Characteristics and comparative analysis of compressive and shear strengths of modified high-water materials

-

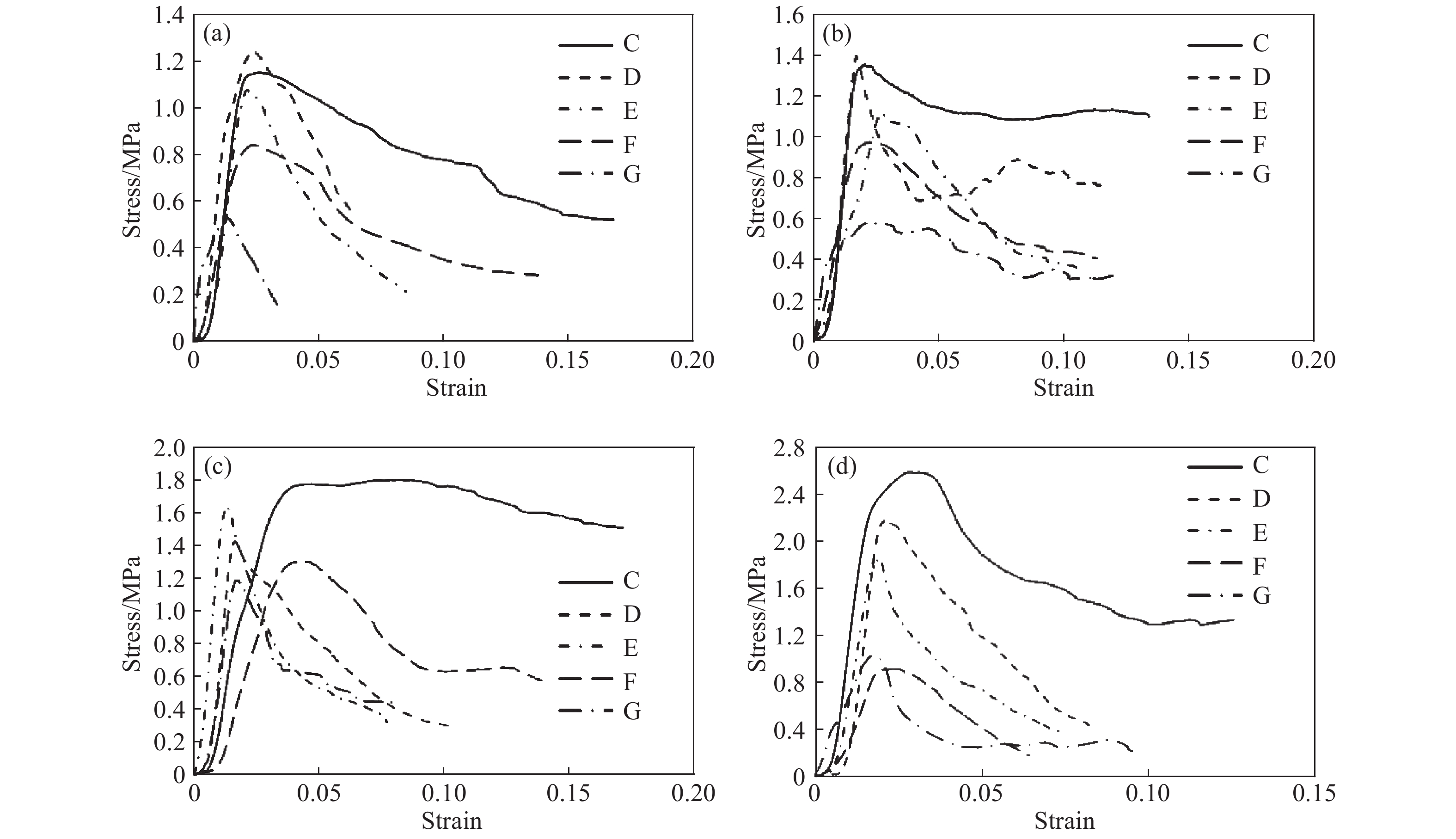

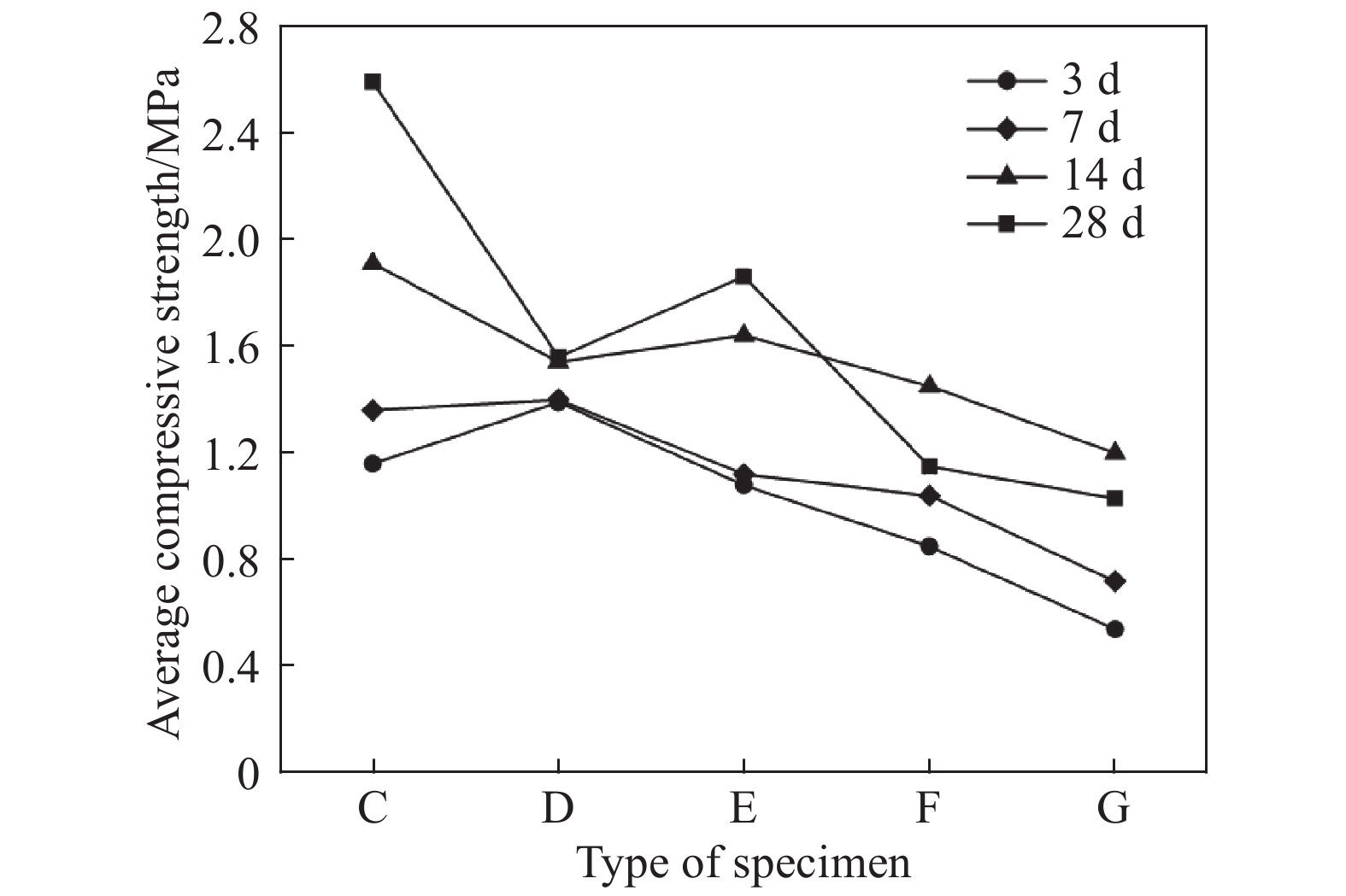

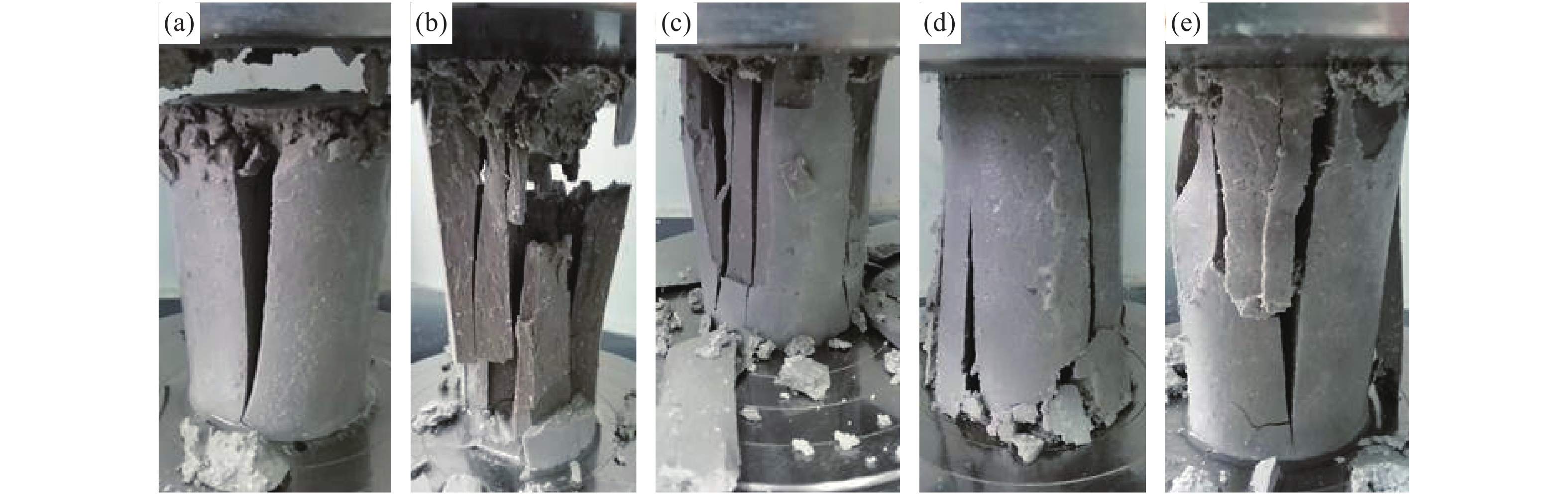

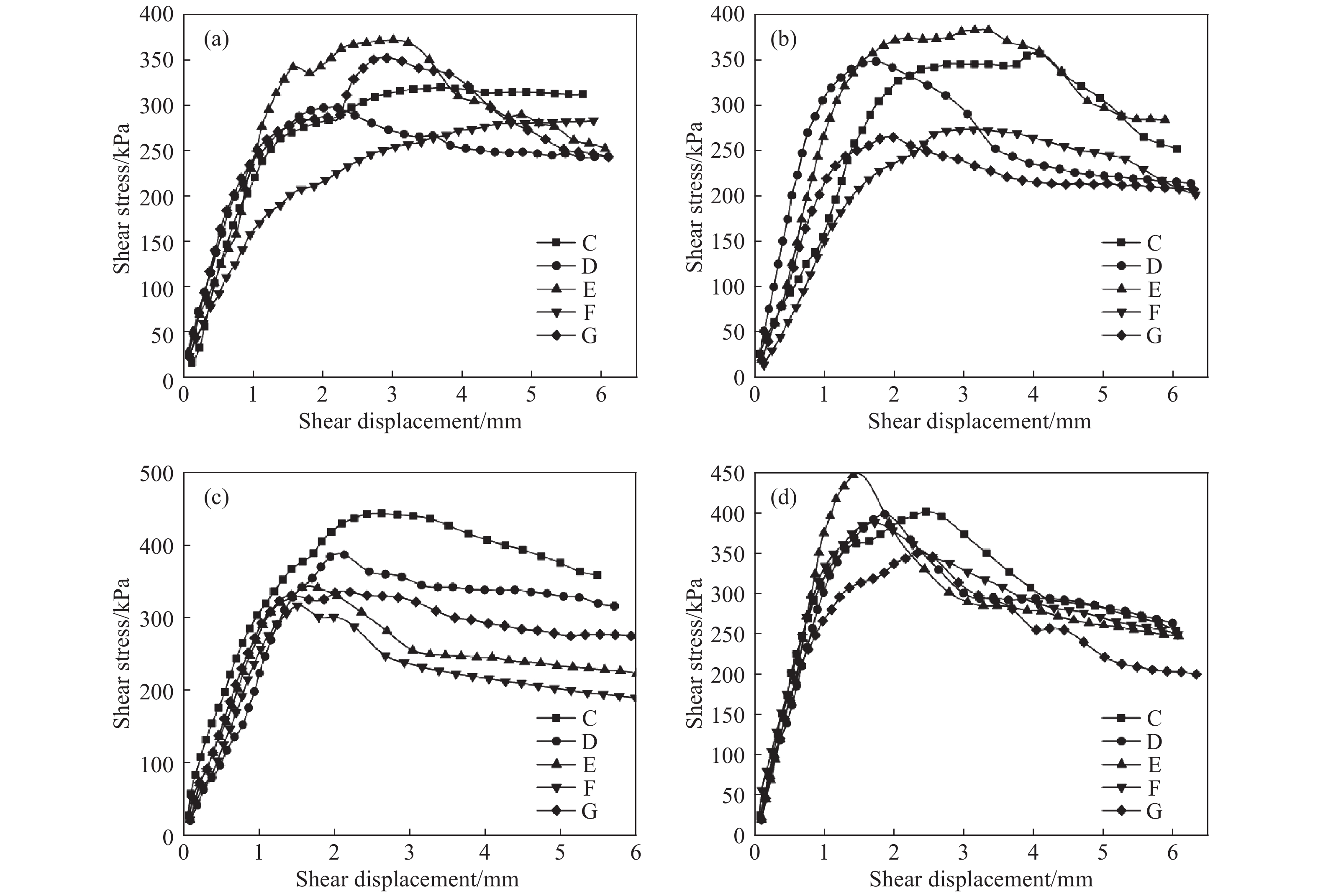

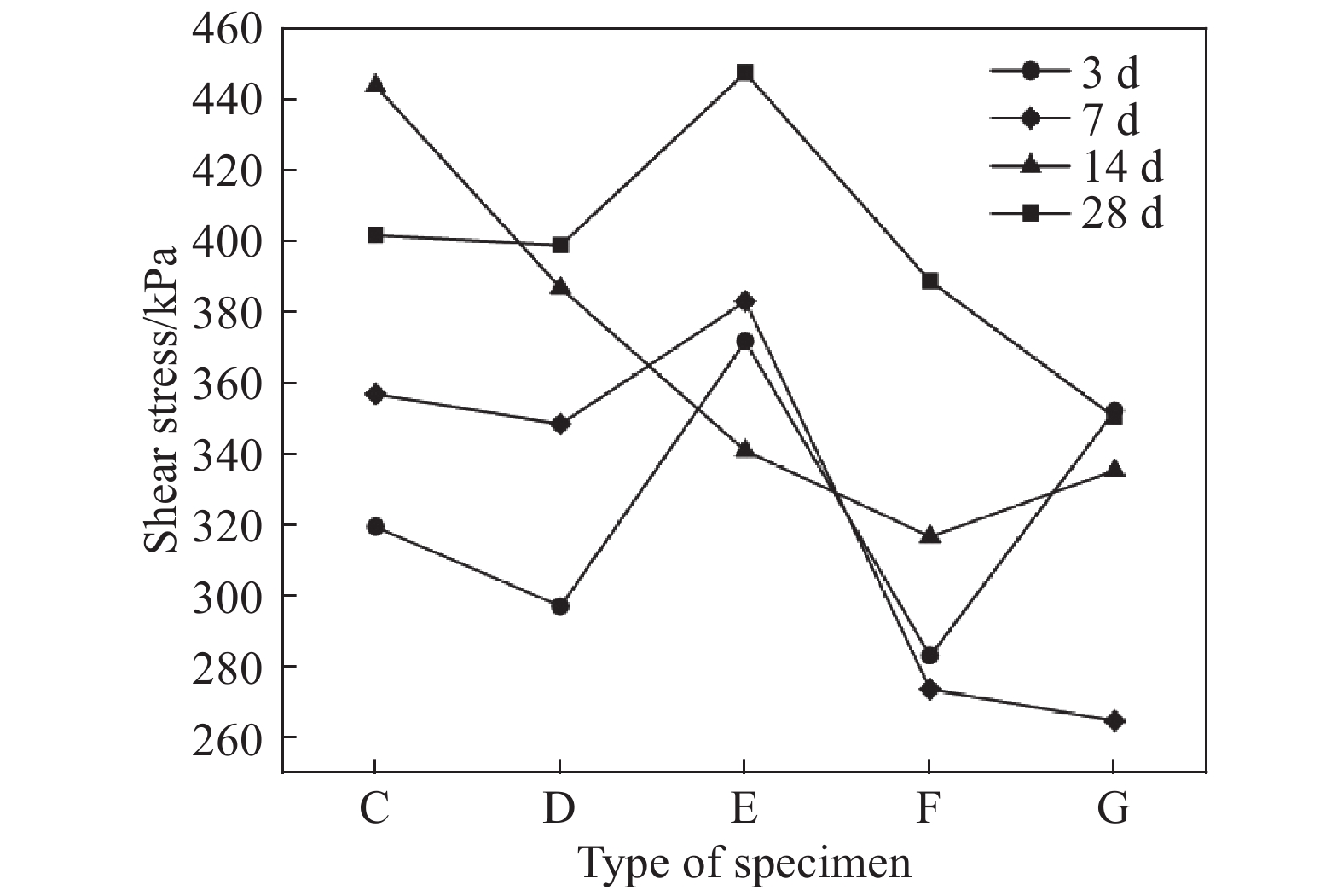

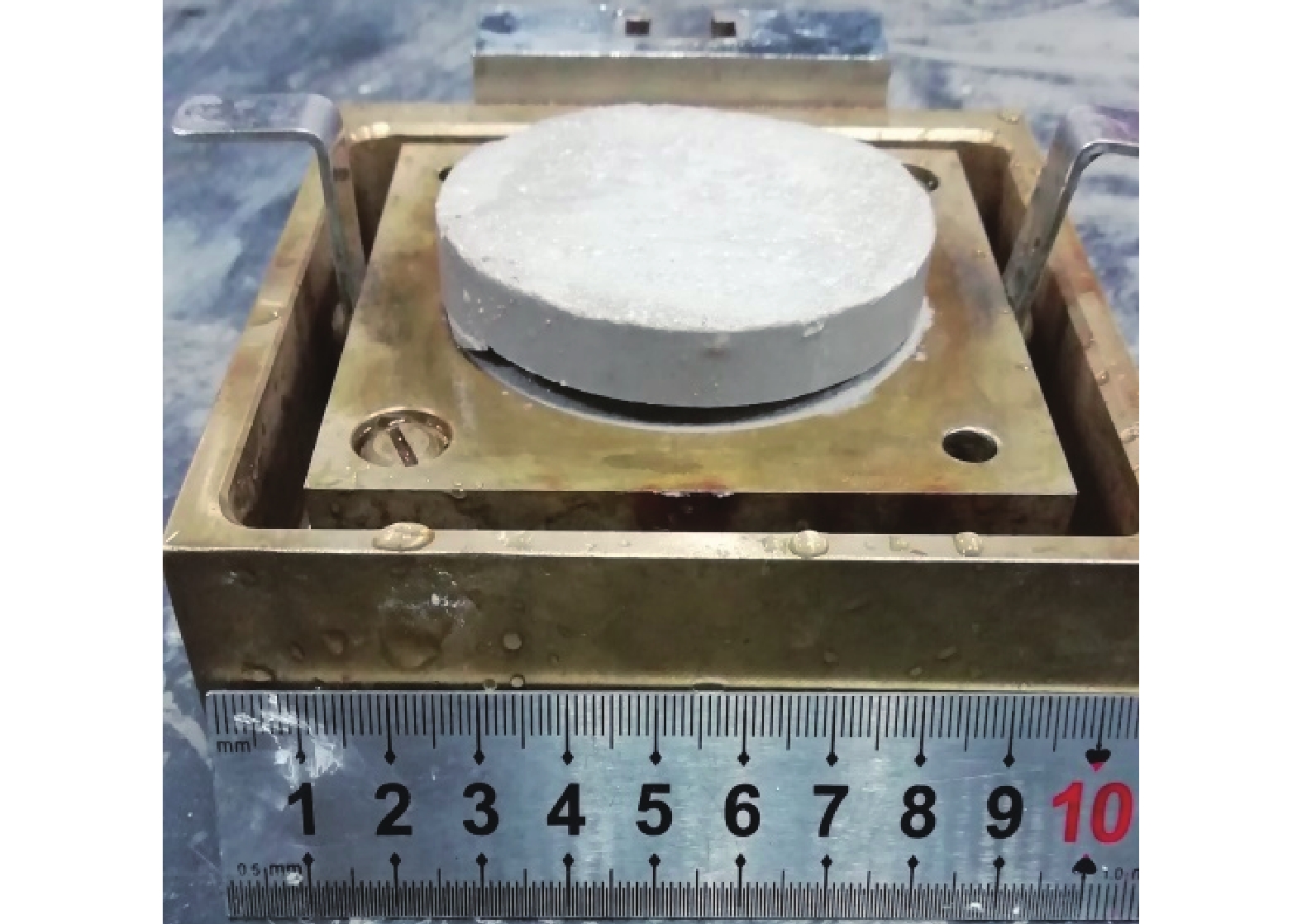

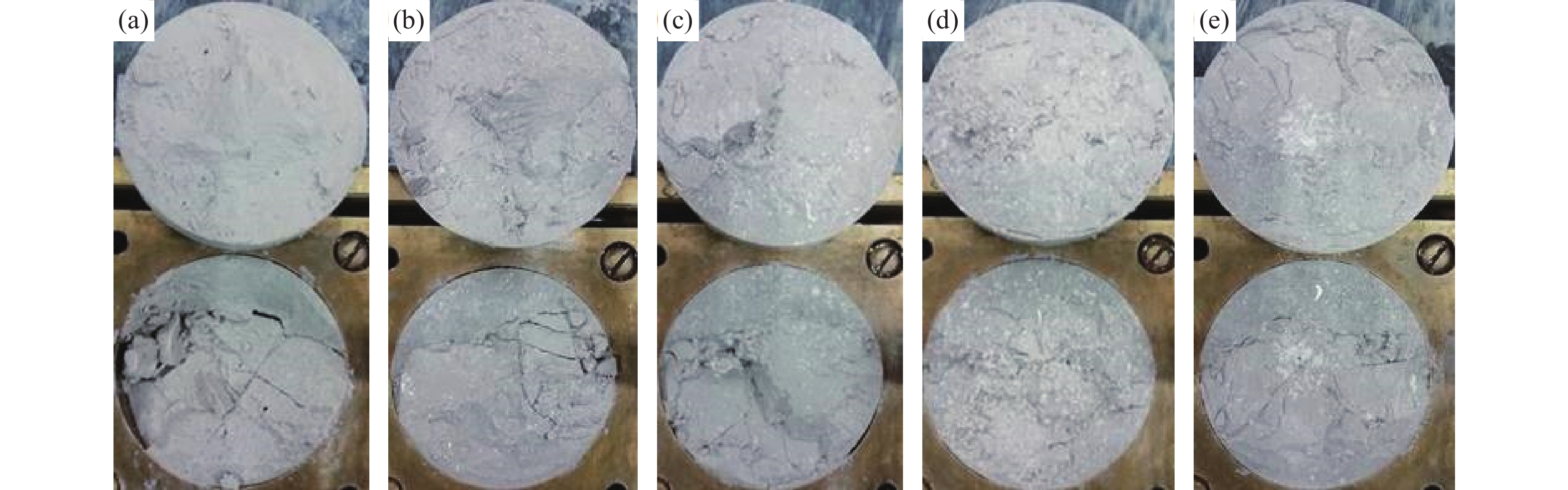

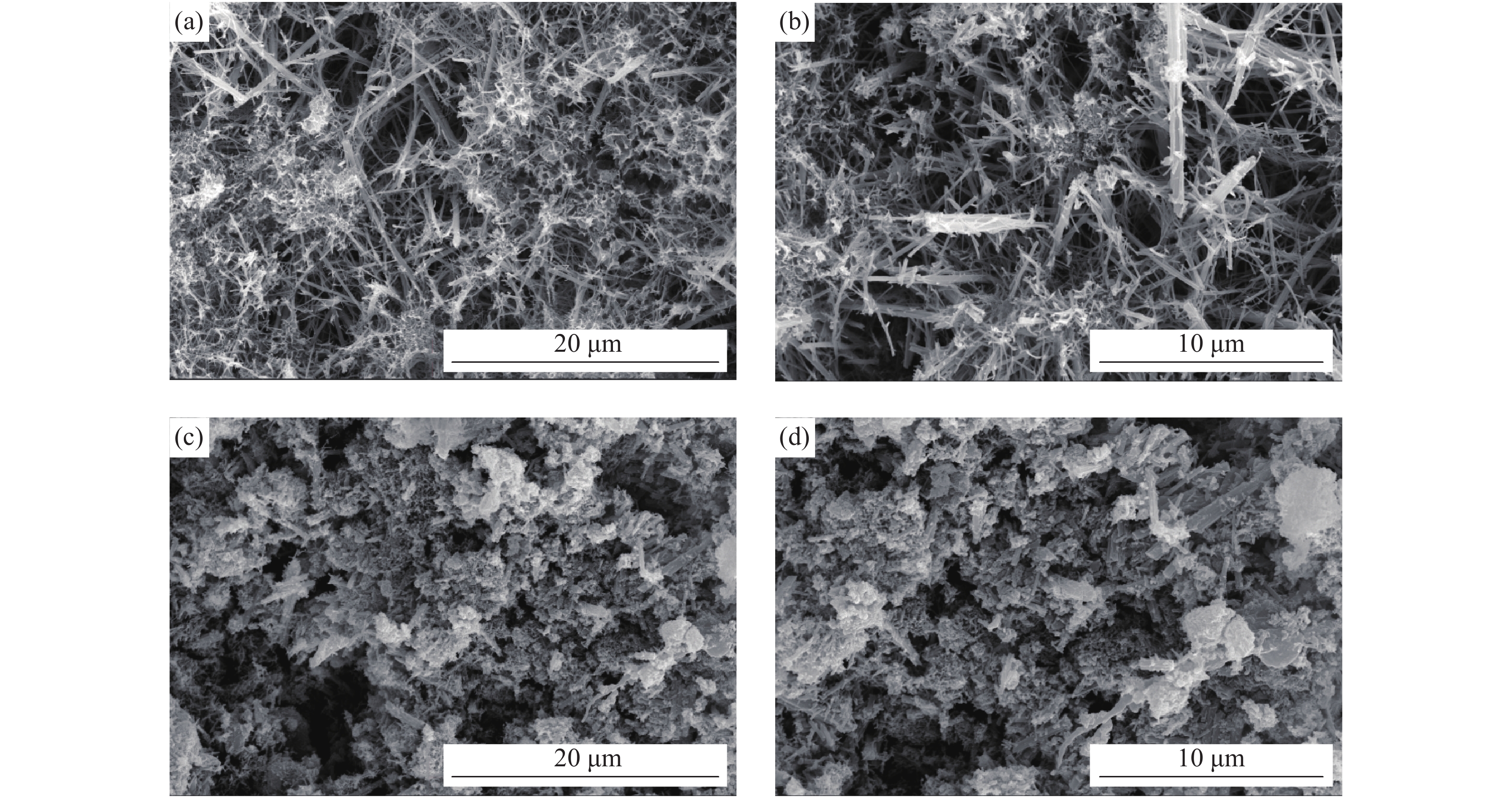

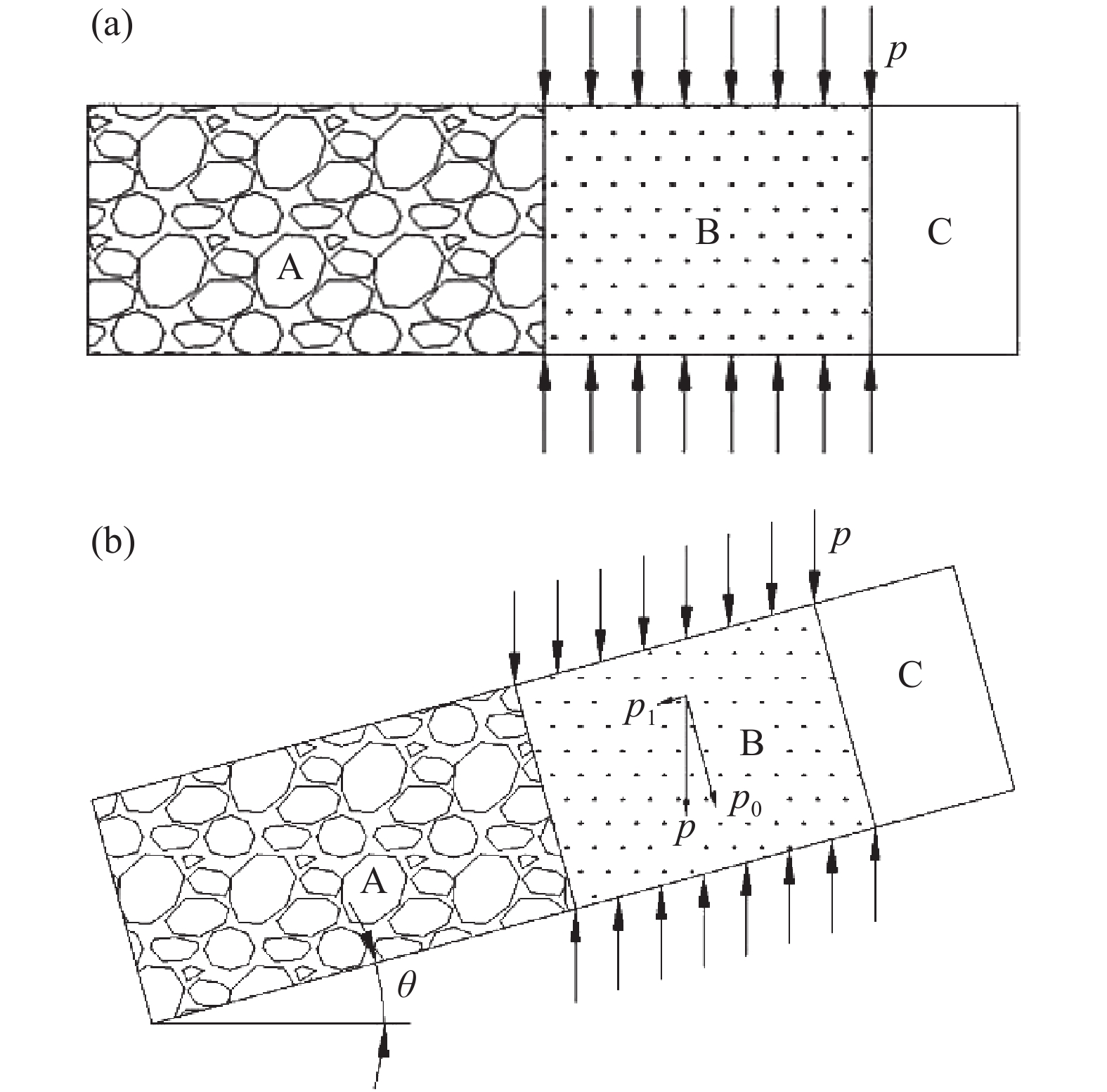

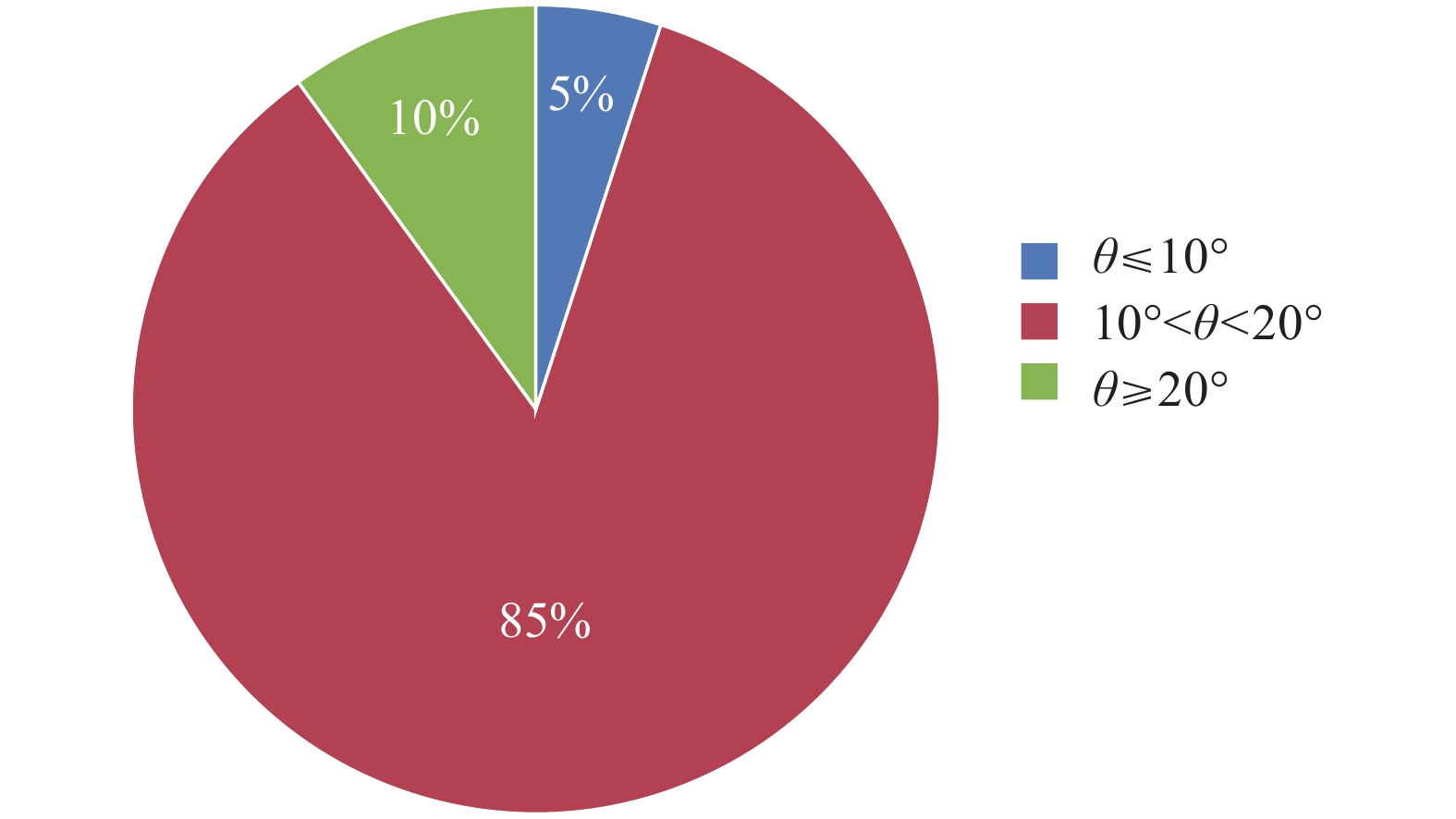

摘要: 以高水充填材料為載體,用聚乙烯塑料(PE)對其進行改性,研究了改性高水材料的抗壓、抗剪強度特征,并對結果進行了對比分析。結果表明:隨PE粉摻量的增加,改性高水材料的抗壓、抗剪強度均呈現降低的趨勢,改性高水材料各應力應變曲線與純高水材料有明顯區別,純高水材料的殘余強度更高,改性高水材料的殘余強度普遍較低,而剪切位移曲線變化不明顯;PE粉的加入明顯改變了材料的生成物形貌以及微觀結構,隨摻量的增加逐漸由纖維網狀結構向絮凝塊狀結構變化,而且生成物之間更容易形成尺寸較大的貫穿孔洞;改性高水材料的抗剪強度明顯低于抗壓強度,表明改性類高水充填材料不宜用于傾角較大的煤層。Abstract: Pollution from waste plastics has become one of today’s most serious environmental problems, and the recycling of waste plastics is a research hotspot. High-water materials are widely used in mine-filling operations, leak prevention, flame-retardant fire extinguishers, and other related applications due to their advantages of not blocking pipes, ease of pumping, high early strength, and environmental friendliness. These materials are also commonly referred to as high-water quick-setting materials and high-water filling materials. Despite their advantages, high-water materials also have some shortcomings in practical applications such as the need for a large volume of materials and their high engineering costs. Currently, research on waste-doped modified high-water materials has become an important focus in the development of high-water materials. Using this approach, waste can be treated effectively at a reduced cost by the appropriate replacement of materials. The high-water filling material modified with polyethylene plastic (PE) was used as a carrier. The compressive and shear strengths of the modified materials were determined, and the results were compared and analyzed. The results reveal that with increases in the PE powder content, the compressive and shear strengths of the modified high-water material exhibit a decreasing trend. The stress–strain curves of the modified high-water material obviously differ from those of unmodified high-water material. The residual strength of the unmodified material is higher, that of the modified high-water material is generally low, and no shear displacement curve is evident. The addition of PE powder obviously changes the morphology and microstructure of the material. With increasing PE content, the material gradually changes from having a fiber network structure to a flocculated block structure, in which the formation of larger through holes easily occurs between the products. The shear strength of the modified high-water material is significantly lower than the compressive strength, which indicates that the modified high-water filling is not suitable for coal seams with a large inclination.

-

Key words:

- waste plastic /

- high-water material /

- compressive strength /

- shear strength /

- micromorphology

-

表 1 材料配比表

Table 1. Material proportions

g Type of specemen Quality of material A Quality of material A–A Quality of material B Quality of material B–B Quality of PE Quality of water C 120 12 120 4.8 0 770.4 D 120 12 120 4.8 12.84 808.92 E 120 12 120 4.8 25.68 847.44 F 120 12 120 4.8 38.52 885.96 G 120 12 120 4.8 51.36 924.48 久色视频表 2 計算得到的θ值

Table 2. Calculated θ values

° Type of specimen Curing for

3 dCuring for

7 dCuring for

14 dCuring for

28 dC 15.4 14.7 13.1 8.8 D 12.1 14 14.1 14.3 E 19 18.9 11.7 13.5 F 18.4 14.7 12.3 18.7 G 33.1 20.2 15.6 18.8 -

參考文獻

[1] Sun H H, Song C Y. High water rapid setting material and its application. Xuzhou: China University of Mining and Technology Press, 1994孫恒虎, 宋存義. 高水速凝材料及其應用. 徐州: 中國礦業大學出版社, 1994 [2] Sun C D, Feng G M. Technology of retaining roadway along gob by stowing with high-water-content material. Coal Min Technol, 2010, 15(1): 58 doi: 10.3969/j.issn.1006-6225.2010.01.020孫春東, 馮光明. 新型高水材料巷旁充填沿空留巷技術. 煤礦開采, 2010, 15(1):58 doi: 10.3969/j.issn.1006-6225.2010.01.020 [3] Feng J H, Feng J. Extinguishing fire in the way of sealing and blocking goaf by high water material and fly ash. Saf Coal Mines, 2004, 35(4): 16 doi: 10.3969/j.issn.1003-496X.2004.04.006馮建華, 馮杰. 高水材料與粉煤灰封堵采空區滅火. 煤礦安全, 2004, 35(4):16 doi: 10.3969/j.issn.1003-496X.2004.04.006 [4] Sun X K, Wang W. Theoretical research on high water material replacement mining the strip coal pillar above confined aquifer. J China Coal Soc, 2011, 36(6): 909孫希奎, 王葦. 高水材料充填置換開采承壓水上條帶煤柱的理論研究. 煤炭學報, 2011, 36(6):909 [5] Gao J H. Application of grouting with high-water rapid hardening materials in soft rock reinforcement. Coal Min Technol, 2005, 10(4): 62 doi: 10.3969/j.issn.1006-6225.2005.04.026高江淮. 高水速凝材料注漿在軟巖加固中的應用實踐. 煤礦開采, 2005, 10(4):62 doi: 10.3969/j.issn.1006-6225.2005.04.026 [6] Hou L T, Tang J W, Jiang K H, et al. Basic characteristics of superabsorbent polymers and its application in port engineering. Port Waterway Eng, 2007(5): 54 doi: 10.3969/j.issn.1002-4972.2007.05.014侯林濤, 唐軍務, 蔣凱輝, 等. 高水材料的基本特性及其在港口工程中的應用. 水運工程, 2007(5):54 doi: 10.3969/j.issn.1002-4972.2007.05.014 [7] Feng B, Liu C W, Xie H, et al. Experimental study and analysis of the mechanical properties of high-water-content materials modified with fly ash. Chin J Eng, 2018, 40(10): 1187馮波, 劉長武, 謝輝, 等. 粉煤灰改性高水材料力學性能試驗研究及機理分析. 工程科學學報, 2018, 40(10):1187 [8] Chen H L, Wang Y P. Modification of clay material for high-water-material based on sulphoaluminate cement. Sichuan Build Sci, 2010, 36(2): 240 doi: 10.3969/j.issn.1008-1933.2010.02.062陳洪令, 王玉平. 粘土礦物對硫鋁酸鹽基高水材料的改性. 四川建筑科學研究, 2010, 36(2):240 doi: 10.3969/j.issn.1008-1933.2010.02.062 [9] Diao Z F, Liu C W, Sun W, et al. Experimental study on the doping and modification of high water filling material by using river sludge. Bull Chin Ceram Soc, 2018, 37(7): 2218刁兆豐, 劉長武, 孫位, 等. 河道污泥用于高水充填材料摻雜改性的試驗研究. 硅酸鹽通報, 2018, 37(7):2218 [10] Sun W, Liu C W, Wu F, et al. Experimental study on mechanical properties of polypropylene fiber high-water material. Met Mine, 2018(1): 53孫位, 劉長武, 吳帆, 等. 聚丙烯纖維高水材料力學性能的試驗研究. 金屬礦山, 2018(1):53 [11] Li P H. Research on the Composite Ash Filling Material Blending Coal Gangue and Flue Dust with the Superhigh-Water Material[Dissertation]. Xuzhou: China University of Mining and Technology, 2014李沛虹. 摻混煤矸石與煙道灰制超高水灰渣充填材料的研究[學位論文]. 徐州: 中國礦業大學, 2014 [12] Zhang L W, Liu C W, Diao Z F, et al. Strength characteristics and failure form of high-water-materials modified by slag of power plant. Sci Technol Eng, 2019, 19(10): 182 doi: 10.3969/j.issn.1671-1815.2019.10.028張連衛, 劉長武, 刁兆豐, 等. 電廠爐渣改性高水材料的強度特征與破壞形式. 科學技術與工程, 2019, 19(10):182 doi: 10.3969/j.issn.1671-1815.2019.10.028 [13] Lu Y H, Liu C W, Feng B, et al. Strength characteristics and mechanism analysis of high water content materials modified by silica fume. Bull Chin Ceram Soc, 2019, 38(9): 2737盧永虎, 劉長武, 馮波, 等. 硅灰改性高水材料的強度特征及機理分析. 硅酸鹽通報, 2019, 38(9):2737 [14] Geyer R, Jambeck J R, Law K L. Production, use, and fate of all plastics ever made. Sci Adv, 2017, 3(7): e1700782 doi: 10.1126/sciadv.1700782 [15] Jambeck J R, Geyer R, Wilcox C, et al. Plastic waste inputs from land into the ocean. Science, 2015, 347(6223): 768 doi: 10.1126/science.1260352 [16] Tu J. Application of recycled plastic building materials in modern home design. China Synthetic Resin Plastics, 2018, 35(6): 100 doi: 10.3969/j.issn.1002-1396.2018.06.022屠君. 再生塑料建材在現代家居設計中的應用. 合成樹脂及塑料, 2018, 35(6):100 doi: 10.3969/j.issn.1002-1396.2018.06.022 [17] Zhao Y C. Preparation and Basic Performance Studies of Recycled Plastic Foamed Concrete[Dissertation]. Maanshan: Anhui University of Technology, 2017趙育超. 再生塑料泡沫混凝土的制備與基本性能研究[學位論文]. 馬鞍山: 安徽工業大學, 2017 [18] Qian Y T, Shen B Q, Zhao Z H, et al. Study on the standardization of application of plastic recycling and regeneration in building materials. Quality Explor, 2018, 15(2): 76錢雨桐, 沈冰清, 趙之涵, 等. 塑料回收與再生在建筑材料中應用的標準化研究. 質量探索, 2018, 15(2):76 [19] Li A J. Study on mechanical properties of waste plastic powder cement concrete. Transpo World, 2012(3-4): 168李愛軍. 廢舊塑料粉水泥混凝土力學性能研究. 交通世界, 2012(3-4):168 [20] Zhang Z, Liu C W, Ye D Y, et al. Experimental study on modification of polyethylene plastic for high water filling materials. Min Res Dev, 2020, 40(5): 50張釗, 劉長武, 葉定陽, 等. 聚乙烯塑料用于高水充填材料改性試驗研究. 礦業研究與開發, 2020, 40(5):50 [21] Ministry of Water Resources of the People’s Republic of China. SL264—2001 Specifications for Rock Tests in Water Conservancy and Hydroelectric Engineering. Beijing: China Water Resources and Hydropower Press, 2001中華人民共和國水利部. SL264—2001水利水電工程巖石試驗規程. 北京: 中國水利水電出版社, 2001 [22] Ministry of Water Resources of the People’s Republic of China. SL237—1999 Specifications of Soil Test. Beijing: China Water Resources and Hydropower Press, 1999中華人民共和國水利部. SL237—1999土工試驗規程. 北京: 中國水利水電出版社, 1999 [23] Cao S G, Chen X Z, Yang H Y, et al. Analysis on roadside control technology of gob-side entry retaining and applicable conditions. Coal Sci Technol, 2016, 44(4): 27曹樹剛, 陳先哲, 楊紅運, 等. 沿空留巷巷旁控制技術及其適用條件分析. 煤炭科學技術, 2016, 44(4):27 [24] Gao Y G, Ma Q. Application research of high-water material gob-side entry retailing technology in Yunjialing 12303 working face. Coal Chem Ind, 2015, 38(9): 42高永格, 馬強. 高水材料沿空留巷技術在云駕嶺12303工作面中的應用研究. 煤炭與化工, 2015, 38(9):42 [25] Zhang H J, Ding K K. Studying and application of gob-side entry retaining high water material of rock burst mine. Coal Min Technol, 2017, 22(1): 77張紅軍, 丁可可. 突出礦井高水材料沿空留巷技術研究與應用. 煤礦開采, 2017, 22(1):77 -

下載:

下載: