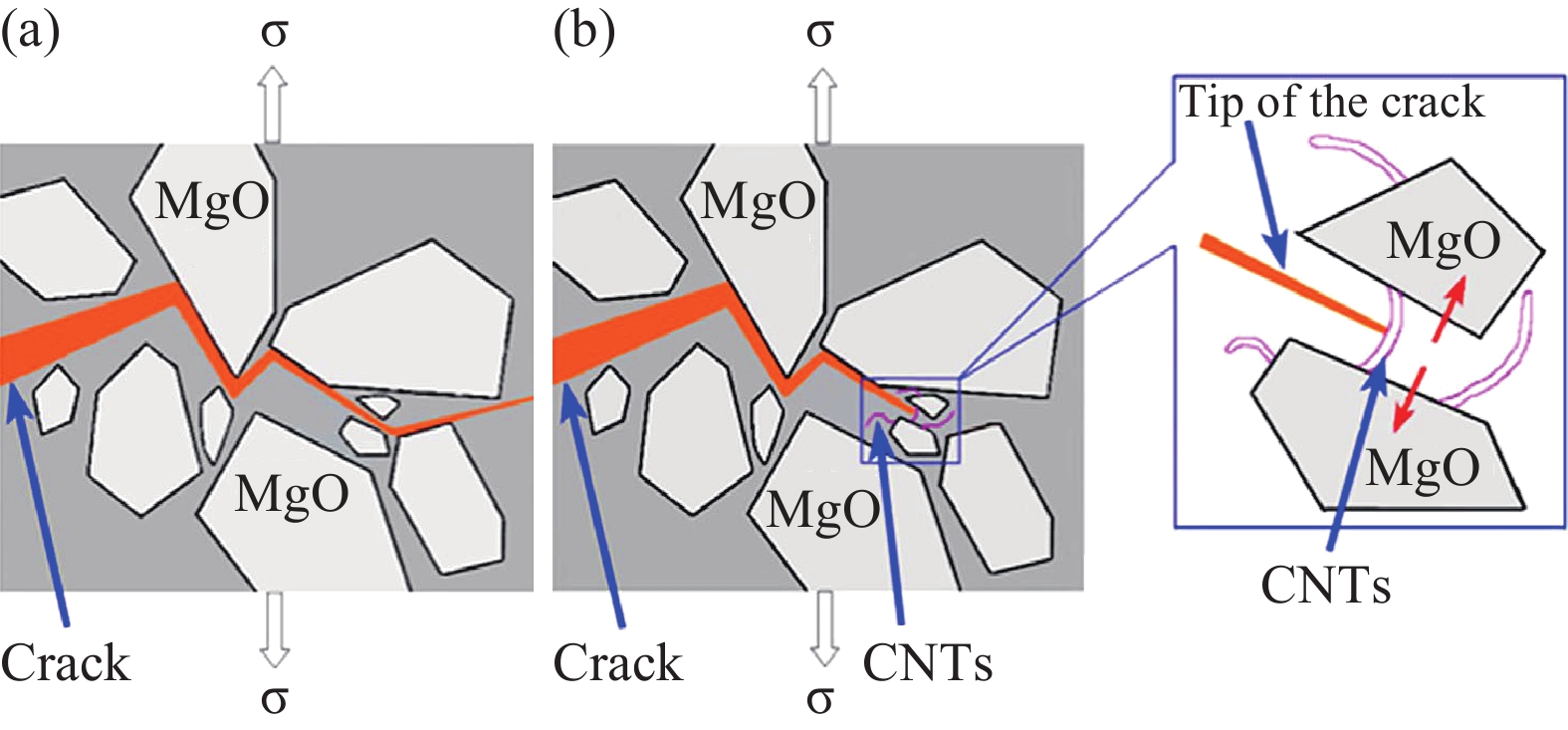

Wang J K. In-situ Catalytic Preparation Mechanism of Carbon Nanotube/SiC and Their Application in MgO –C Refractory[Dissertation]. Wuhan: Wuhan University of Science and Technology, 2018王軍凱. 碳納米管/碳化硅原位催化制備、機理及其在MgO–C耐火材料中的應用[學位論文]. 武漢: 武漢科技大學, 2018

|

| [14] |

Rastegar H, Bavand-vandchali M, Nemati A, et al. Phase and microstructural evolution of low carbon MgO–C refractories with addition of Fe-catalyzed phenolic resin. Ceram Int, 2019, 45(3): 3390 doi: 10.1016/j.ceramint.2018.10.253

|

| [15] |

Liu Z Y, Yuan L, Yu J K. Improvements in the mechanical properties and oxidation resistance of MgO–C refractories with the addition of nano-Y2O3 powder. Adv Appl Ceram, 2019, 118(5): 249 doi: 10.1080/17436753.2018.1564414

|

| [16] |

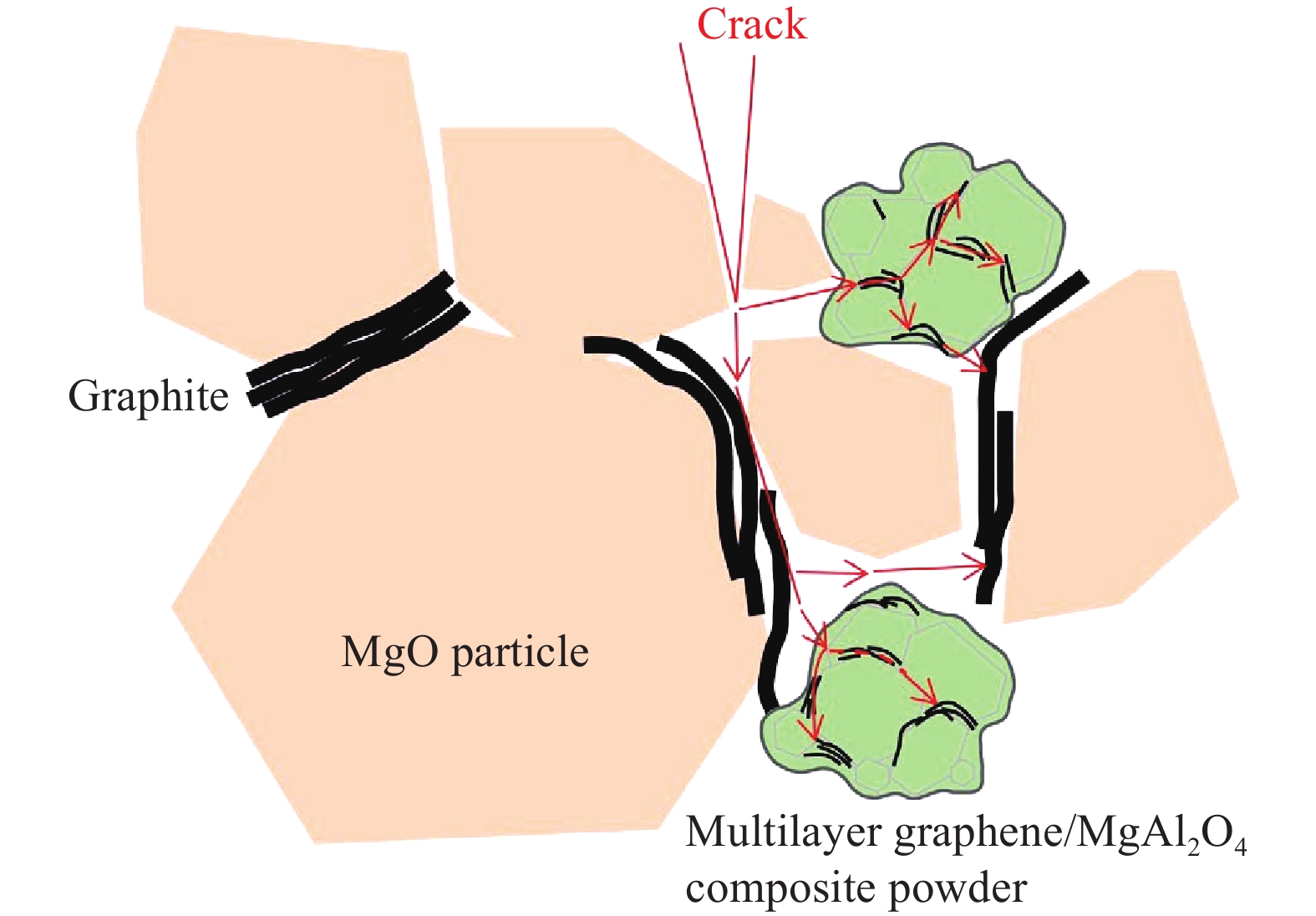

Ding D H, Lv L H, Xiao G Q, et al. Improved properties of low-carbon MgO–C refractories with the addition of multilayer graphene/MgAl2O4 composite powders. Int J Appl Ceram Technol, 2020, 17(2): 645 doi: 10.1111/ijac.13347

|

| [17] |

Zhu T B, Li Y W, Sang S B, et al. Improved thermal shock resistance of magnesia-graphite refractories by the addition of MgO–C pellets. Mater Des, 2017, 124: 16 doi: 10.1016/j.matdes.2017.03.054

|

| [18] |

Wei G P, Zhu B Q, Li X C, et al. Microstructure and mechanical properties of low-carbon MgO–C refractories bonded by an Fe nanosheet-modified phenol resin. Ceram Int, 2015, 41(1): 1553 doi: 10.1016/j.ceramint.2014.09.091

|

| [19] |

Yeprem H A. Effect of iron oxide addition on the hydration resistance and bulk density of doloma. J Eur Ceram Soc, 2007, 27(2-3): 1651 doi: 10.1016/j.jeurceramsoc.2006.05.010

|

| [20] |

Ghosh A, Tripathi H S. Sintering behaviour and hydration resistance of reactive dolomite. Ceram Int, 2012, 38(2): 1315 doi: 10.1016/j.ceramint.2011.09.005

|

| [21] |

Lee J K, Choi H S, Lee S J. Effect of Fe2O3 additions on the hydration resistance of CaO. J Ceram Process Res, 2012, 13(5): 646

|

| [22] |

Shahraki A, Ghasemi-Kahrizsangi S, Nemati A. Performance improvement of MgO–CaO refractories by the addition of nano-sized Al2O3. Mater Chem Phys, 2017, 198: 354 doi: 10.1016/j.matchemphys.2017.06.026

|

| [23] |

Dehsheish H G, Karamian E, Owsalou R G, et al. Improvement in performance of MgO–CaO refractory composites by addition of Iron (III) oxide nanoparticles. Ceram Int, 2018, 44(13): 15880 doi: 10.1016/j.ceramint.2018.06.003

|

| [24] |

Ghasemi-Kahrizsangi S, Sedeh M B, Dehsheikh H G, et al. Densification and properties of ZrO2 nanoparticles added magnesia–doloma refractories. Ceram Int, 2016, 42(14): 15658 doi: 10.1016/j.ceramint.2016.07.021

|

| [25] |

Ghasemi-Kahrizsangi S, Dehsheikh H G, Karamian E, et al. Effect of MgAl2O4 nanoparticles addition on the densification and properties of MgO–CaO refractories. Ceram Int, 2017, 43(6): 5014 doi: 10.1016/j.ceramint.2017.01.011

|

| [26] |

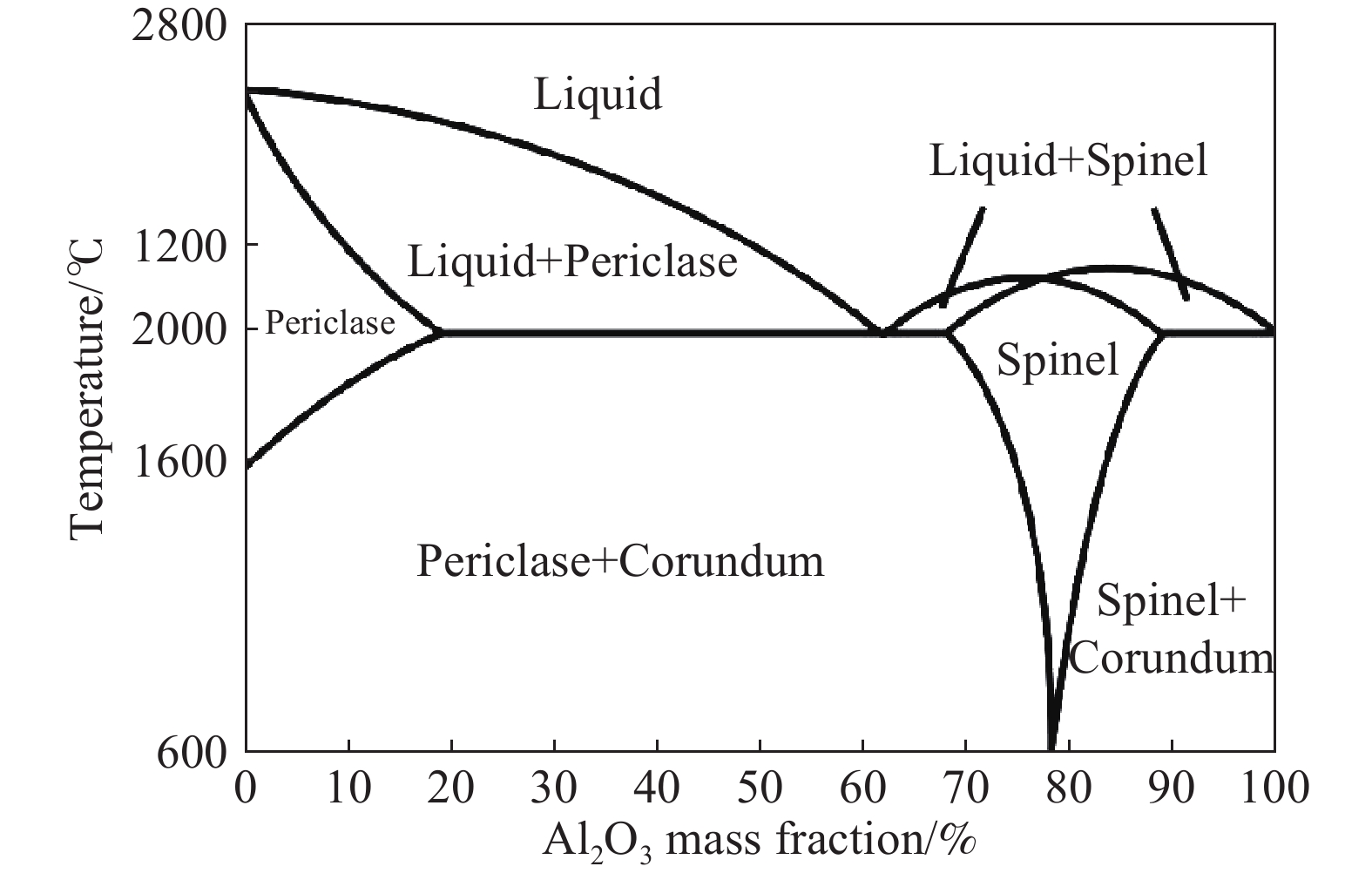

Mao H H, Selleby M, Sundman B. A re-evaluation of the liquid phases in the CaO–Al2O3 and MgO–Al2O3 systems. Calphad, 2004, 28(3): 307 doi: 10.1016/j.calphad.2004.09.001

|

| [27] |

Beketov I V, Medvedev A I, Samatov O M, et al. Synthesis and luminescent properties of MgAl2O4:Eu nanopowders. J Alloys Compd, 2014, 586(Suppl 1): S472

|

| [28] |

Yang L, Meng Q, Lu N, et al. Combustion synthesis and spark plasma sintering of MgAl2O4-graphene composites. Ceram Int, 2019, 45(6): 7635 doi: 10.1016/j.ceramint.2019.01.060

|

| [29] |

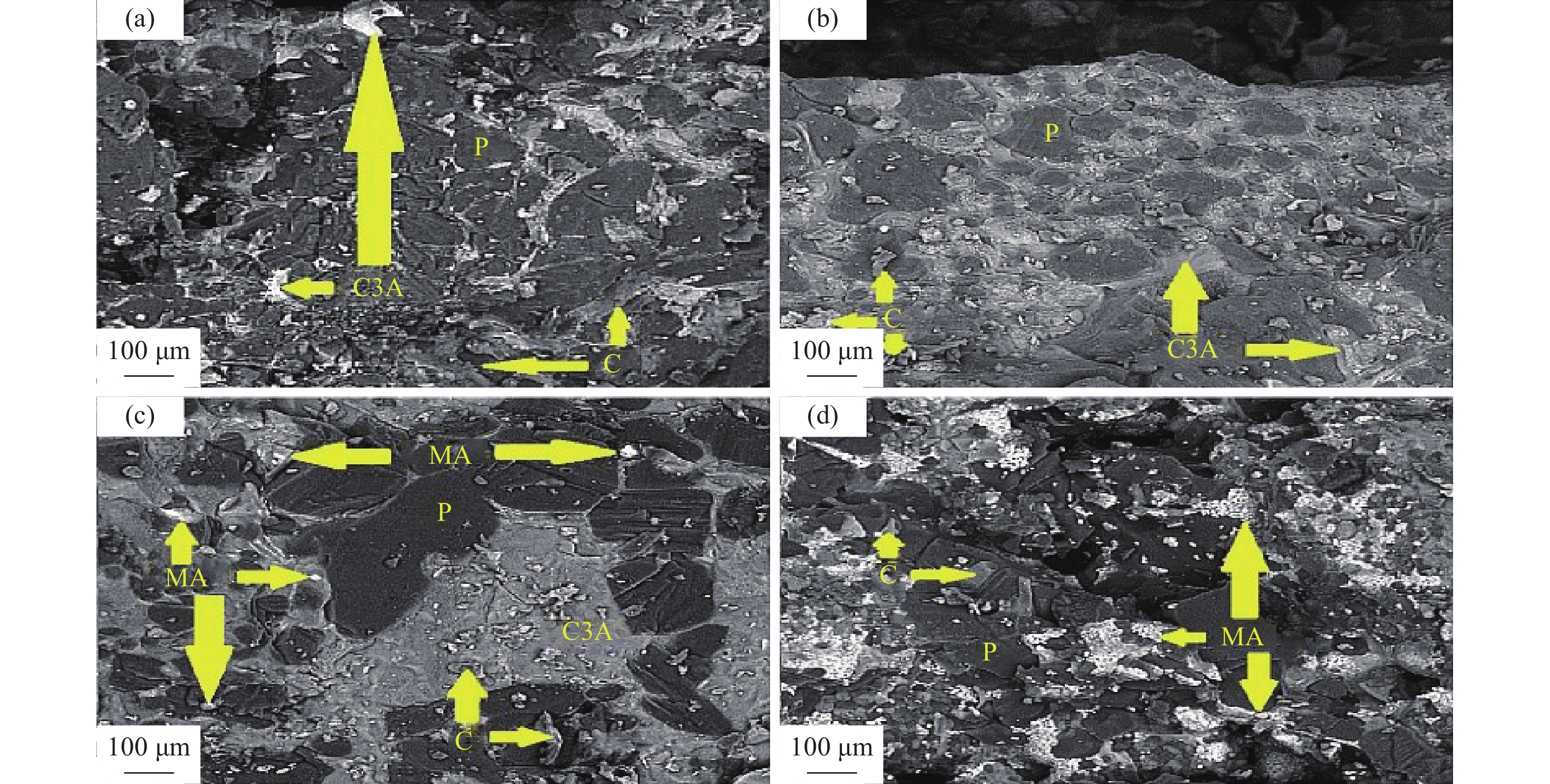

Tong S H, Zhao J Z, Zhang Y C, et al. Corrosion mechanism of Al–MgO–MgAl2O4 refractories in RH refining furnace during production of rail steel. Ceram Int, 2020, 46(8): 10089 doi: 10.1016/j.ceramint.2019.12.277

|

| [30] |

Hashimoto S, Honda S, Hiramatsu T, et al. Fabrication of porous spinel (MgAl2O4) from porous alumina using a template method. Ceram Int, 2013, 39(2): 2077 doi: 10.1016/j.ceramint.2012.08.062

|

| [31] |

Aksel C, Rand B, Riley F L, et al. Thermal shock behaviour of magnesia–spinel composites. J Eur Ceram Soc, 2004, 24(9): 2839 doi: 10.1016/j.jeurceramsoc.2003.07.017

|

| [32] |

Gu Q, Zhao F, Liu X H, et al. Preparation and thermal shock behavior of nanoscale MgAl2O4 spinel-toughened MgO-based refractory aggregates. Ceram Int, 2019, 45(9): 12093 doi: 10.1016/j.ceramint.2019.03.107

|

| [33] |

Sako E Y, Braulio M A L, Pandolfelli V C. How effective is the addition of nanoscaled particles to alumina–magnesia refractory castables? Ceram Int, 2012, 38(6): 5157 doi: 10.1016/j.ceramint.2012.03.021

|

| [34] |

Aksel C, Warren P D, Riley F L. Fracture behaviour of magnesia and magnesia–spinel composites before and after thermal shock. J Eur Ceram Soc, 2004, 24(8): 2407 doi: 10.1016/j.jeurceramsoc.2003.07.005

|

| [35] |

Shafiee H, Salehirad A, Samimi A. Effect of synthesis method on structural and physical properties of MgO/MgAl2O4 nanocomposite as a refractory ceramic. Appl Phys A, 2020, 126(3): 198 doi: 10.1007/s00339-020-3369-z

|

下載:

下載: