Commercialization and future development of the solid oxide fuel cell (SOFC) in Europe

-

摘要: 固體氧化物燃料電池(SOFC)具有燃料適用范圍廣、能量轉換效率高(發電效率40%~60%,綜合能效≥80%)、全固態結構、模塊化組裝、零污染等優點,作為固定式或分布式發電可增強電網清潔供電的能力、安全性、可靠性和穩定性。SOFC具有多種不同的結構,其發電規模覆蓋幾十瓦至百兆瓦,可根據不同的應用場景選擇不同的結構,應用場景主要包括固定式發電、分布式供電、熱(冷)電聯供、交通車輛輔助動力電源等領域。國內的SOFC技術發展較晚,目前已取得一定的研究進展,并且能夠自主研發出十幾千瓦的SOFC發電系統,但與國際領先水平還有很大的差距,主要體現在輸出功率、生產成本及使用壽命等方面。歐洲的SOFC技術處于國際領先水平,具有一批成功實現產品化的公司,通過對其技術和產品的調研,可深入的了解歐洲SOFC技術現狀和發展趨勢,為國內SOFC技術的發展提供借鑒作用。Abstract: With the continuous consumption of fossil fuels, the increasingly serious problem of environmental pollution and increasing demand for electricity in China have forced the need to gradually increase the capacity of renewable energy technologies such as wind and photovoltaic power. The randomness and intermittence associated with in the generation of wind and photovoltaic power bring new challenges to the safety and stability of power-grid operations. With respect to the generation of either stationary or distributed power, the solid oxide fuel cell (SOFC) power-generation system can be designed according to the actual demands of specific users and effectively supplement shortages in the generation of centralized power, and thereby significantly improve the efficiency, reliability, and stability of the power supply. SOFCs have many advantages, including fuel flexibility, high energy-conversion efficiency (power-generation efficiency ranging of 40%–60%, comprehensive energy efficiency ≥80%), a whole solid structure, modular assembly, and near-zero pollution. SOFCs have a variety of different structures, and their power-generation scales range from tens of watts to hundreds of megawatts, with different structures selected for different application scenarios. These application scenarios mainly include fixed power generation, distributed power supply, combined heat (cold) and power supply, and auxiliary power units for traffic vehicles. SOFC technology in China has developed more recently than that in foreign countries and has made some progress. Manufacturers in China can independently develop SOFC power generation systems that produce more than 10 kW of power, but there remains a big gap between the systems developed in China and those developed by SOFC technology leaders elsewhere in the world, which is mainly reflected in the output power, production cost, and durability. Europe's SOFC technology is at the forefront, with a number of successful companies having realized effective products. Through the investigation of their technology and products, we can gain an in-depth understanding of the current situation and development trends of SOFC technology as a reference for improving China’s SOFC technology.

-

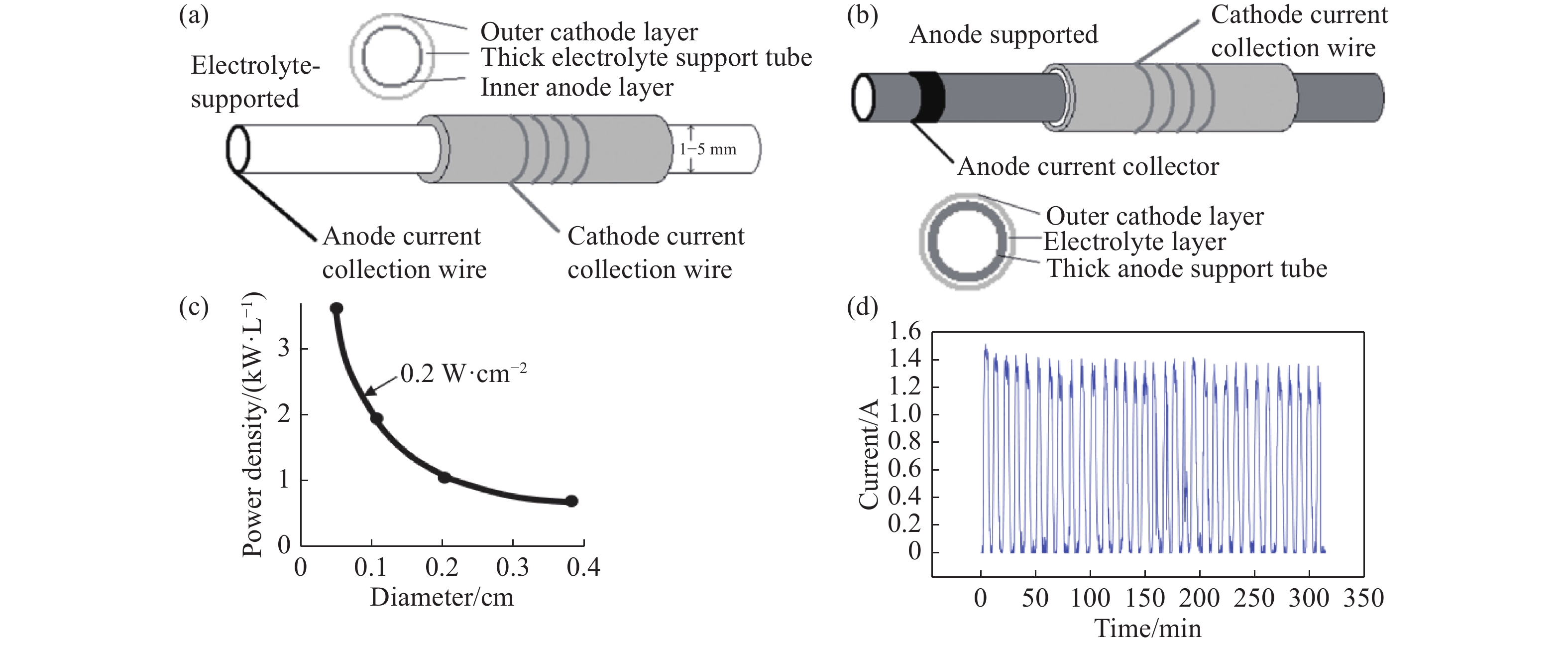

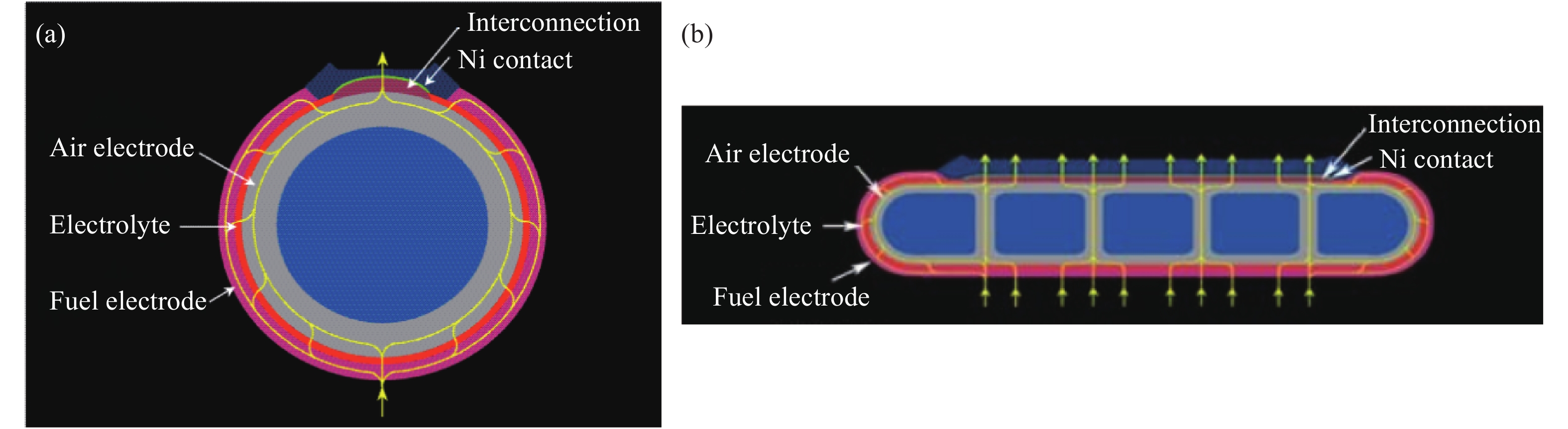

圖 4 微管式SOFC結構圖及性能曲線[5, 10-12]. (a)電解質支撐微管式SOFC結構示意圖;(b)陽極支撐蜂微管式SOFC結構示意圖;(c)管徑與輸出功率關系曲線;(d)微管式SOFC熱循環性能

Figure 4. Schematic diagrams and performance curve of microtubular SOFC[5, 10-12]: (a) schematic diagram of electrolyte-supported microtubular SOFC; (b) schematic diagram of anode-supported microtubular SOFC; (c) influence of pipe diameter on output power; (d) thermal cycling results for microtubular SOFC

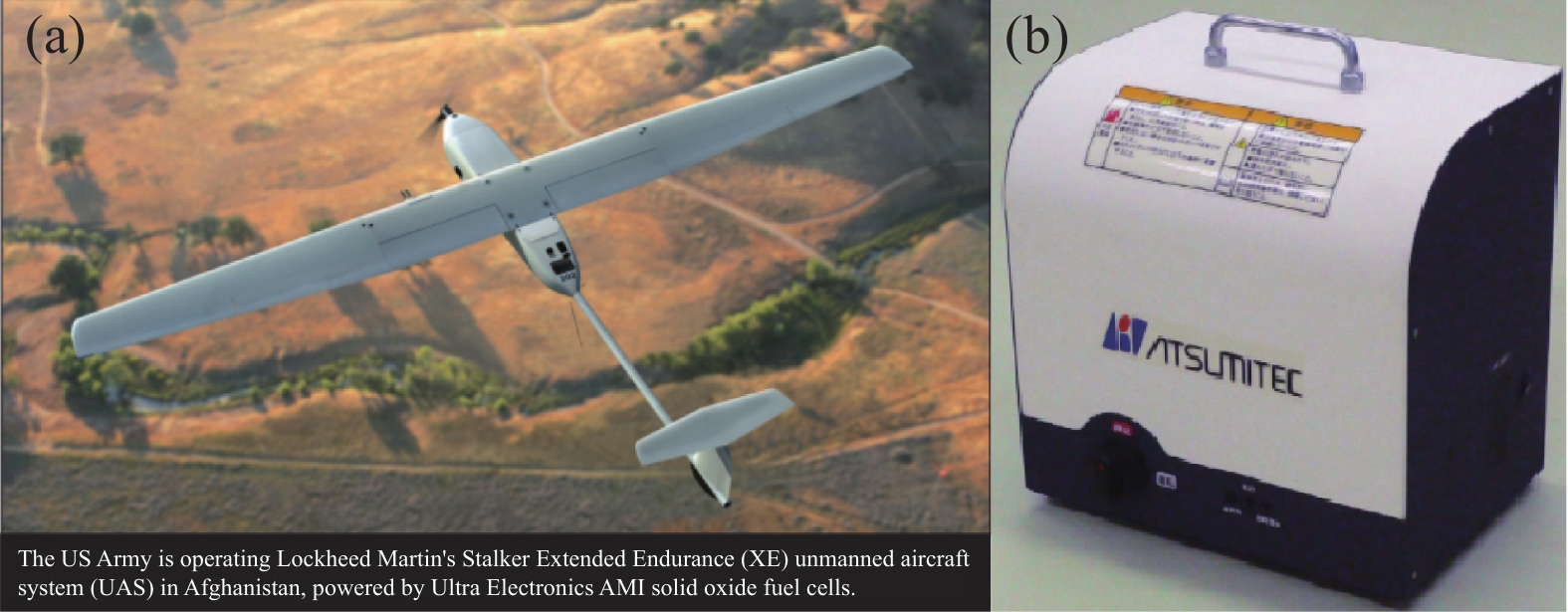

圖 8 微型SOFC發電系統。(a)Ultra Electronics AMI公司開發的ROAMIO D245XR燃料電池系統;(b)Atsumitec公司開發的100 W的便攜式SOFC發電系統[39-40]

Figure 8. Micro SOFC power generation systems: (a) ROAMIO D245XR fuel cell system developed by Ultra Electronics AMI; (b) 100 W portable SOFC power generation system developed by Atsumitec[39-40]

Country Company/Institution Concept Power achieved/kW USA Siemens-Westinghouse Tubular 220 Flatten-tubular 3.3 Delta 0.00041 Acumentrics Micro-tubular 0.25–10 Ultra Electronics AMI Micro-tubular 0.2–0.3 Japan Mitsubishi Heavy Industries, MHI Tubular 250 Segmented in series flatten-tubular 21 Kyocera Segmented in series flatten-tubular 3 Osaka Gas Flatten-tubular 0.7 Tokyo Gas Segmented in series flatten-tubular 3 TOTO Micro-tubular 3.2 UK Adelan Micro-tubular 0.2 表 2 平板式SOFC支撐結構、特點及部分廠家[15-16]

Table 2. Supported structures, features, and manufacturers of planar SOFCs[15-16]

Supported structures Illustration Features Manufacturers Electrolyte-supported

High operating temperatures required for sufficient oxygen ion conductivity; Relatively strong structural support; Less susceptible to failure due to anode re-oxidation; Higher resistance due to low electrolyte conductivity HEXIS, Bloom Energy, Sunfire Anode-supported

Lower operating temperature (<800 ℃) via

use of thin electrolytes; Highly conductive anode;

Mass transport limitation due to thick anodes;

Potential anode re-oxidationFuel Cell Energy (Versa Power), Delphi, Ceramic Fuel Cells, POSCO Energy Metal interconnect-supported

Lower operating temperature (<600 ℃); Stronger structures from metallic interconnects; Interconnect oxidation; Flowfield design limitation due to cell support requirement Ceres Power, Plansee,

Topsoe Fuel Cell久色视频Country Company/Institution Power achieved USA Delphi Automotive Systems 9 kW stack, system, and APU GE 50 kW stack and system Fuel Cell Energy 50 kW system LG Fuel Cell Systems 200 kW system Bloom Energy 100–300 kW system Denmark Topsoe 1–50 kW stack and system Finland Convion/W?rtsil? 58 kW system Elcogen 1 kW and 3 kW stack Switzerland Sulzer Hexis 1.5 kW system UK Ceres Power 1–30 kW stack and system Rolls Royce The target is a 1 MW power

generation systemGermany Sunfire 0.75–50 kW stack and system Italy SolidPower 1.5 kW and 2.5 kW system Japan Kansai Electric Power 10 kW system NGK Spark Plug Cells Murata Cells Korea POSCO energy 10 kW system Australia CFCL 1.5 kW system -

參考文獻

[1] Yi B L. Fuel Cell-Principle, Technology and Application. Beijing: Chemical Industry Press, 2003衣寶廉. 燃料電池: 原理·技術·應用. 北京: 化學工業出版社, 2003 [2] Yi B L. Fuel Cell-An Efficient and Environmentally Friendly Way to Generate Electricity. Beijing: Chemical Industry Press, 2000衣寶廉. 燃料電池—高效、環境友好的發電方式. 北京: 化學工業出版社, 2000 [3] Li J. Solid oxide fuel cells: development status and key technologies. J Funct Mater Devices, 2007, 13(6): 683 doi: 10.3969/j.issn.1007-4252.2007.06.032李箭. 固體氧化物燃料電池: 發展現狀與關鍵技術. 功能材料與器件學報, 2007, 13(6):683 doi: 10.3969/j.issn.1007-4252.2007.06.032 [4] Hassmann K. SOFC power plants, the Siemens‐Westinghouse approach. Fuel Cells, 2001, 1(1): 78 doi: 10.1002/1615-6854(200105)1:1<78::AID-FUCE78>3.0.CO;2-Q [5] Timurkutluk B, Timurkutluk C, Mat M D, et al. A review on cell/stack designs for high performance solid oxide fuel cells. Renewable Sustainable Energy Rev, 2016, 56: 1101 doi: 10.1016/j.rser.2015.12.034 [6] Suzuki T, Yamaguchi T, Fujishiro Y, et al. Improvement of SOFC performance using a microtubular, anode-supported SOFC. J Electrochem Soc, 2006, 153(5): A925 doi: 10.1149/1.2185284 [7] Zhang Y H, Liu J, Yin J, et al. Fabrication and performance of cone‐shaped segmented-in-series solid oxide fuel cells. Int J Appl Ceram Technol, 2008, 5(6): 568 doi: 10.1111/j.1744-7402.2008.02253.x [8] Wetzko M, Belzner A, Rohr F J, et al. Solid oxide fuel cell stacks using extruded honeycomb type elements. J Power Sources, 1999, 83(1-2): 148 doi: 10.1016/S0378-7753(99)00289-X [9] Yamaguchi T, Shimizu S, Suzuki T, et al. Fabrication and evaluation of a novel cathode-supported honeycomb SOFC stack. Mater Lett, 2009, 63(29): 2577 doi: 10.1016/j.matlet.2009.09.009 [10] Kendall K. Progress in microtubular solid oxide fuel cells. Int J Appl Ceram Technol, 2010, 7(1): 1 doi: 10.1111/j.1744-7402.2008.02350.x [11] Kendall K, Dikwal C M, Bujalski W. Comparative analysis of thermal and redox cycling for microtubular SOFCs. ECS Trans, 2007, 7(1): 1521 [12] Bujalski W, Dikwal C M, Kendall K. Cycling of three solid oxide fuel cell types. J Power Sources, 2007, 171(1): 96 doi: 10.1016/j.jpowsour.2007.01.029 [13] Vora S. Development of high power density seal-less SOFCs. ECS Trans, 2007, 7(1): 149 [14] Larminie J, Dicks A, McDonald M S. Fuel Cell Systems Explained. Chichester: J. Wiley, 2003 [15] Stolten D, Samsun R C, Garland N. Fuel Cells: Data, Facts, and Figures. New Jersey: Wiley-VCH, 2016 [16] Singnal S C, Kendall K. High Temperature Solid Oxide Fuel Cell: Fundamentals, Design and Applications. Beijing: Science Press, 2007 [17] Hickey D, Alinger M, Shapiro A, et al. Stack development at GE-fuel cells. ECS Trans, 2017, 78(1): 107 doi: 10.1149/07801.0107ecst [18] Mukerjee S, Haltiner K, Kerr R, et al. Latest update on Delphi's solid oxide fuel cell stack for transportation and stationary applications. ECS Trans, 2011, 35(1): 139 [19] Vora S D, Lundberg W L, Pierre J F. Overview of US department of energy office of fossil energy’s solid oxide fuel cell program. ECS Trans, 2017, 78(1): 3 doi: 10.1149/07801.0003ecst [20] Noponen M, Torri P, G??s J, et al. Status of solid oxide fuel cell development at elcogen. ECS Trans, 2015, 68(1): 151 doi: 10.1149/06801.0151ecst [21] Barrett S. Convion C50 product being validated for distributed generation. Fuel Cells Bull, 2015, 2015(4): 6 [22] Mai A, Fleischhauer F, Denzler R, et al. Progress in HEXIS’Development: Galileo 1000 N and HEXIS'Next Generation SOFC System. ECS Trans, 2017, 78(1): 97 doi: 10.1149/07801.0097ecst [23] Beale S. Precision engineering for future propulsion and power systems: a perspective from Rolls-Royce. Philos Trans R Soc A, 2012, 370(1973): 4130 doi: 10.1098/rsta.2011.0162 [24] Brabandt J, Posdziech O. System approach of a pressurized high-temperature electrolysis. ECS Trans, 2017, 78(1): 2987 doi: 10.1149/07801.2987ecst [25] Bertoldi M, Bucheli O, Ravagni A. Development, manufacturing and deployment of SOFC-based products at Solid power. ECS Trans, 2015, 68(1): 117 doi: 10.1149/06801.0117ecst [26] Inagaki T, Nishiwaki F, Yamasaki S, et al. Intermediate temperature solid oxide fuel cell based on lanthanum gallate electrolyte. J Power Sources, 2008, 181(2): 274 doi: 10.1016/j.jpowsour.2007.10.088 [27] Nirasawa H. Current status of national SOFC Projects in Japan. ECS Trans, 2017, 78(1): 33 doi: 10.1149/07801.0033ecst [28] Blum L, Meulenberg W A, Nabielek H, et al. Worldwide SOFC technology overview and benchmark. Int J Appl Ceram Technol, 2005, 2(6): 482 doi: 10.1111/j.1744-7402.2005.02049.x [29] EG&G Technical Services, Inc. Fuel Cell Handbook, 2004: 1 [30] Vora S D. SECA program overview and status. ECS Trans, 2013, 57(1): 11 doi: 10.1149/05701.0011ecst [31] Christiansen N, Primdahl S, Wandel M, et al. Status of the solid oxide fuel cell development at topsoe fuel cell A/S and DTU energy conversion. ECS Trans, 2013, 57(1): 43 doi: 10.1149/05701.0043ecst [32] Halinen M, Saarinen J, Noponen M, et al. Experimental analysis on performance and durability of SOFC demonstration unit. Fuel Cells, 2010, 10(3): 440 doi: 10.1002/fuce.200900152 [33] Nakanishi A, Hattori M, Sakaki Y, et al. Development of MOLB type SOFC. ECS Proc Vol, 2003, 2003: 53 [34] Carter J D, Cruse T A, Bae J M, et al. Bipolar plate-supported solid oxide fuel cells for auxiliary power units//2002 MRS Fall Meeting. Boston, 2003: 545 [35] Visco S J, Jacobson C P, Villareal I, et al. Development of low-cost alloy supported SOFCs. ECS Proc Vol, 2003, 2003: 1040 [36] Leah R T, Bone A, Hammer E, et al. Development progress on the ceres power steel cell technology platform: further progress towards commercialization. ECS Trans, 2017, 78(1): 87 doi: 10.1149/07801.0087ecst [37] Veyo S E, Shockling L A, Dederer J T, et al. Tubular solid oxide fuel cell/gas turbine hybrid cyclepower systems: status. J Eng Gas Turbines Power, 2002, 124(4): 845 doi: 10.1115/1.1473148 [38] Rechberger J, Kaupert A, Hagerskans J, et al. Demonstration of the first European SOFC APU on a heavy duty truck. Transp Res Procedia, 2016, 14: 3676 doi: 10.1016/j.trpro.2016.05.442 [39] Barrett S. AMI demos UGV power pod on iRobot PackBot. Fuel Cells Bull, 2009, 2009(11): 4 [40] Kachman D. Adaptive materials demonstrates fuel cell success in commercial markets. Fuel Cells Bull, 2013, 2013(12): 12 doi: 10.1016/S1464-2859(13)70423-1 [41] Tallgren J, Himanen O, Noponen M. Experimental characterization of low temperature solid oxide cell stack. ECS Trans, 2017, 78(1): 3103 doi: 10.1149/07801.3103ecst [42] Barrett S, Elcogen, Convion supply SOFC CHP systems to business district smart grid project in Finland. Fuel Cells Bull, 2018, 2018(2): 1 [43] Blennow P, Hjelm J, Klemens? T, et al. Manufacturing and characterization of metal-supported solid oxide fuel cells. J Power Sources, 2011, 196(17): 7117 doi: 10.1016/j.jpowsour.2010.08.088 [44] Barrett S, Ceres Power, Weichai finalise strategic collaboration, JV deal. Fuel Cells Bull, 2019, 2019(1): 11 [45] Barrett S, Ceres, Weichai Power develop first range-extender bus prototype. Fuel Cells Bull, 2019, 2019(10): 4 [46] Leah R T, Bone A, Selcuk A, et al. Latest results and commercialization of the CERES power Steelcell technology platform. ECS Trans, 2019, 91(1): 51 doi: 10.1149/09101.0051ecst [47] Barrett S, Solid power produces 1000th BlueGEN SOFC generator. Fuel Cells Bull, 2018, 2018(1): 6 [48] Barrett S, Solid power agrees German distribution with Bosch's Buderus. Fuel Cells Bull, 2018, 2018(7): 12 [49] Strohbach T, Mittmann F, Walter C, et al. Sunfire industrial SOC stacks and modules. ECS Trans, 2015, 68(1): 125 doi: 10.1149/06801.0125ecst [50] Zhu Y, Du C, Wang S, et al. Research progress on the stability of perovskite solar cells. Chin J Eng, 2020, 42(1): 16朱彧, 杜晨, 王碩, 等. 鈣鈦礦太陽能電池穩定性研究進展. 工程科學學報, 2020, 42(1):16 -

下載:

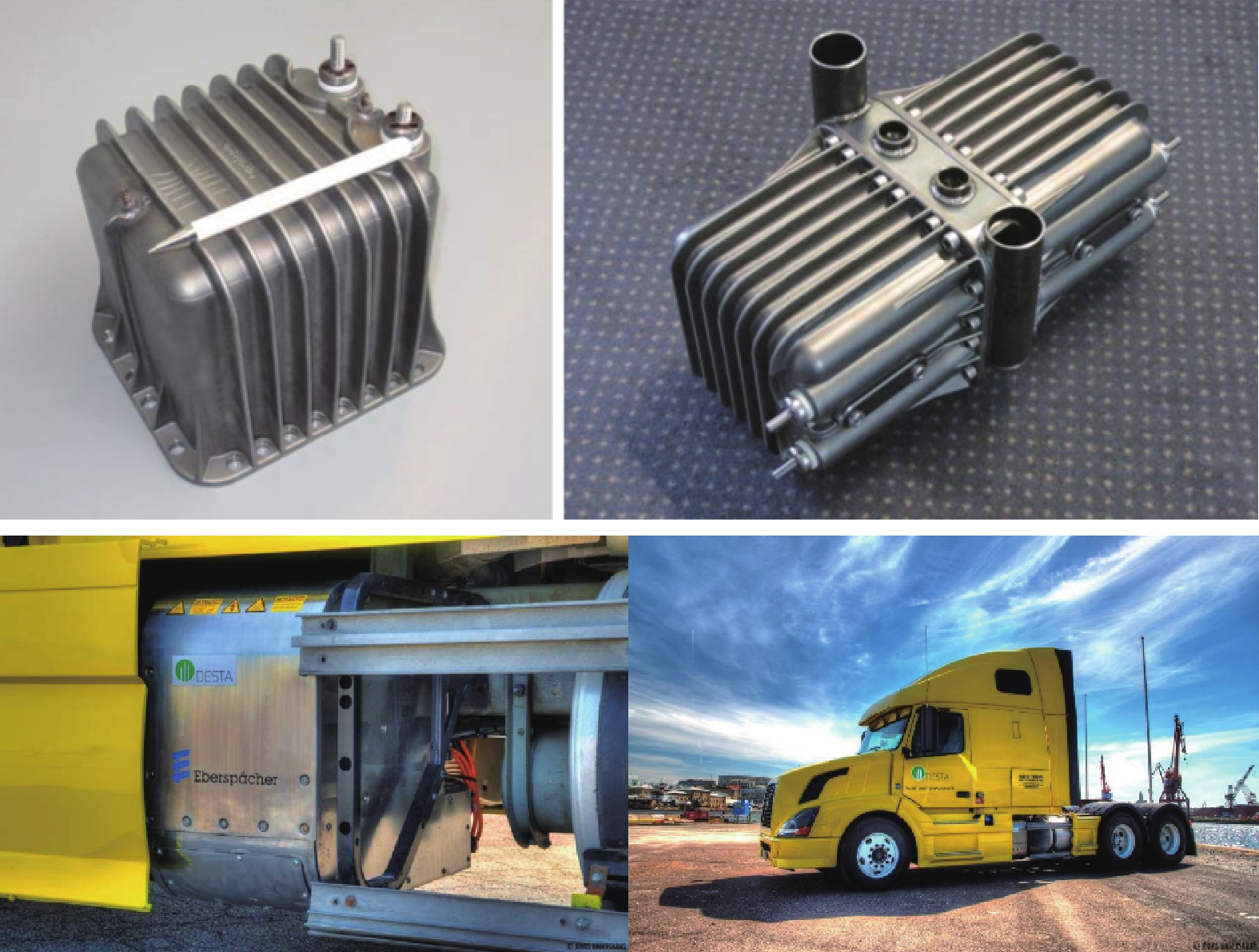

下載: