-

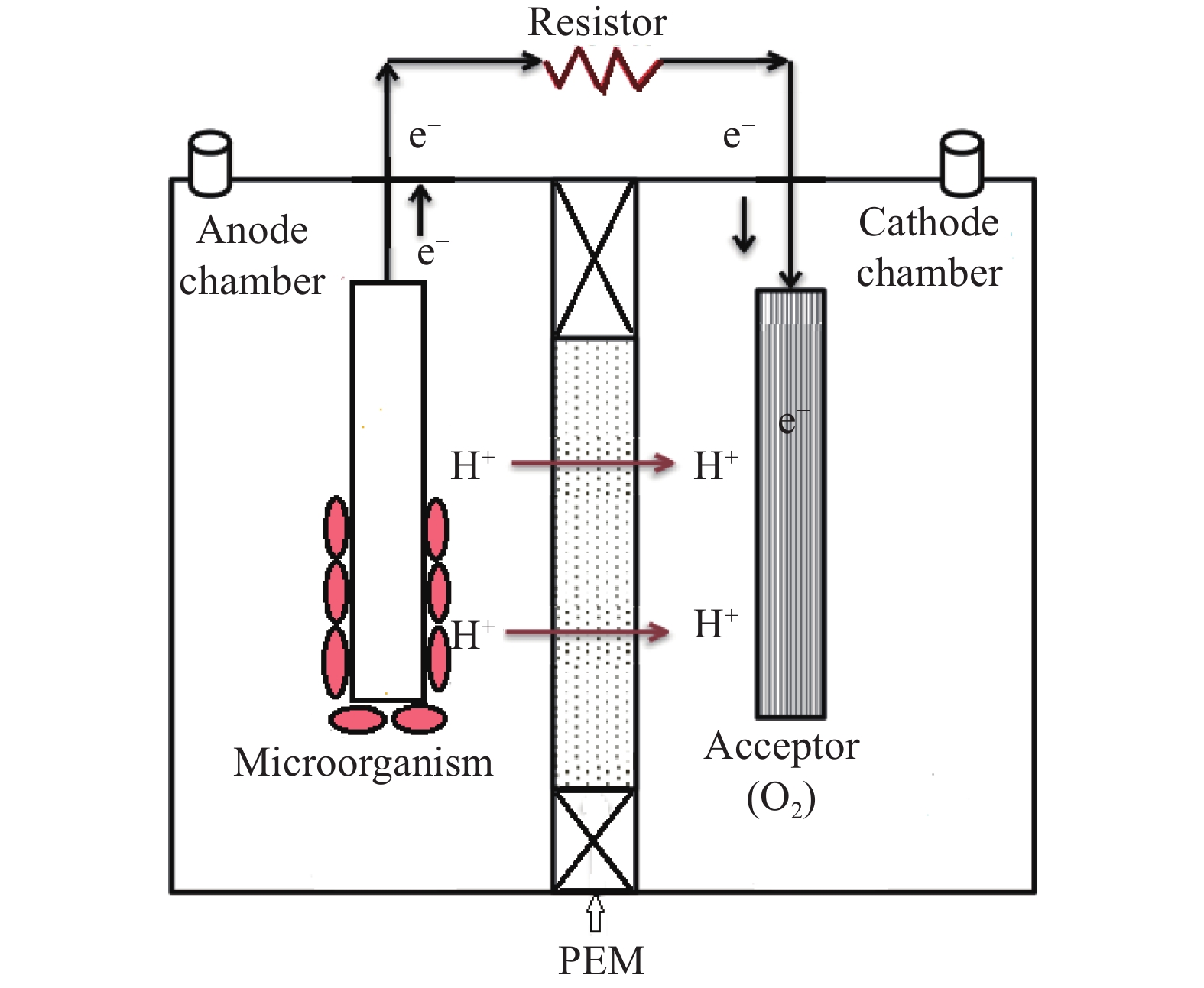

摘要: 微生物燃料電池(Microbial fuel cells, MFCs)是一種綠色能源技術,通過微生物的催化氧化代謝污水中的有機物同時產生電能,具有清潔環境和產電的雙重優勢,為可生物降解及可循環利用的廢棄物轉變成清潔能源提供了潛在的機會,在環境治理和能源利用方面表現出較好的應用前景。然而,目前相對較低的產電效率限制了MFCs的實際應用,其中陽極電極是產電微生物富集和傳遞電子的重要場所,與電池極化、電子導電性、生物相容性密切相關,是影響電池性能和運行成本的關鍵因素。碳納米材料具有導電性好、比表面積大、孔隙率高、成本低等特點,被認為是微生物燃料電池重要的陽極材料,得到了廣泛的研究和關注。本文主要從陽極電極種類、電極結構設計和電極材料改性等方面總結改善電極生物相容性、增加產電微生物附著量、提高反應活性位點的方法,并對提高產電性能的機理進行論述。最后對碳基電極材料進行展望,以期為制備高電化學活性的陽極材料提供理論指導。Abstract: The overuse of resources and the frequent occurrence of environmental problems have necessitated the use of sustainable energy technologies. The microbial fuel cell (MFC) is a kind of green energy-generation technology that metabolizes the organic compounds in wastewater by the catalytic oxidation of microorganisms. This new technology provides the dual advantages of cleaning the environment and generating electricity. As MFCs can potentially convert biodegradable and recyclable wastes into clean energy, they are a promising application prospect in environmental treatment and energy utilization. However, the practical applicability of present-day MFCs is limited by their low power-generation efficiency. Anode electrodes can enrich the power generation and electron transfer of microorganisms, but require high polarization, electronic conductivity, and biological compatibility with the fuel cell. Broadly speaking, the anode electrode affects the performance and operating costs of an MFC. Commonly used carbon-based materials include graphite sheets, carbon cloths, carbon paper, and carbon felt. However, most of these materials are two-dimensional structures providing few attachment sites for microorganisms; other materials have few reactive sites, which limits their electrochemical reactive surface areas and slows the initiation of the MFC. Carbon nanomaterials have been extensively researched for their high electrical conductivity, large specific surface area, high porosity, and low cost. All of these properties are demanded in the anode materials of MFCs. This paper summarized and analyzed methods for improving the biological compatibility of electrodes, increasing the adhesion of electrically-producing microorganisms, and improving the reactive activation sites. To this end, it discussed various types of anode electrodes, electrode structure designs, and electrode material modifications. A mechanism that improved the electricity generation performance was also discussed. Finally, carbon-based electrode materials might provide theoretical guidance for preparing anode materials with high electrochemical activity.

-

Key words:

- microbial fuel cell /

- anode electrode /

- carbon nanomaterials /

- electrode modification /

- biocompatibility

-

久色视频

表 1 納米材料修飾碳基電極的特點

Table 1. Characteristics of carbon-based electrode modified by nanomaterials

Name of nanomaterials Physicochemical and electrochemical properties Electron transfer mechanism Carbon-based synthetic materials:carbon nanotube; graphene; partially processed high performance carbon material Large specific surface area; good biocompatibility; good conductivity. Reduce the internal resistance of the electrode;

increase microbial enrichment.Nanomaterial modification:nano-metallic material; nano-conductive polymer High capacitance; good electron transfer intermediate; faster electron transfer rate;

good stability; good biocompatibility.The synergy between the metal and the anode; conductive polymers promote microbial adhesion; high conductivity facilitates electron transfer. -

參考文獻

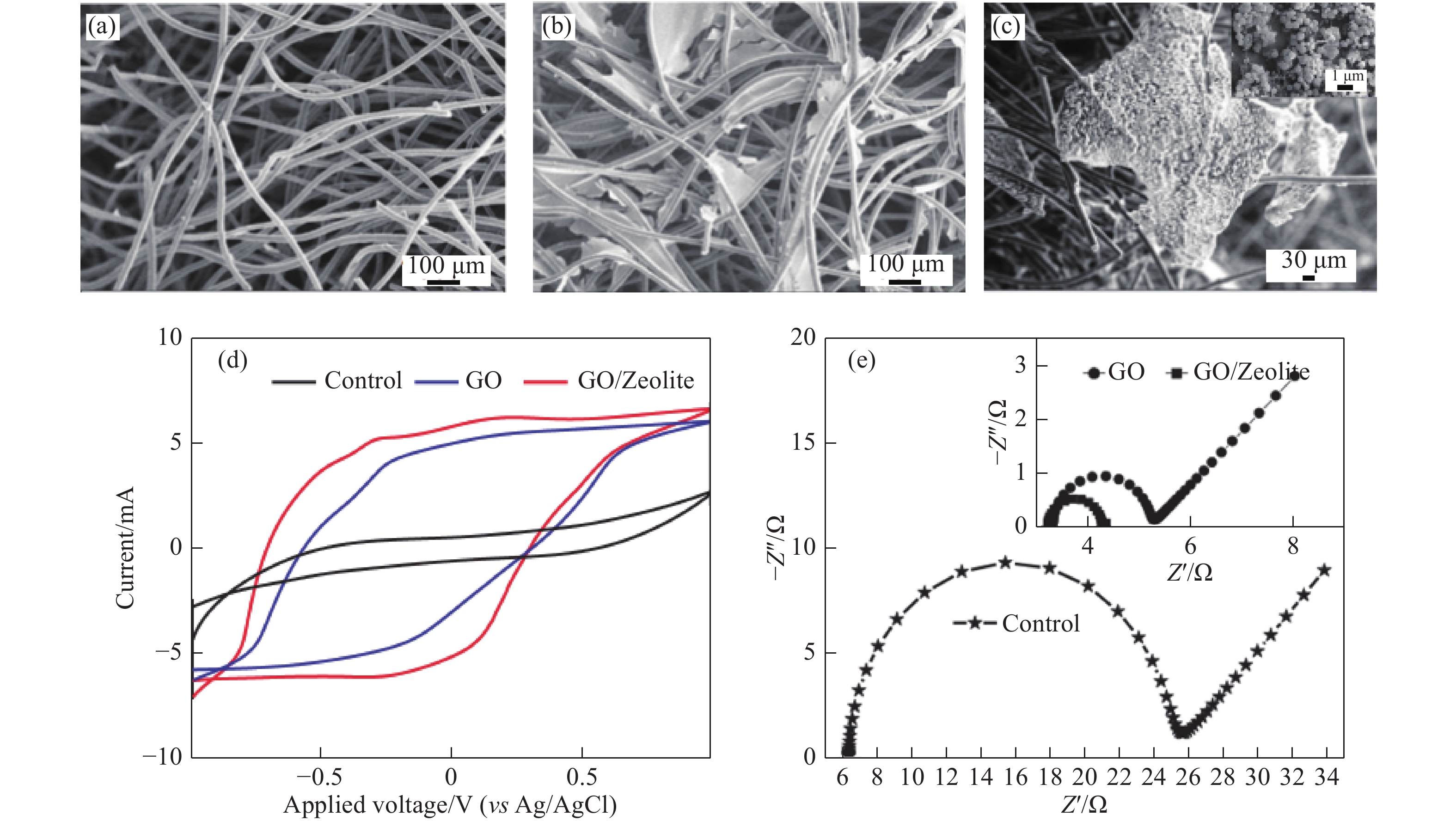

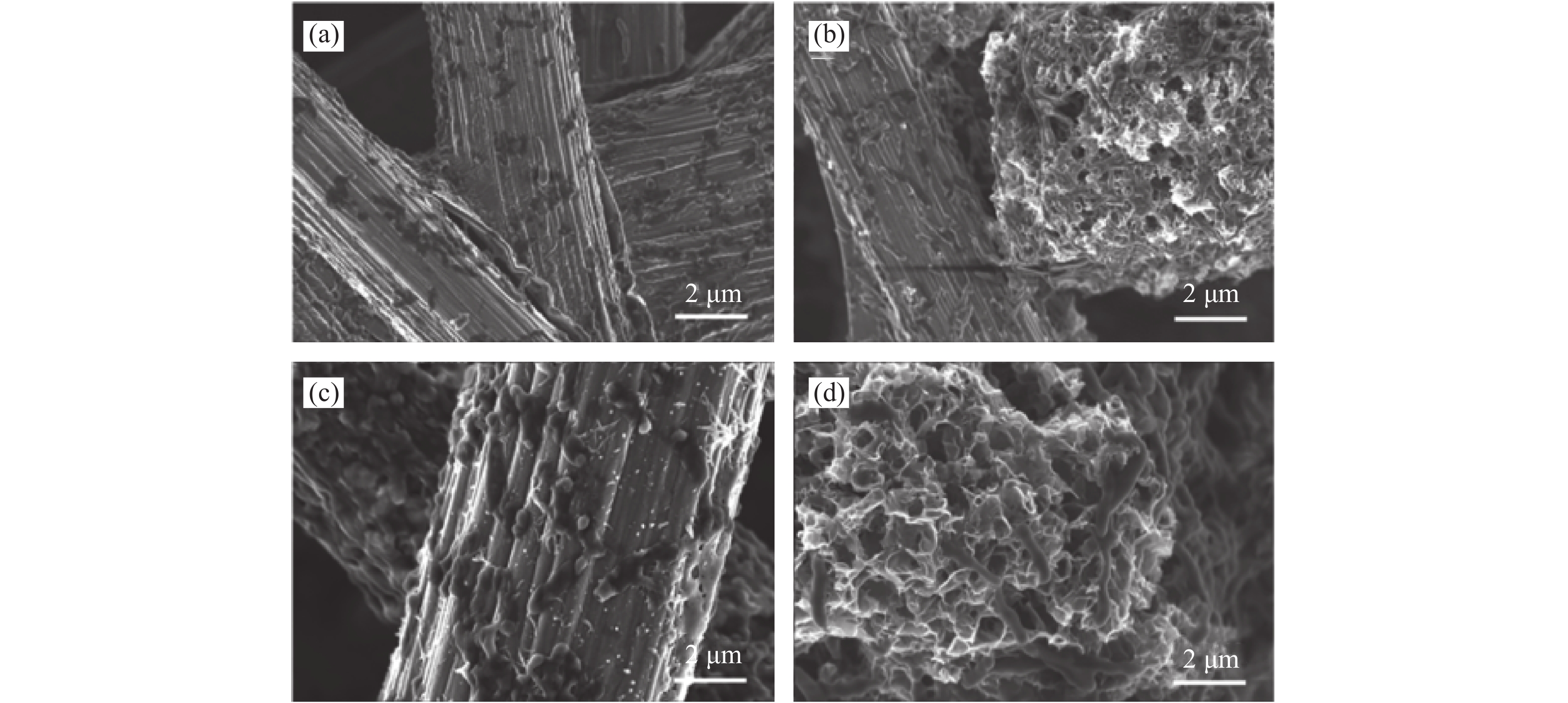

[1] Houghton J, Santoro C, Soavi F, et al. Supercapacitive microbial fuel cell: characterization and analysis for improved charge storage/delivery performance. Bioresour Technol, 2016, 218: 552 doi: 10.1016/j.biortech.2016.06.105 [2] Liu Y F, Wang Z Z, Liu J B, et al. Direct scarlet simulated wastewater treatment by microbial fuel cell. J Qingdao Univ Sci Technol Nat Sci Ed, 2016, 37(2): 180劉遠峰, 王在釗, 劉建波, 等. 微生物燃料電池處理直接大紅模擬廢水. 青島科技大學學報: 自然科學版, 2016, 37(2):180 [3] Liu Y F, Geng F H, Liu J B, et al. Study on treatment of copper-containing wastewater by microbial fuel cell. Environ Pollut Control, 2017, 39(2): 185劉遠峰, 耿鳳華, 劉建波, 等. 微生物燃料電池處理含銅廢水的研究. 環境污染與防治, 2017, 39(2):185 [4] Liu Y F, Sun W, Gong L. Effect of electron acceptors on electricity generation property of MFC. Environ Pollut Control, 2016, 38(11): 84劉遠峰, 孫偉, 宮磊. 電子受體對微生物燃料電池產電性能的影響. 環境污染與防治, 2016, 38(11):84 [5] Slate A J, Whitehead K A, Brownson D A C, et al. Microbial fuel cells: an overview of current technology. Renewable Sustainable Energy Rev, 2019, 101: 60 doi: 10.1016/j.rser.2018.09.044 [6] Sonawane J M, Yadav A, Ghosh P C, et al. Recent advantages in the development and utilization of modern anode materials for high performance microbial fuel cells. Biosens Bioelectron, 2017, 90: 558 doi: 10.1016/j.bios.2016.10.014 [7] Palanisamy G, Jung H Y, Sadhasivam T, et al. A comprehensive review on microbial fuel cell technologies: Processes, utilization, and advanced developments in electrodes and membranes. J Cleaner Prod, 2019, 221: 598 doi: 10.1016/j.jclepro.2019.02.172 [8] Zhang X L, Fan W, Li H, et al. Extending cycling life of lithium-oxygen batteries based on novel catalytic nanofiber membrane and controllable screen-printed method. J Mater Chem A, 2018, 6(43): 21458 [9] Knupp W G, Ribeiro M S, Mir M, et al. Dynamics of hydroxyapatite and carbon nanotubes interaction. Appl Surf Sci, 2019, 495: 143493 doi: 10.1016/j.apsusc.2019.07.235 [10] Zhang P, Liu J, Qu Y P, et al. Enhanced performance of microbial fuel cell with a bacteria/multi-walled carbon nanotube hybrid biofilm. J Power Sources, 2017, 361: 318 doi: 10.1016/j.jpowsour.2017.06.069 [11] Ma H Y, Xia T, Bian C C, et al. Bacterial electroactivity and viability depends on carbon nanotube-coated sponge anode used in a microbial fuel cell. Bioelectrochemistry, 2018, 122: 26 doi: 10.1016/j.bioelechem.2018.02.008 [12] Iftimie S, Dumitru A. Enhancing the performance of microbial fuel cells (MFCs) with nitrophenyl modified carbon nanotubes-based anodes. Appl Surf Sci, 2019, 492: 661 doi: 10.1016/j.apsusc.2019.06.241 [13] Guan L L, Lu J H, Lian F. Mesoporous composite of core-shell FeS_2micron spheres with multi-walled CNTs and its application in lithium ion batteries. Chin J Eng, 2019, 41(4): 489官亮亮, 魯建豪, 連芳. 具有核殼結構的FeS_2微米球與碳納米管原位復合介孔材料的構建及其在鋰離子電池中的應用. 工程科學學報, 2019, 41(4):489 [14] Pareek A, Sravan J S, Mohan S V. Fabrication of three-dimensional graphene anode for augmenting performance in microbial fuel cells. Carbon Resour Convers, 2019, 2(2): 134 doi: 10.1016/j.crcon.2019.06.003 [15] Zhou L F, Qiu H M, Xu M, et al. Synthesis and electrochemical properties of graphene/MnO2 composites. Chin J Eng, 2016, 38(9): 1300周龍斐, 邱紅梅, 徐美, 等. 石墨烯/二氧化錳復合材料的制備及其電化學性能. 工程科學學報, 2016, 38(9):1300 [16] Zhou S W, Lin M, Zhang Z C, et al. Biosynthetic graphene enhanced extracellular electron transfer for high performance anode in microbial fuel cell. Chemosphere, 2019, 232: 396 doi: 10.1016/j.chemosphere.2019.05.191 [17] Huang L H, Li X F, Ren Y P, et al. In-situ modified carbon cloth with polyaniline/graphene as anode to enhance performance of microbial fuel cell. Int J Hydrogen Energy, 2016, 41(26): 11369 doi: 10.1016/j.ijhydene.2016.05.048 [18] Paul D, Noori M T, Rajesh P P, et al. Modification of carbon felt anode with graphene oxide-zeolite composite for enhancing the performance of microbial fuel cell. Sustainable Energy Technol Assessments, 2018, 26: 77 doi: 10.1016/j.seta.2017.10.001 [19] Yu F, Wang C, Ma J. Capacitance-enhanced 3D graphene anode for microbial fuel cell with long-time electricity generation stability. Electrochim Acta, 2018, 259: 1059 doi: 10.1016/j.electacta.2017.11.038 [20] Zhang L J, He W H, Yang J C, et al. Bread-derived 3D macroporous carbon foams as high performance free-standing anode in microbial fuel cells. Biosens Bioelectron, 2018, 122: 217 doi: 10.1016/j.bios.2018.09.005 [21] Lan L H, Li J, Feng Q, et al. Enhanced current production of the anode modified by microalgae derived nitrogen-rich biocarbon for microbial fuel cells. Int J Hydrogen Energy, 2019, 45: 3833 [22] Chen Q, Pu W H, Hou H J, et al. Activated microporous-mesoporous carbon derived from chestnut shell as a sustainable anode material for high performance microbial fuel cells. Bioresour Technol, 2018, 249: 567 doi: 10.1016/j.biortech.2017.09.086 [23] Chang S H, Liou J S, Liu J L, et al. Feasibility study of surface-modified carbon cloth electrodes using atmospheric pressure plasma jets for microbial fuel cells. J Power Sources, 2016, 336: 99 doi: 10.1016/j.jpowsour.2016.10.058 [24] Zhang X L, Fan W, Zhao S Y, et al. An efficient, bifunctional catalyst for lithium-oxygen batteries obtained through tuning the exterior Co2+/Co3+ ratio of CoOx on N-doped carbon nanofibers. Catal Sci Technol, 2019, 9: 1998 doi: 10.1039/C9CY00477G [25] Wei J C, Liang P, Huang X. Recent progress in electrodes for microbial fuel cells. Bioresour Technol, 2011, 102(20): 9335 doi: 10.1016/j.biortech.2011.07.019 [26] Hindatu Y, Annuar M S M, Gumel A M. Mini-review: Anode modification for improved performance of microbial fuel cell. Renewable Sustainable Energy Rev, 2017, 73: 236 doi: 10.1016/j.rser.2017.01.138 [27] Yu B, Li Y H, Feng L. Enhancing the performance of soil microbial fuel cells by using a bentonite-Fe and Fe3O4 modified anode. J Hazard Mater, 2019, 377: 70 doi: 10.1016/j.jhazmat.2019.05.052 [28] Zeng L Z, Zhang W G, Xia P, et al. Porous Ni0.1Mn0.9O1.45 microellipsoids as high-performance anode electrocatalyst for microbial fuel cells. Biosens Bioelectron, 2018, 102: 351 doi: 10.1016/j.bios.2017.11.046 [29] Taskan E, Bulak S, Taskan B, et al. Nitinol as a suitable anode material for electricity generation in microbial fuel cells. Bioelectrochemistry, 2019, 128: 118 doi: 10.1016/j.bioelechem.2019.03.008 [30] Xu H D, Quan X C, Xiao Z T, et al. Effect of anodes decoration with metal and metal oxides nanoparticles on pharmaceutically active compounds removal and power generation in microbial fuel cells. Chem Eng J, 2018, 335: 539 doi: 10.1016/j.cej.2017.10.159 [31] Sekar A D, Jayabalan T, Muthukumar H, et al. Enhancing power generation and treatment of dairy waste water in microbial fuel cell using Cu-doped iron oxide nanoparticles decorated anode. Energy, 2019, 172: 173 doi: 10.1016/j.energy.2019.01.102 [32] Quan X C, Xu H D, Sun B, et al. Anode modification with palladium nanoparticles enhanced Evans Blue removal and power generation in microbial fuel cells. Int Biodeterior Biodegrad, 2018, 132: 94 doi: 10.1016/j.ibiod.2018.01.001 [33] Pu K B, Ma Q, Cai W F, et al. Polypyrrole modified stainless steel as high performance anode of microbial fuel cell. Biochem Eng J, 2018, 132: 255 doi: 10.1016/j.bej.2018.01.018 [34] Nie J T, Guo M, Zhang M, et al. Electrodeposition of polyaniline nanowires and their electrochemical properties. J Univ Sci Technol Beijing, 2010, 32(4): 494聶景濤, 郭敏, 張梅, 等. 電沉積聚苯胺納米線及其電化學性質. 北京科技大學學報, 2010, 32(4):494 [35] Zeng L Z, Zhao S F, He M. Macroscale porous carbonized polydopamine-modified cotton textile for application as electrode in microbial fuel cells. J Power Sources, 2018, 376: 33 doi: 10.1016/j.jpowsour.2017.11.071 [36] Wang Y X, Li W Q, Zong W M, et al. Polyaniline-decorated honeycomb-like structured macroporous carbon composite as an anode modifier for enhanced bioelectricity generation. Sci Total Environ, 2019, 696: 133980 doi: 10.1016/j.scitotenv.2019.133980 [37] Liu X, Zhao X H, Yu Y Y, et al. Facile fabrication of conductive polyaniline nanoflower modified electrode and its application for microbial energy harvesting. Electrochim Acta, 2017, 255: 41 doi: 10.1016/j.electacta.2017.09.153 [38] Yin T, Zhang H, Yang G Q, et al. Polyaniline composite TiO2 nanosheets modified carbon paper electrode as a high performance bioanode for microbial fuel cells. Synth Met, 2019, 252: 8 doi: 10.1016/j.synthmet.2019.03.027 [39] Zhang W Z, Xie B Z, Yang L G, et al. Brush-like polyaniline nanoarray modified anode for improvement of power output in microbial fuel cell. Bioresour Technol, 2017, 233: 291 doi: 10.1016/j.biortech.2017.02.124 [40] Yuan H R, Deng L F, Chen Y, et al. MnO2/Polypyrrole/MnO2 multi-walled-nanotube-modified anode for high-performance microbial fuel cells. Electrochim Acta, 2016, 196: 280 doi: 10.1016/j.electacta.2016.02.183 [41] Li Z L, Yang S K, Song Y N, et al. In-situ modified titanium suboxides with polyaniline/graphene as anode to enhance biovoltage production of microbial fuel cell. Int J Hydrogen Energy, 2019, 44(13): 6862 doi: 10.1016/j.ijhydene.2018.12.106 [42] Sonawane J M, Patil S A, Ghosh P C, et al. Low-cost stainless-steel wool anodes modified with polyaniline and polypyrrole for high-performance microbial fuel cells. J Power Sources, 2018, 379: 103 doi: 10.1016/j.jpowsour.2018.01.001 -

下載:

下載: