-

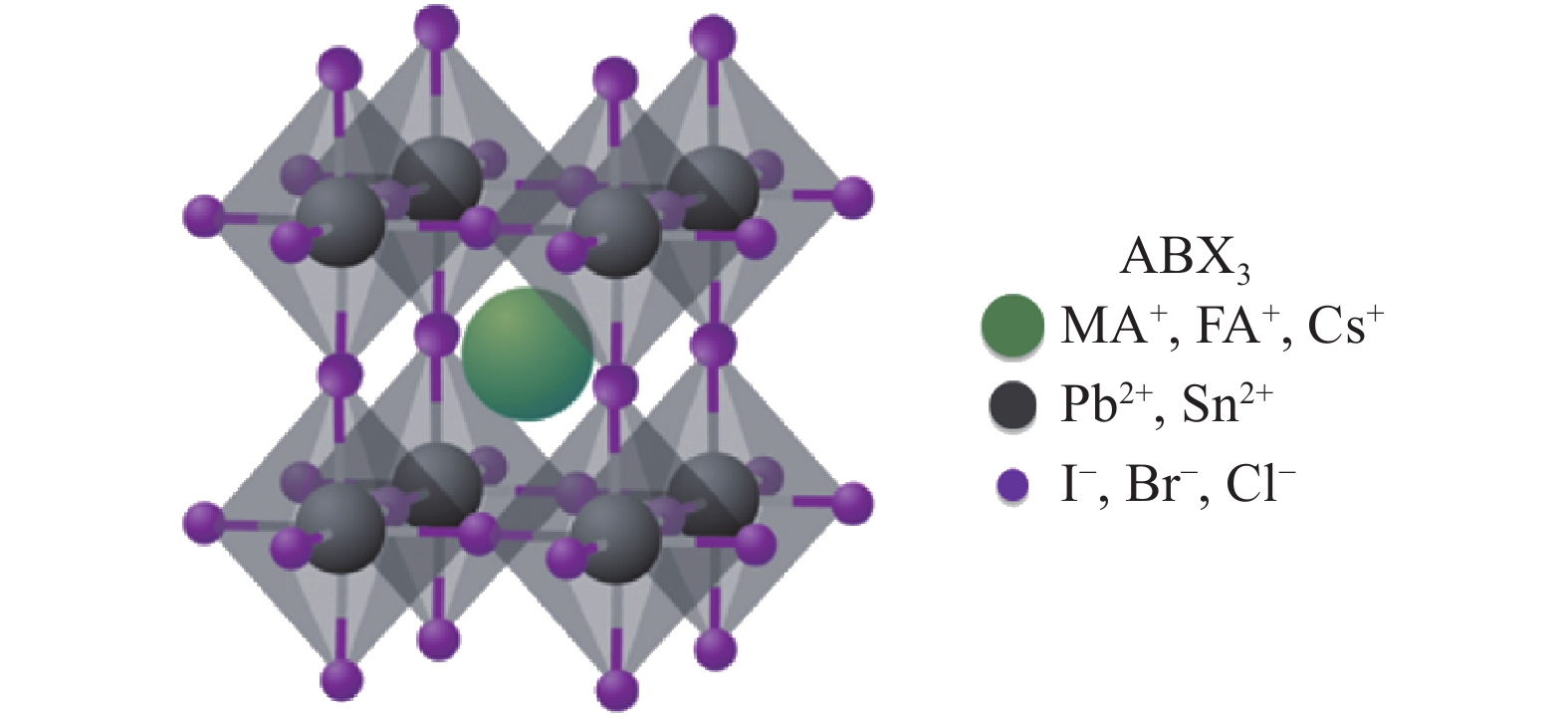

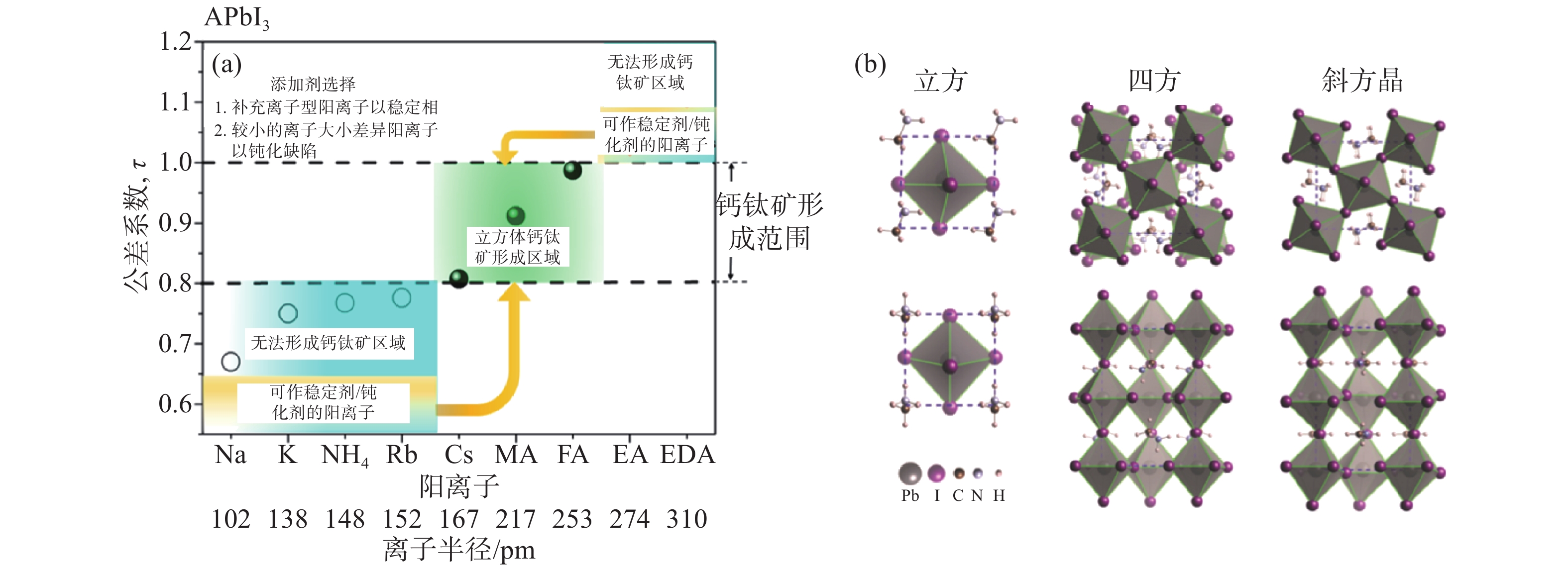

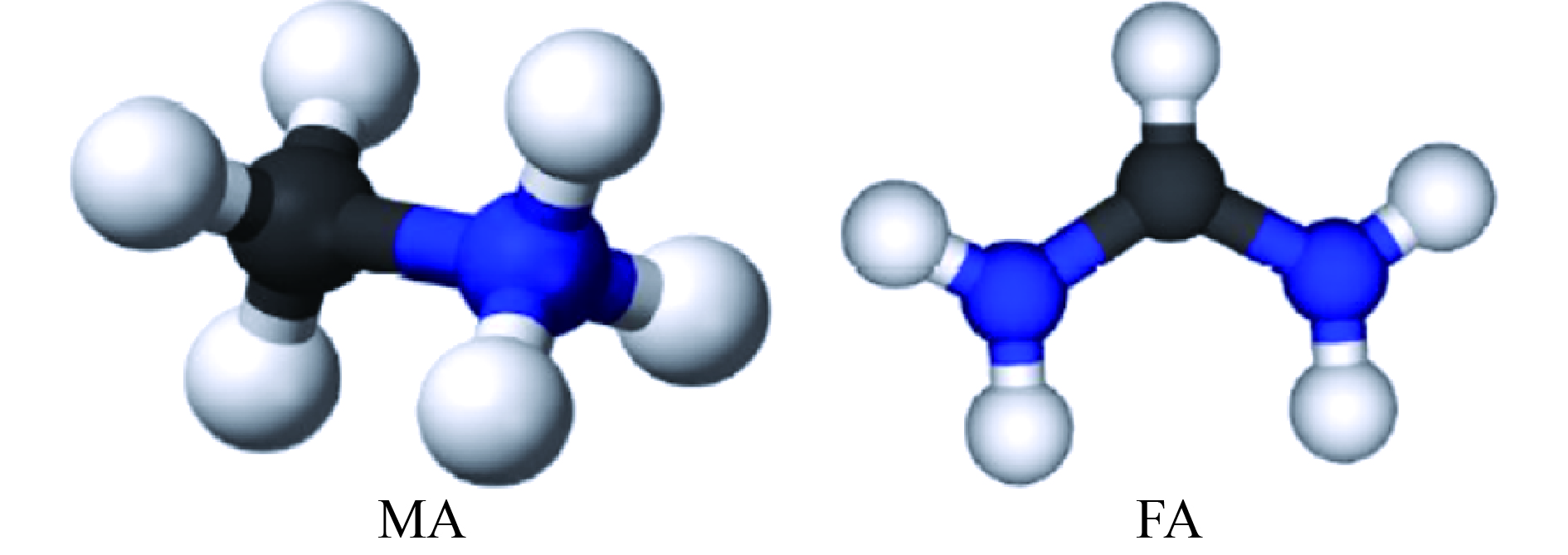

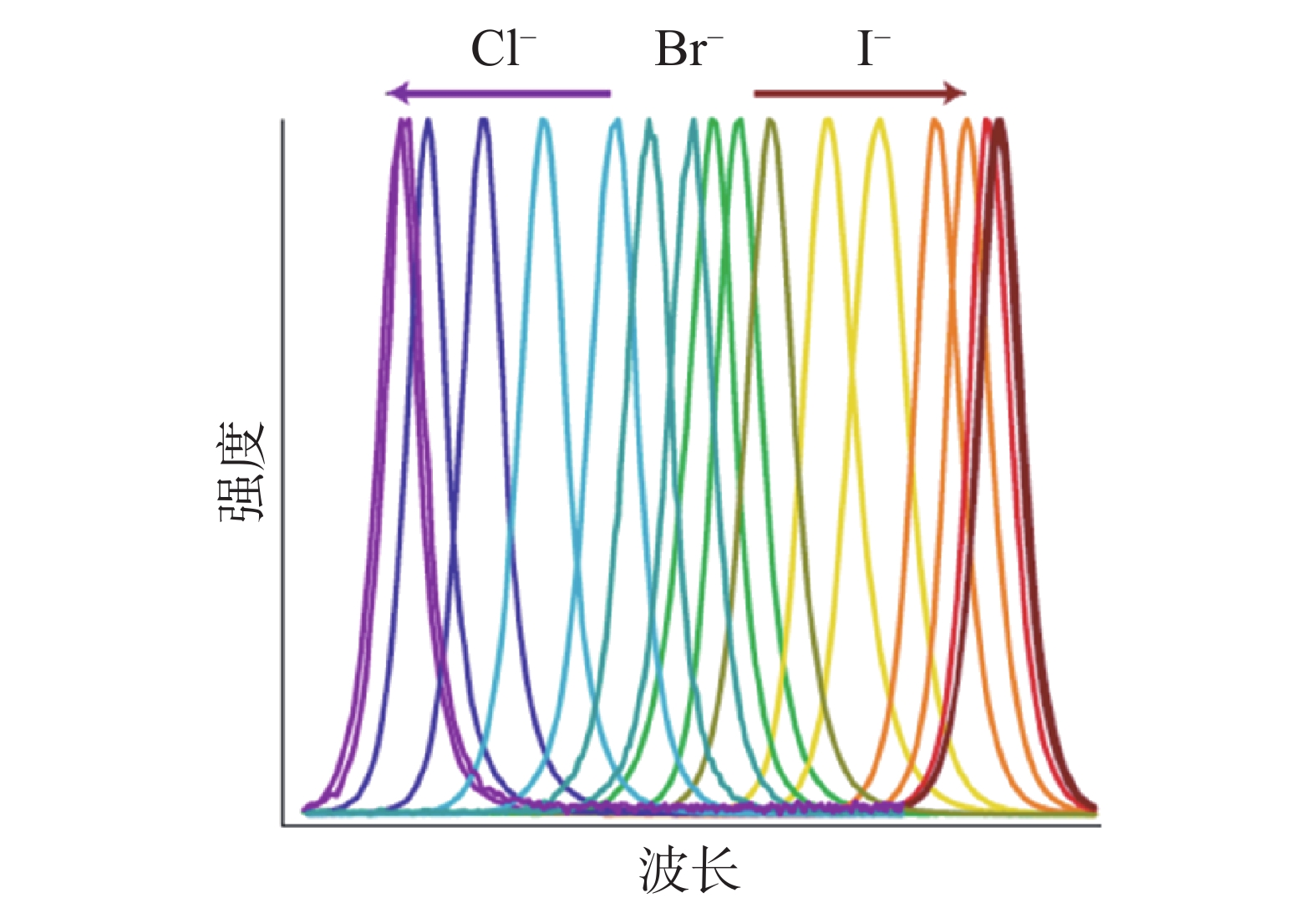

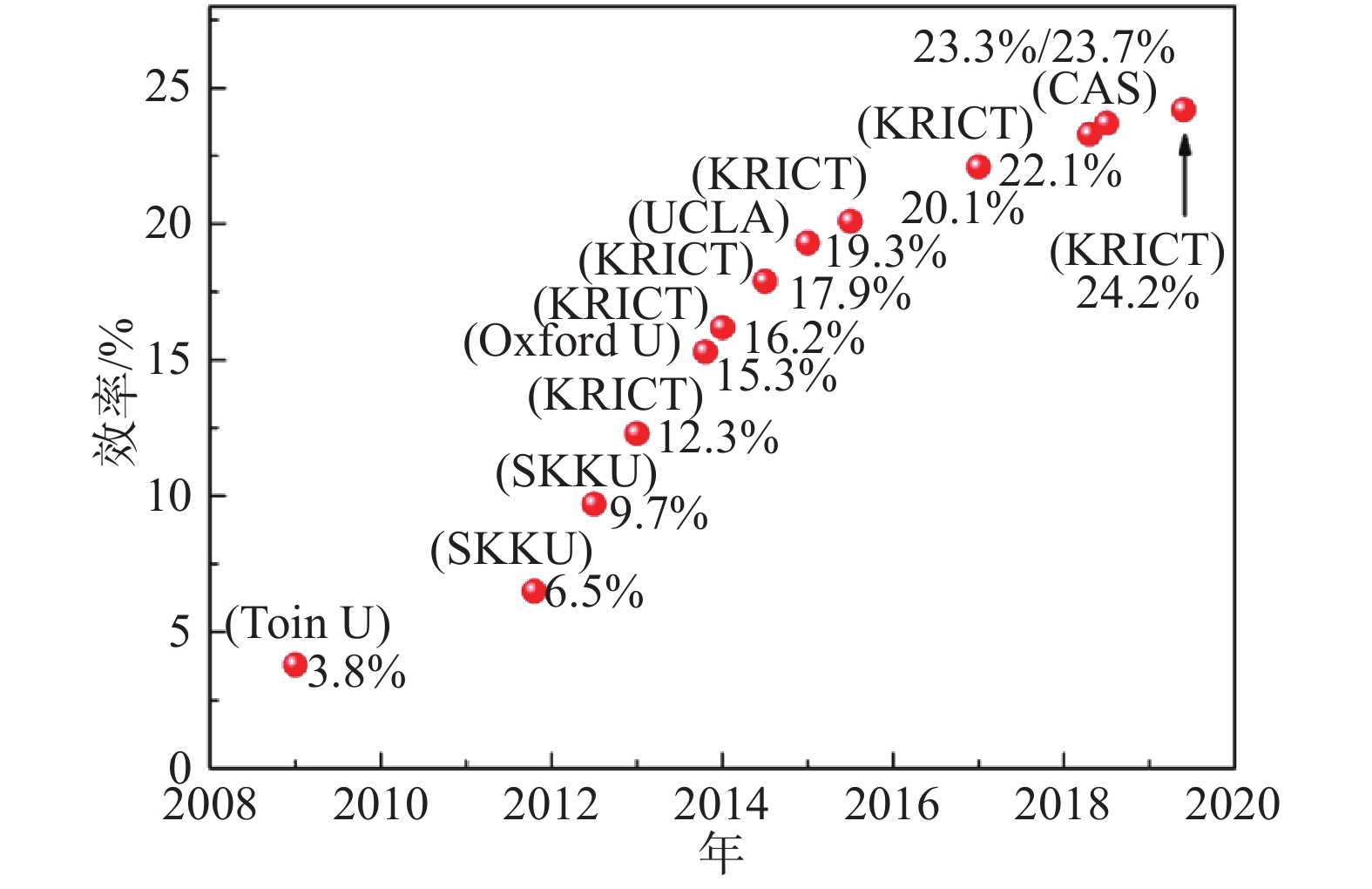

摘要: 從鈣鈦礦晶格結構和器件結構入手,介紹了鈣鈦礦電池的發展歷程,總結了A位,B位及X位的組分調控方法、一步法、兩步法及其他成膜方法,形貌控制方法,最后,詳細討論了鈣鈦礦太陽能電池穩定性的影響因素,光熱濕等因素是引起鈣鈦礦晶體分解,導致電池性能下降的主要原因。最后,穩定性問題已經成為阻礙鈣鈦礦電池產業化的最大的障礙,介紹了鈣鈦礦太陽能電池當前穩定性問題的主要解決方案:開發更穩定的鈣鈦礦結構,開發用于控制晶粒生長的新添加劑,以及選擇具有優異性能的空穴傳輸層和電子傳輸層。Abstract: In recent years, with the rapid development of new energy and industrial technologies, the solar cell industry has begun to receive considerable attention. Perovskite solar cells are regarded as the third-generation solar cells. As of April 2019, on the basis of the international certification, the maximum power conversion efficiency of perovskite solar cells is 24.2%, which is similar to the highest power conversion efficiency of silicon solar cells. Perovskite solar cells exhibit high power conversion efficiency, low cost, simple preparation, and diversity of structure, which makes them the leaders in next-generation thin-film photovoltaic devices. In this paper the development history of perovskite solar cells was reported; the perovskite crystal structure and device structure were discussed in detail; and a tolerance factor for obtaining a more stable perovskite structure was introduced. We then summarized the A-site, B-site, and X-site composition engineering, the one-step, two-step and other fabrication methods and morphology control methods of perovskite thin films that could stabilize the perovskite crystal structure, reduce the pollution and harm of lead in perovskite films, control the growth of perovskite film, and regulate the band gaps. In addition, the influencing factors on the stability of perovskite solar cells was also discuss; light stability, thermal stability, and humidity stability that are the main causes of the decomposition of perovskite crystals, resulting in a serious decrease in device performance owing to the phase transition and degradation. The biggest obstacle for the industrialization of perovskite solar cells is the stability. Finally a series of methods that can improve the stability of perovskite solar cells were analyzed. The main solutions to the current stability problems of perovskite solar cells include the development of more stable 2D/3D perovskite structures, the development of new additives to control the growth of grains using the interfacial medication methods, and the selection of suitable hole and electron transport materials with superior properties.

-

Key words:

- perovskite solar cell /

- stability /

- structure /

- influencing factors /

- regulation

-

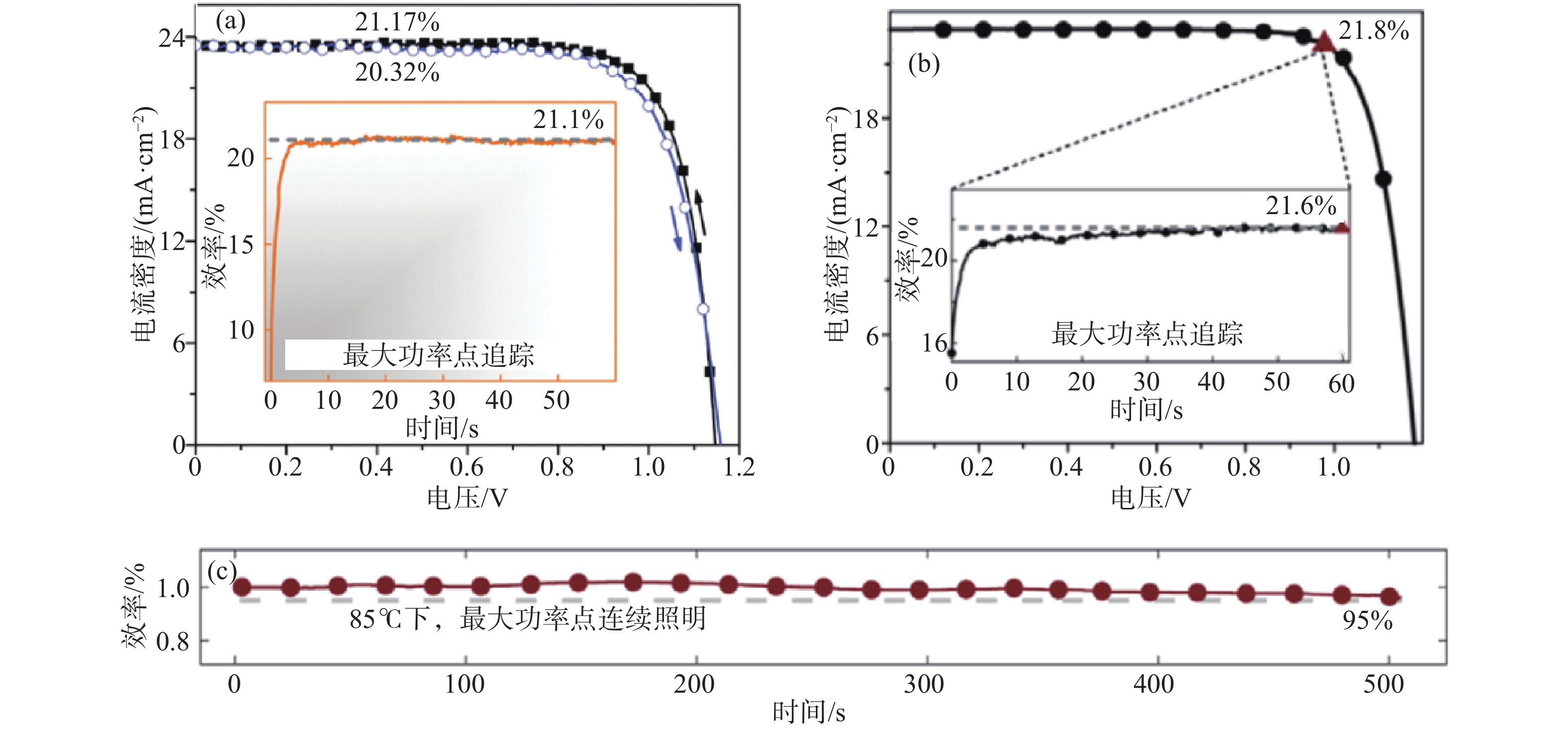

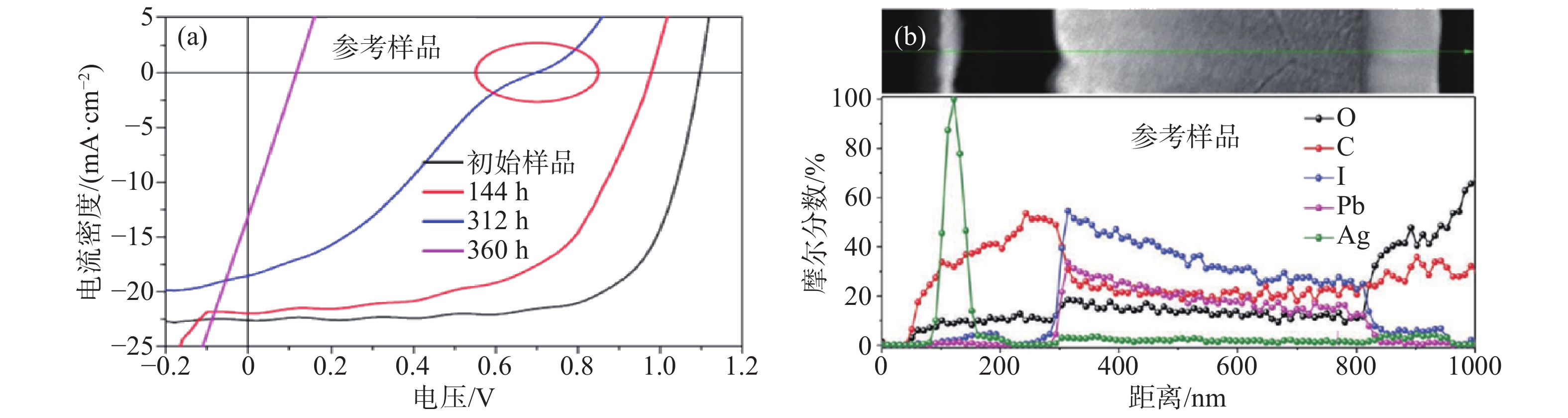

圖 5 銣、銫摻雜部分取代甲脒陽離子制備的器件性能測試曲線. (a) Cs摻雜鈣鈦礦器件的性能;(b) Rb摻雜鈣鈦礦器件的性能;(c) Rb摻雜鈣鈦礦器件的穩定性測試[20]

Figure 5. Rubidium and cesium doped part substituted formamidine cationic preparation of the device performance test curves: (a) performance of Cs doped perovskite devices; (b) performance of Rb doped perovskite devices; (c) stability testing of Rb doped perovskite devices[20]

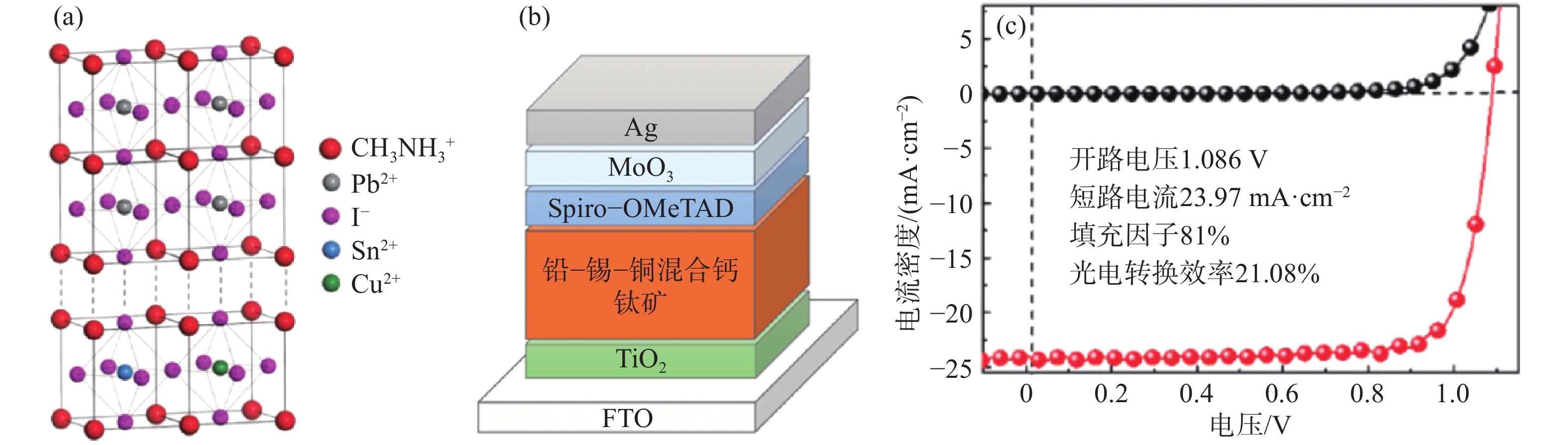

圖 6 (a) MAPb1?a?bSnaCubI3?2bBr2b鈣鈦礦結構示意圖;(b) 鉛?錫?銅三元體系鈣鈦礦器件結構圖;(c) MAPb0.9Sn0.05Cu0.05I2.9Br0.1組分的器件效率[24]

Figure 6. (a) Schematic diagram of the MAPb1?a?bSnaCubI3?2bBr2b perovskite structure; (b) Pb?Sn?Cu ternary system perovskite device structure diagram; (c) MAPb0.9Sn0.05Cu0.05I2.9Br0.1 component device efficiency[24]

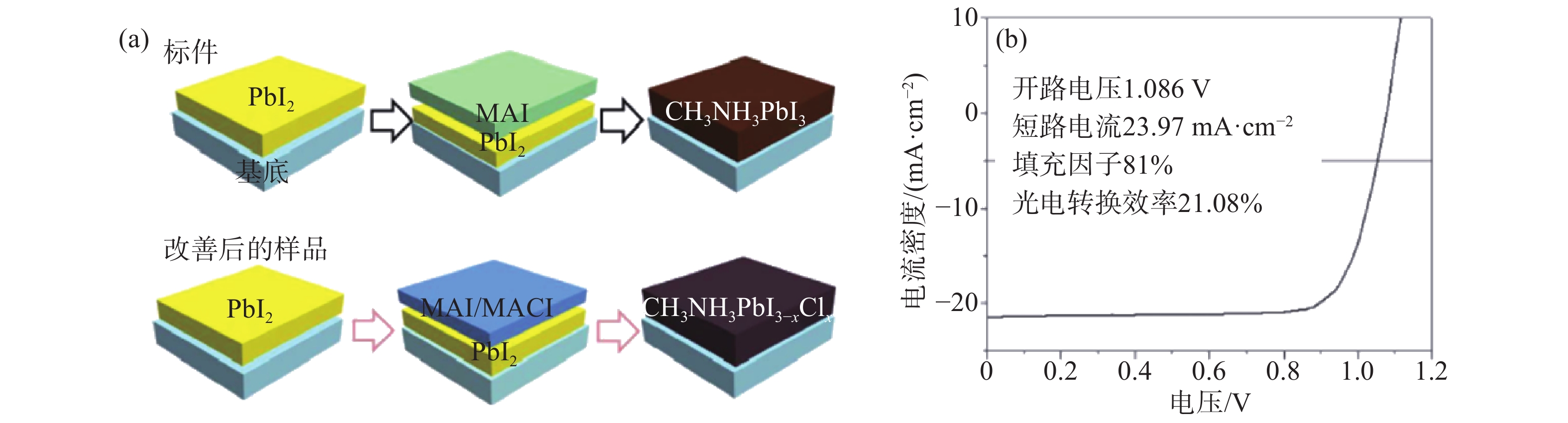

圖 8 通過Cl離子摻雜控制鈣鈦礦結晶形貌[27]. (a) 實驗流程示意圖(PbI2:碘化鉛,MAI:甲基碘化銨,MACl:甲基氯化銨);(b) Cl離子摻雜器件的最佳性能圖

Figure 8. Crystal morphology of perovskite controlled by Cl ion doping[27]: (a) schematic diagram of experimental process (PbI2: lead iodide, MAI: methyl ammonium iodide, MACl: methyl ammonium chloride); (b) optimal performance diagram of Cl ion doped devices

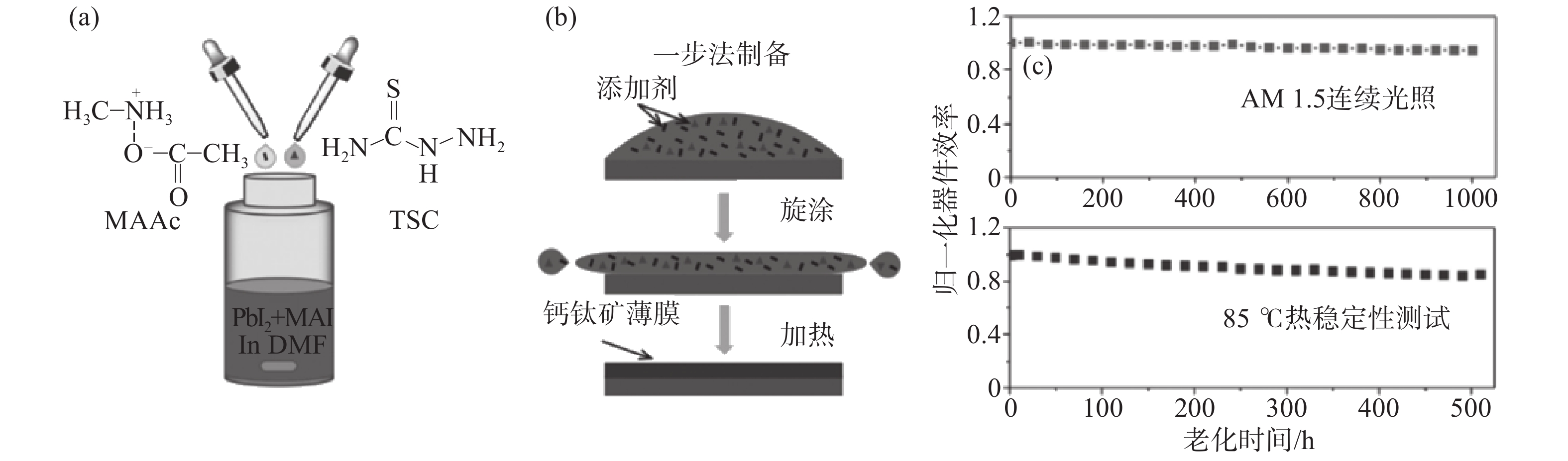

圖 12 MAAc/TSC添加劑制備鈣鈦礦薄膜. (a) MAAc/TSC添加劑的結構示意圖;(b) CH3NH3PbI3薄膜生長過程;(c) 器件的連續光照穩定性和熱穩定性測試[55]

Figure 12. Preparation of perovskite thin films by MAAc/TSC additive: (a) schematic diagram of the MAAc/TSC additive; (b) CH3NH3PbI3 film growth process; (c) continuous illumination stability and thermal stability test[55]

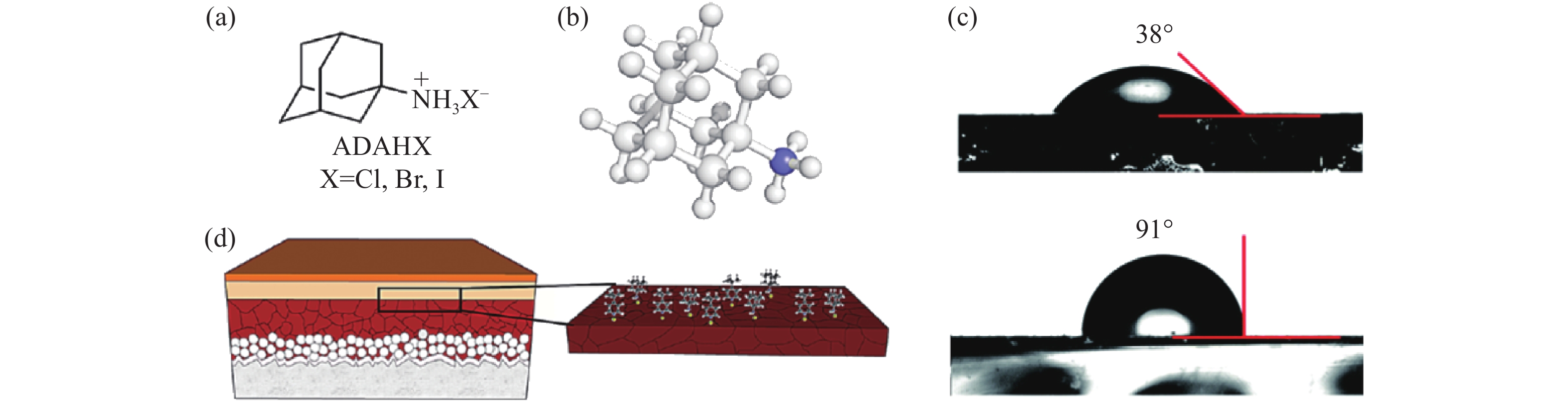

圖 13 ADAHX對鈣鈦礦薄膜的界面修飾. (a) ADAHX結構式;(b) ADAHX分子模型;(c) 鈣鈦礦薄膜的接觸角測試;(d) 界面修飾示意圖[58]

Figure 13. Interface modification of perovskite thin films by ADAHX: (a) structural formula of ADAHX; (b) molecular model of ADAHX; (c) contact angle test of perovskite thin films; (d) schematic diagram of interface modification[58]

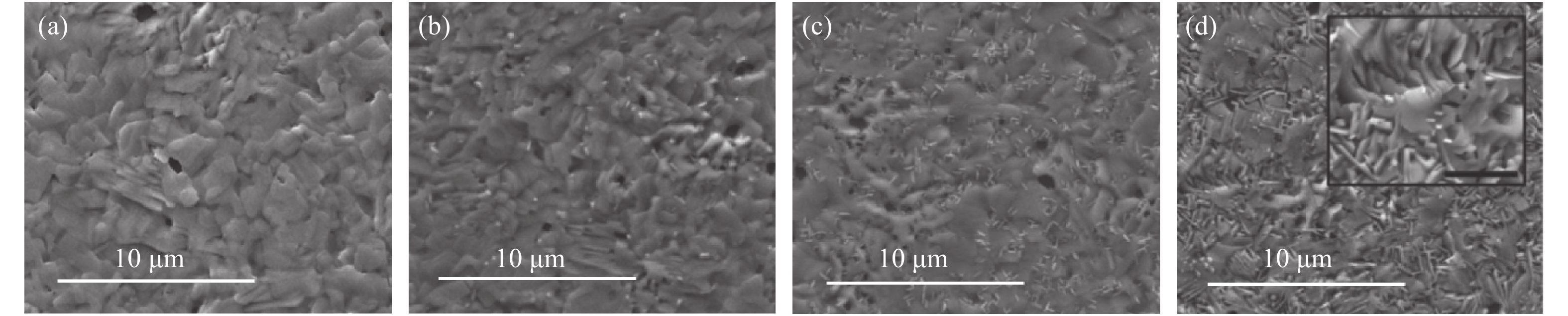

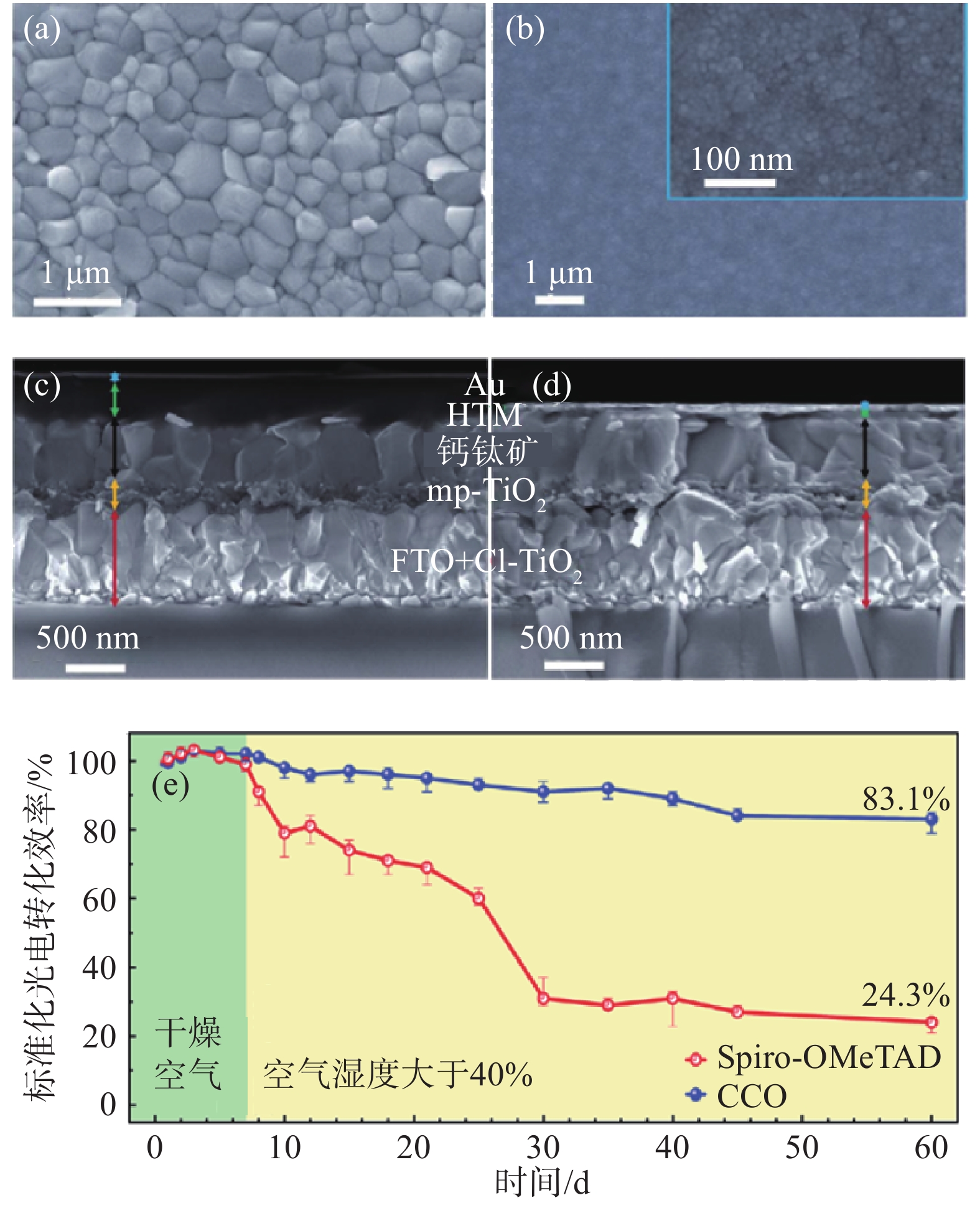

久色视频圖 14 CuCrO2作為空穴傳輸層所制備的器件表征圖. (a) 鈣鈦礦表面形貌;(b) CuCrO2薄膜表面形貌;(c) Spiro-OMeTAD做空穴傳輸層的器件截面圖;(d) CuCrO2做空穴傳輸層的器件截面圖;(e) 器件濕度穩定性測試(CCO:CuCrO2,cl-TiO2:致密TiO2層,mp-TiO2:介孔TiO2層,HTM:空穴傳輸層)

Figure 14. Device characterization diagram prepared by CuCrO2 as a hole transport layer: (a) surface morphology of perovskite; (b) surface morphology of CuCrO2 film; (c) cross section of device for hole transport layer of Spiro-OMeTAD; (d) cross-sectional view of device for hole transport layer of CuCrO2; (e) device humidity stability test (CCO: CuCrO2, cl-TiO2: compact TiO2 layer, mp-tio2: mesoporous TiO2 layer, HTM: hole transport layer)

-

參考文獻

[1] Kojima A, Teshima K, Shirai Y, et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J Am Chem Soc, 2009, 131(17): 6050 doi: 10.1021/ja809598r [2] Wang S H, Sakurai T, Wen W J, et al. Energy level alignment at interfaces in metal halide perovskite solar cells. Adv Mater Interfaces, 2018, 5(22): 1800260 doi: 10.1002/admi.201800260 [3] Li Y, Ji L, Liu R G, et al. A review on morphology engineering for highly efficient and stable hybrid perovskite solar cells. J Mater Chem A, 2018, 6(27): 12842 doi: 10.1039/C8TA04120B [4] Petrus M L, Schlipf J, Li C, et al. Capturing the sun: a review of the challenges and perspectives of perovskite solar cells. Adv Energy Mater, 2017, 7(16): 1700264 doi: 10.1002/aenm.201700264 [5] Gong J, Guo P J, Benjamin S E, et al. Cation engineering on lead iodide perovskites for stable and high-performance photovoltaic applications. J Energy Chem, 2018, 27(4): 1017 doi: 10.1016/j.jechem.2017.12.005 [6] Im J H, Lee C R, Lee J W, et al. 6.5% efficient perovskite quantum-dot-sensitized solar cell. Nanoscale, 2011, 3(10): 4088 doi: 10.1039/c1nr10867k [7] Kim H S, Lee C R, Im J H, et al. Lead iodide perovskite sensitized all-solid-state submicron thin film mesoscopic solar cell with efficiency exceeding 9%. Sci Rep, 2012, 2: 591 doi: 10.1038/srep00591 [8] Yang W S, Noh J H, Jeon N J, et al. High-performance photovoltaic perovskite layers fabricated through intramolecular exchange. Science, 2015, 348(6240): 1234 doi: 10.1126/science.aaa9272 [9] Jiang Q, Zhao Y, Zhang X W, et al. Surface passivation of perovskite film for efficient solar cells. Nat Photonics, 2019, 13: 460 doi: 10.1038/s41566-019-0398-2 [10] Yang S, Chen S, Mosconi E, et al. Stabilizing halide perovskite surfaces for solar cell operation with wide-bandgap lead oxysalts. Science, 2019, 365(6452): 473 doi: 10.1126/science.aax3294 [11] Chen Q, De Marco N, Yang Y M, et al. Under the spotlight: the organic–inorganic hybrid halide perovskite for optoelectronic applications. Nano Today, 2015, 10(3): 355 doi: 10.1016/j.nantod.2015.04.009 [12] Green M A, Ho-Baillie A, Snaith H J. The emergence of perovskite solar cells. Nat Photonics, 2014, 8: 506 doi: 10.1038/nphoton.2014.134 [13] Kim H S, Im S H, Park N G. Organolead halide perovskite: new horizons in solar cell research. J Phys Chem C, 2014, 118(11): 5615 doi: 10.1021/jp409025w [14] Sum T C, Mathews N. Advancements in perovskite solar cells: photophysics behind the photovoltaics. Energy Environ Sci, 2014, 7(8): 2518 doi: 10.1039/C4EE00673A [15] Han G F, Hadi H D, Bruno A, et al. Additive selection strategy for high performance perovskite photovoltaics. J Phys Chem C, 2017, 122(25): 13884 [16] Da P M, Zheng G F. Tailoring interface of lead-halide perovskite solar cells. Nano Res, 2017, 10(5): 1471 doi: 10.1007/s12274-016-1405-2 [17] Gholipour S, Saliba M. From exceptional properties to stability challenges of perovskite solar cells. Small, 2018, 14(46): 1802385 doi: 10.1002/smll.201802385 [18] Pang S P, Hu H, Zhang J L, et al. NH2CH═NH2PbI3: an alternative organolead iodide perovskite sensitizer for mesoscopic solar cells. Chem Mater, 2014, 26(3): 1485 doi: 10.1021/cm404006p [19] Jeon N J, Noh J H, Yang W S, et al. Compositional engineering of perovskite materials for high-performance solar cells. Nature, 2015, 517(7535): 476 doi: 10.1038/nature14133 [20] Saliba M, Matsui T, Seo J Y, et al. Cesium-containing triple cation perovskite solar cells: improved stability, reproducibility and high efficiency. Energy Environ Sci, 2016, 9(6): 1989 doi: 10.1039/C5EE03874J [21] Shi Z J, Guo J, Chen Y H, et al. Lead-free organic?inorganic hybrid perovskites for photovoltaic applications: recent advances and perspectives. Adv Mater, 2017, 29(16): 1605005 doi: 10.1002/adma.201605005 [22] Jokar E, Chien C H, Fathi A, et al. Slow surface passivation and crystal relaxation with additives to improve device performance and durability for tin-based perovskite solar cells. Energy Environ Sci, 2018, 11(9): 2353 doi: 10.1039/C8EE00956B [23] Xiao Z W, Song Z N, Yan Y F. From lead halide perovskites to lead-free metal halide perovskites and perovskite derivatives. Adv Mater, 2019, 31(47): 1803792 doi: 10.1002/adma.201803792 [24] Li M, Wang Z K, Zhuo M P, et al. Pb–Sn?Cu ternary organometallic halide perovskite solar cells. Adv Mater, 2018, 30(20): 1800258 doi: 10.1002/adma.201800258 [25] Saliba M, Correa-Baena J P, Gr?tzel M, et al. Perovskite solar cells: from the atomic level to film quality and device performance. Angew Chem Int Ed, 2018, 57(10): 2554 doi: 10.1002/anie.201703226 [26] Eperon G E, Stranks S D, Menelaou C, et al. Formamidinium lead trihalide: a broadly tunable perovskite for efficient planar heterojunction solar cells. Energy Environ Sci, 2014, 7(3): 982 doi: 10.1039/c3ee43822h [27] Chen Q, Zhou H P, Fang Y H, et al. The optoelectronic role of chlorine in CH3NH3PbI3(Cl)-based perovskite solar cells. Nat Commun, 2015, 6: 7269 doi: 10.1038/ncomms8269 [28] Conings B, Drijkoningen J, Gauquelin N, et al. Intrinsic thermal instability of methylammonium lead trihalide perovskite. Adv Energy Mater, 2015, 5(15): 1500477 doi: 10.1002/aenm.201500477 [29] Huang J B, Tan S Q, Lund P D, et al. Impact of H2O on organic–inorganic hybrid perovskite solar cells. Energy Environ Sci, 2017, 10(11): 2284 doi: 10.1039/C7EE01674C [30] Eperon G E, Habisreutinger S N, Leijtens T, et al. The importance of moisture in hybrid lead halide perovskite thin film fabrication. ACS Nano, 2015, 9(9): 9380 doi: 10.1021/acsnano.5b03626 [31] Fu Q X, Tang X L, Huang B, et al. Recent progress on the long-term stability of perovskite solar cells. Adv Sci, 2018, 5(5): 1700387 doi: 10.1002/advs.201700387 [32] Jeon N J, Na H, Jung E H, et al. A fluorene-terminated hole-transporting material for highly efficient and stable perovskite solar cells. Nat Energy, 2018, 3: 682 doi: 10.1038/s41560-018-0200-6 [33] Zhang C X, Deng X S, Zheng J F, et al. Solution-synthesized SnO2 nanorod arrays for highly stable and efficient perovskite solar cells. Electrochim Acta, 2018, 283: 1134 doi: 10.1016/j.electacta.2018.07.028 [34] Tavakoli M M, Yadav P, Tavakoli R, et al. Surface engineering of TiO2 ETL for highly efficient and hysteresis?less planar perovskite solar cell (21.4%) with enhanced open?circuit voltage and stability. Adv Energy Mater, 2018, 8(23): 1800794 doi: 10.1002/aenm.201800794 [35] Mahmoudi T, Wang Y S, Hahn Y B. Stability enhancement in perovskite solar cells with perovskite/silver–graphene composites in the active layer. ACS Energy Lett, 2019, 4(1): 235 doi: 10.1021/acsenergylett.8b02201 [36] Li Z, Xiao C X, Yang Y, et al. Extrinsic ion migration in perovskite solar cells. Energy Environ Sci, 2017, 10(5): 1234 doi: 10.1039/C7EE00358G [37] Wei D, Ma F S, Wang R, et al. Ion-migration inhibition by the cation-π interaction in perovskite materials for efficient and stable perovskite solar cells. Adv Mater, 2018, 30(31): 1707583 doi: 10.1002/adma.201707583 [38] Liu L, Huang S, Lu Y, et al. Grain-boundary “patches” by in situ conversion to enhance perovskite solar cells stability. Adv Mater, 2018, 30(29): 1800544 doi: 10.1002/adma.201800544 [39] Tsai H, Asadpour R, Blancon J C, et al. Design principles for electronic charge transport in solution-processed vertically stacked 2D perovskite quantum wells. Nat Commun, 2018, 9: 2130 doi: 10.1038/s41467-018-04430-2 [40] Chen P, Bai Y, Wang S C, et al. In situ growth of 2D perovskite capping layer for stable and efficient perovskite solar cells. Adv Funct Mater, 2018, 28(17): 1706923 doi: 10.1002/adfm.201706923 [41] Lin Y, Bai Y, Fang Y J, et al. Enhanced thermal stability in perovskite solar cells by assembling 2D/3D stacking structures. J Phys Chem Lett, 2018, 9(3): 654 doi: 10.1021/acs.jpclett.7b02679 [42] Thote A, Jeon I, Lee J W, et al. Stable and reproducible 2D/3D formamidinium–lead–iodide perovskite solar cells. ACS Appl Energy Mater, 2019, 2(4): 2486 doi: 10.1021/acsaem.8b01964 [43] Lee J W, Dai Z H, Han T H, et al. 2D perovskite stabilized phase-pure formamidinium perovskite solar cells. Nat Commun, 2018, 9: 3021 doi: 10.1038/s41467-018-05454-4 [44] Li M H, Yeh H S, Chiang Y H, et al. Highly efficient 2D/3D hybrid perovskite solar cells via low-pressure vapor-assisted solution process. Adv Mater, 2018, 30(30): 1801401 doi: 10.1002/adma.201801401 [45] Smith I C, Hoke E T, Solis-Ibarra D, et al. A layered hybrid perovskite solar-cell absorber with enhanced moisture stability. Angew Chem Int Ed, 2014, 53(42): 11232 doi: 10.1002/anie.201406466 [46] Quan L N, Yuan M J, Comin R, et al. Ligand-stabilized reduced-dimensionality perovskites. J Am Chem Soc, 2016, 138(8): 2649 doi: 10.1021/jacs.5b11740 [47] Seok S I, Gr?tzel M, Park N G. Methodologies toward highly efficient perovskite solar cells. Small, 2018, 14(20): 1704177 doi: 10.1002/smll.201704177 [48] Li L, Chen Y H, Liu Z H, et al. The additive coordination effect on hybrids perovskite crystallization and high-performance solar cell. Adv Mater, 2016, 28(44): 9862 doi: 10.1002/adma.201603021 [49] Huang P H, Wang Y H, Ke J C, et al. The effect of solvents on the performance of CH3NH3PbI3 perovskite solar cells. Energies, 2017, 10(5): 599 doi: 10.3390/en10050599 [50] Han F, Luo J S, Malik H A, et al. A functional sulfonic additive for high efficiency and low hysteresis perovskite solar cells. J Power Sources, 2017, 359: 577 doi: 10.1016/j.jpowsour.2017.05.084 [51] Fei C B, Li B, Zhang R, et al. Highly efficient and stable perovskite solar cells based on monolithically grained CH3NH3PbI3 film. Adv Energy Mater, 2017, 7(9): 1602017 doi: 10.1002/aenm.201602017 [52] Niu T Q, Lu J, Munir R, et al. Stable high-performance perovskite solar cells via grain boundary passivation. Adv Mater, 2018, 30(16): 1706576 doi: 10.1002/adma.201706576 [53] Li X D, Zhang W X, Wang Y C, et al. In-situ cross-linking strategy for efficient and operationally stable methylammoniun lead iodide solar cells. Nat Commun, 2018, 9: 3806 doi: 10.1038/s41467-018-06204-2 [54] Feng J S, Zhu X J, Yang Z, et al. Record efficiency stable flexible perovskite solar cell using effective additive assistant strategy. Adv Mater, 2018, 30(35): 1801418 doi: 10.1002/adma.201801418 [55] Wu Y Z, Xie F X, Chen H, et al. Thermally stable MAPbI3 perovskite solar cells with efficiency of 19.19% and area over 1 cm2 achieved by additive engineering. Adv Mater, 2017, 29(28): 17011073 [56] Tavakoli M M, Bi D Q, Pan L F, et al. Adamantanes enhance the photovoltaic performance and operational stability of perovskite solar cells by effective mitigation of interfacial defect states. Adv Energy Mater, 2018, 8(19): 1800275 doi: 10.1002/aenm.201800275 [57] Tavakoli M M, Yadav P, Prochowicz D, et al. Controllable perovskite crystallization via antisolvent technique using chloride additives for highly efficient planar perovskite solar cells. Adv Energy Mater, 2019, 9(17): 1803587 doi: 10.1002/aenm.201803587 [58] Tavakoli M M, Tress W, Mili? J V, et al. Addition of adamantylammonium iodide to hole transport layers enables highly efficient and electroluminescent perovskite solar cells. Energy Environ Sci, 2018, 11(11): 3310 doi: 10.1039/C8EE02404A [59] Li X, Yang J Y, Jiang Q H, et al. Perovskite solar cells employing an eco-friendly and low-cost inorganic hole transport layer for enhanced photovoltaic performance and operational stability. J Mater Chem A, 2019, 7(12): 7065 doi: 10.1039/C9TA01499C [60] Kung P K, Li M H, Lin P Y, et al. A review of inorganic hole transport materials for perovskite solar cells. Adv Mater Interfaces, 2018, 5(22): 1800882 doi: 10.1002/admi.201800882 [61] Kang J S, Kim J Y, Yoon J, et al. Room-temperature vapor deposition of cobalt nitride nanofilms for mesoscopic and perovskite solar cells. Adv Energy Mater, 2018, 8(13): 1703114 doi: 10.1002/aenm.201703114 [62] Arora N, Dar M I, Hinderhofer A, et al. Perovskite solar cells with CuSCN hole extraction layers yield stabilized efficiencies greater than 20%. Science, 2017, 358(6364): 768 doi: 10.1126/science.aam5655 [63] Zhang H, Wang H, Chen W, et al. CuGaO2: a promising inorganic hole-transporting material for highly efficient and stable perovskite solar cells. Adv Mater, 2017, 29(8): 1604984 doi: 10.1002/adma.201604984 [64] Akin S, Liu Y H, Dar M I, et al. Hydrothermally processed CuCrO2 nanoparticles as an inorganic hole transporting material for low-cost perovskite solar cells with superior stability. J Mater Chem A, 2018, 6(41): 20327 doi: 10.1039/C8TA07368F -

下載:

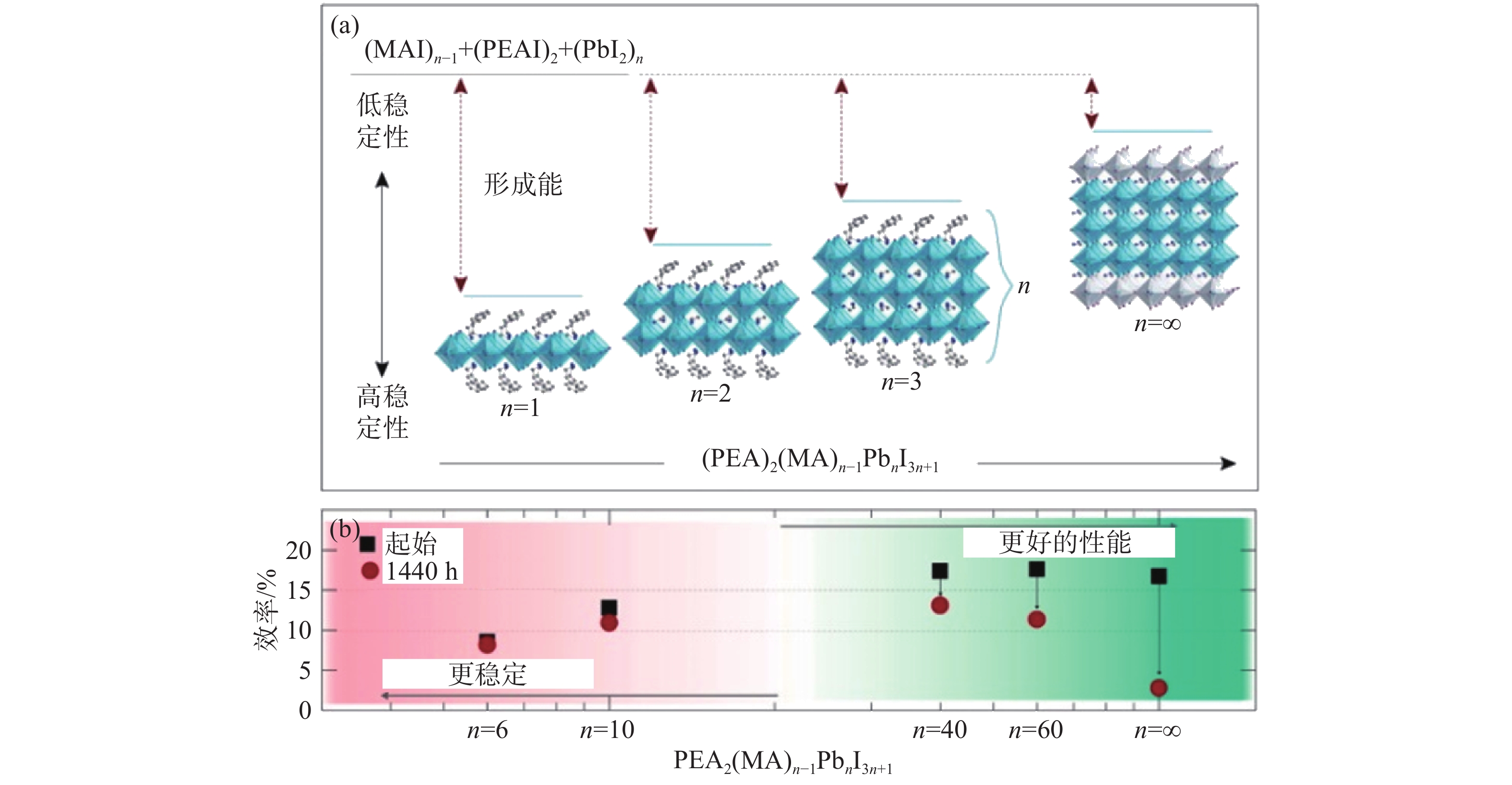

下載: